Facility for forming battery electrode plate

A battery electrode and forming equipment technology, applied in the direction of electrode manufacturing, etc., can solve the problems of large-scale equipment, battery electrode plate breakage, productivity and quality reduction, etc., to prevent bending or flattening, stable press forming, and easy replacement operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below with reference to the drawings.

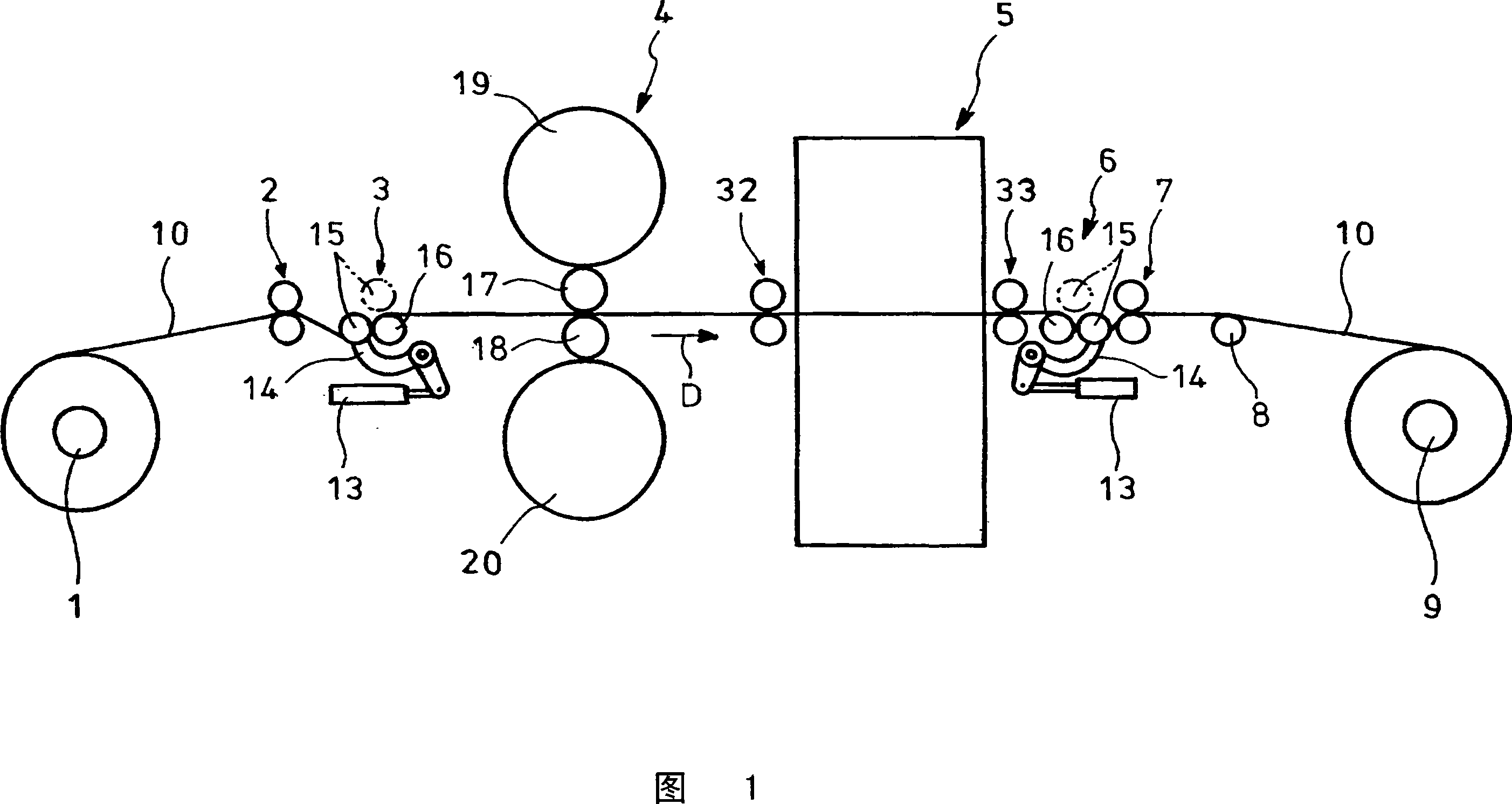

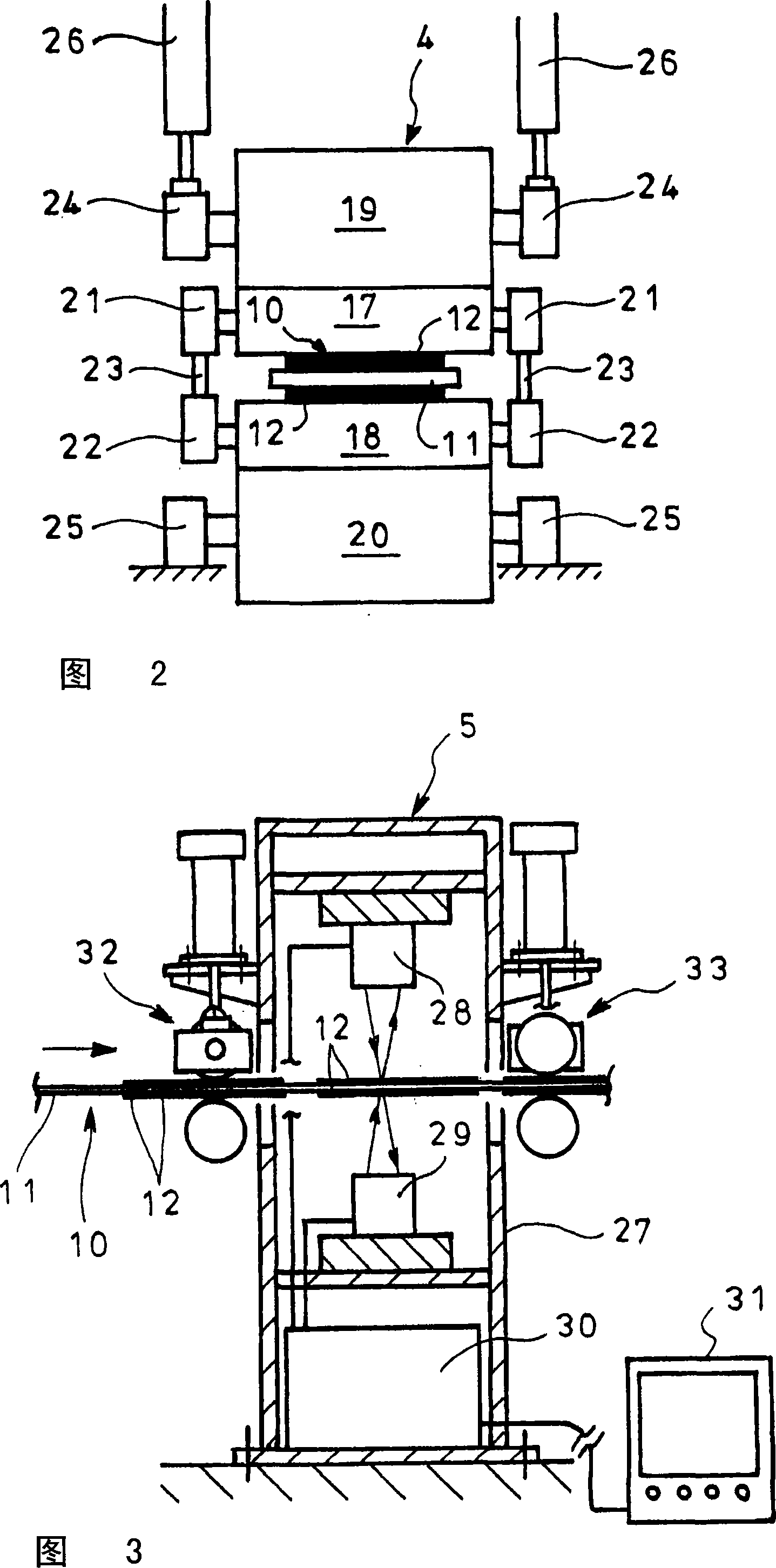

[0029] 1 to 10 are an embodiment of the present invention. In the figure, 1 is an uncoiler, 2 is a pinch roller, 3 is a tension imparting device, 4 is a rolling device, 5 is a thickness detection device, 6 is a tension imparting device, 7 is a pinch roller, and 8 is a deflector roller. rol1), 9 is a winding machine. The uncoiler 1, the pinch roller 2, the tension imparting device 3, the roll pressing device 4, the thickness detection device 5, the tension imparting device 6, the pinch roller 7, Lifting roller 8, winding machine 9.

