A kind of hand-shaking milk with foaming properties and preparation method thereof

A technology for milk and foaming effect, applied in milk preparations, dairy products, applications, etc., can solve the problems of poor taste, insufficient foam and high cost, and achieve the effects of long foam holding time, dense foam and smooth taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

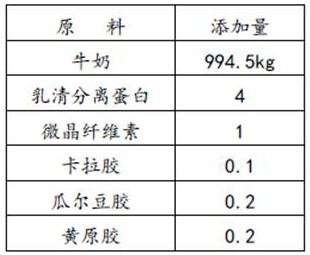

[0025] Product formula (per ton of final product):

[0026]

[0027] The preparation method includes the following steps:

[0028] 1) According to the formula, use a gouache mixer to disperse whey protein isolate, microcrystalline cellulose, carrageenan, guar gum, and xanthan gum into milk, and mix well;

[0029] 2); Homogenize the liquid obtained in step 1) at a homogenization temperature of 65°C, and perform a primary homogenization of 200 bar;

[0030] 3) Sterilize the homogenized liquid in step 2), the sterilization condition is 120°C, and the time is 15 seconds;

[0031] 4) Cool the liquid obtained after sterilization in step 3) to 0-5°C;

[0032] 5) Filling the liquid in step 4) to obtain the foamed milk product of the present invention.

Embodiment 2

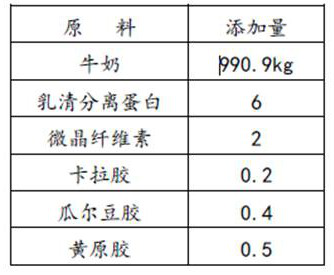

[0034] Product formula (per ton of final product):

[0035]

[0036] The preparation method includes the following steps:

[0037] 1) According to the formula, use a gouache mixer to disperse whey protein isolate, microcrystalline cellulose, carrageenan, guar gum, and xanthan gum into milk, and mix well;

[0038] 2); Homogenize the liquid obtained in step 1) at a homogenization temperature of 75°C, and perform a first-level homogenization of 300 bar;

[0039] 3) Sterilize the homogenized liquid in step 2), the sterilization condition is 140°C, and the time is 3 seconds;

[0040] 4) Cool the liquid obtained after sterilization in step 3) to 2-6°C;

[0041] 5) Filling the liquid in step 4) to obtain the foamed milk product of the present invention.

Embodiment 3

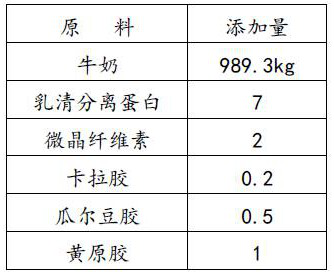

[0043] Product formula (per ton of final product):

[0044]

[0045] The preparation method includes the following steps:

[0046] 1) According to the formula, use a gouache mixer to disperse whey protein isolate, microcrystalline cellulose, carrageenan, guar gum, and xanthan gum into milk, and mix well;

[0047] 2); Homogenize the liquid obtained in step 1) at a homogenization temperature of 65°C, and perform a first-level homogenization of 100 bar;

[0048] 3) Sterilize the homogenized liquid in step 2), the sterilization condition is 65°C, and the time is 30 minutes;

[0049] 4) Cool the liquid obtained after sterilization in step 3) to 1-4°C;

[0050] 5) Filling the liquid in step 4) to obtain the foamed milk product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com