Magnetic material composition and coil component

A coil component and magnetic body technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of difficult magnetic saturation, low insulation, high saturation magnetic flux density, etc., and achieve good plating solution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

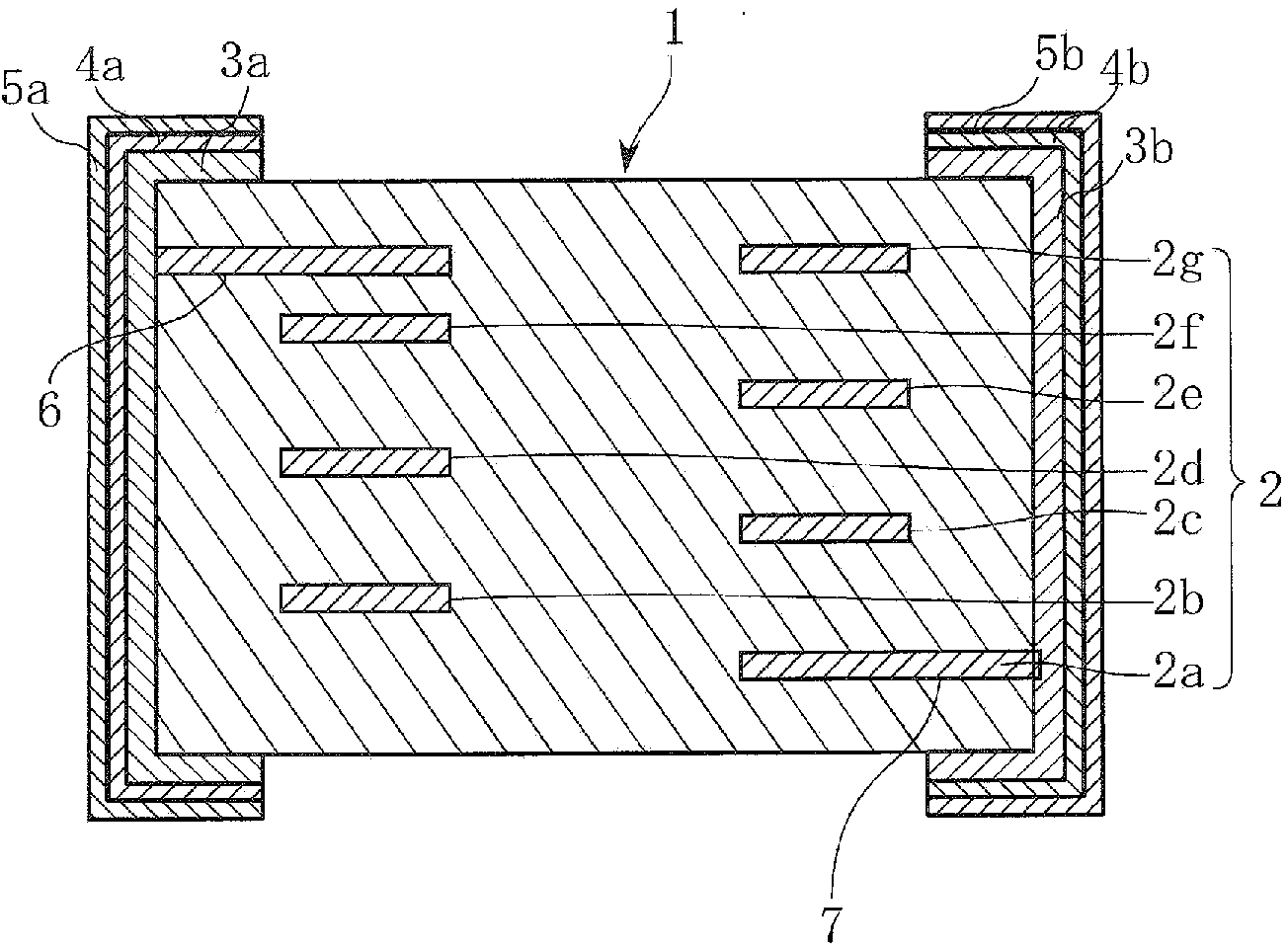

Embodiment 1

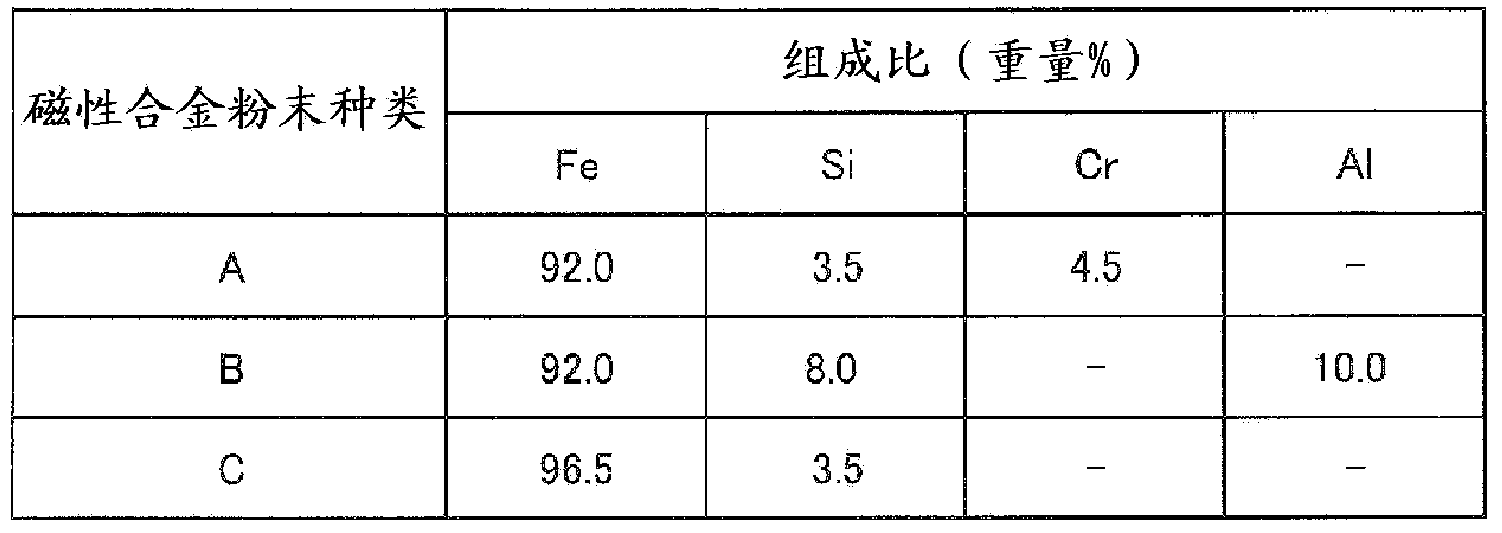

[0083] Commercially available Fe—Si—Cr-based magnetic alloy particles (magnetic alloy particles A), Fe—Si—Al-based magnetic alloy particles (magnetic alloy particles B) and Fe—Si-based magnetic alloy particles (magnetic alloy particles B) shown in Table 1 were prepared. Alloy particles C). It should be noted that the average particle diameters of these magnetic alloy particles A to C are all 6 μm.

[0084] Table 1 shows the respective composition ratios of the magnetic alloy particles A to C.

[0085] [Table 1]

[0086] [Table 1]

[0087]

[0088] In addition, prepare SiO 2 , B 2 o 3 、K2 Each glass raw material of O and ZnO was mixed so that it might become the composition shown in Table 2, and glass components a-f were produced. Then, the softening points of these glass components a to f were measured in accordance with JIS3103-1. In addition, the average particle diameters of the glass components were all 1 micrometer.

[0089] Table 2 shows the respective composi...

Embodiment 2

[0117] Magnetic pastes used in sample numbers 4, 7, 9, 12, and 19 of Example 1 were prepared.

[0118] In addition, an internal conductor paste containing Ag powder, lacquer, and organic solvent is prepared.

