Patents

Literature

50results about How to "Good structural support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

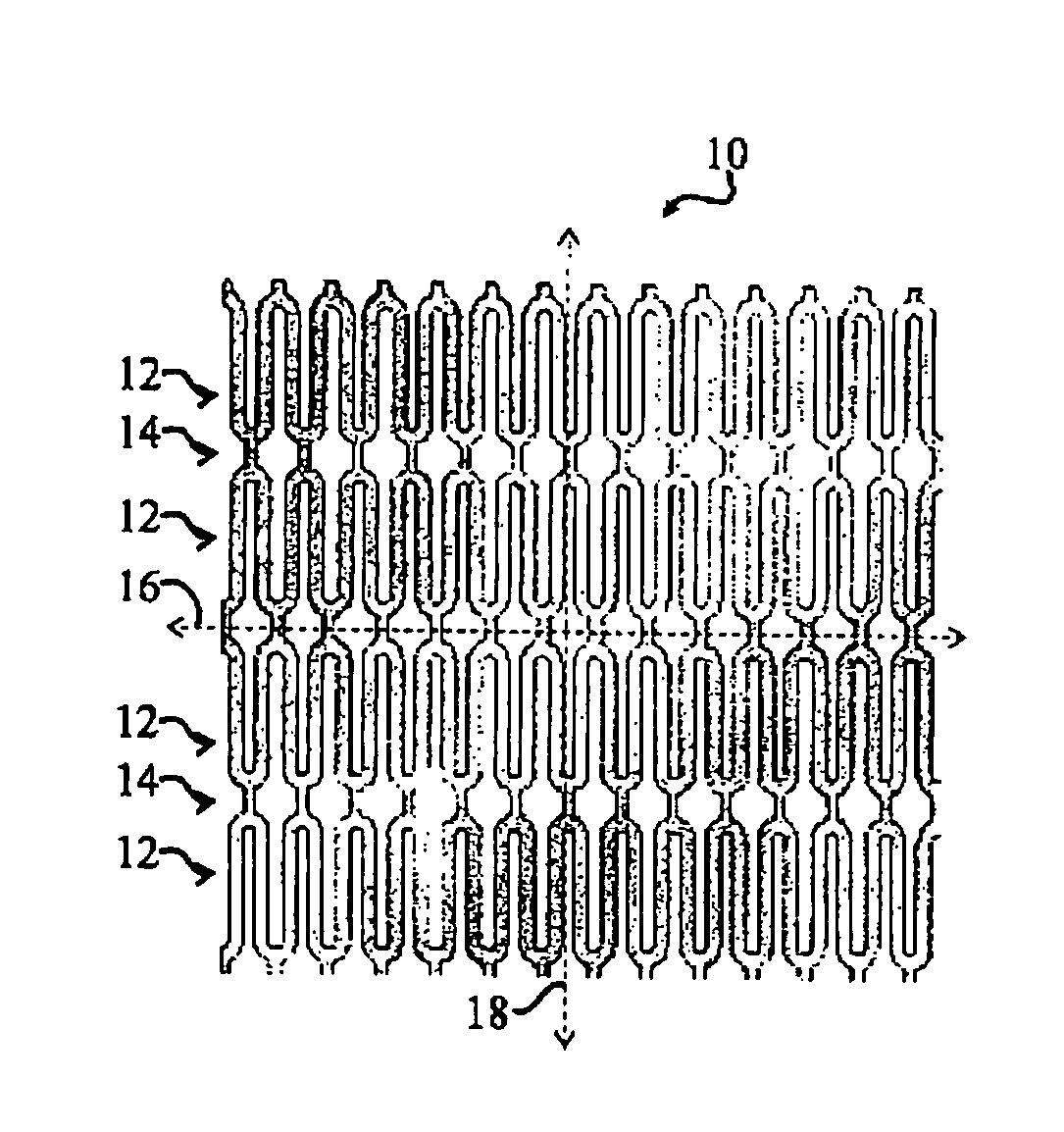

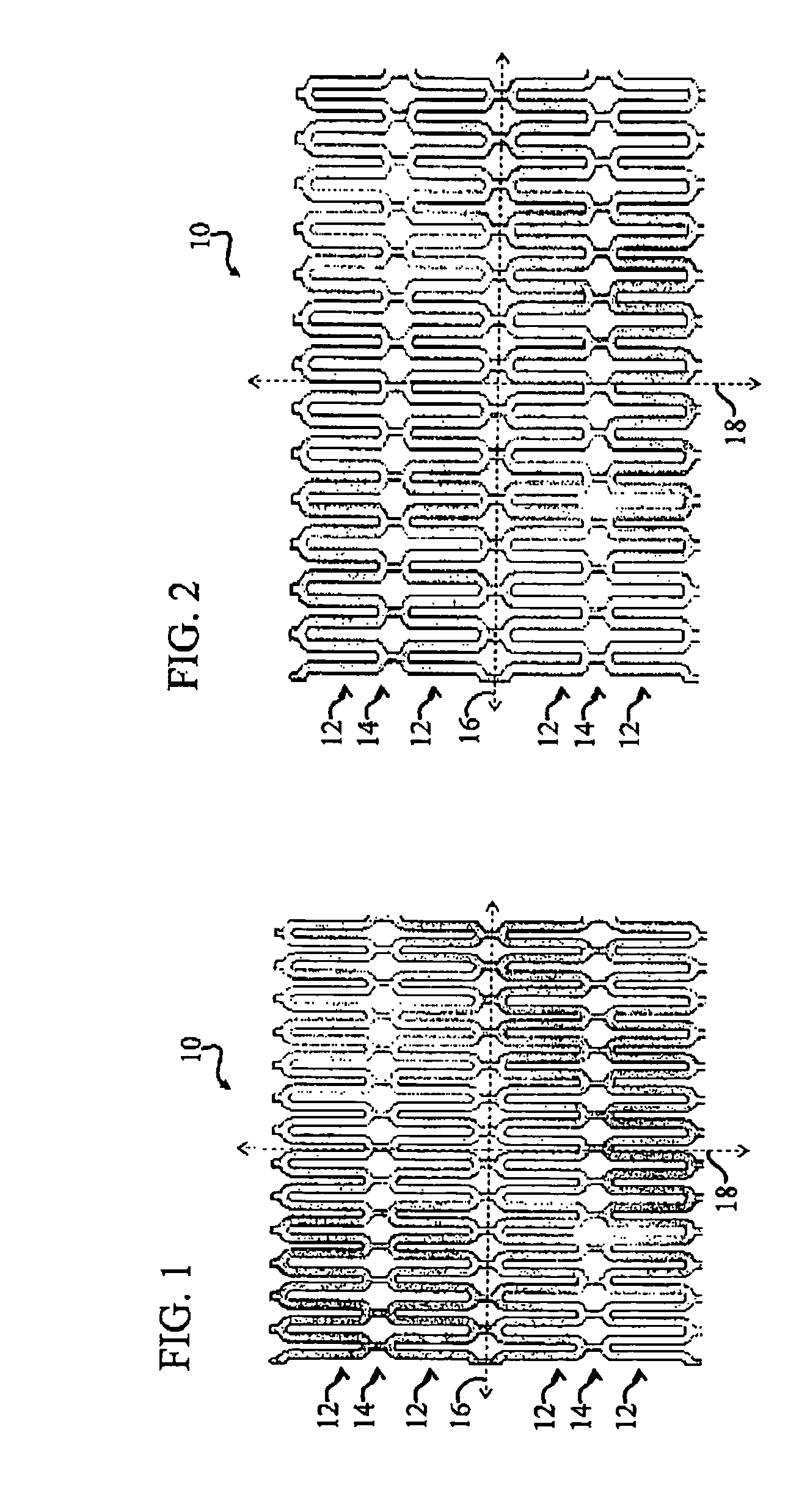

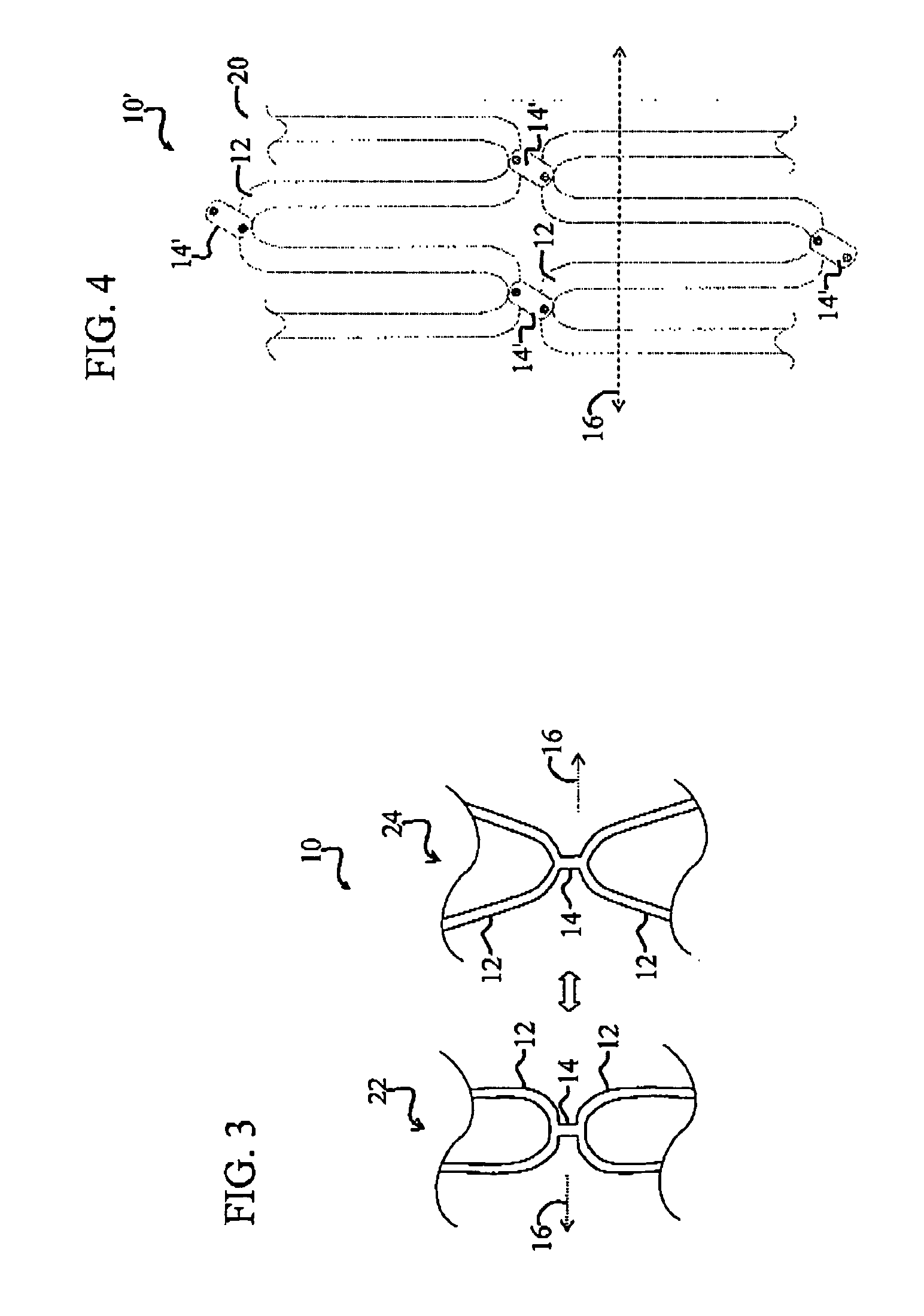

Transformable skin

InactiveUS20070138341A1Facilitate implementationInhibits bending deformationWing adjustmentsFuselagesShearing deformationEngineering

