Refrigerator condensator installation structure

A technology of installation structure and condenser, applied in the direction of evaporator/condenser, household refrigeration device, refrigerator, etc., can solve the problems of poor heat transfer effect of condenser aluminum tube and high energy consumption, and achieve size reduction and energy consumption reduction , the effect of reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below with reference to the drawings.

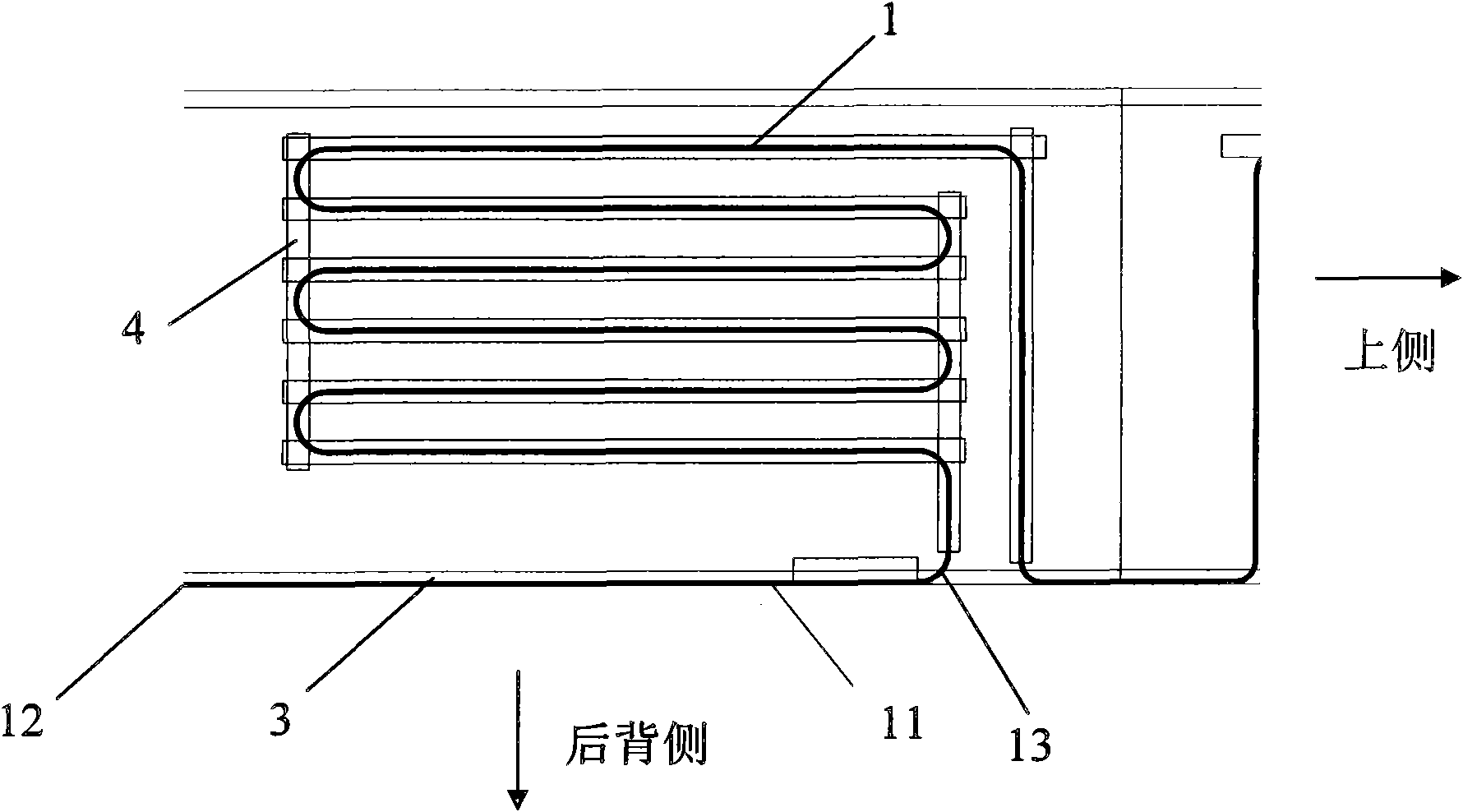

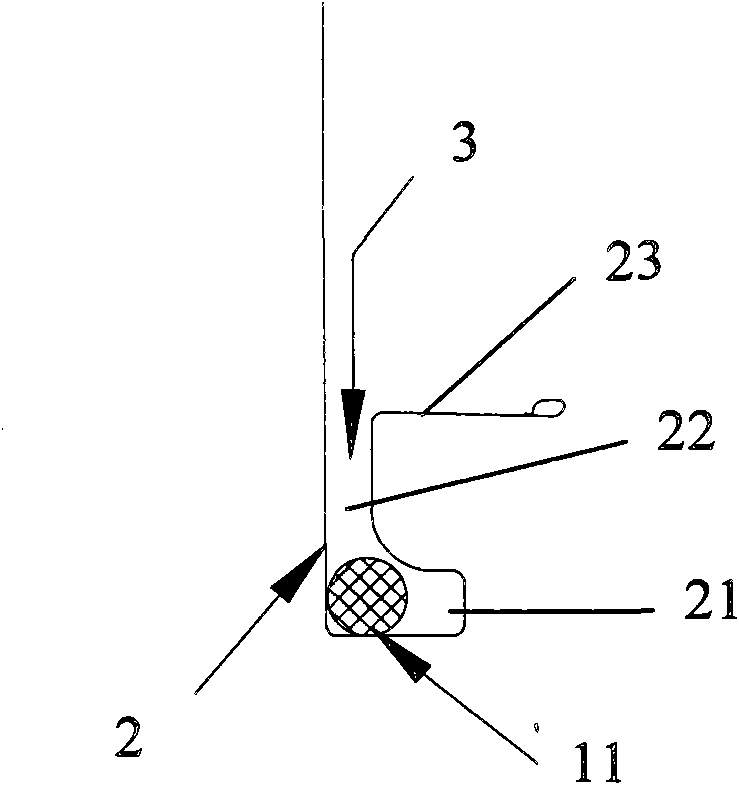

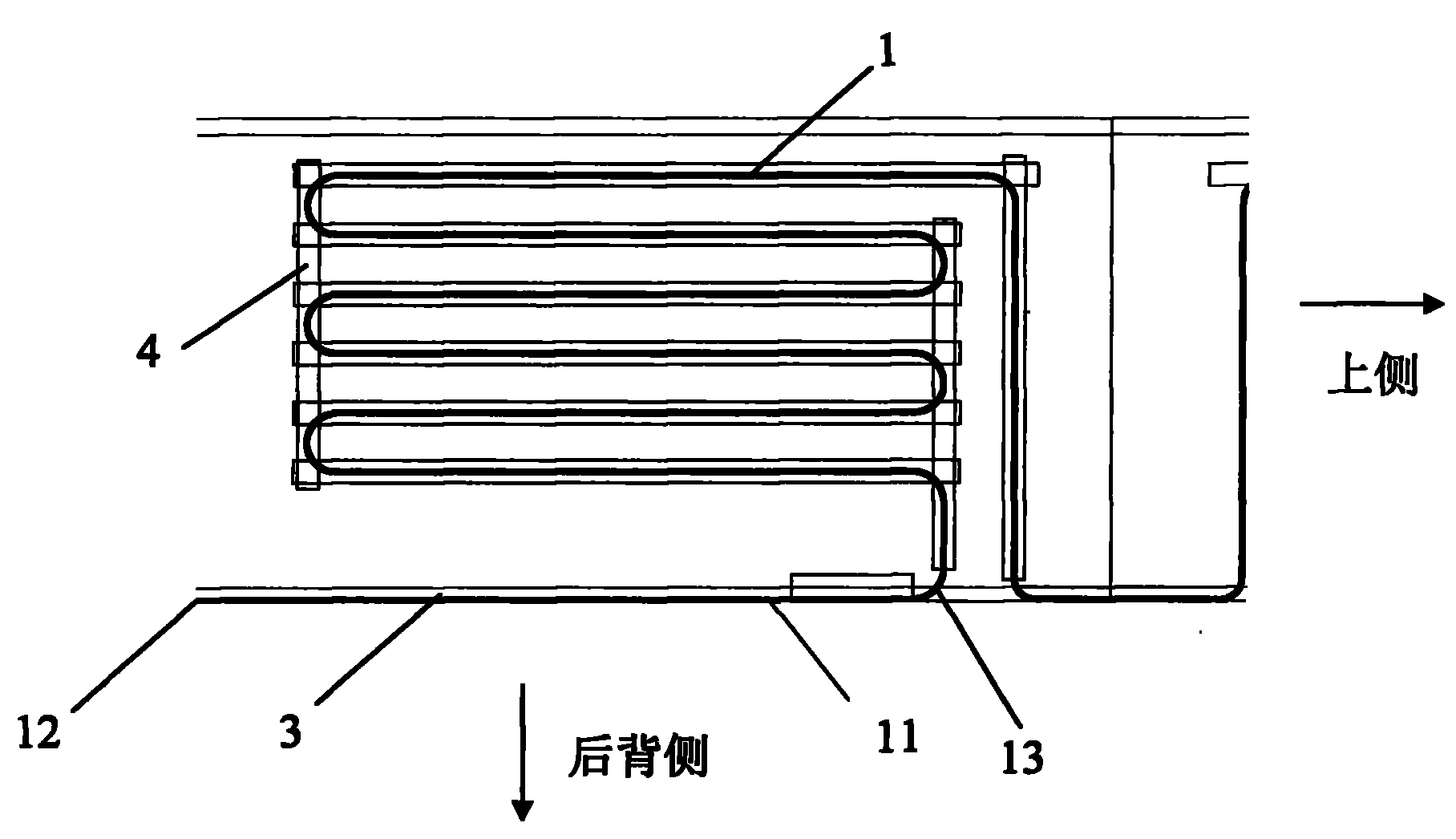

[0027] figure 1 The middle right side is the upper side of the refrigerator case, figure 1 The middle and lower side is the back side of the refrigerator box shell. like figure 1 As shown in , the condenser 1 is a light tube structure, which is bent back and arranged in the refrigerator case 2 (refer to figure 2 . Commonly known as U shell, including the top plate and two side plates, in the shape of the letter U) the inner side of the side plate ( figure 1 The outer side of the paper surface), and fixed by aluminum foil 4.

[0028] On the rear side of the refrigerator case, along the vertical direction ( figure 1 middle, left and right direction) is formed with a back card slot 3, the first row of pipelines of the condenser 1 counted from the back side of the refrigerator, that is, the pipeline 11 of the initial section from the condenser inlet 12 to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com