Method for preparing large-aperture three-dimensional network SiC ceramic material

A three-dimensional network, ceramic material technology, applied in the field of ceramic materials, can solve the problems of easy generation of wall pores, containing closed pores, and many closed pores, etc., to achieve the effect of improving the strength of the green body, improving the degree of connectivity, and easy to organize production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Mix SiC powder with B 4 C powder is mixed at a mass ratio of 99:1, ammonia water, sucrose, acrylamide, N,N-methylenebisacrylamide and water ball mill are added to form a SiC mixed slurry;

[0037] (2) Add surfactants accounting for 0.8‰ of SiC mixed slurry mass, 8% foaming agent hydrogen peroxide and 8% polyvinyl alcohol aqueous solution as binders to SiC mixed slurry, SiC mixed slurry and The mass ratio of the binder is 1:1, stir evenly, then add the initiator, continue to stir for 30s, then foam the gel at 80°C for 1h, transfer to -17°C for 4h, and then at room temperature, Using absolute ethanol or industrial ethanol as the extractant, extract the water in the frozen slurry once for 8 hours, and then dry it at 100°C for 4 hours to obtain a foaming gel;

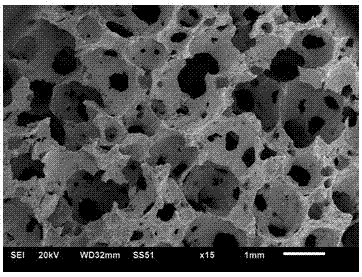

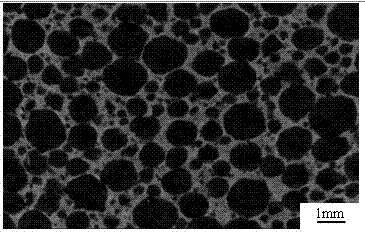

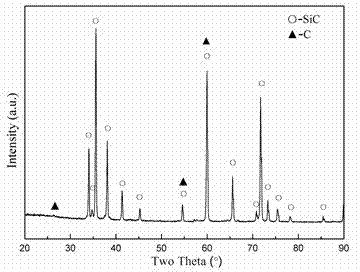

[0038] (3) Under the protection of an inert atmosphere, the foamed gel was sintered at 1950 ° C for 1 hour to obtain a large-pore three-dimensional network SiC ceramic material. The scanning electron microscope ...

Embodiment 2

[0043] (1) Mix SiC powder with B 4 C powder is mixed at a mass ratio of 99:1, ammonia water, sucrose, acrylamide, N,N-methylenebisacrylamide and water ball mill are added to form a SiC mixed slurry;

[0044] (2) Add surfactants accounting for 2.0‰ of SiC mixed slurry mass, 8% foaming agent hydrogen peroxide and 8% polyvinyl alcohol aqueous solution as binders to SiC mixed slurry, SiC mixed slurry and The mass ratio of the binder is 1:1, stir evenly, then add the initiator, continue to stir for 30s, then foam the gel at 80°C for 1h, transfer to -17°C for 4h, and then at room temperature, Using absolute ethanol or industrial ethanol as the extractant, extract the water in the frozen slurry once, each extraction time is 8h, and then dry at 100°C for 4h to obtain a foaming gel;

[0045] (3) Under the protection of an inert atmosphere, the foamed gel was sintered at 1950 ° C for 1 hour to obtain a large-pore three-dimensional network SiC ceramic material. The scanning electron mic...

Embodiment 3

[0050] (1) Mix SiC powder with B 4 C powder is mixed at a mass ratio of 99:1, ammonia water, sucrose, acrylamide, N,N-methylenebisacrylamide and water ball mill are added to form a SiC mixed slurry;

[0051] (2) Add surfactants accounting for 3.2‰ of SiC mixed slurry mass, 6% foaming agent hydrogen peroxide and 8% polyvinyl alcohol aqueous solution as binders to SiC mixed slurry, and SiC mixed slurry The mass ratio to the binder is 1:0.75, stir evenly, then add the initiator, continue to stir for 40s, foam at 70°C for 1h, transfer to -15°C for 12h, and then freeze at room temperature , using absolute ethanol or industrial ethanol as the extractant, extracting the water in the frozen slurry twice, each extraction time is 6h, and then drying at 100°C for 4h to obtain a foaming gel;

[0052] (3) Under the protection of an inert atmosphere, heat-preserve and sinter the foamed gel at 2000°C for 0.8h to obtain a large-aperture three-dimensional network SiC ceramic material. The sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com