Processing and forming device for PE double-wall corrugated pipe

A double-wall corrugated pipe, processing and forming technology, applied in metal processing, tubular items, other household appliances, etc., can solve the problems of not much help in forming speed, little prospect of performance improvement, poor cooling effect, etc. Product quality, improve production and processing efficiency, and improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

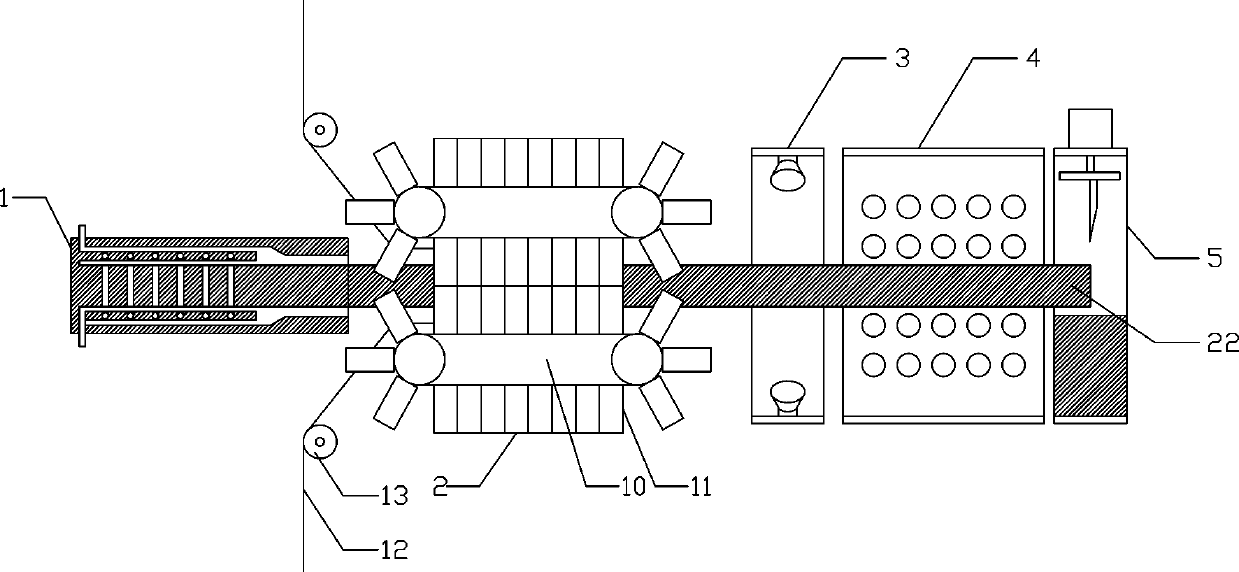

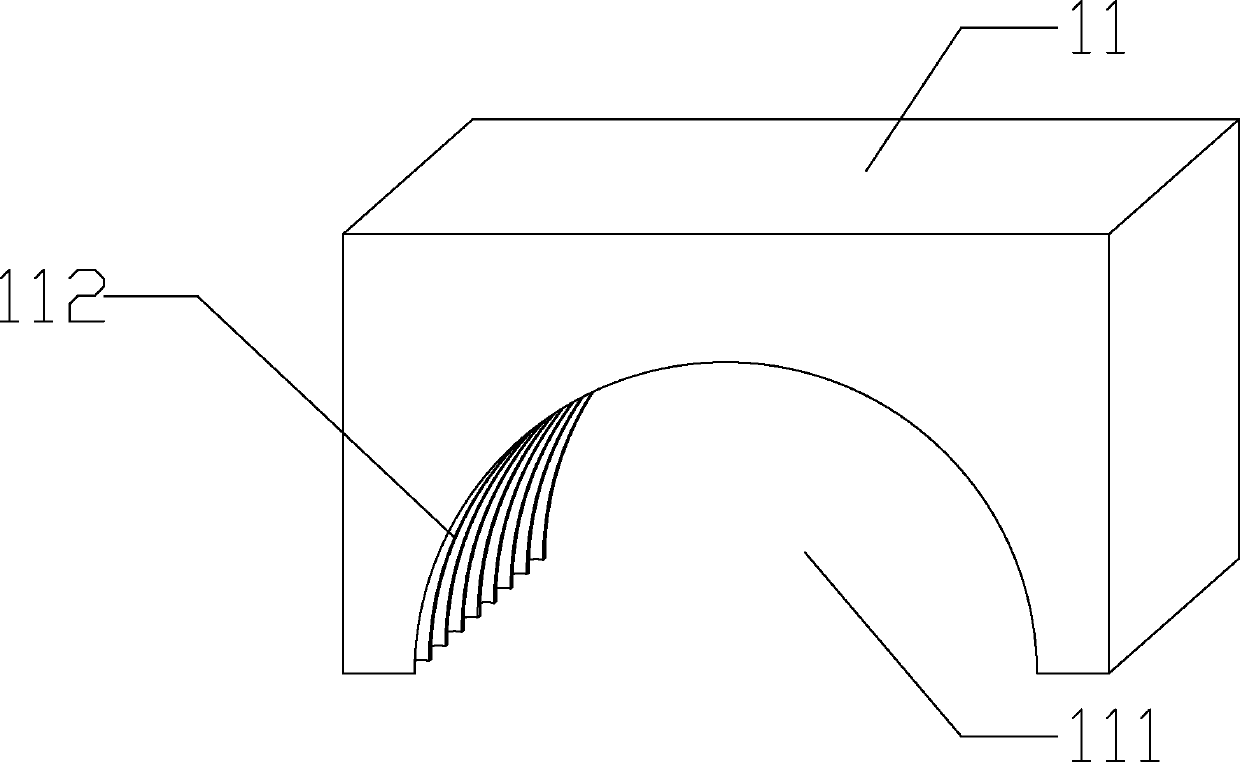

[0029] Such as Figure 1-6 Among them, a PE double-wall corrugated pipe processing molding device includes an injection mold 1, the output end of the injection mold 1 is provided with a molding device 2, and the output end of the molding device 2 is provided with a