Movable straw solidification device

A solidifying and mobile technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems affecting the popularization and application of existing technologies, large storage area, large acquisition and transportation costs, etc. The effect of organizing production, low manufacturing cost, and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

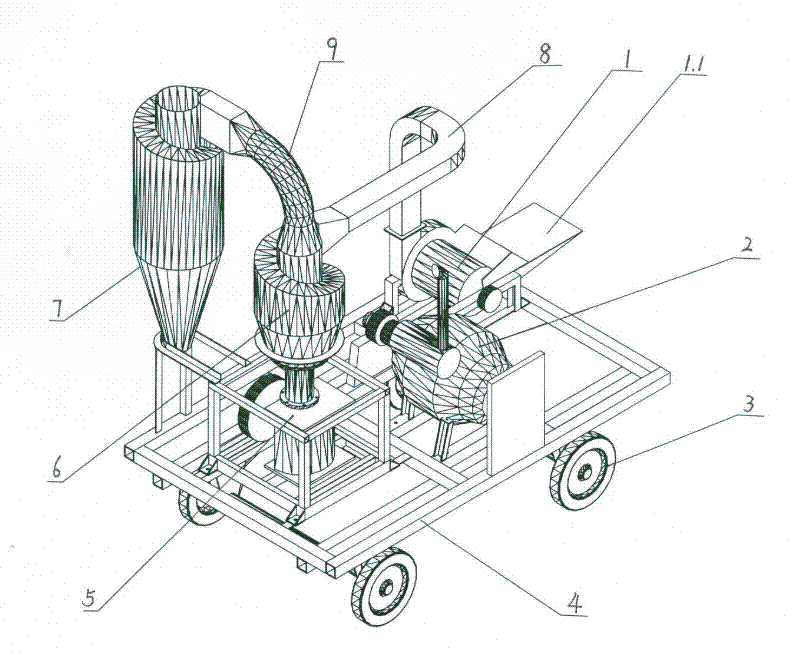

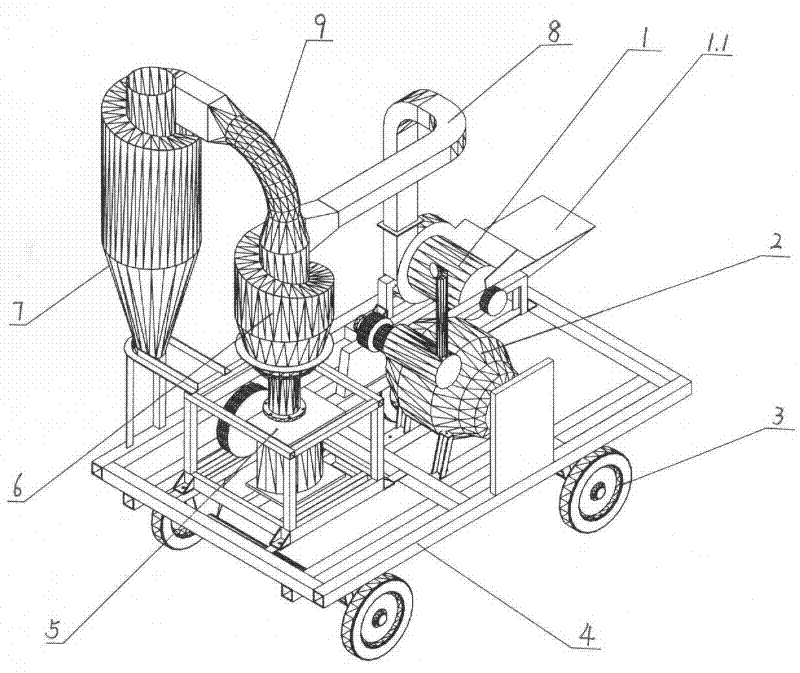

[0013] figure 1 Shown mobile stalk curing molding device, it comprises crushing kneading machine 1, internal combustion engine 2, wheel 3, vehicle frame 4, briquetting machine 5, settler 6, dust catcher 7, feeding pipe 8 and conduit 9. The vehicle frame 4 is a flat rectangular frame, the four corners of the bottom are provided with rotating wheels 3, and the internal combustion engine 2 is installed in the middle of the upper plane. The drive between the machine 1 and the briquetting machine 5 is driven by a belt transmission mechanism. The feed port 1.1 of crushing and kneading machine 1 faces outwards during installation, which is convenient for artificial feeding of stalks. The inlet end of briquetting machine 5 is upwards and is connected with the settler 6 outlet end that is in upper position, and the stalk material of compacting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com