Method for preparing high purity lysine sulfate through fermenting

A technology of lysine sulfate and lysine, applied in the field of amino acid fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

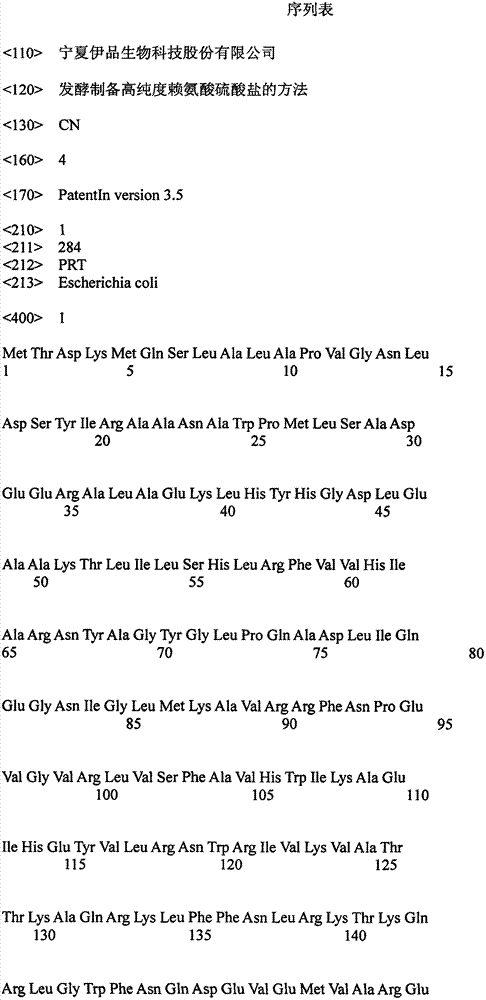

[0075] The preparation of embodiment 1 RNA polymerase sigma-32 factor gene construct

[0076] According to the amino acid sequence of the protein accession number AAB18436.1 of NCBI (http: / / www.ncbi.nlm.nih.gov), the inventors designed a moderate expression codon (non-expression optimized codon), and obtained The pathway commissioned Shanghai Sangon Biotechnology Co., Ltd. to synthesize the gene encoding RNA polymerase sigma-32 factor and construct it into E. coli expression plasmid pET-20b(+) (available from Novagen, USA, product number Cat.No.69739-3 )middle. The cloning process was carried out according to the "Molecular Cloning Experiment Guide" and the operation guide of the commercial reagents used. The brief process is as follows:

[0077] Synthesize nucleic acid fragments of the RNA polymerase sigma-32 factor gene by an automatic DNA synthesizer, use T4 polynucleotide kinase (purchased from TaKaRa company) to phosphorylate the 5' ends of these nucleic acid fragments, ...

Embodiment 2

[0079] Embodiment 2 Escherichia coli fermentation produces L-lysine

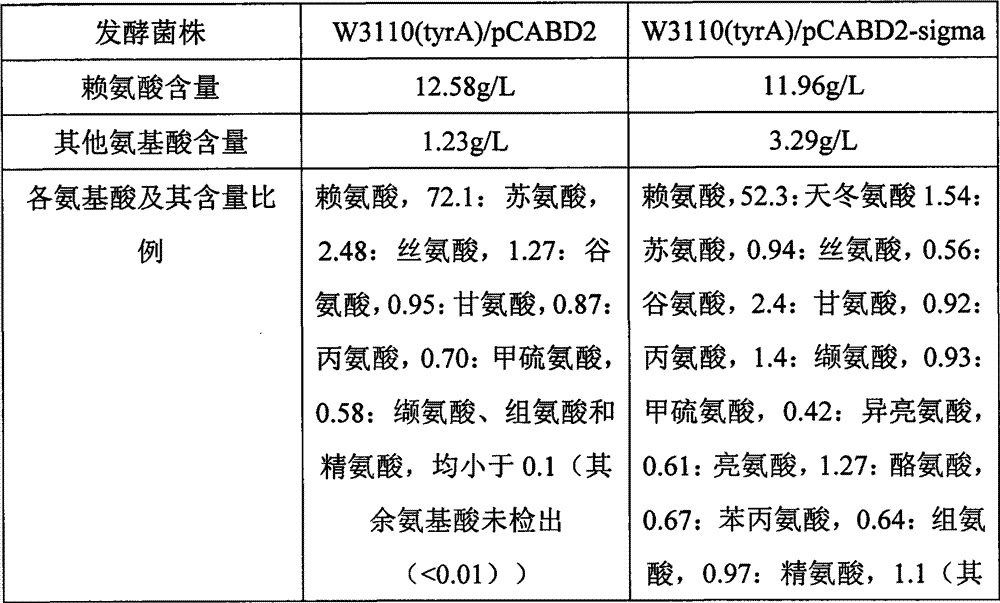

[0080] The L-lysine-producing Escherichia coli strain W3110(tyrA) / pCABD2 constructed by the method described in Chinese Patent No. 94194962 was transformed into a pET-sigma plasmid, and a positive clone was obtained after identification (named as W3110(tyrA) / pCABD2 -sigma), the strains W3110(tyrA) / pCABD2 and W3110(tyrA) / pCABD2-sigma were subjected to lysine fermentation experiments with reference to Chinese Patent No. 03120099. In short, the bacterial strain was inserted into the liquid LB medium for shaking culture until the OD500 reached 0.35, and was inserted into the lysine fermentation medium with a 5% inoculum size (the formulation of the medium per liter was: 100g glucose, 60g (NH 4 ) 2 SO 4 , 50g CaCO 3 , 35mL peptone-B (Soy Protein Enzymatic Hydrolysate, purchased from Shanghai Xinran Biotechnology Co., Ltd., the total nitrogen content is not less than 3%), 1g KH 2 PO 4 , 400mgMgSO 4 ·7H 2 O,...

Embodiment 3

[0084] The refining of embodiment 3L-lysine sulfate product

[0085] The supernatants obtained from strains W3110(tyrA) / pCABD2 and W3110(tyrA) / pCABD2-sigma described in Example 2 were respectively taken out by 1 / 4 volume and purified first: these supernatants were loaded on Sephadex G-10 Chromatographic column, eluted with pure water, collected fractions with a molecular weight between 100 and 200Da, and quantified the L-lysine content and other components in the fractions by HPLC, wherein: W3110(tyrA) / pCABD2 The composition distribution of lysine is as follows: lysine, 92.60%; threonine, 3.23%; serine, 1.70%; glutamic acid, 1.33; methionine, 0.76%; ); the composition distribution of W3110(tyrA) / pCABD2-sigma was: lysine, 80.73%; aspartic acid, 2.39%; threonine, 1.51%; serine, 0.89%; glutamic acid, 3.73%; valine Acid, 1.37%; Methionine, 0.68%; Isoleucine, 0.97%; Leucine, 1.97%; Tyrosine, 1.12%; Phenylalanine, 0.99%; Histidine, 1.50%; Arginine, 1.72%; other impurity components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com