Main leaf spring eye shaping equipment and processing method thereof

A technology of leaf springs and processing methods, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem that the perpendicularity between the ear hole and the reed leaf cannot meet the requirements, the hydraulic ear rolling equipment is complex, and the center distance between the two ear holes fluctuates greatly, etc. problems, to achieve the effect of compact structure, low power and fast production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings in the specification, so as to facilitate the understanding of those skilled in the art.

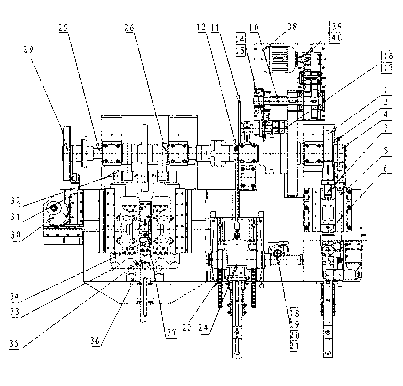

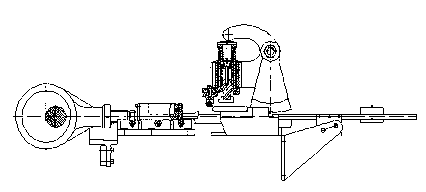

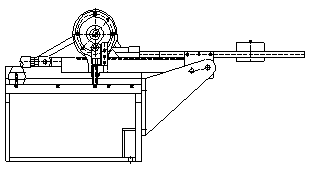

[0019] Such as figure 1 As shown, a leaf spring main sheet rolling ear shaping equipment and its processing method include a cutting head system, a rolling ear system and a shaping system arranged on a frame. The cutting head system includes a cutting head blade 6, a cutting head blade 6 The ball screw 3 is connected to the rocker arm 1. The rocker arm 1 is provided with an eccentric wheel 2, and the eccentric wheel 2 is provided with a compression cam 4. The lug system includes a drive spindle 10, which is connected to a pull wheel through a clutch flywheel 14 11 is connected, the traction wheel 11 is connected to the rack 22 through the traction rod 12, the rack 22 is connected with the lug rotating drum 24, and the lug rotating drum 24 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com