Modified zirconia ceramic with high biological activity and high mechanical strength and preparation method thereof

A zirconia ceramic, bioactive technology, applied in the field of dental restoration medical materials, to achieve the effect of improving bioactivity, promoting bone regeneration, and good bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

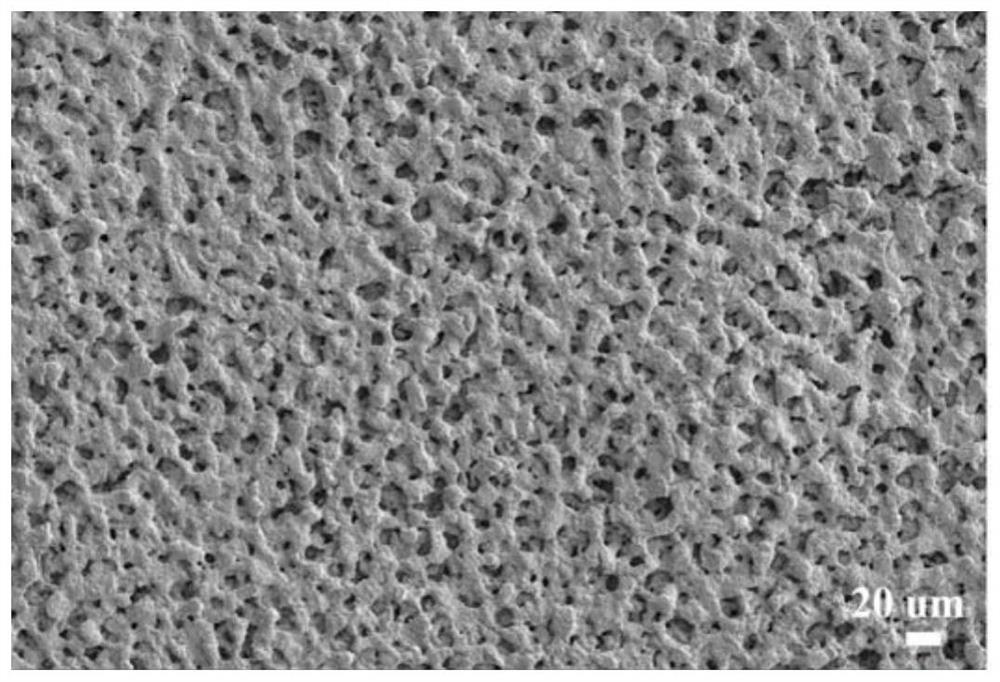

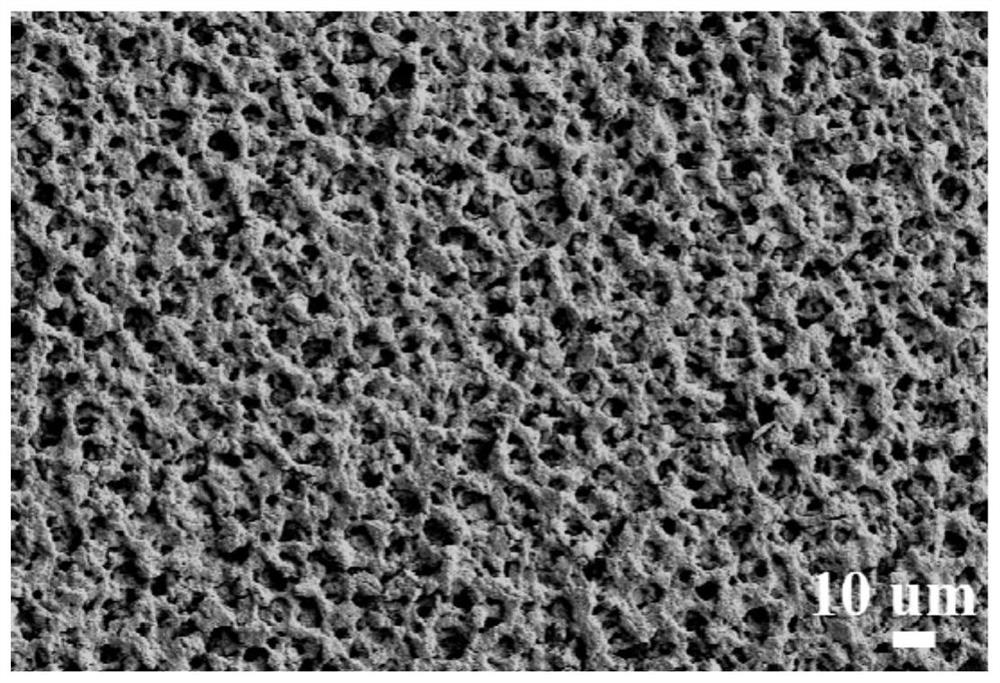

Image

Examples

Embodiment 1

[0072] (1) Preparation of calcium-magnesium-silicon bioactive powder: add 10g ethyl orthosilicate, 20g calcium nitrate, 30g magnesium nitrate to 50g deionized water, mix evenly to obtain a mixed solution, adjust the pH of the mixed solution to 8.0, make it Hydrolysis polycondensation reaction occurs (reaction time is 12h) to form calcium-magnesium-silica sol, the sol is left to age for 6h, dried at 60°C for 12h, calcined at 1200°C for 48h, ball milled (rotating speed 1000 rpm, time 12h) to obtain calcium-magnesium-silicon bioactive powder;

[0073] (2) The yttria-stabilized zirconia powder is press-molded, the pressure of the press-molding is 220 MPa, and the time of the press-molding is 2 minutes, and the zirconia ceramic green body is prepared, and the pre-sintering process is carried out under the condition of raising the temperature to 500°C, The pre-sintering treatment time is 2 hours, and the heating rate is 10°C / min to obtain a zirconia ceramic pre-sintered body;

[00...

