Three-dimensional woven material based on space group P*

A technology of three-dimensional weaving and weaving materials, which is applied in the direction of braids, textiles and papermaking, and can solve the problems that the feasibility and performance research of three-dimensional weaving materials has not yet been carried out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

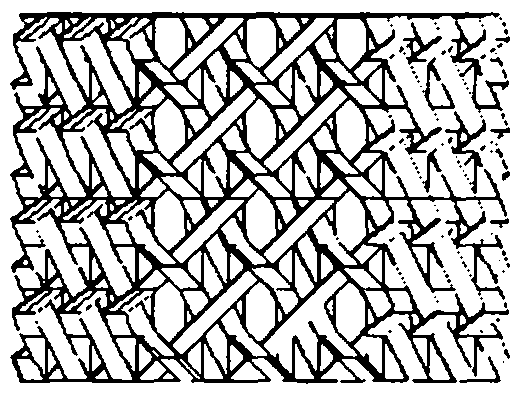

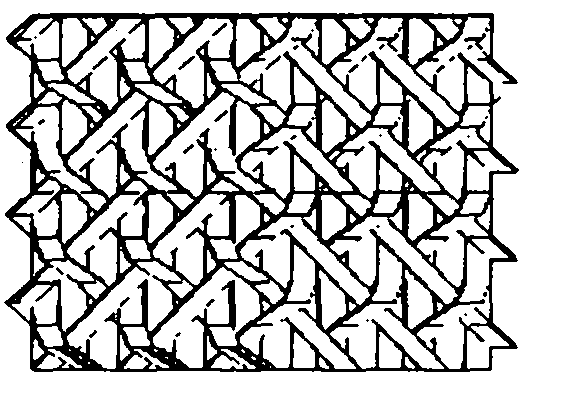

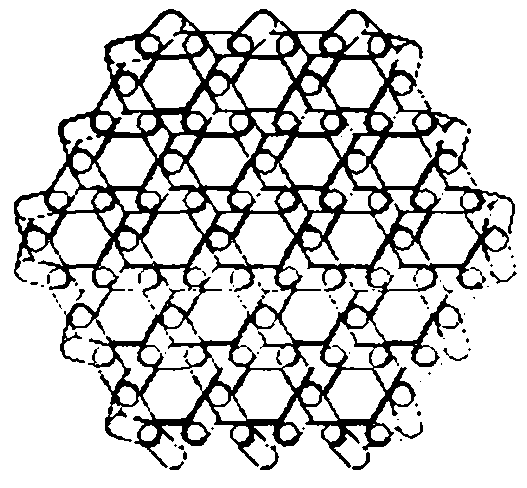

Image

Examples

Embodiment Construction

[0042] Concrete structure of the present invention is introduced as follows:

[0043] 1. Description of the combined unit cell structure of the yarn segment

[0044] space point group The group elements of (n is 1~6), the generator of the group is s 6 . The corresponding symmetry operation can be expressed as

[0045] s 6 z = c 6 z σ xy = [ x 2 - 3 2 y , 3 2 x + y 2 , z ]

[0046] s 6 z 2 ( x , y , z ) = [ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com