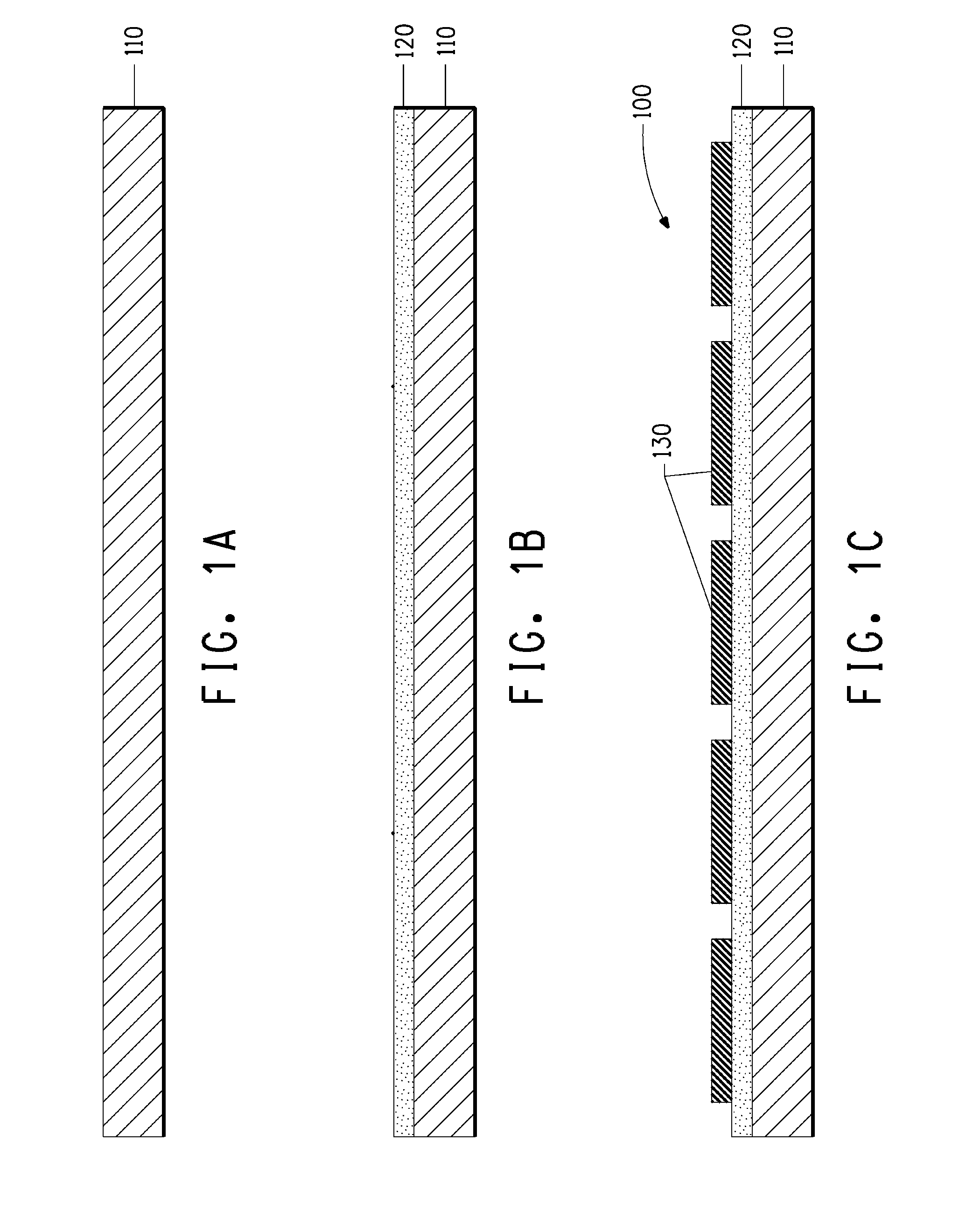

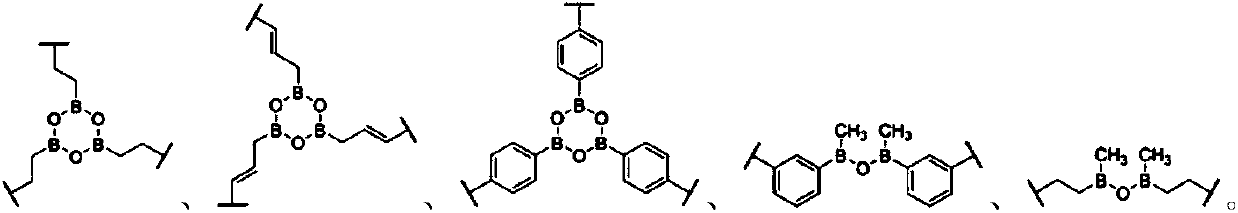

A transformable skin. The transformable skin includes a first mechanism for enabling a first type of deformation of the skin. A second mechanism resists a second type of deformation that is different than the first type of deformation in direction or form. In a more specific embodiment, the first mechanism and the second mechanism are interconnected. The first type of deformation is strain deformation along a first path that is inline with a first axis of the skin. In the specific embodiment, the second type of deformation includes shear deformation and strain deformation that is inline with a second axis that is approximately perpendicular to the first axis. The first mechanism includes a plural partially planar spring structures arranged parallel to each other. The plural partially planar spring structures are resistant to bending and are interconnected via rigid connecting structures. The spring structures are partially planar, and the connecting structures are covered with an elastomeric material.

