Polypropylene composite material for shell of filter bottle of water purifier, and preparation method and applications thereof

A composite material and polypropylene technology, which is applied in the field of polypropylene composite materials for water purifier filter bottle shells, can solve the problems of not taking into account the welding performance of products, and no patent reports on product materials for water purifier filter bottle shells, etc. The effect of slowing down the complete crystallization time, increasing toughness, and improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of polypropylene composite material for water purifier filter bottle shell

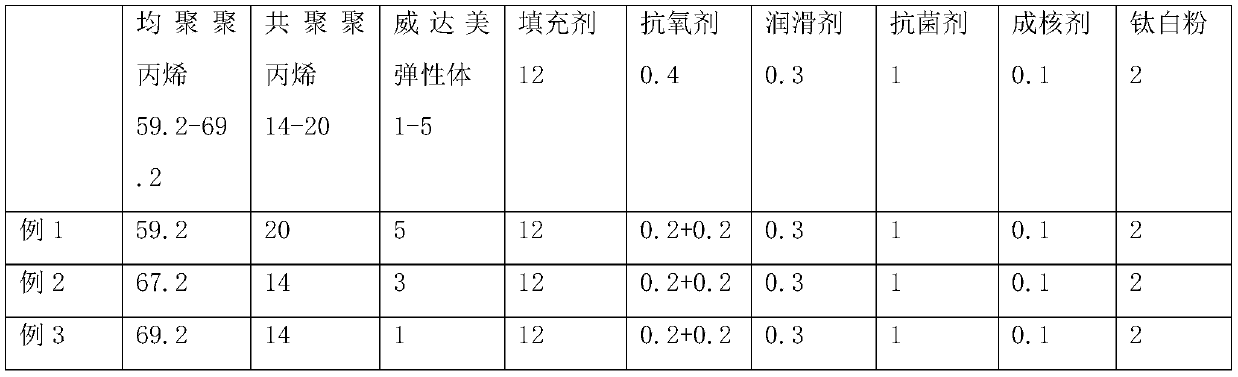

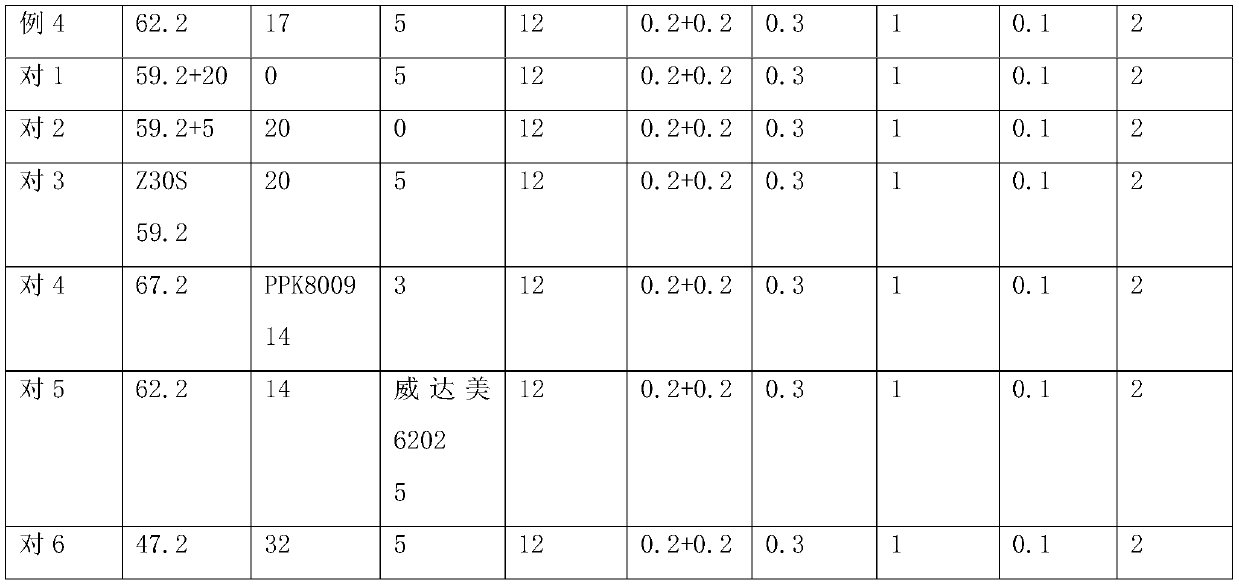

[0028] Weigh the corresponding raw materials according to the above weight parts: see Table 1