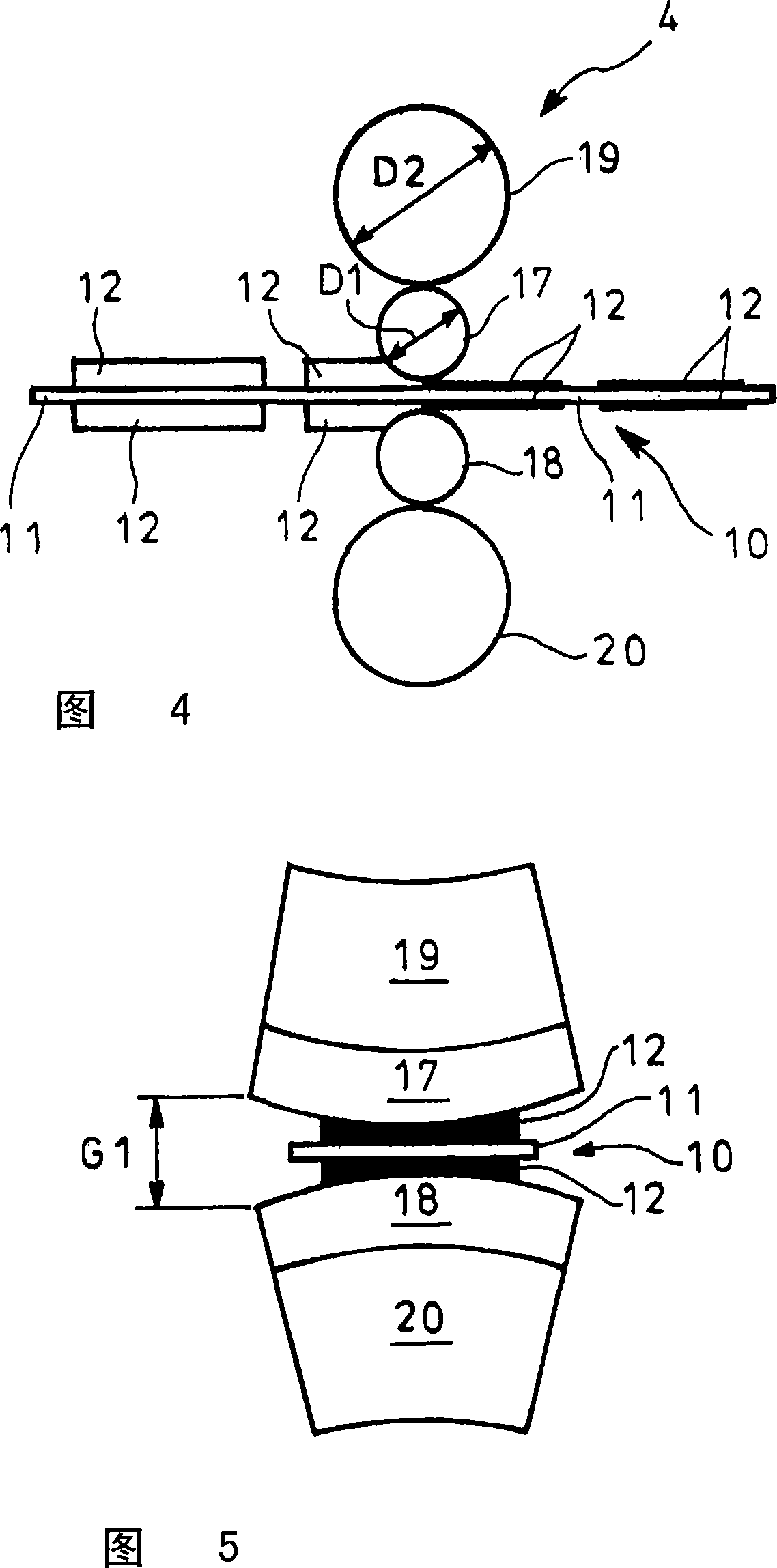

[0030] As shown in Fig. 3 and Fig. 4, the battery electrode plate 10 has the following shape, that is, on the upper and lower surfaces of the strip-shaped core material 11, which is a metal foil current collector made of aluminum foil, the coating is discontinuously coated at intervals along the longitudinal direction. The positive electrode act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com