Pipe punching bending device

A tube bending device and arc technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as difficulty in controlling the bending angle and strength, squeezing of the lumen channel, and inability to use it normally, achieving easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

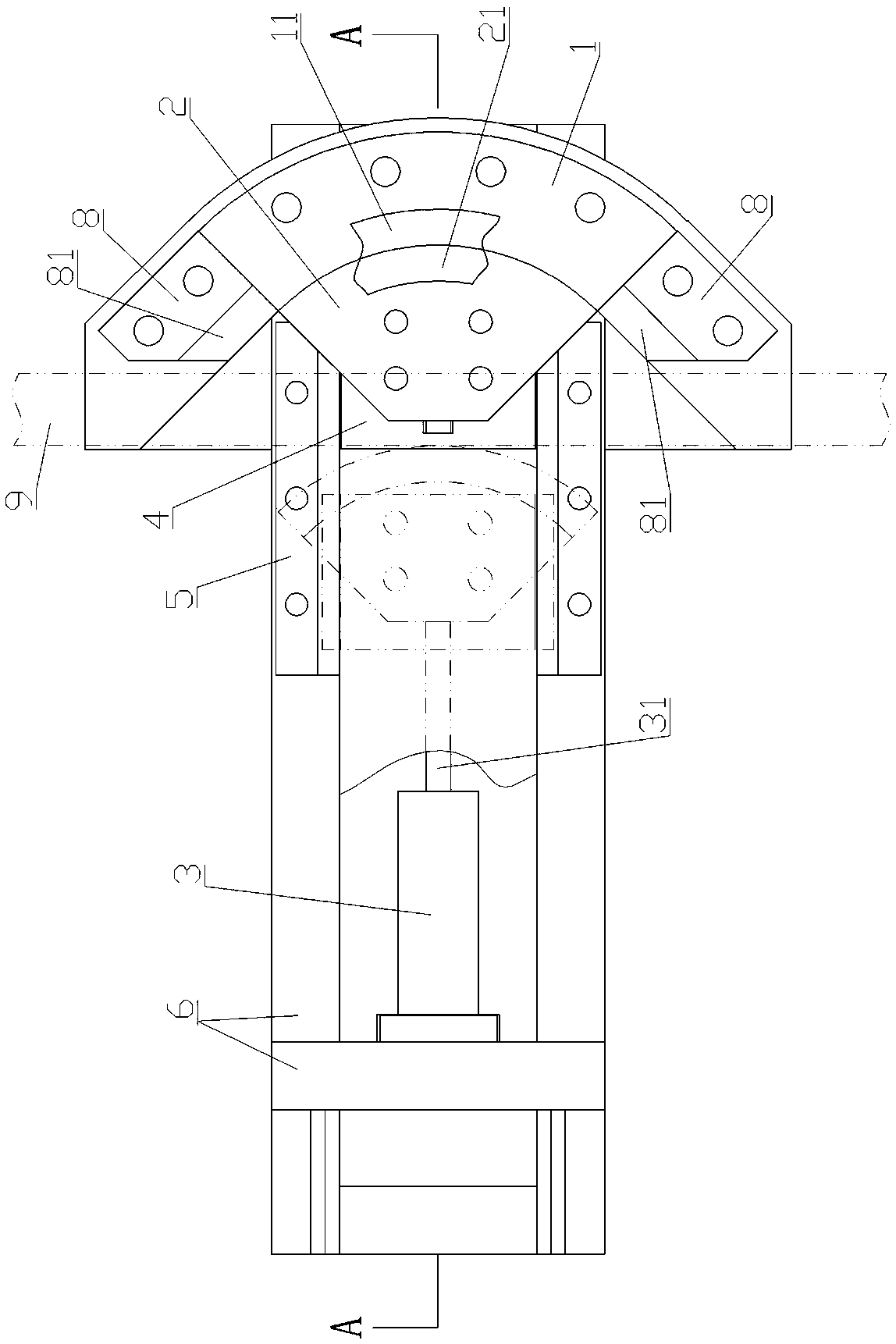

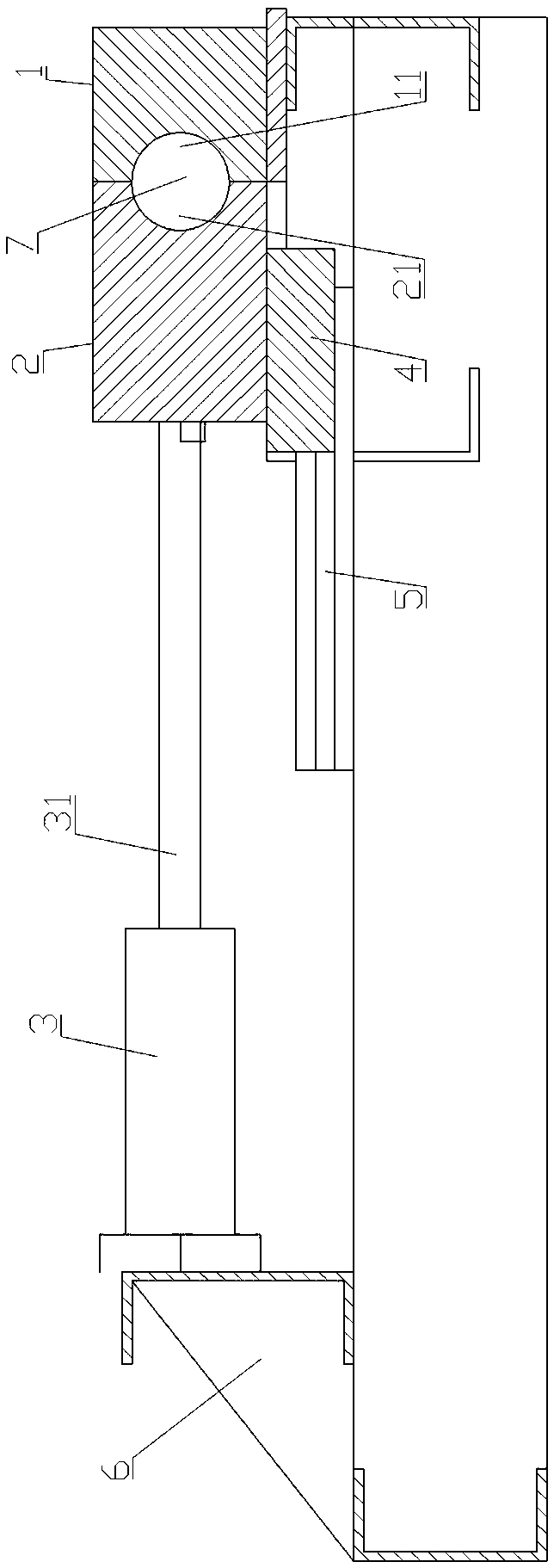

[0017] like figure 1 , 2 As shown, the stamping pipe bending device includes an arc outer mold 1, an arc inner mold 2, a jack 3, a slider 4, a slide rail 5 and a support 6.

[0018] The arc outer mold 1 is fan-cylindrical, and its lower end surface is fixedly connected on the support 6, and its inner arc surface is provided with a concave arc-shaped groove B11; the arc inner mold 2 is fan-cylindrical, and its lower end surface Fixed on the slide block 4, the outer arc surface is provided with a concave arc groove A21, the arc groove A21 is facing the arc groove B11 of the arc outer mold 1, and the other arc groove opposite to the outer arc surface One end face is the piston rod connection surface 22; the jack 3 is fixedly connected to the support 6, and its piston rod 31 extends horizontally and is connected to the piston rod connection surface 22 of the arc inner mold 2; the slider 4 is movably installed on the on the slide rail 5; the slide rail 5 is fixedly installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com