Advanced heating system for ammonia synthesis catalyst and heating method

A technology of ammonia synthesis and catalyst, which is applied in the heating system and heating field, can solve the problems of low synthetic ammonia synthesis efficiency, long start-up process cycle, waste of process gas, etc., and achieve the effect of improving effective utilization rate, shortening start-up time, and saving start-up costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

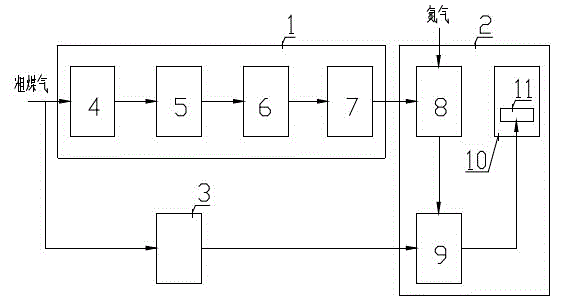

[0046] Example. A system for raising the temperature of an ammonia synthesis catalyst in advance, consisting of figure 1 As shown, the ammonia synthesis unit 2 is included, and the ammonia synthesis unit 2 is respectively connected with a pretreatment unit 1 and an unshifted gas scrubber 3; the pretreatment unit 1 includes a CO conversion device 4, and the CO conversion device 4 passes through a shifted gas scrubber 5 is connected with molecular sieve 6, and molecular sieve 6 is connected with liquid nitrogen washing device 7; Described ammonia synthesis unit 2 comprises ammonia synthesis gas compressor 8, and ammonia synthesis gas compressor 8 is connected with ammonia synthesis device 10 through start-up heating furnace 9, ammonia synthesis unit 2 The synthesis unit 10 is provided with an ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com