Double-cutter cotton-escape preventing fiber cutting machine

A cotton fiber cutting machine technology, applied in fiber processing, decomposing fiber-containing substances, fiber bundles into fiber slivers/yarns, etc., can solve the problems of increasing air impurity content, increasing fiber processing costs, and reducing fiber processing efficiency. Achieve the effects of increasing air humidity, increasing weight, and reducing cotton content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

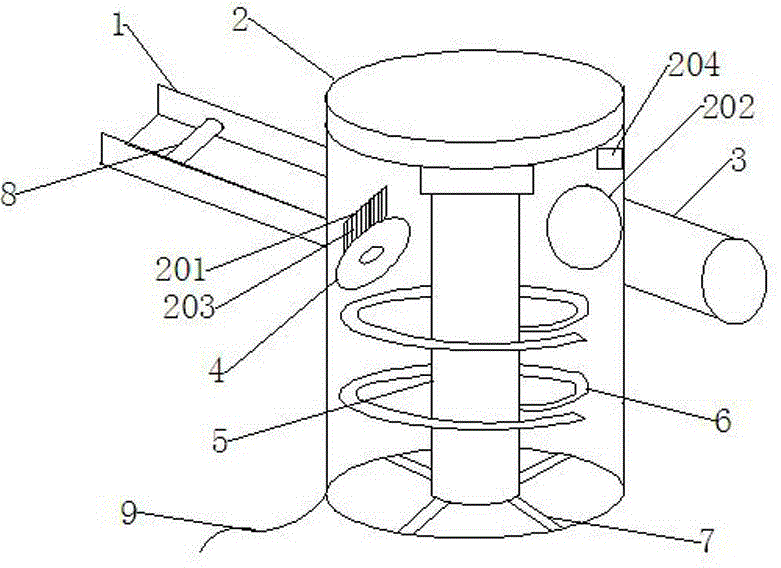

[0024] Such as figure 1 As shown, a double-knife anti-running cotton fiber cutting machine includes a feeding device 1 , a box body 2 , a discharge cylinder 3 , a knife group 4 at a feed inlet and a rolling knife group 5 .

[0025] The box body 2 is provided with a material inlet 201 and a material outlet 202 , and the feeding device 1 and the material outlet barrel 3 communicate with the box body 2 through the material inlet 201 and the material outlet 202 respectively.

[0026] The feed inlet knife group 4 is arranged below the feed inlet 201, and the feed inlet knife group 4 is driven by the first motor through a transmission mechanism.

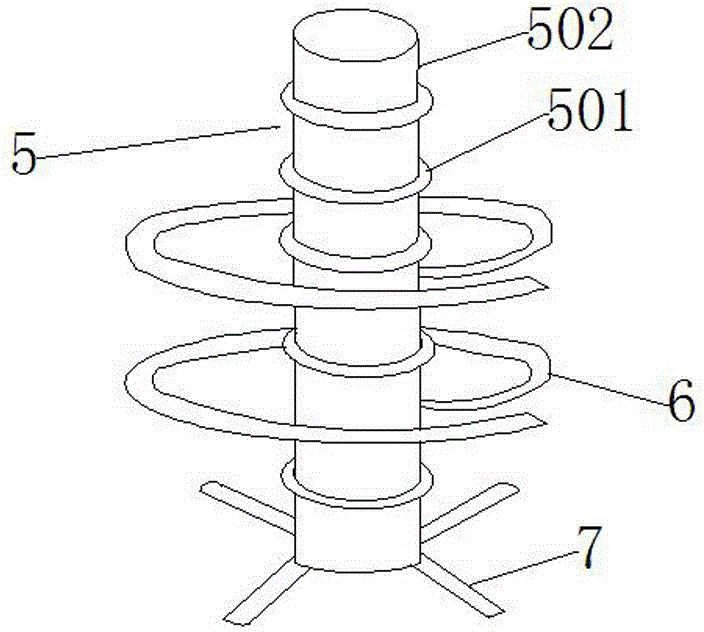

[0027] The rolling knife group 5 is vertically arranged in the box, and the rolling knife group 5 is driven by the second motor through the transmission mechanism; the rolling knife group 5 is fixedly provided with a stirring fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com