Owner:JOSHI SHIV P +1

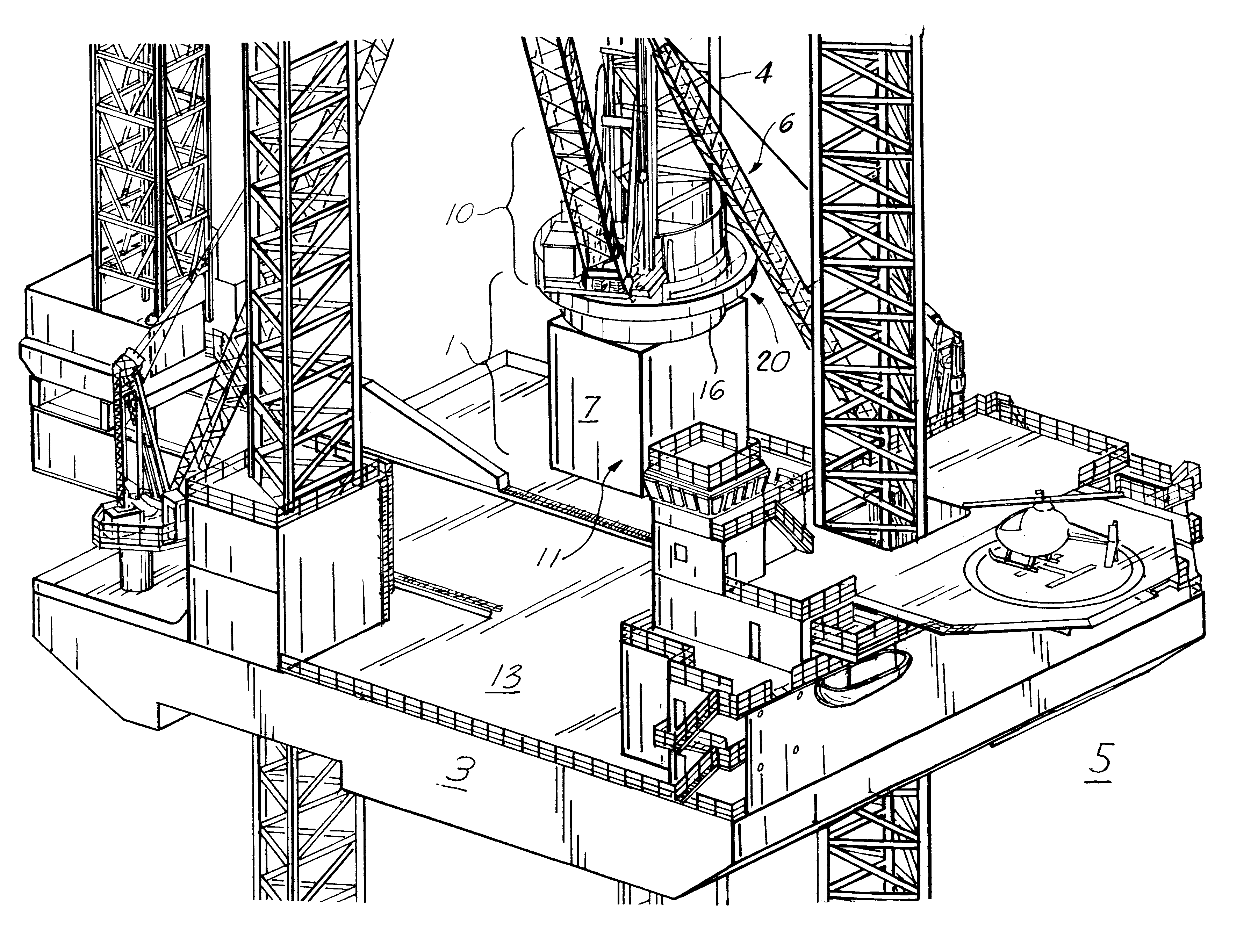

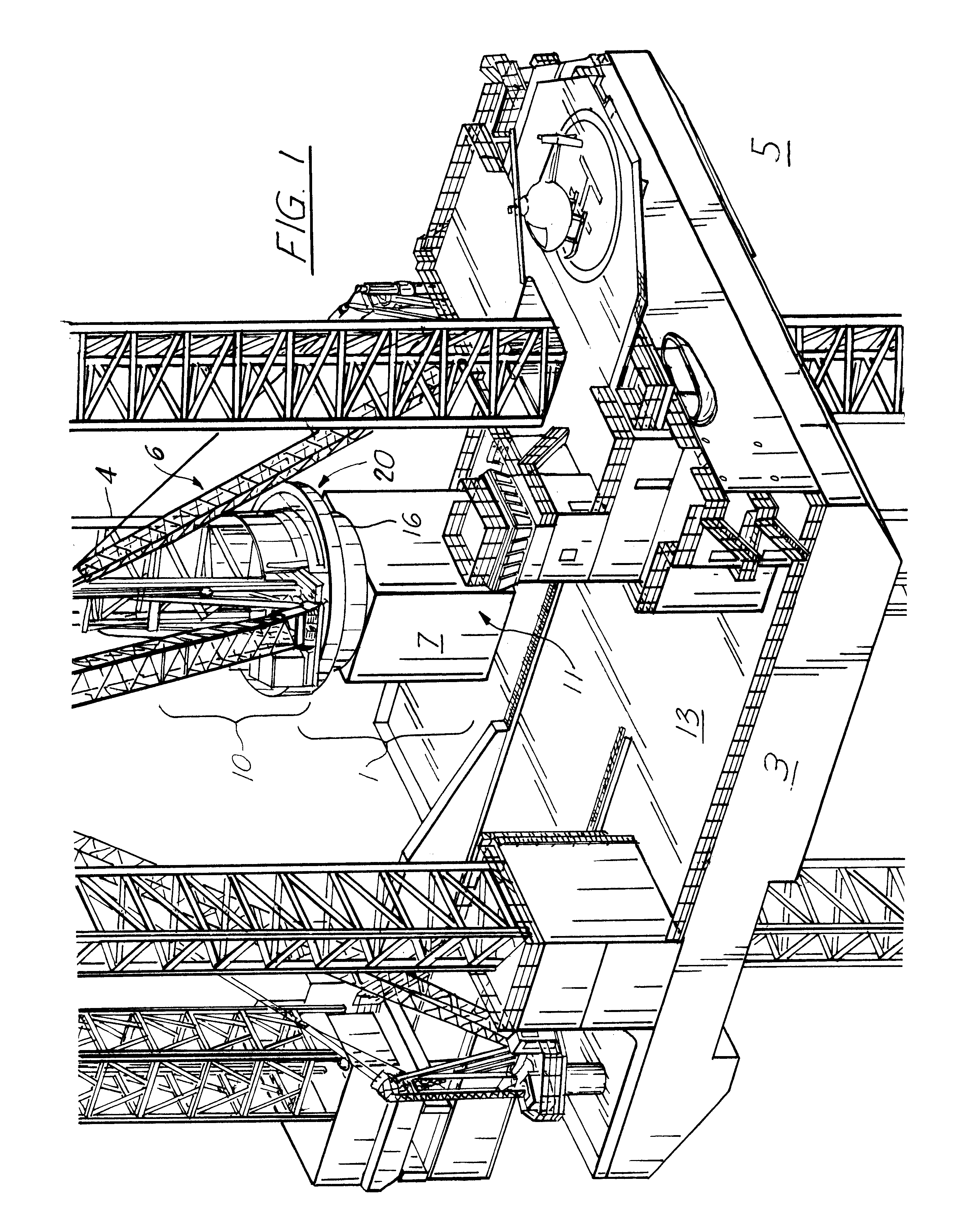

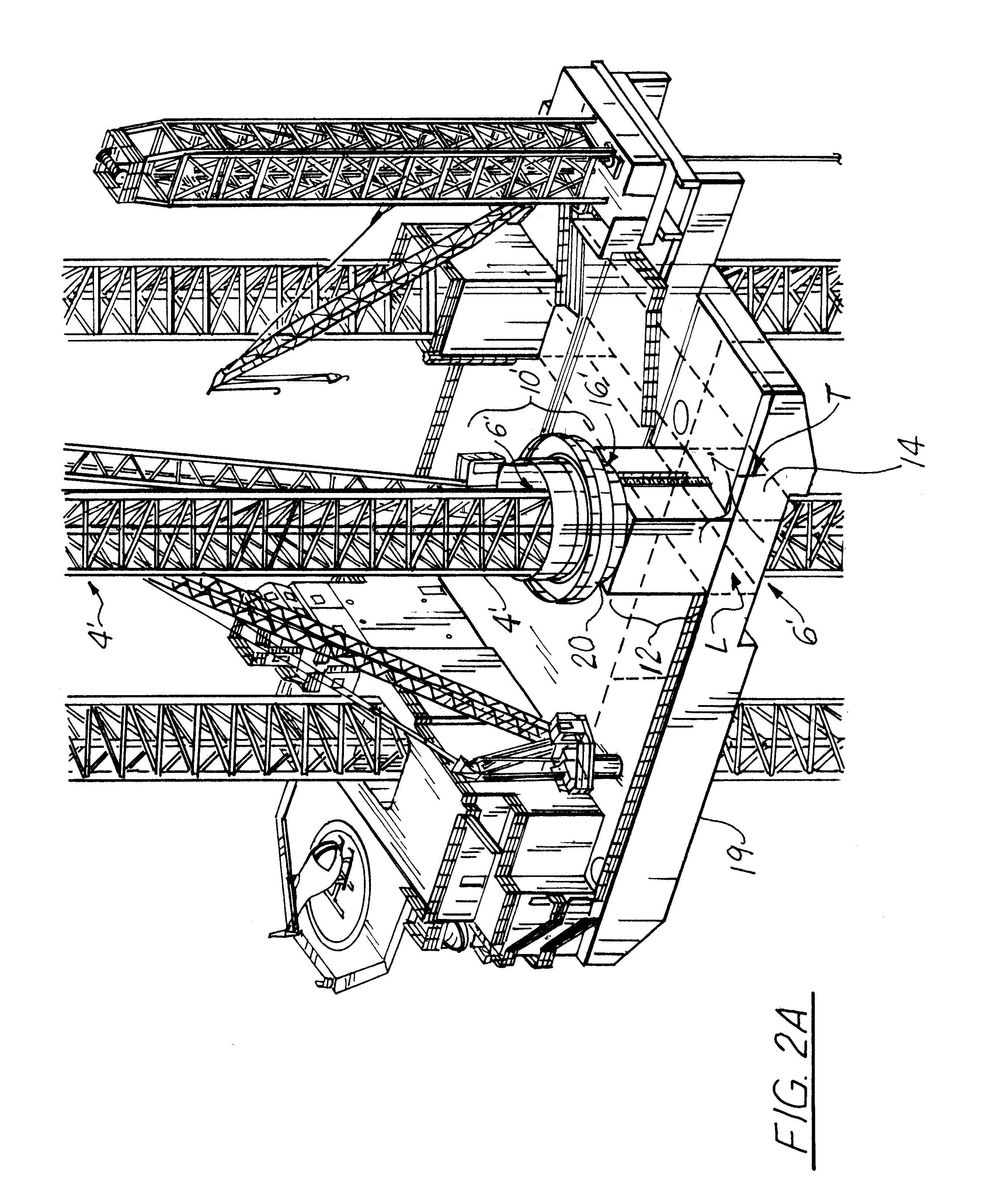

Elevated crane support system and method for elevating a lifting apparatus

InactiveUS6607331B2Save spaceImprove abilitiesArtificial islandsDrilling rodsSupporting systemMarine engineering

Owner:THE LEVINGSTON

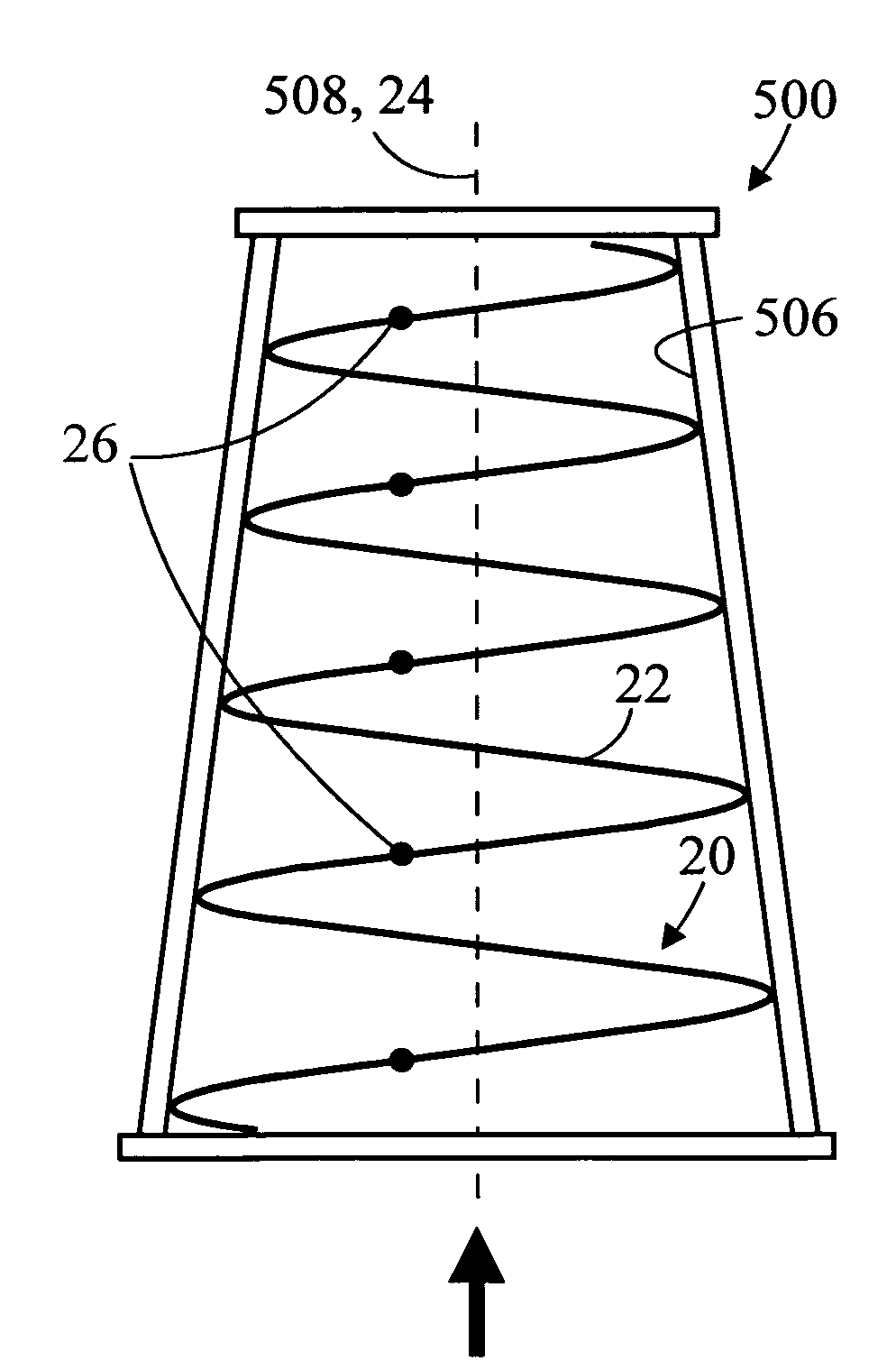

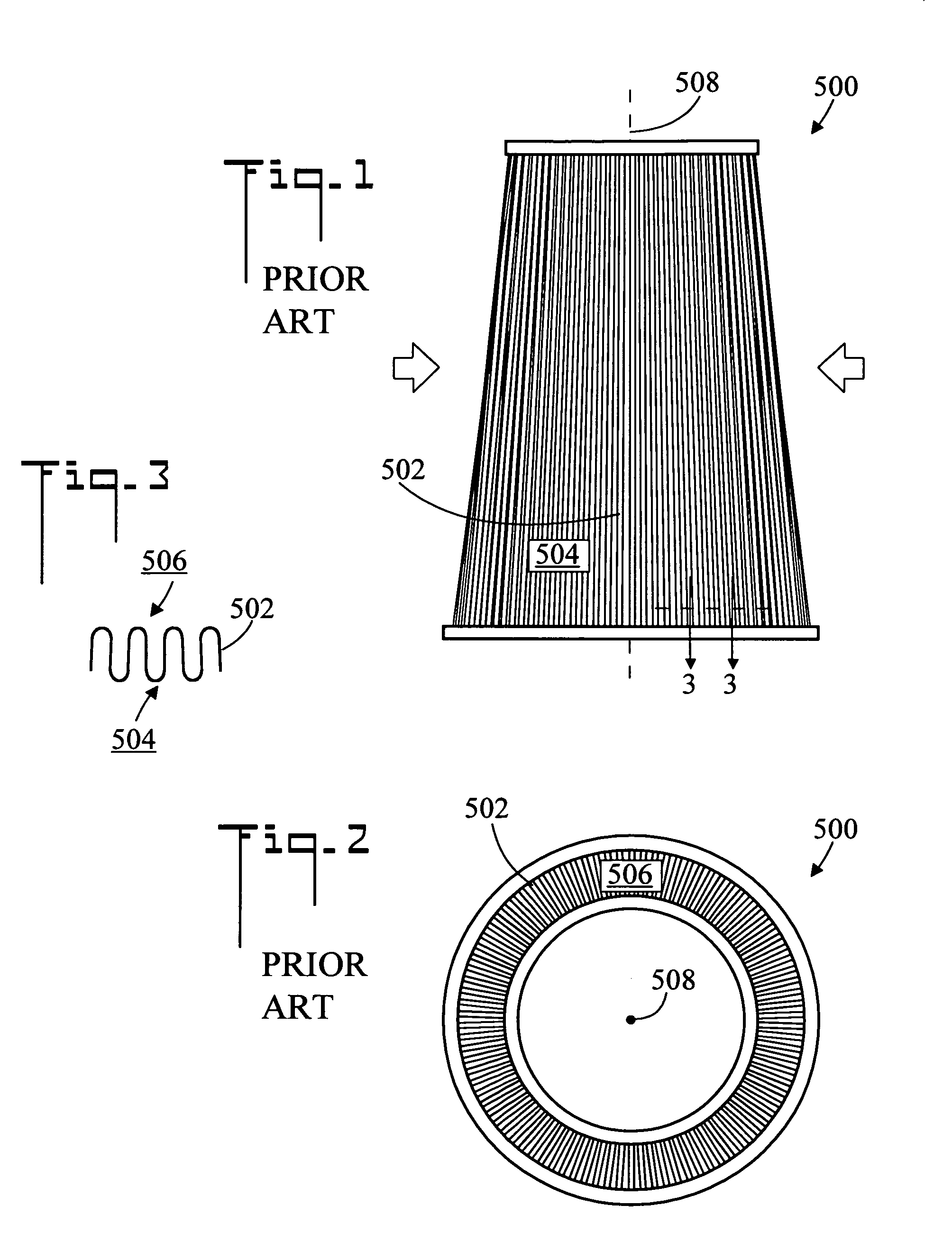

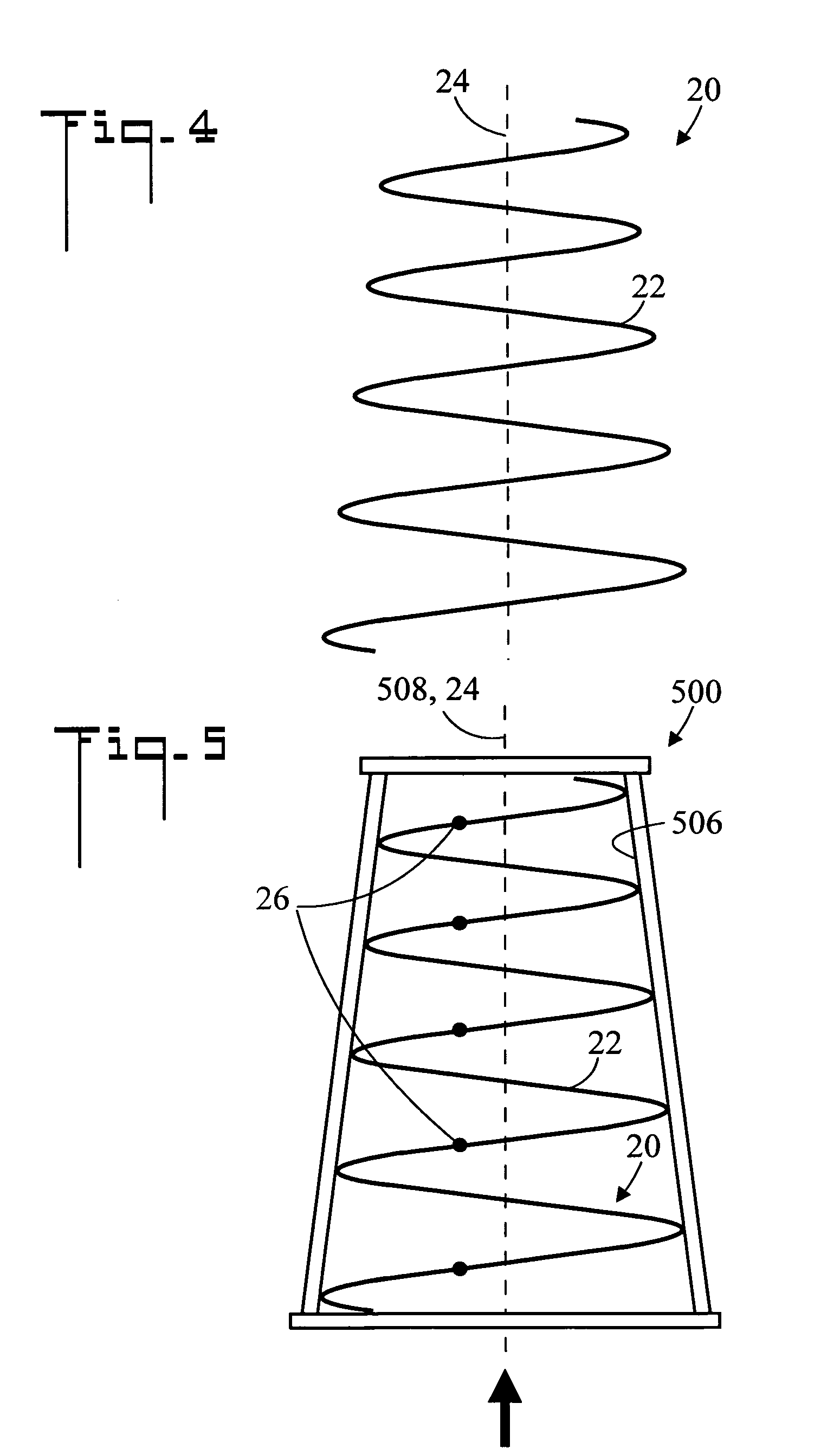

Support for an air filter

ActiveUS7404838B1Improve engine performanceGood structural supportDispersed particle filtrationUsing liquid separation agentAir filterClassical mechanics

An internal support for an air filter includes a helical member which is shaped and dimensioned to fit against the inside surface of the air filter to provide structural support which prevents the air filter from inwardly collapsing. In another embodiment of the invention, a plurality of support rings are installed in spaced apart parallel relationship inside the air filter.