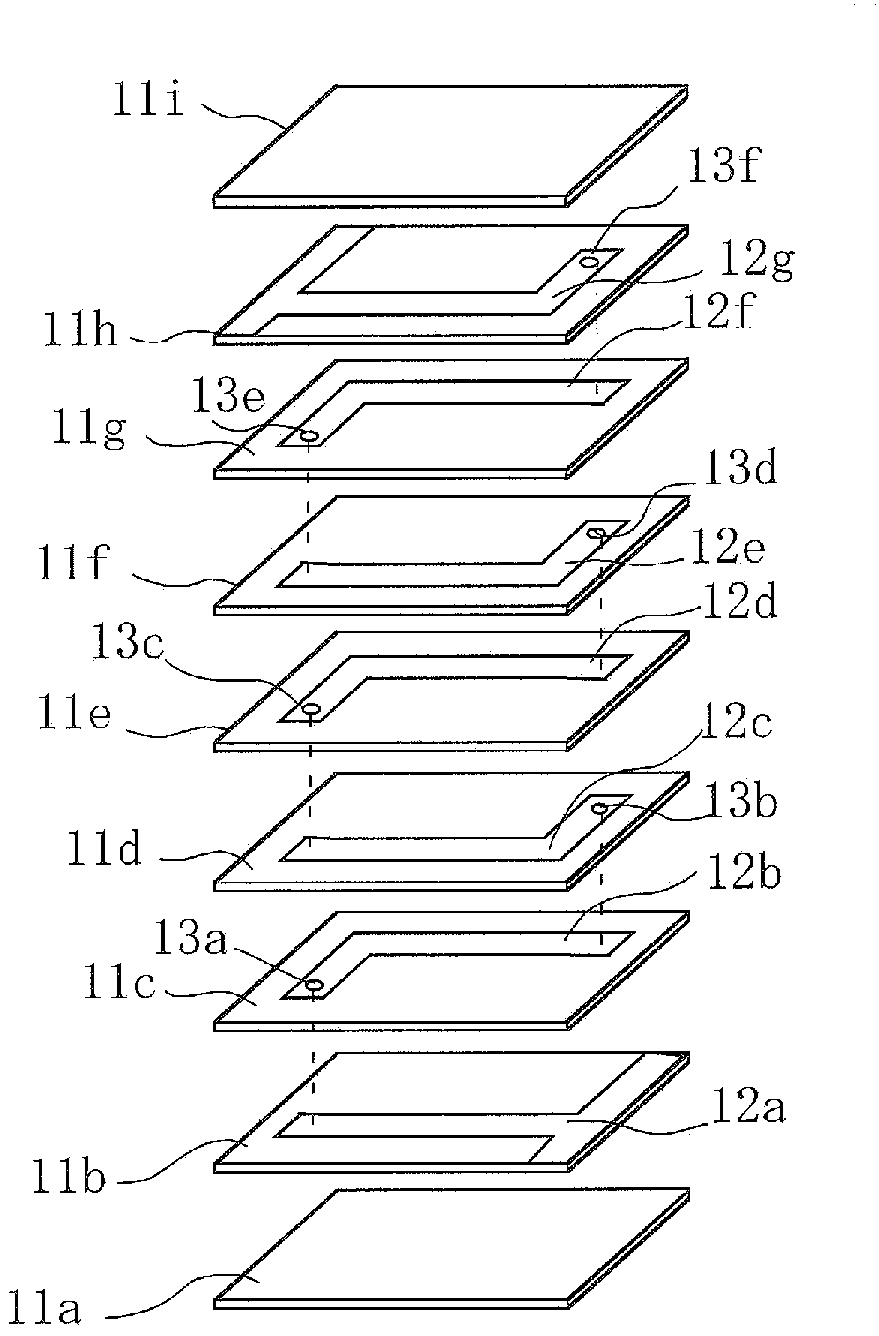

[0119] Next, the magnetic substance paste was applied and dried on the PET film, and this operation was repeated a predetermined number of times to produce a magnetic substance sheet. Next, the internal conductor paste was applied on the surface of the magnetic sheet by the screen printing method, and dried to form a conductor layer in a predetermined pattern.

[0120] Next, the magnetic substance paste was applied on the magnetic substance sheet on which the conductor layer was formed, and it dried, and the magnetic substance sheet was produced. At this time, through holes are formed at predetermined positions of the magnetic sheet. Next, the internal conductor paste was applied to the surface of the magnetic sheet by a screen printing method, and dried to form a cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com