cutting device 5, and the molding device 2 and the cutting device A cooling device 3 and a drying device 4 are arranged between the devices 5;

[0030] The output end of the injection mold 1 is provided with a guide block 22, the guide block 22 is arranged horizontally and the guide block 22 passes through the molding device 2, the cooling device 3, the drying device 4 and the cutting device 5 in sequence.

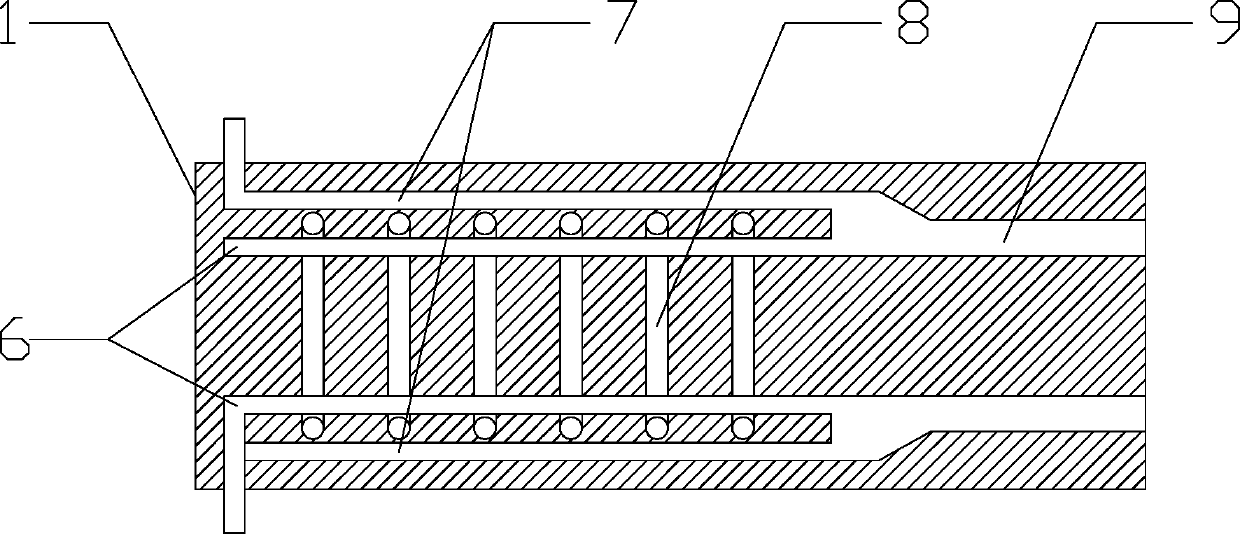

[0031] In a preferred solution, the injection mold 1 is provided with an annular inner cavity 6 and an outer cavity 7, and a heating wire 8 is arranged in the injection mold 1 between the inner cavity 6 and the outer cavity 7;

[0032] The injection mold 1 is also provided with a bonding cavity 9, the bonding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com