Owner:PATHAK PINAKIN Y

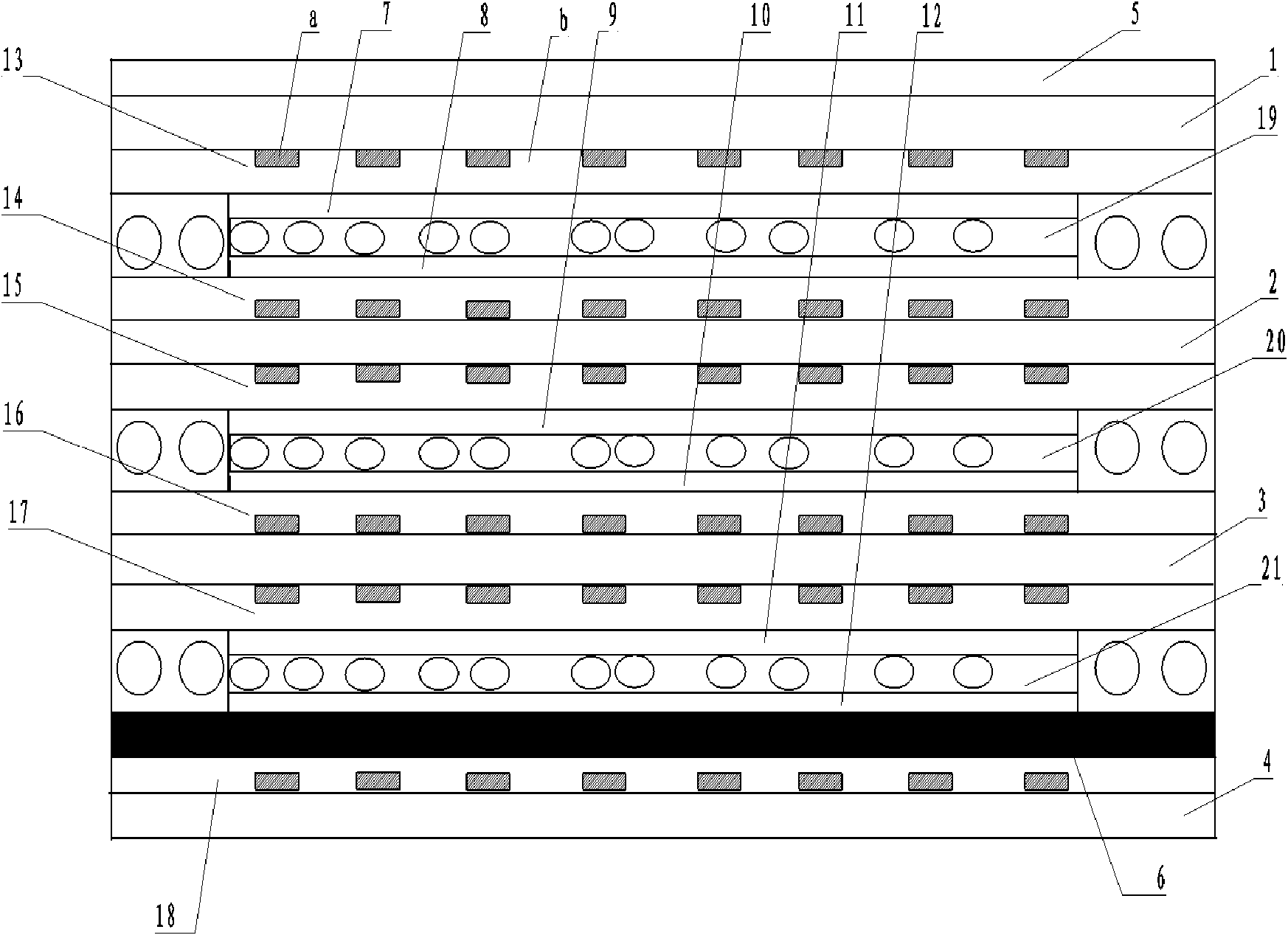

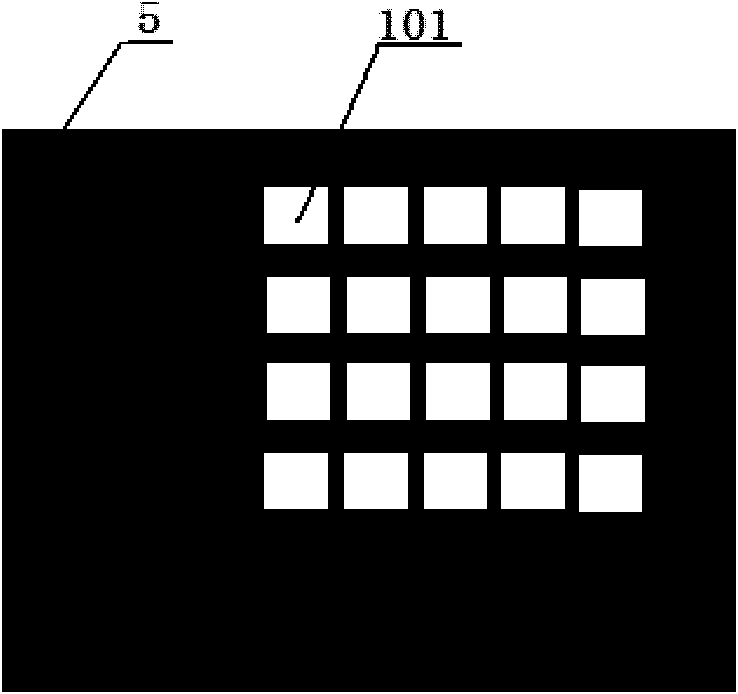

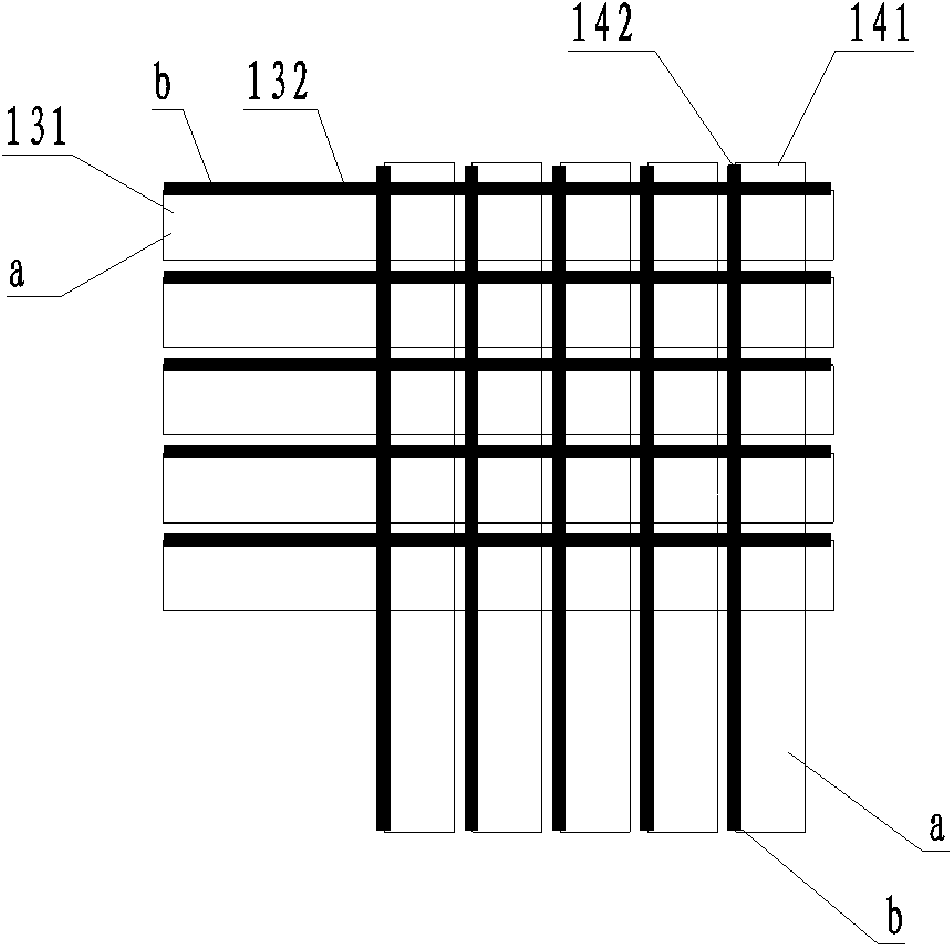

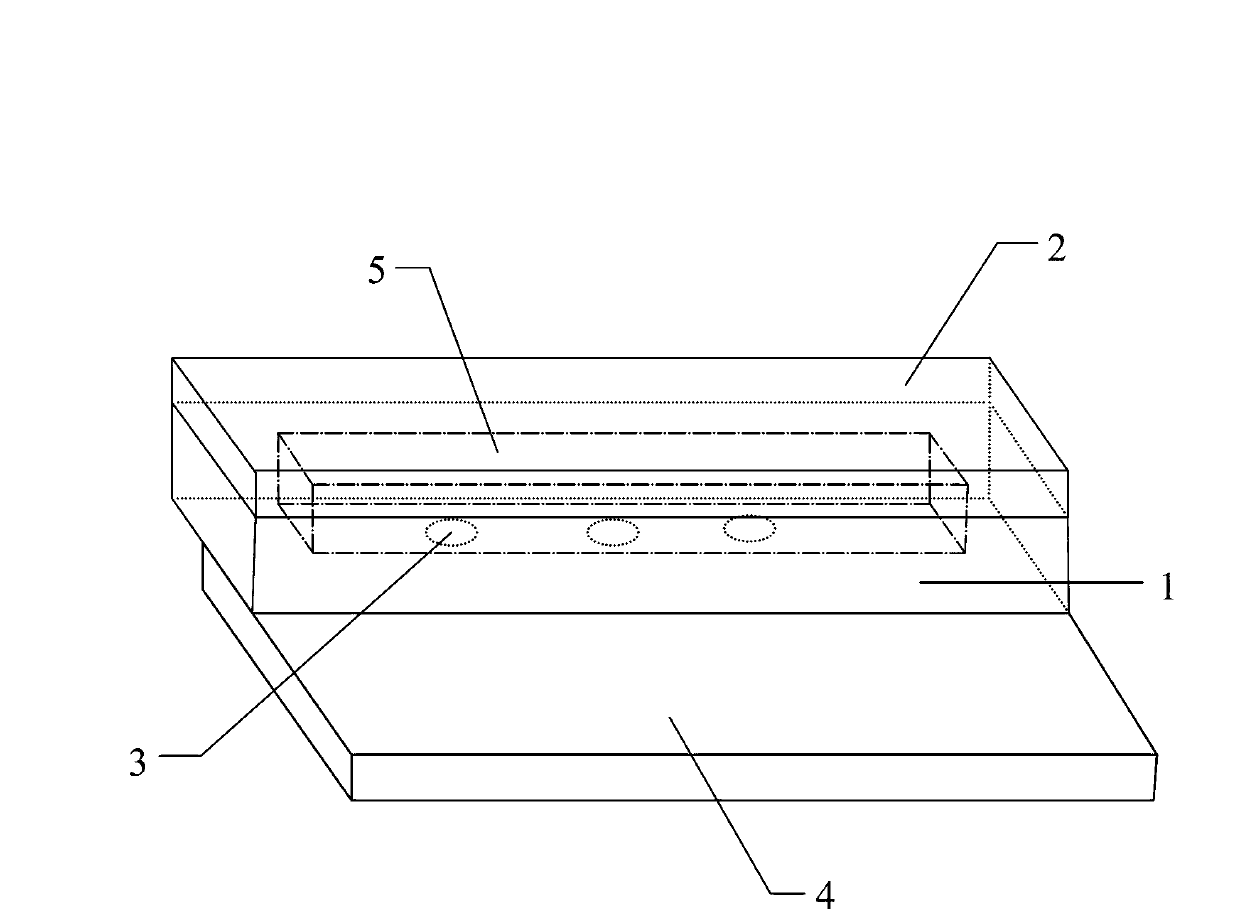

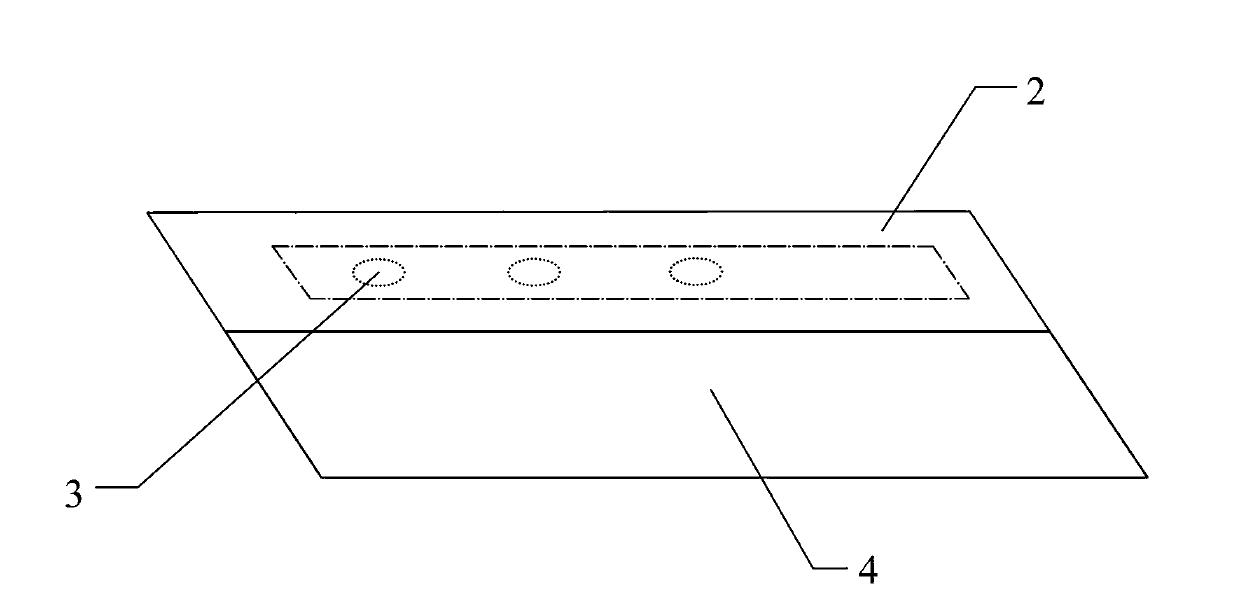

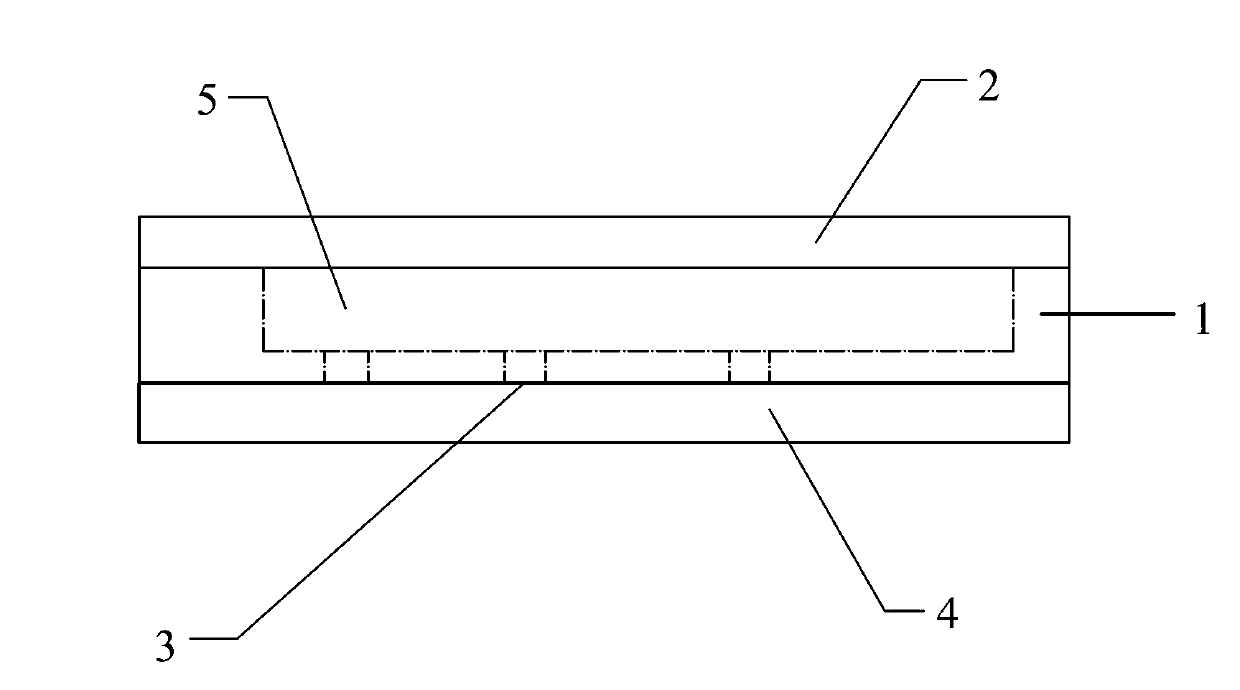

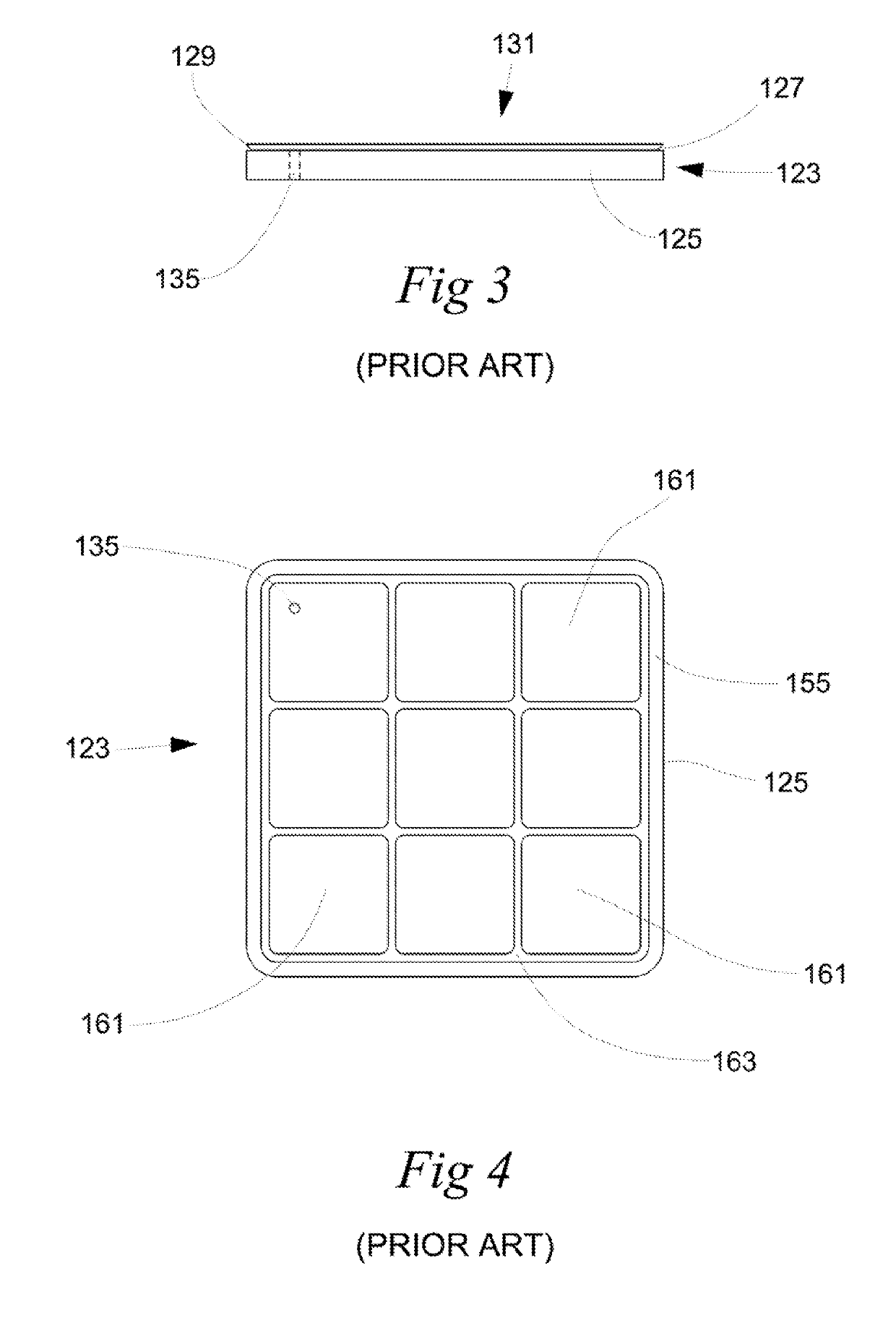

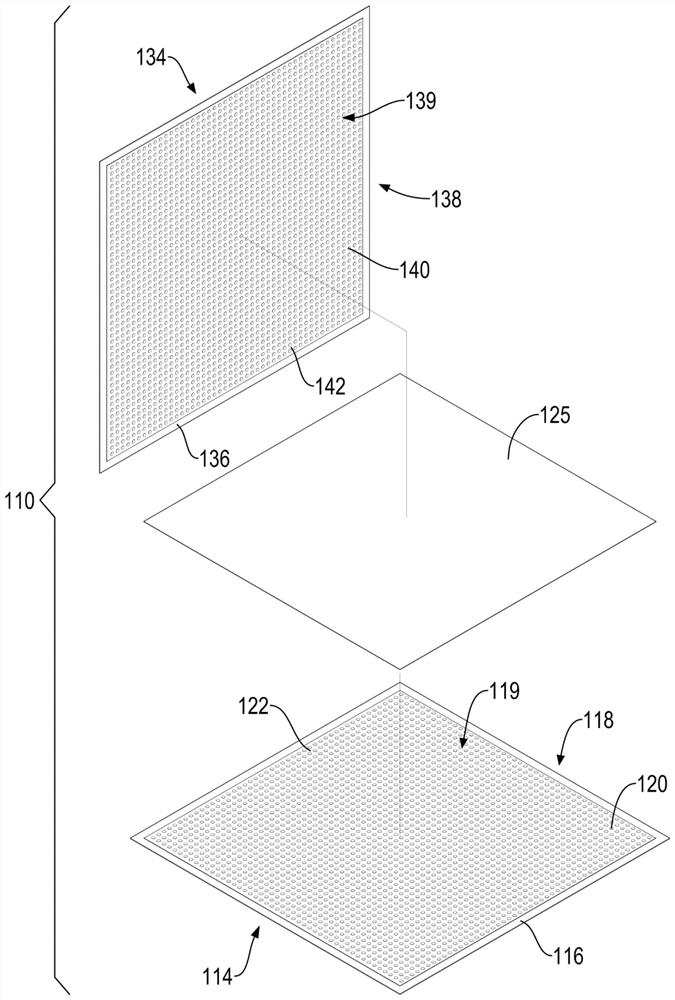

Full-color cholesteric liquid crystal electronic paper

The invention provides full-color cholesteric liquid crystal electronic paper. The full-color cholesteric liquid crystal electronic paper comprises three liquid crystal boxes formed by vertically overlapping four layers of substrates, cholesteric liquid crystal layers capable of reflecting red, green and blue light, and a light shield layer for shielding the light leakage of a non-display area so as to obviate the negative influences of the light leakage of the non-display area on the contrast and the brightness of the display area, wherein the cholesteric liquid crystal layers are respectively packaged in the three liquid crystal boxes; a substrate electrode adopting the combination of a metal electrode and a transparent electrode can reduce the lead resistance; and a light absorption layer is built in the electronic paper to ensure that the incident light from the substrate electrode can be absorbed completely by the light absorption layer. On the premise of saving the cost and reducing the thickness, the full-color cholesteric liquid crystal electronic paper provided by the invention can achieve high-contrast and high-brightness display by increasing the transmittance and reducing the reflectance, and can obviate the poor display effect caused by the external mechanical force. The invention provides an excellent structure support for the large-size manufacture of the full-color liquid crystal electronic paper and the improvement on the display performance of the full-color cholesteric liquid crystal electronic paper.

