Method and apparatus for controlling a material ejector system

A material and controller technology, which is applied in the direction of freight vehicles, vehicles with push plates, transport objects, etc., can solve the problems that materials cannot be spread evenly and increase the difficulty of vehicle operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

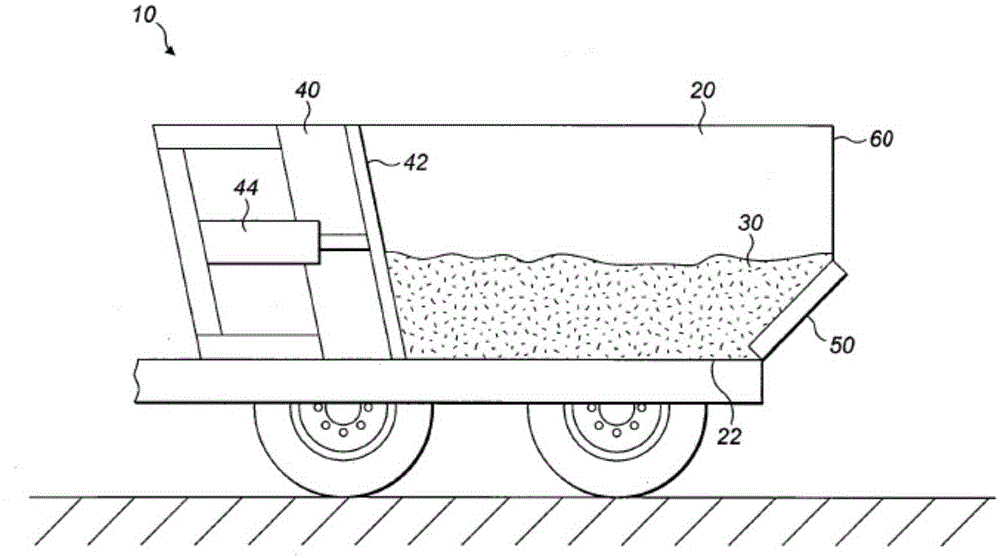

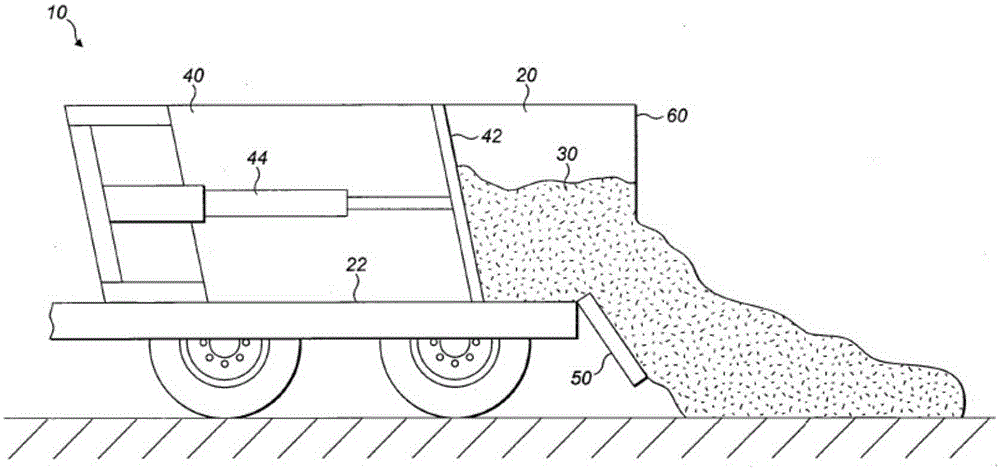

[0014] figure 1 Vehicle 10 is shown equipped with a material ejection system 40 for ejecting material 30 located in material container 20 . The vehicle 10 may be a vehicle with drive wheels (such as a truck), or a vehicle without drive wheels (such as a trailer designed to be towed by other vehicles with drive wheels). exist figure 1 In the configuration shown, the ejection of the material 30 in the material container 20 has not yet started. Thus, the door 50 is in the closed position to assist in retaining the material 30 in the material container 20, and the material ejection system 40 is in the initial position. As the vehicle 10 moves between fields, it can remain in a position such as figure 1 The configuration shown is such that material 30 remains in vehicle 10 .

[0015] The material pushing system 40 may include a push plate 42 and a multistage hydraulic cylinder 44, which is configured to move the push plate 42 from figure 1 The initial position shown in is move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com