A cutting system for stone slab processing based on the Internet of Things

A slab processing and cutting system technology, applied in the direction of stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of slab breakage, easy breakage, slate waste, etc., to prevent waste water from flowing out, avoid damage and breakage, and benefit The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

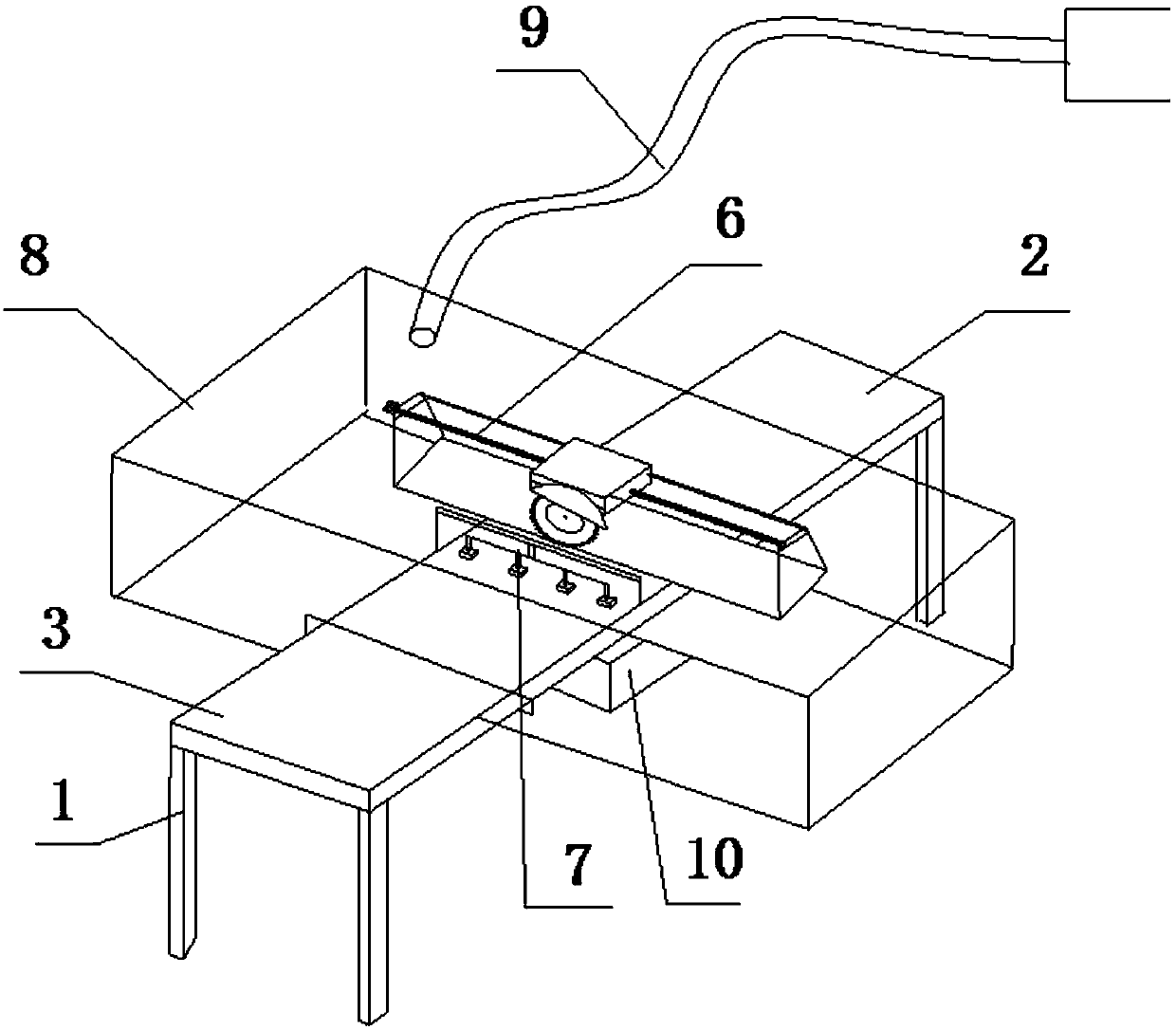

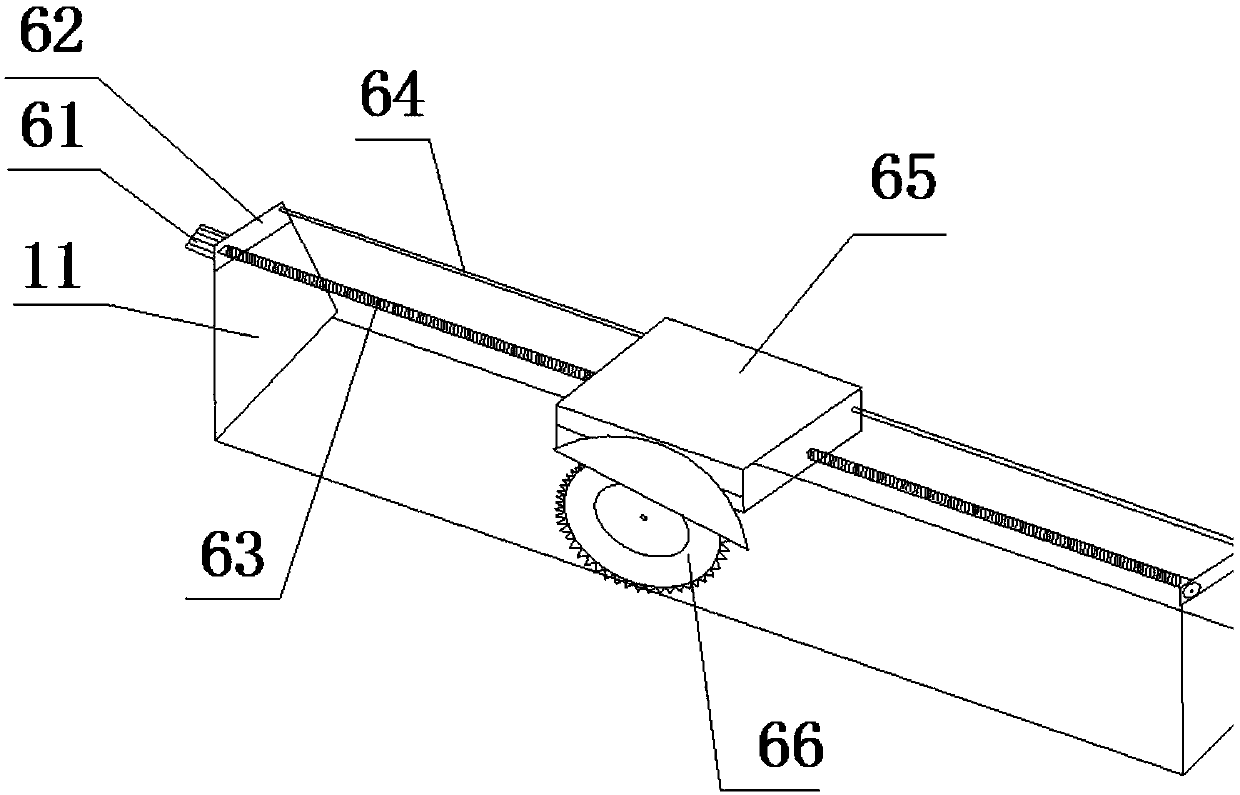

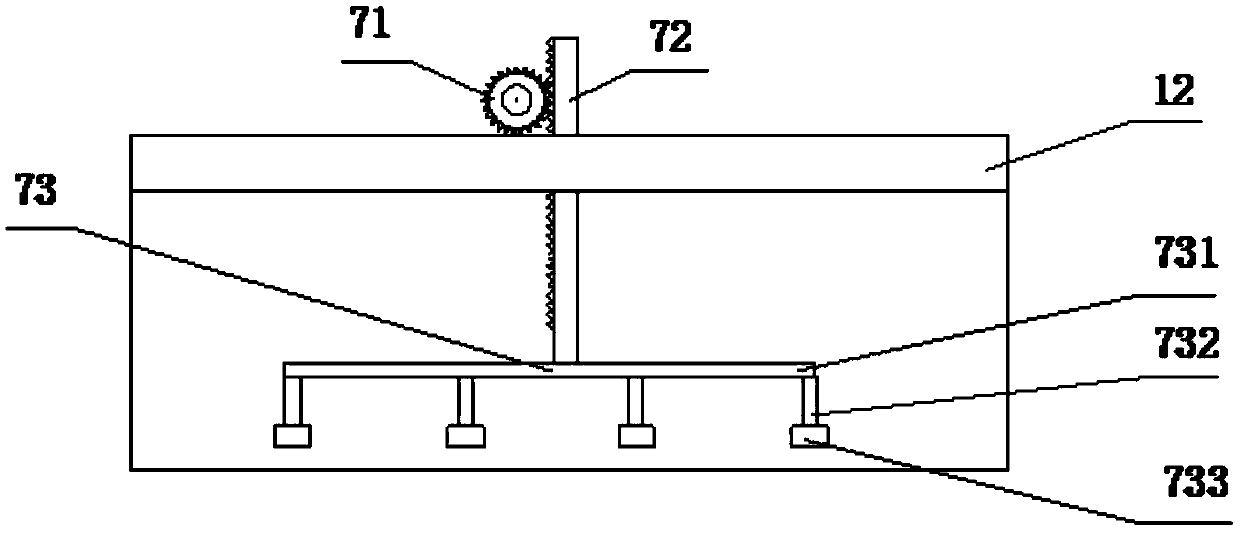

[0027] Embodiment 1: A cutting system for stone plate processing based on the Internet of Things, including a frame 1, the frame 1 is provided with a plate feeding area, a plate discharging area and a plate cutting area, and the plate cutting The area is located between the sheet material input area and the sheet material output area; the sheet material input area is provided with a sheet material input channel 2, and the sheet material output area is provided with a sheet material output channel 3, a sheet material input channel 2 and a sheet material output channel 3 Side plates 4 are provided on both sides, and anti-collision buffer devices 5 are arranged on the side plates 4. The anti-collision buffer devices 5 include anti-collision strips 51 arranged along the side plates, and the anti-collision strips 51 pass through a group of buffer springs. 52 is fixedly connected with the side plate 4; there is a gap between the sheet material inlet channel 2 and the sheet material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com