Owner:DALIAN DKE LCD CO LTD

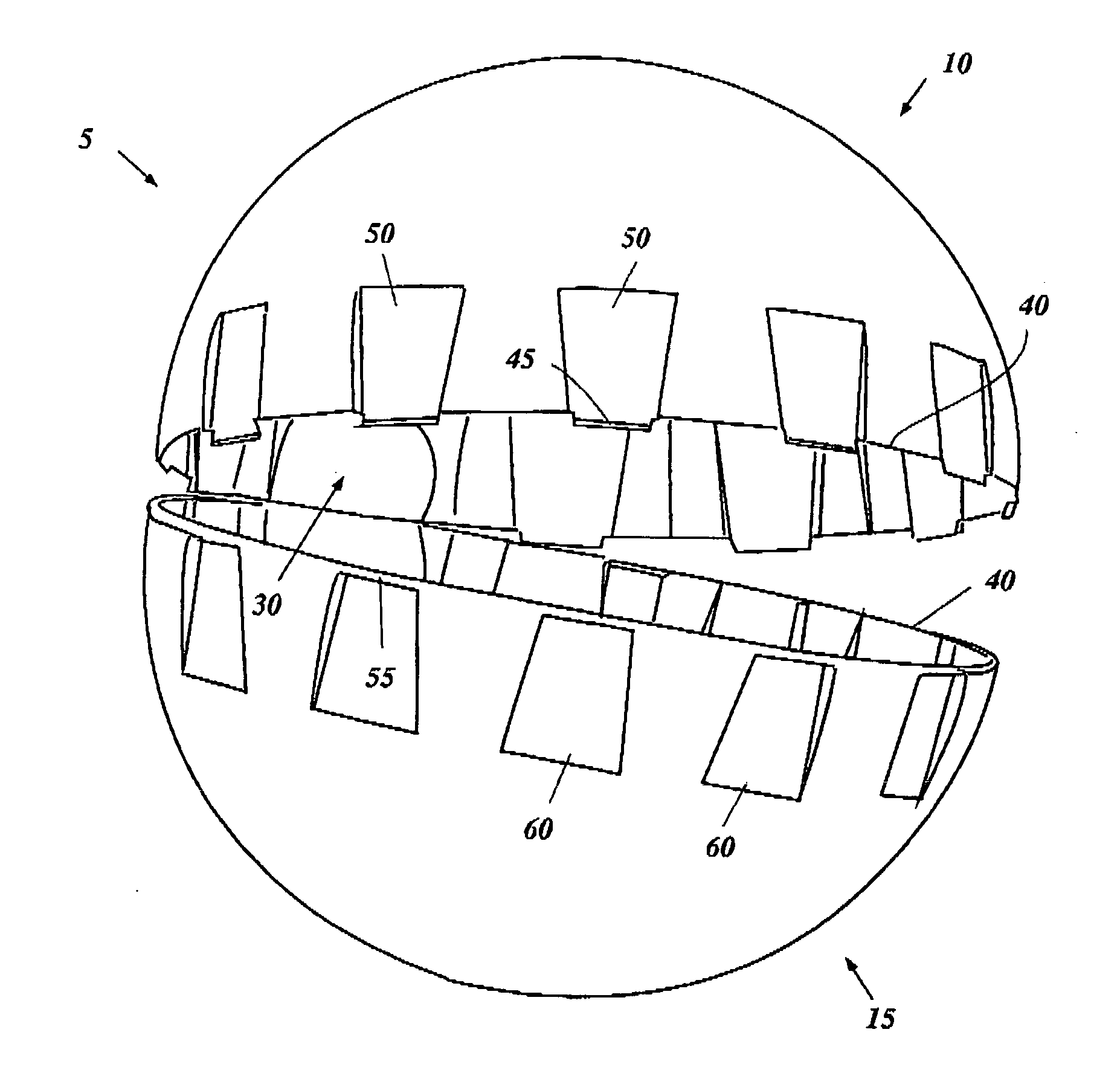

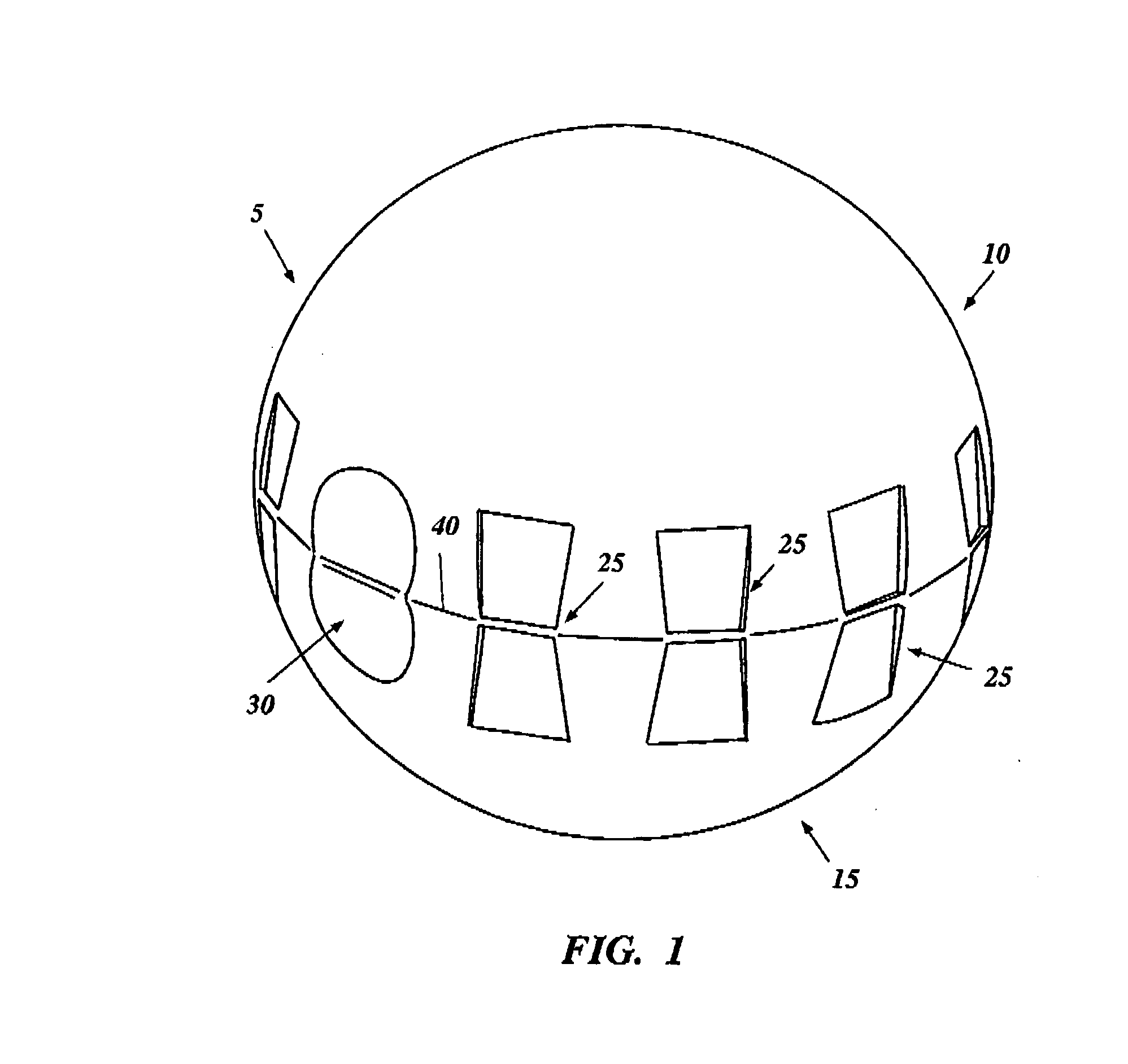

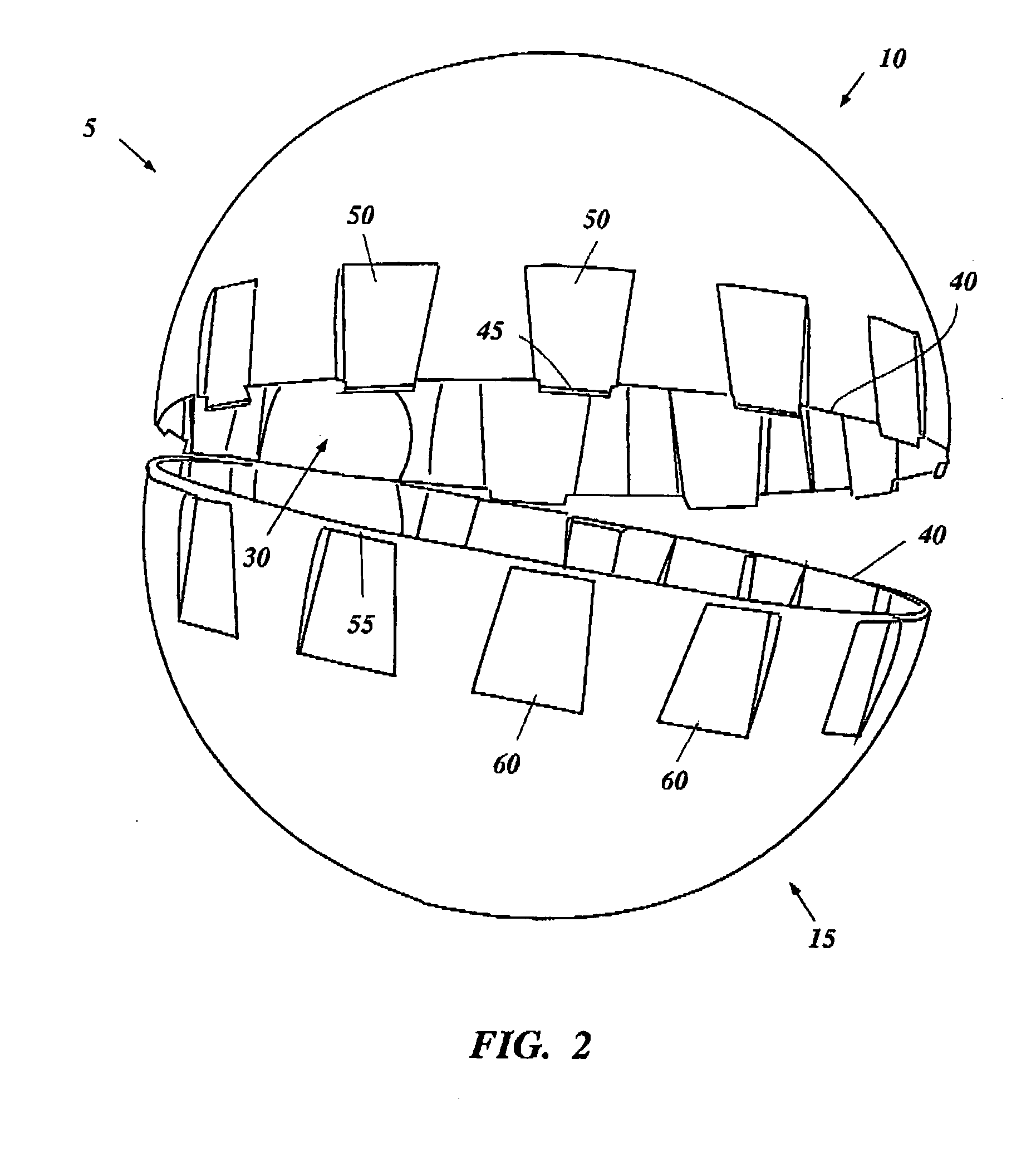

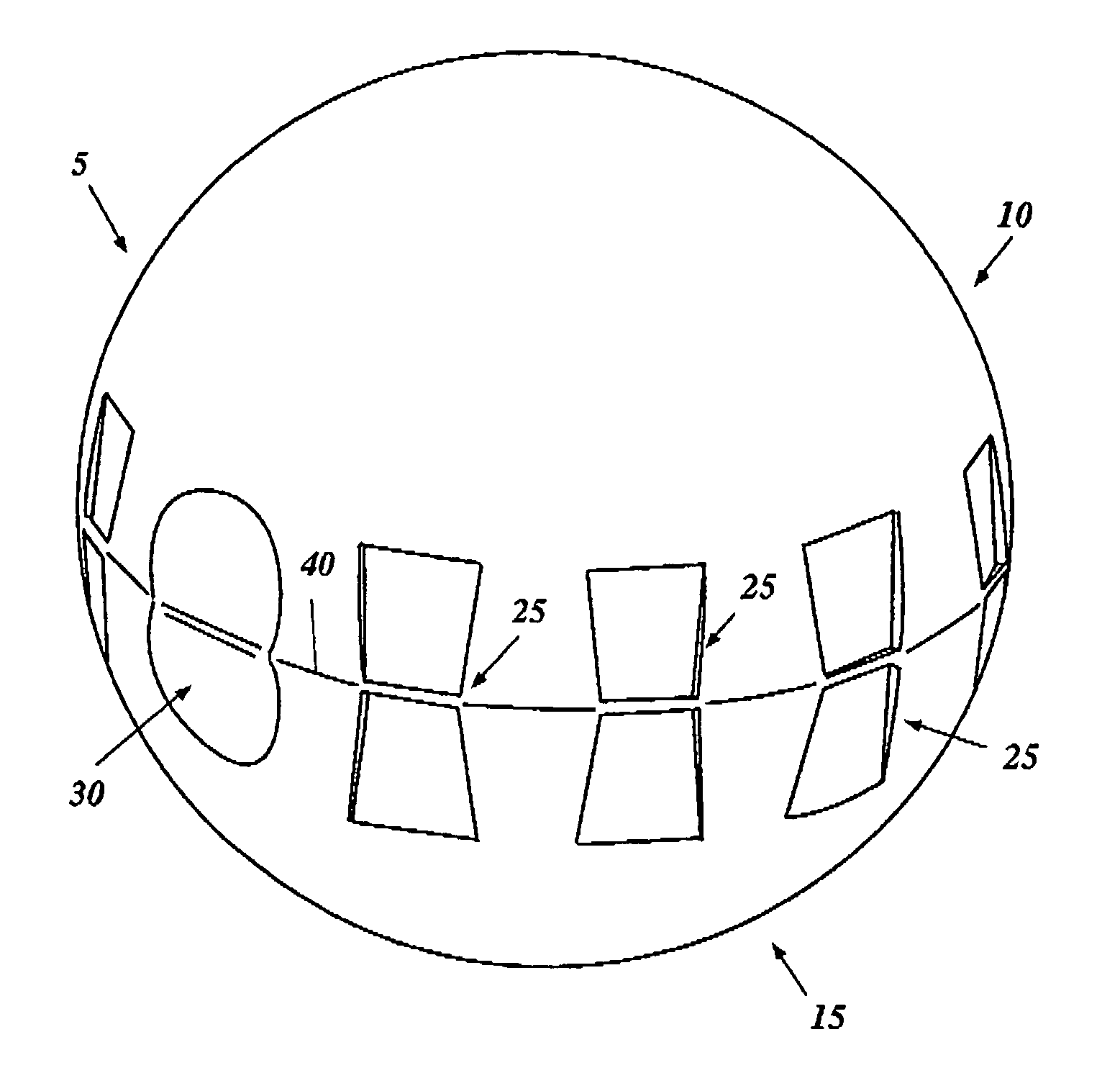

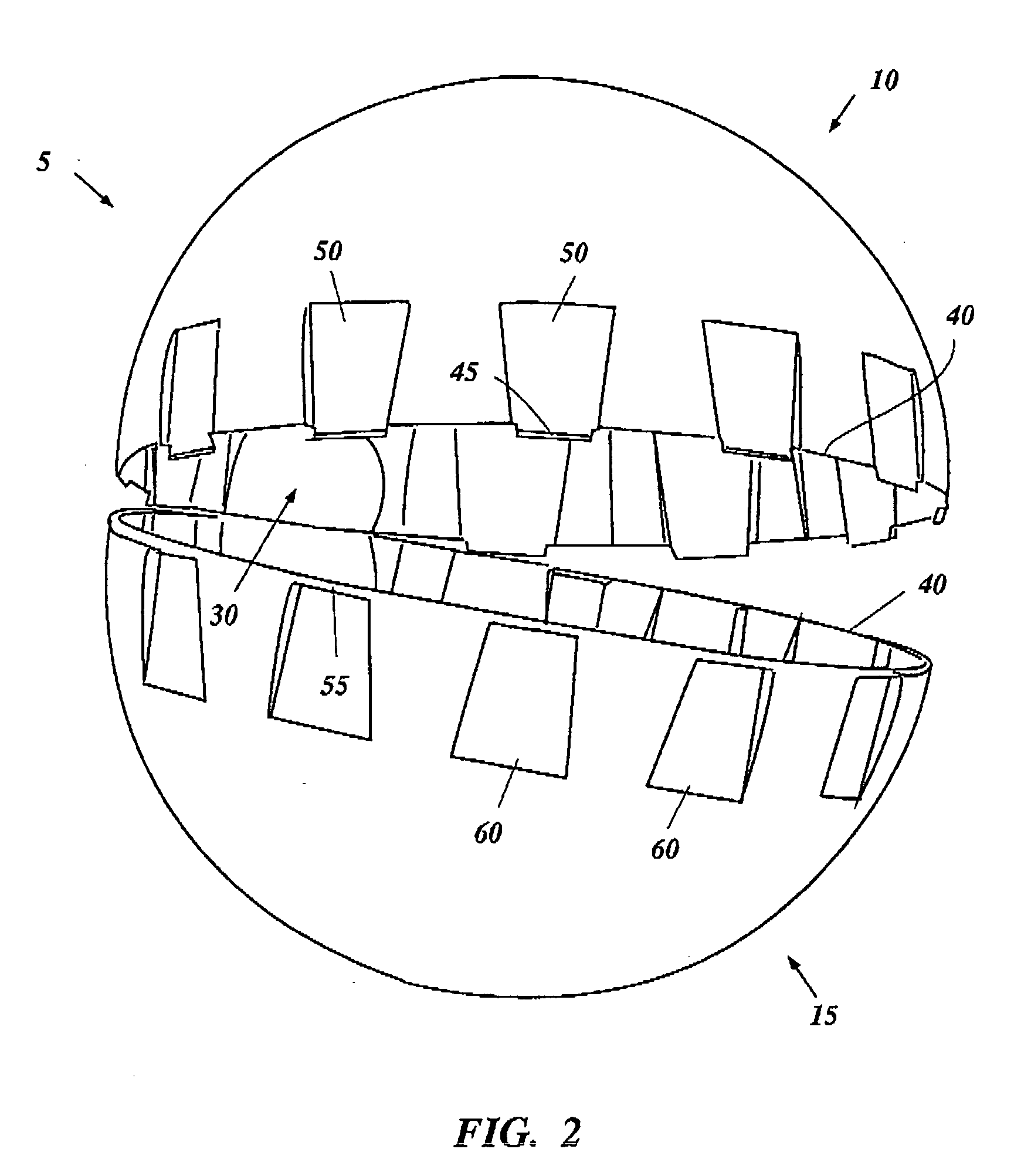

Nestable structural hollow body and related methods

ActiveUS20100132290A1Easy to moveGood structural supportStrutsConstruction materialEngineeringUltimate tensile strength

A multi-piece interconnected body for use in at least structural support and / or in creating internal cavities for an improved strength-to-weight ratio in a variety of structures is nestable prior to its assembly and use. When assembled, the device preferably forms a generally spherical and hollow body, with (1) one or more ribs or similar structural support network associated with and / or integrally formed in the body; (2) at least one latch mechanism to help hold the pieces in a desired assembled relationship with each other; and (3) a hinge or other interconnecting element that facilitates nesting and / or stacking of a plurality of the bodies with each other prior to assembly, association of the multiple parts of each body with each other prior to assembly, and ready repositioning of those parts into a desired assembled position.

Owner:ROPAK CORP

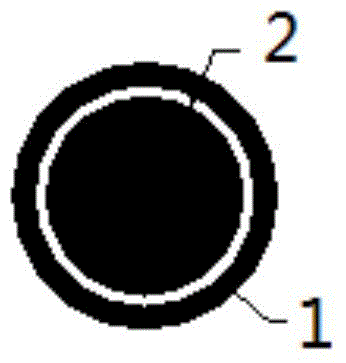

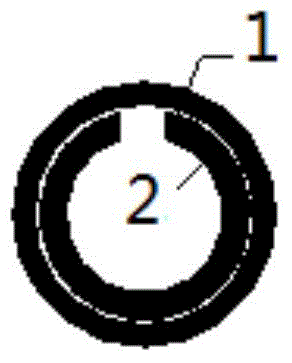

Preparation method of hollow fiber internal pressure composite film

ActiveCN102489176AGood separation performance and mechanical propertiesAvoid filament ruptureSemi-permeable membranesWater soluble polymersWater soluble

The invention discloses a preparation method of a hollow fiber internal pressure composite film, and aims to provide a preparation method of a hollow fiber internal pressure composite film with high supporting property and high pressure resistance. The preparation method comprises the following steps of: uniformly blending an outer layer film forming material, an outer layer film forming diluent and an outer layer film forming additive in a fusing process to obtain a thermally induced phase separation method outer layer