Roll forming method of 0Cr19Ni9 stainless steel thin-walled ring forging

A 0cr19ni9, stainless steel technology, applied in the direction of metal rolling, etc., can solve problems such as unstable production, small machining allowance, coarse grain, etc., and achieve the effect of saving steel and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] To implement the roll forming method of the 0Cr19Ni9 stainless steel thin-walled ring according to the present invention, it is necessary to provide equipment such as forging heating furnace, press machine, ring rolling machine, and manipulator.

[0032] The main chemical element content (percentage by weight) of the steel is: C content 0.08%, Mn content 2.00%, P content 0.045%, S content 0.030%, Si content 1.00%, Cr content 18.0%~20.0 %, 8.0% to 10.5% of Ni content, 0.10% of N content, and Fe as the balance.

[0033] The process steps of the steel from the bar to the production of qualified thin-walled rings are as follows:

[0034] Step 1: Blank making.

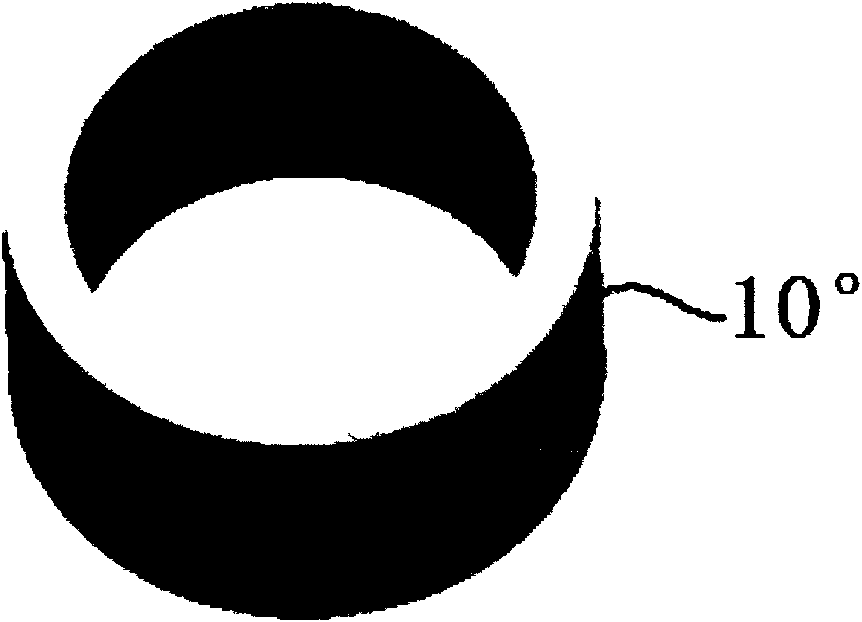

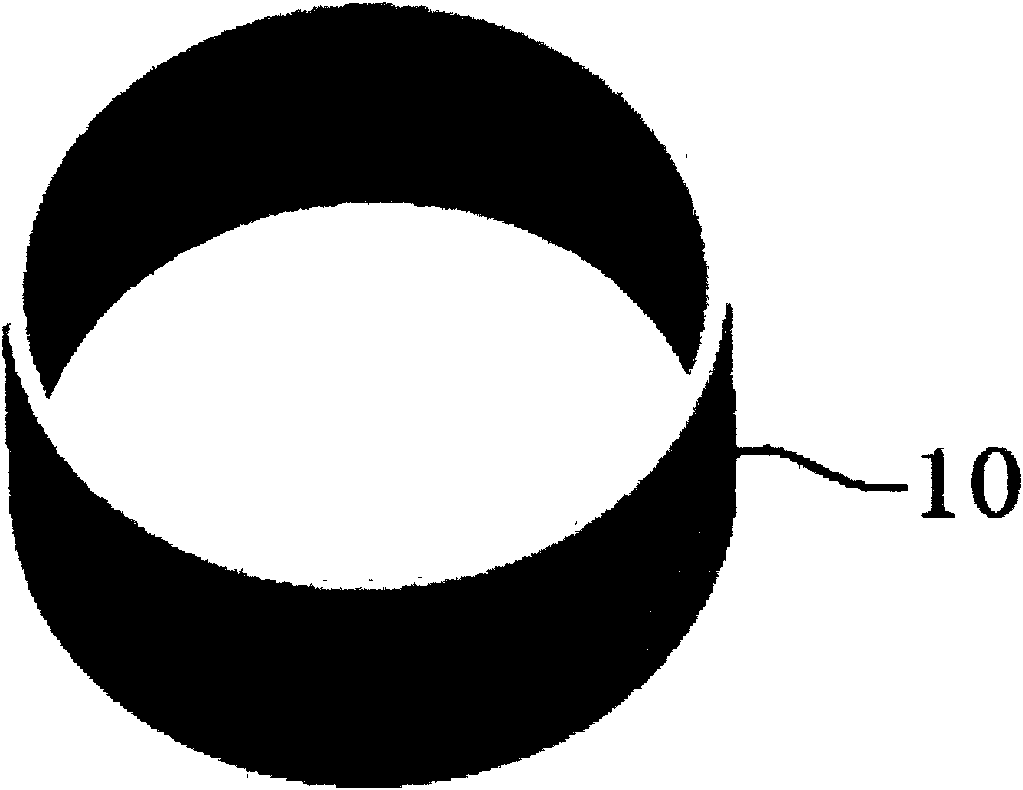

[0035] The 0Cr19Ni9 stainless steel bar blanked according to the specifications is heated, upset, punched, drawn, and pre-rolled to produce a pre-rolled billet 10°, and its shape is as follows: figure 1 shown.

[0036] Step 2: Install the computer.

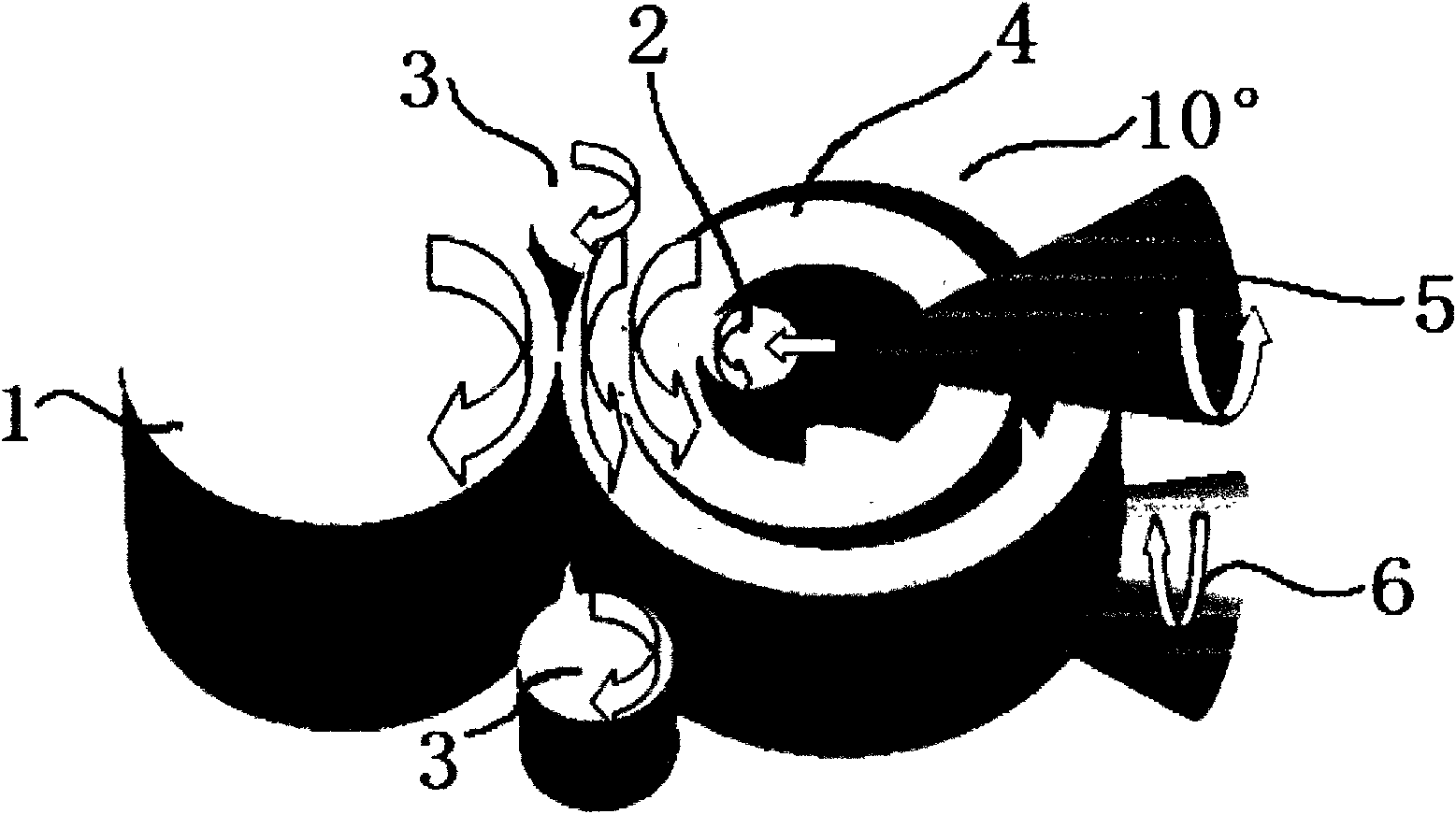

[0037] Such as figure 2 As shown, the pre-rolled billet is he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com