A modified zirconia ceramic with a surface composite bioactive substance and its preparation method

A technology of biologically active substances, zirconia ceramics, applied in the field of dental restoration medical materials, to achieve the effect of improving biological activity, improving biological activity, and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

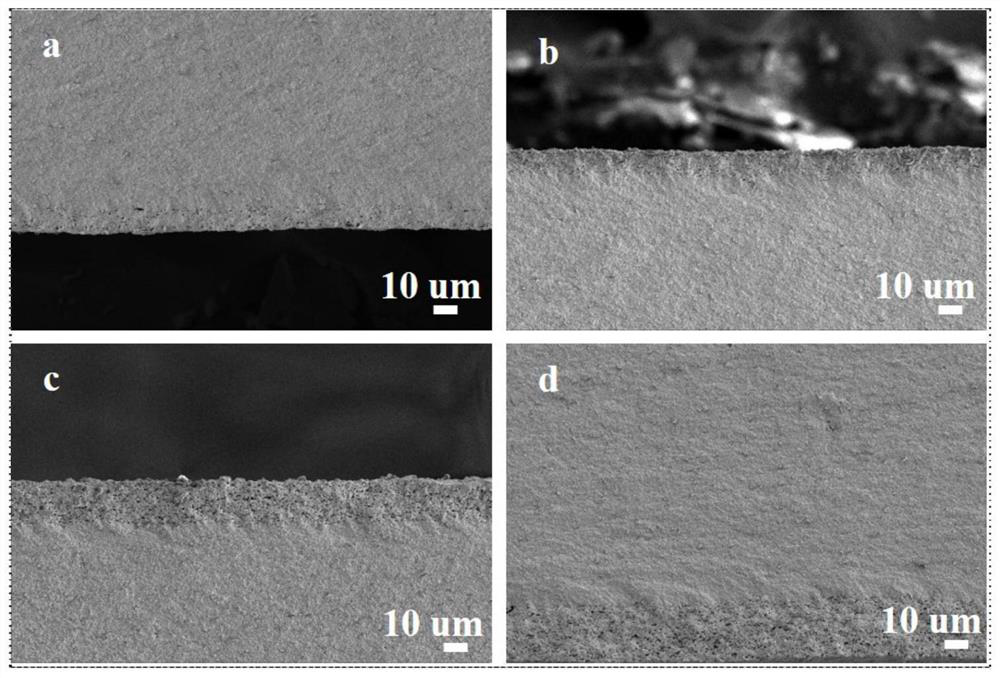

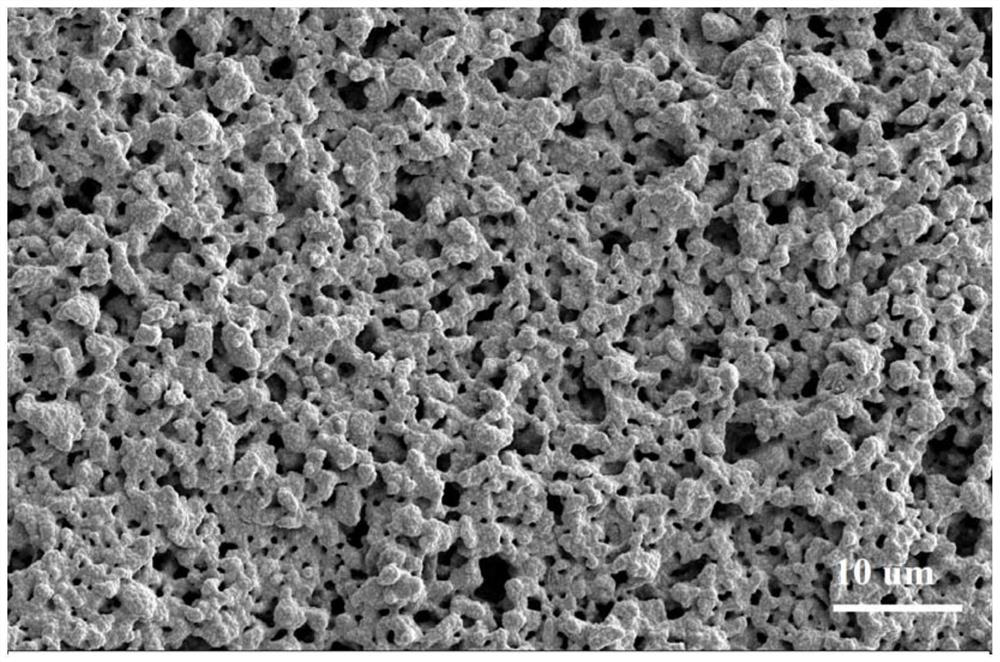

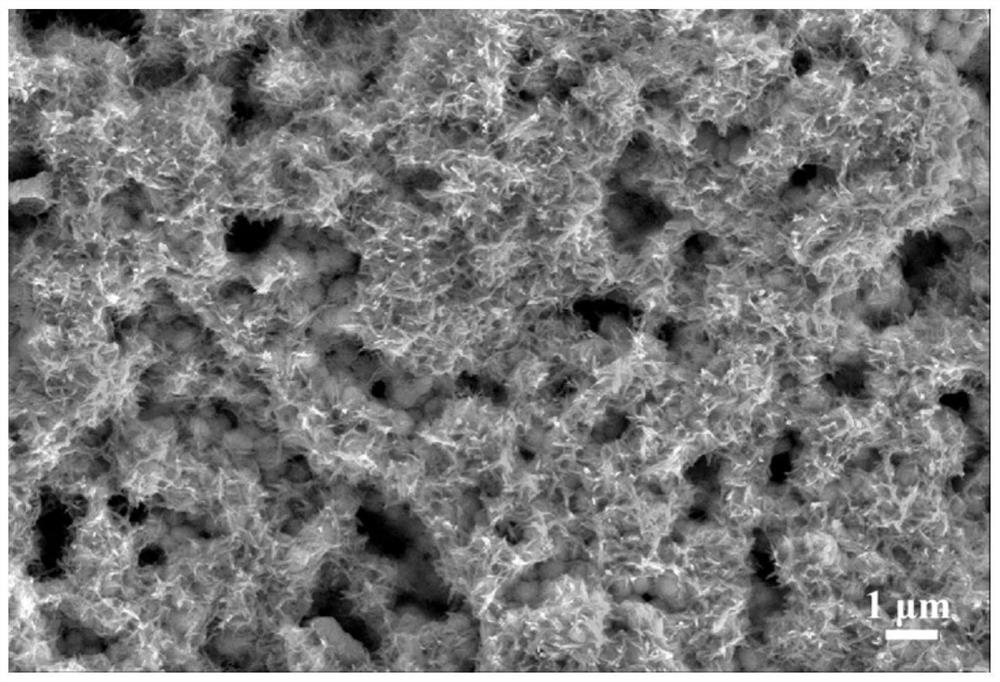

Image

Examples

Embodiment 1

[0060] (1) Preparation of calcium-magnesium-silicon biologically active sol: add 10g of ethyl orthosilicate, 20g of calcium nitrate, and 30g of magnesium nitrate in 50g of deionized water, mix well to obtain a mixed solution, adjust the pH of the mixed solution to 8.0, and make it happen Hydrolysis and polycondensation reaction (reaction time is 12h) to form calcium magnesium silica sol;

[0061] (2) The yttria-stabilized zirconia powder is press-molded, the pressure of the press-molding is 220MPa, and the press-molding time is 2min to prepare a green zirconia ceramic body, and the pre-sintering treatment is carried out under the condition that the temperature is raised to 500°C, The pre-sintering treatment time is 2h, and the heating rate is 10°C / min to obtain a zirconia ceramic pre-sintered body;

[0062] (3) Preparation of zirconia suspension: polyethyl acrylate microspheres, polyvinyl alcohol, polyacrylic acid, deionized water and zirconia powder are mixed according to the...

Embodiment 2

[0071] (1) Preparation of calcium magnesium silicon bioactive sol: add 10g ethyl orthosilicate, 20g calcium nitrate, 30g magnesium citrate in 50g deionized water, mix well to obtain a mixed solution, adjust the pH of the mixed solution to 8.0, and make it happen Hydrolysis and polycondensation reaction (reaction time is 24h) to form calcium magnesium silica sol;

