Process for machining heat exchange device of heat exchanger

A technology of processing technology and heat exchange device, applied in the field of mechanical processing and manufacturing, can solve problems such as tube sheet deformation, crevice corrosion at welds, easy pulling, etc., to achieve quality and reliability improvement, strength and stiffness guarantee, and simplify processing procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

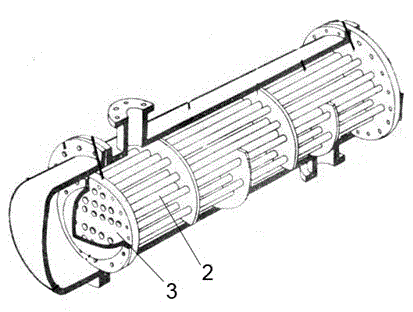

[0036] Adopt processing technology of the present invention to manufacture the heat exchanging device (as figure 1shown), the specific process is as follows:

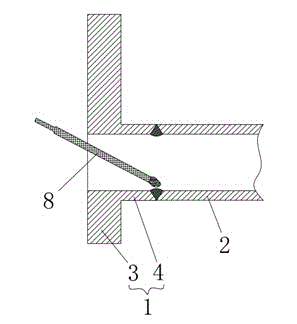

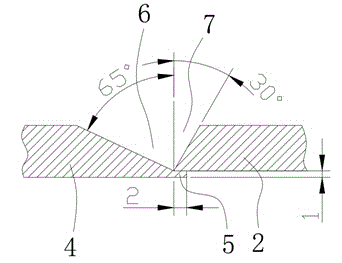

[0037] (1) Subsection manufacturing: Subsection manufacturing is carried out according to the design structure of the heat exchange device. The subsection manufacturing components include: a tube base 1 and several heat exchange tubes 2 connected to the tube base 1, and the tube base 1 includes a tube plate 3 and several joints 4 corresponding to the heat exchange tubes 2, the joints 4 and the tube plate 3 are integrally structured, and the The end is provided with an annular step 5, the thickness of the annular step 5 is 1 mm, the length of the annular step 5 is 2 mm, and the inner wall of the annular step 5 matches the outer wall of the heat exchange tube 2 , the inner wall of the joint 4 and the junction of the annular step 5 are also provided with a first groove 6, and the end of the heat exchange tube 2 that coope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com