film forming system; dissolving and uniformly mixing an inner layer film forming material, an inner layer film forming solvent and an inner layer film pore forming agent to obtain a non-solvent induced phase separation method inner layer film forming system, wherein the inner layer film pore forming agent contains over 70 percent of water-soluble polymer; and extruding and spinning in a composite way by introducing a core liquid into a central pipe, taking the inner layer film forming system as a middle layer and taking the outer layer film forming system as the outside, quickly soaking into a coagulation bath, fully curing an outer layer and an inner layer under the actions of the coagulation bath and the core liquid, and extracting and washing to obtain the hollow fiber internal pressure composite film. The large-inner-diameter hollow fiber internal pressure composite film prepared with the method disclosed by the invention can be used for replacing a tubular film during application.

Owner:TIANJIN MOTIMO MEMBRANE TECH

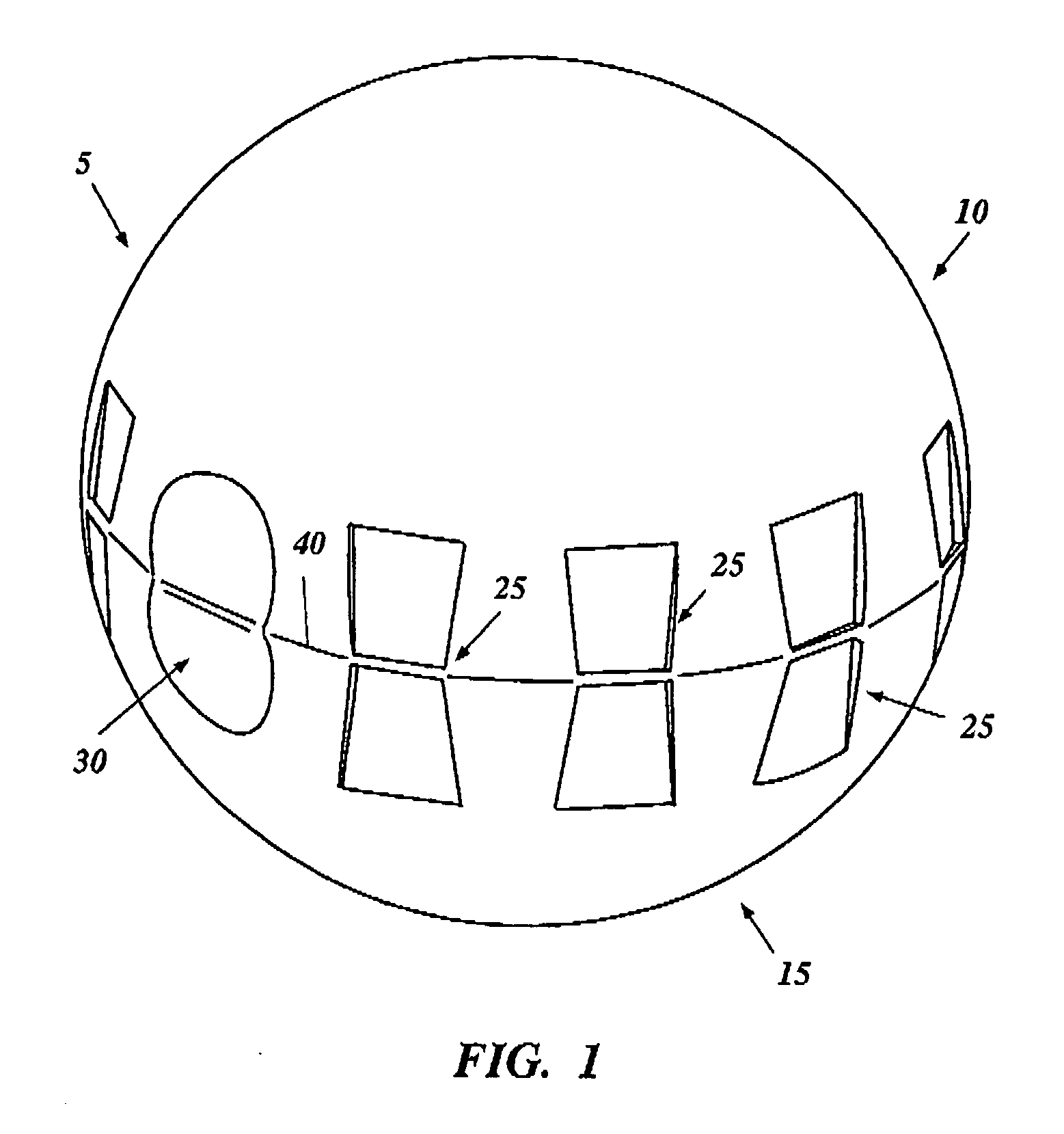

Nestable structural hollow body and related methods

InactiveUS20070199254A1Strength-to-weight ratio can be improvedEasy to moveBuilding roofsFloorsEngineeringUltimate tensile strength

A multi-piece interconnected body for use in at least structural support and / or in creating internal cavities for an improved strength-to-weight ratio in a variety of structures is nestable prior to its assembly and use. When assembled, the device preferably forms a generally spherical and hollow body, with (1) one or more ribs or similar structural support network associated with and / or integrally formed in the body; (2) at least one latch mechanism to help hold the pieces in a desired assembled relationship with each other; and (3) a hinge or other interconnecting element that facilitates nesting and / or stacking of a plurality of the bodies with each other prior to assembly, association of the multiple parts of each body with each other prior to assembly, and ready repositioning of those parts into a desired assembled position.