[0029] After that, the homopolypropylene, copolymer polypropylene, Vistamaxx elastomers, fillers, antioxidants, lubricants, antibacterial agents, nucleating agents, and titanium dioxide weighed in proportion are mixed uniformly from the main feed The port is added to the parallel twin-screw extruder, so that all the component materials are sheared, melt-blended and extruded in the parallel twin-screw extruder. The processing temperature of the twin-screw extruder is 180°C in the first zone and 190°C in the second zone. , Three-zone 200℃, four-zone 220℃, five-zone 220℃, six-zone 215℃, seven-zone 215℃, eight-zone 215℃, nine-zone 210℃, ten-zone 210℃, machine head 220℃;

[0030] Finally, the material strips exiting the die of the parallel twin-screw extruder are cooled, dried, and pellet...

Embodiment 2

[0034] Example 2: Preparation of polypropylene composite material for water purifier filter bottle shell

[0035] Weigh the corresponding raw materials according to the above weight parts: see Table 1

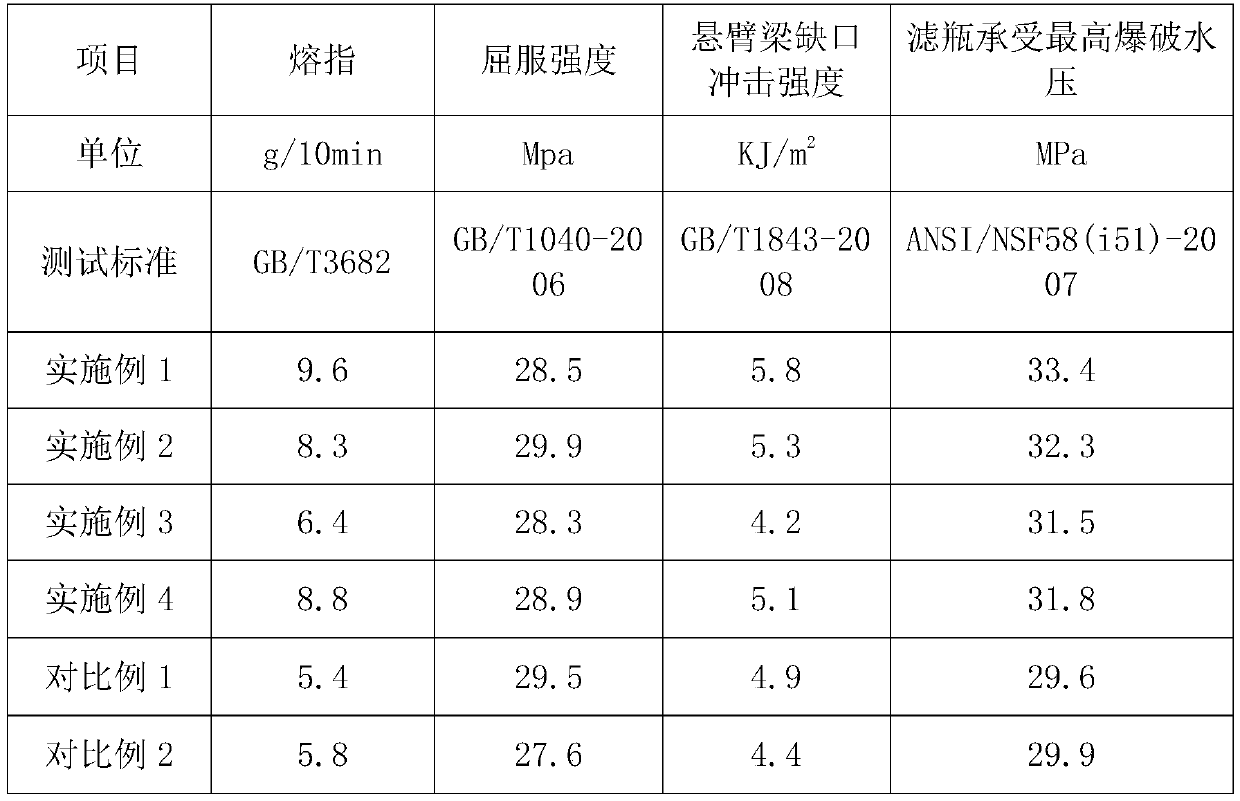

[0036] The preparation method is the same as in Example 1, and the effect is shown in Table 2.

Embodiment 3

[0037] Example 3: Preparation of polypropylene composite material for water purifier filter bottle shell

[0038] Weigh the corresponding raw materials according to the above weight parts: see Table 1

[0039] The preparation method is the same as in Example 1, and the effect is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com