[0072] (2) The yttria-stabilized zirconia powder is press-molded, the pressure of press-molding is 100MPa, and the time of press-molding is 30min, to prepare a green zirconia ceramic body, and pre-sintering is carried out under the condition that the temperature is raised to 500°C, The pre-sintering treatment time is 2h, and the heating rate is 2°C / min to obtain a zirconia ceramic pre-sintered body;

[0073] (3) Preparation of zirconia suspension: polyethyl acrylate microspheres, polyvinyl alcohol, polyacrylic acid, deionized water and zirconia powder are mixed according to the mass ratio of 10:10:2:53:25, and the mi...

Embodiment 3

[0081] (1) Preparation of calcium-silicon-phosphorus bioactive sol: add 31g of ethyl orthosilicate, 29g of calcium nitrate, and 20g of sodium phosphate in 20g of deionized water, mix well to obtain a mixed solution, adjust the pH of the mixed solution to 8.0, and make it hydrolyzed Polycondensation reaction (reaction time is 24h) to form calcium-silicon-phosphorus sol;

[0082] (2) The yttria-stabilized zirconia powder is press-molded, the pressure of press-molding is 180MPa, and the time of press-molding is 10min, to prepare a zirconia ceramic green body, and pre-sintering is carried out under the condition that the temperature is raised to 500°C, The pre-sintering treatment time is 2h, and the heating rate is 5°C / min, to obtain a zirconia ceramic pre-sintered body;

[0083] (3) Preparation of zirconia suspension: polyethyl acrylate microspheres, polyvinyl alcohol, polyacrylic acid, deionized water and zirconia powder are mixed according to the mass ratio of 10:10:2:53:25, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com