Special construction waste crusher

A technology of construction waste and crusher, which is applied in the direction of cleaning methods and utensils, smoke and dust removal, grain processing, etc., can solve the problems of sand entering the glasses, bad breathing, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

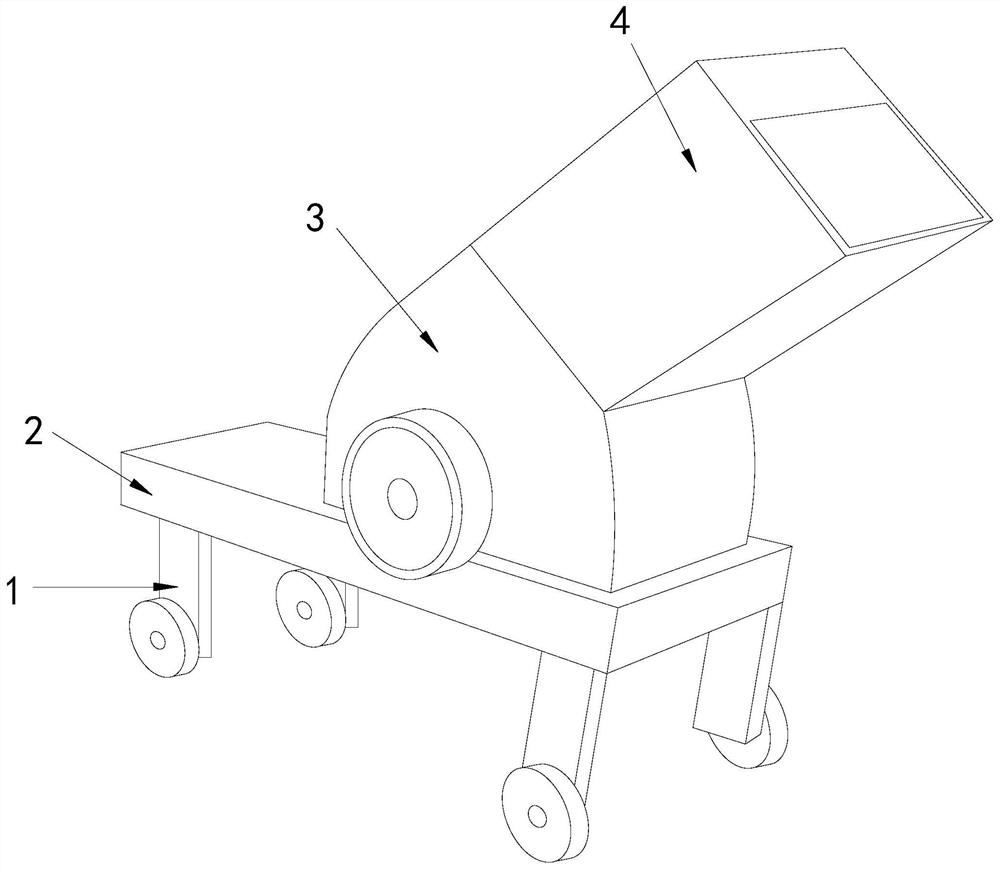

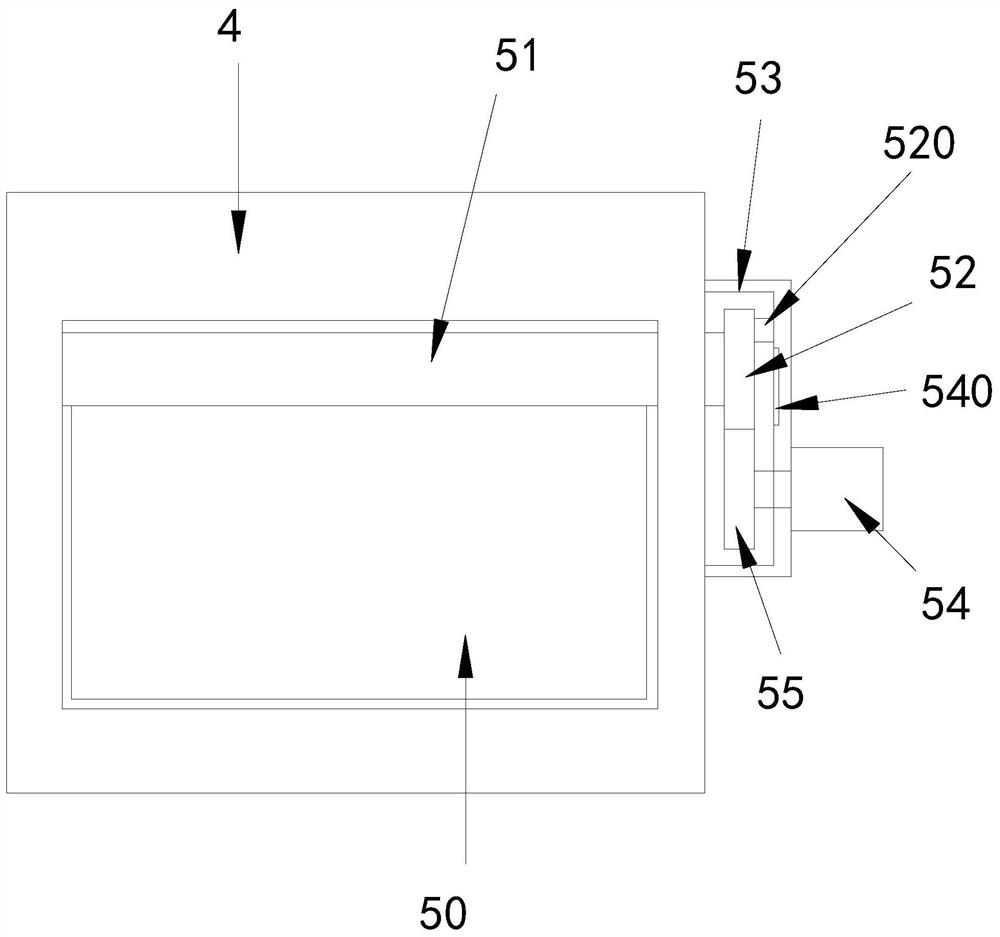

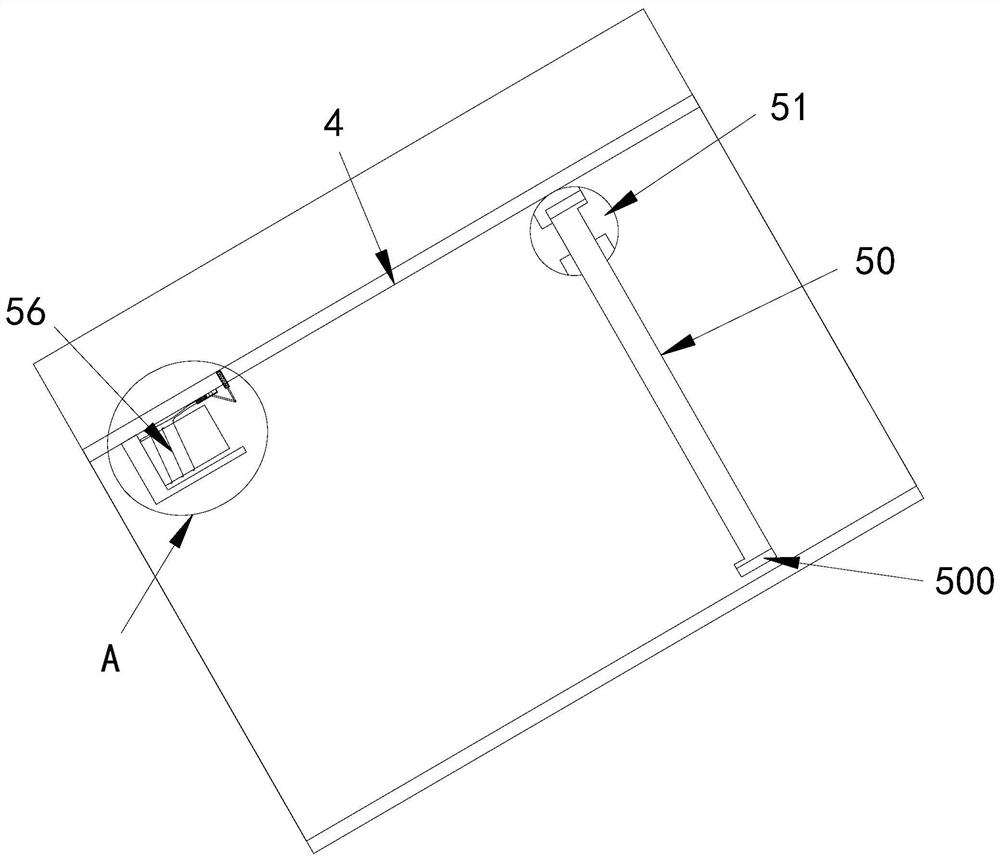

[0030] see Figure 1-6 , the present invention provides a special construction waste crusher technical solution: its structure includes a moving wheel 1, a base 2, a body 3, a feeding pipe 4, and a dust suppression device 5, the bottom of the base 2 is connected with a moving wheel 1, the The top of the base 2 is welded with an organic body 3, the top of the body 3 is connected with a feed pipe 4, and the feed pipe 4 is equipped with a dust suppression device 5, and the dust suppression device 5 includes a dust suppression plate 50, a rotating shaft 51, a rotating disk 52, Protective cover 53, motor 54, gear 55, electromagnetic structure 56, described rotating shaft 51 is installed in the feeding pipe 4, described rotating shaft 51 is provided with dust suppression board 50, described protective cover 53 is connected on the outside of feeding pipe 4 , the gear 55 is located in the protective cover 53 and is connected with the motor 54, a turntable 52 is arranged above the gear...

Embodiment 2

[0033] see Figure 1-6, the present invention provides a special construction waste crusher technical solution: its structure includes a moving wheel 1, a base 2, a body 3, a feeding pipe 4, and a dust suppression device 5, the bottom of the base 2 is connected with a moving wheel 1, the The top of the base 2 is welded with an organic body 3, the top of the body 3 is connected with a feed pipe 4, and the feed pipe 4 is equipped with a dust suppression device 5, and the dust suppression device 5 includes a dust suppression plate 50, a rotating shaft 51, a rotating disk 52, Protective cover 53, motor 54, gear 55, electromagnetic structure 56, described rotating shaft 51 is installed in the feeding pipe 4, described rotating shaft 51 is provided with dust suppression board 50, described protective cover 53 is connected on the outside of feeding pipe 4 , the gear 55 is located in the protective cover 53 and is connected with the motor 54, a turntable 52 is arranged above the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com