Embodiment 2

[0084] (1) Preparation of calcium-magnesium-silicon bioactive powder: add 10g ethyl orthosilicate, 20g calcium nitrate, 30g magnesium citrate to 50g deionized water, mix evenly to obtain a mixed solution, adjust the pH of the mixed solution to 8.0, and make it A hydrolysis polycondensation reaction occurs (reaction time is 24 hours) to form a calcium magnesium silica sol. The sol is left to age for 6 hours, dried at 60°C for 12 hours, calcined at 1400°C for 48 hours, ball milled (rotating speed 1000 rpm, time 12h) to obtain calcium magnesium silicon bioactive powder;

[0085] (2) The yttria-stabilized zirconia powder is press-molded, the pressure of the press-molding is 100 MPa, and the time of the press-molding is 30 minutes, and the zirconia ceramic green body is prepared, and the pre-sintering process is carried out under the condition of raising the temperature to 500°C, The pre-sintering treatment time is 2 hours, and the heating rate is 2°C / min to obtain a zirconia ceram...

Embodiment 3

[0095] (1) Preparation of calcium silicon phosphorus bioactive powder: Add 31g of tetraethyl orthosilicate, 29g of calcium nitrate, and 20g of sodium phosphate into 20g of deionized water, mix well to obtain a mixed solution, adjust the pH of the mixed solution to 8.0, and make it occur Hydrolysis polycondensation reaction (reaction time is 24h) to form calcium-silicon-phosphorus sol, the sol is left to age for 6h, dried at 60°C for 12h, calcined at 800°C for 48h, ball milled (rotating speed 1000 rpm, time is 12h) Obtaining calcium silicon phosphorus bioactive powder;

[0096] (2) The yttria-stabilized zirconia powder is press-molded, the pressure of the press-molding is 180 MPa, and the time of the press-molding is 10 minutes, and the zirconia ceramic green body is prepared, and the pre-sintering process is carried out under the condition of raising the temperature to 500°C, The pre-sintering treatment time is 2 hours, and the heating rate is 5°C / min to obtain a zirconia cera...

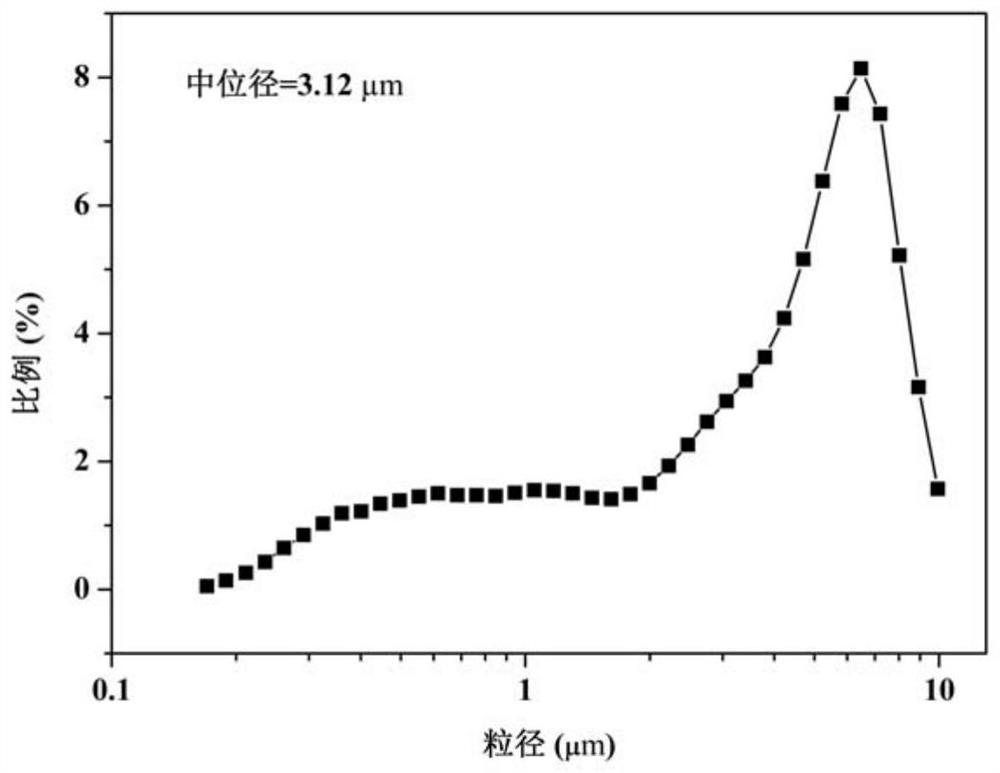

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com