Negative resist composition

A technology of negative resist and composition, which is applied in the direction of instruments, optomechanical equipment, coatings, etc., and can solve the problems of reduced transmittance, low thermal stability of photoresist, and contamination of liquid crystal displays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

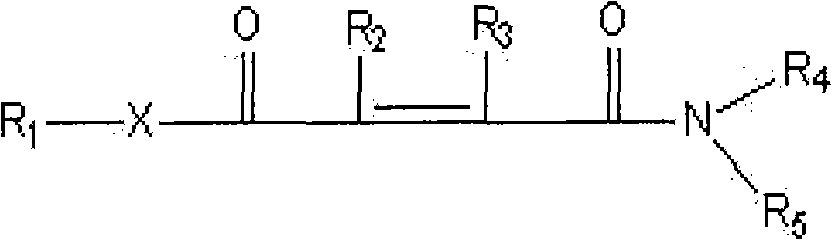

Method used

Image

Examples

Embodiment 1

[0040]150 ml of propylene glycol methyl ether acetate (PGMEA) was placed in a mixing chamber with a UV blocking membrane and a stirrer. According to the compositions and contents shown in Table 1 below, a binder resin, a multifunctional (meth)acryl monomer, and a photoinitiator were sequentially added. And 0.1% by weight of FC-430 (manufactured by 3M, a leveling agent) was added. Then, a negative resist composition was prepared and stirred at room temperature. Next, PGMEA was added to control the viscosity of the composition to 18 cps.

Embodiment 2-9

[0042] According to the composition and content in Table 1 below, a negative resist composition was prepared in the same manner as in Example 1.

[0043] Table 1

[0044]

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com