Surface chemico-thermal treatment method for mechanical parts and equipment used thereby

A technology of surface chemistry and mechanical parts, applied in lighting and heating equipment, coatings, furnace types, etc., can solve the problem that cycle furnaces or cycle furnaces cannot be heat-treated with the depth of carburized layer, etc., to achieve convenient production organization and play The effect of equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Take the carburizing and quenching of automobile gears as an example. The heat treatment requirements for three kinds of gears are set as shown in Table 1; according to the requirements of Table 1, the corresponding heat treatment process is compiled as Table 2:

[0065] Table 1. Heat treatment requirements for three gears

[0066]

[0067] Table 2 heat treatment process parameters

[0068]

[0069]

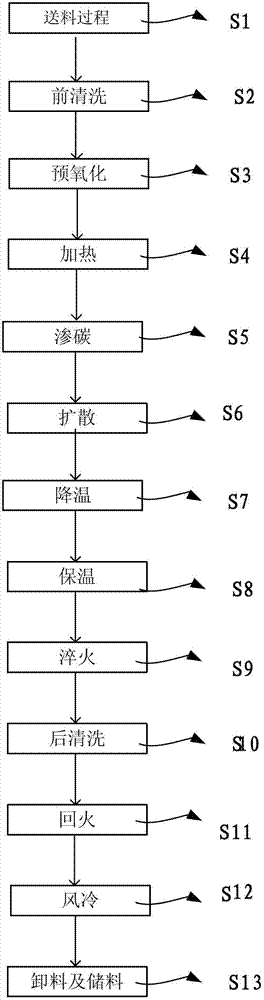

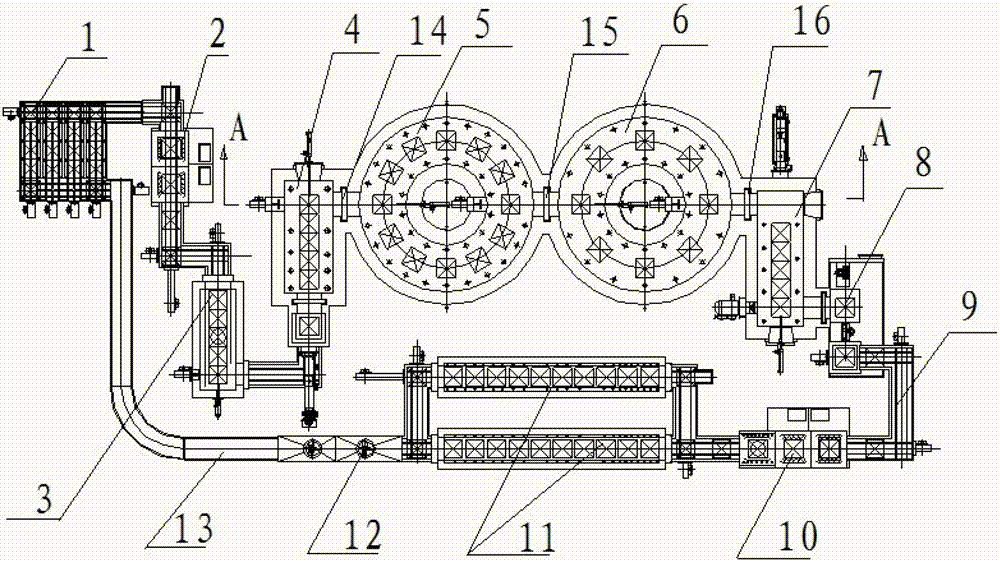

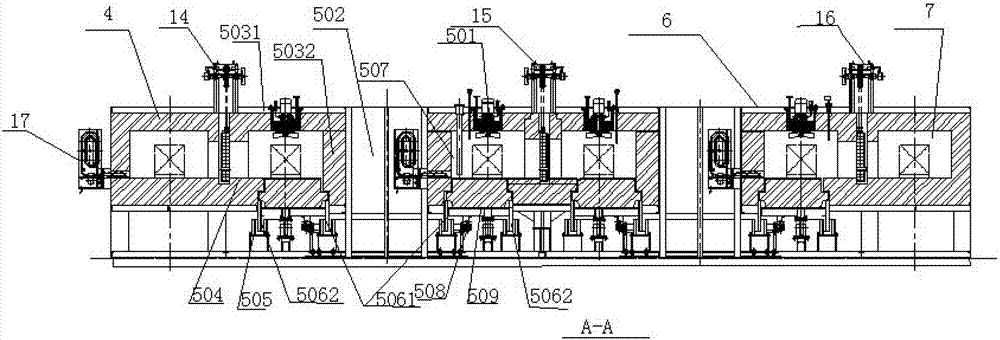

[0070] The above-mentioned three kinds of automotive gears go through the process of carburizing and diffusion after feeding and preparing materials→pre-cleaning→pre-oxidation→heating process: each process of carburizing in the circular rotary bottom carburizing furnace and circular rotary bottom diffusion furnace on the process line The station residence time is 15-35min. There are 12 stations in the infiltration furnace and 8 stations in the diffusion furnace. Set the production beat to 30min.

[0071] After the 3 kinds of gears are installed on the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com