Plastic grinder

A pulverizer and plastic technology, applied in grain processing, etc., can solve problems such as low work efficiency, dust flying all over the sky, serious splashing, etc., and achieve high work efficiency, reduce dust flying out, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

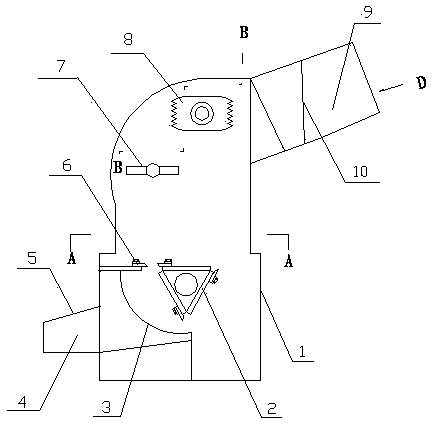

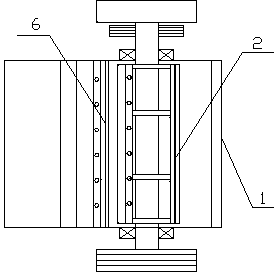

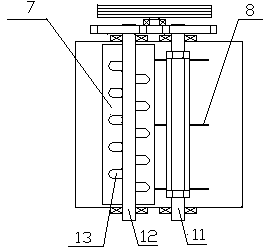

[0022] see figure 1 , figure 2 , Figure 5 , the body 1 of the pulverizer is a box-type structure, and a moving knife 2 and a fixed knife 6 are installed under it, a sieve plate 3 is installed under the moving knife 2 and the fixed knife 6, and a dial is installed above the moving knife 2 and the fixed knife 6. Wheel cutter 7, a winch wheel 8 is installed above the crushing chamber near the feeding port 9, and a closing curtain 10 is installed inside the feeding port 9 (see Figure 4 ), the outlet 4 is equipped with a discharge baffle 5 through the hinge, the discharge baffle 5 is a two-stage opening structure, and when the first stage is opened, it forms a discharge nozzle structure that can be inserted into the packaging bag with the discharge port When fully opened (that is, fully opened i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com