Owner:ROPAK CORP

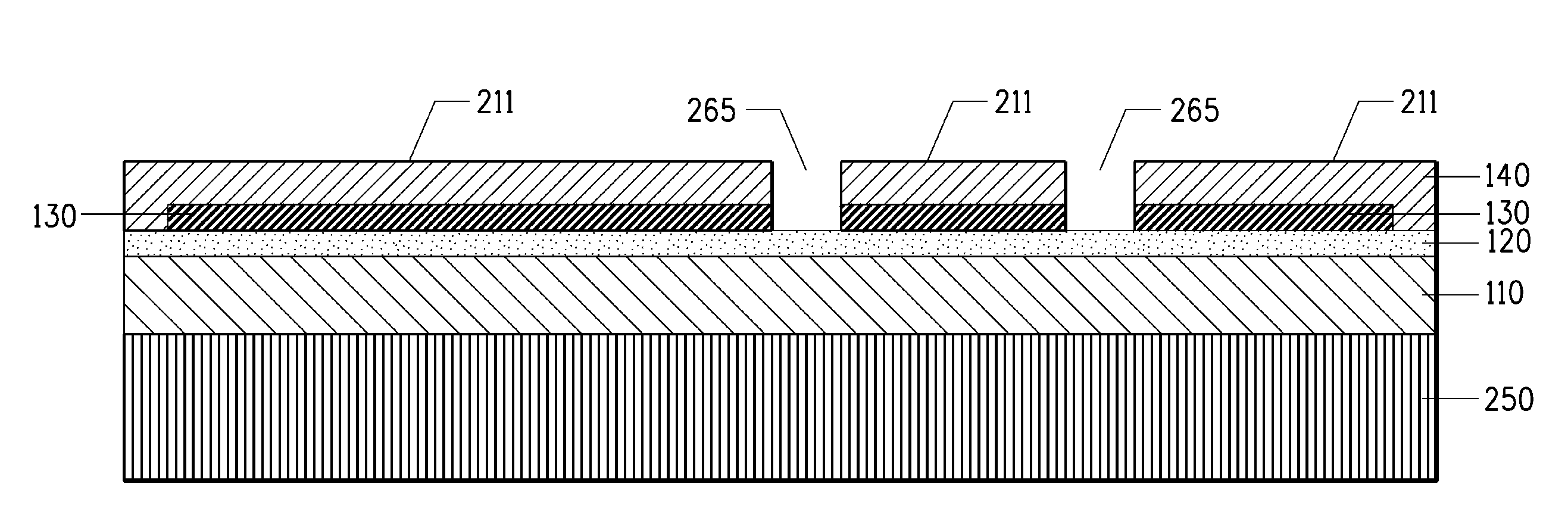

Stereo display electrode and manufacturing method thereof

ActiveCN103107285ALower resistanceIncrease in sizeSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionDisplay device

The invention discloses a stereo display electrode which comprises a transparent film display electrode and a stereo auxiliary electrode which is connected with the transparent film display electrode. The stereo display electrode is characterized in that the stereo auxiliary electrode comprises a formed insulating layer and a sealed insulating layer fixed at the upper end of the formed insulating layer, wherein a groove used for containing an electric conduction part is formed in the formed insulating layer, and the stereo auxiliary electrode is communicated with the transparent film display electrode through at least one communication hole which is formed at the lower end of the formed insulating layer. The invention further discloses a manufacturing method of the stereo display electrode. According to the stereo display electrode, the features of low resistance and high transparence are achieved, and low resistance, width minimization, even electric conductivity and flexibility and complete separation from display materials are achieved through the adjustment of thickness and material property of the stereo auxiliary electrode. The stereo display electrode can effectively reduce the resistance of an electrode, fully utilize redundancy space of an inner electrode of a display, and improve the resolution rate, refresh rate and contrast ratio of the display.

Owner:DALIAN LONGNING TECH

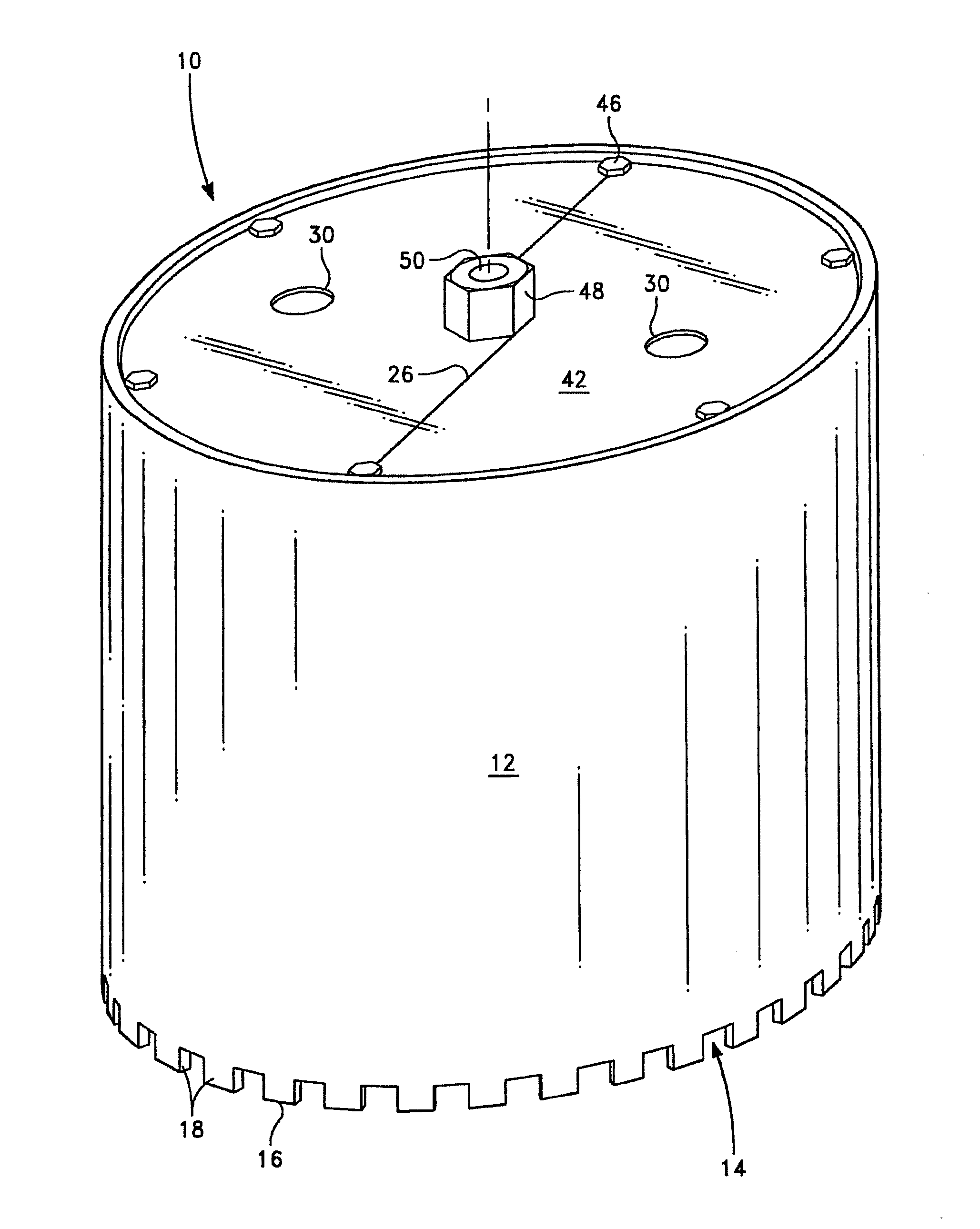

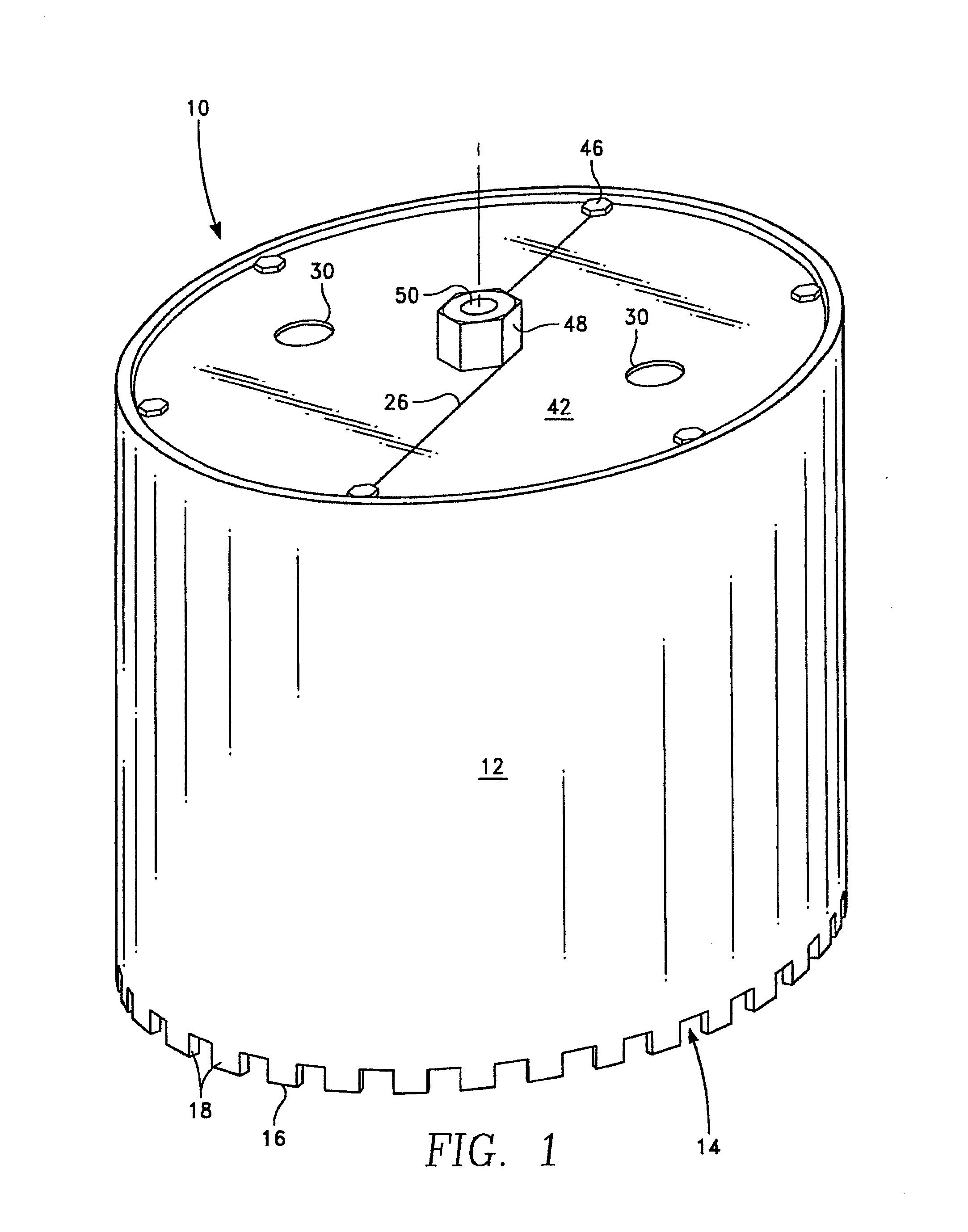

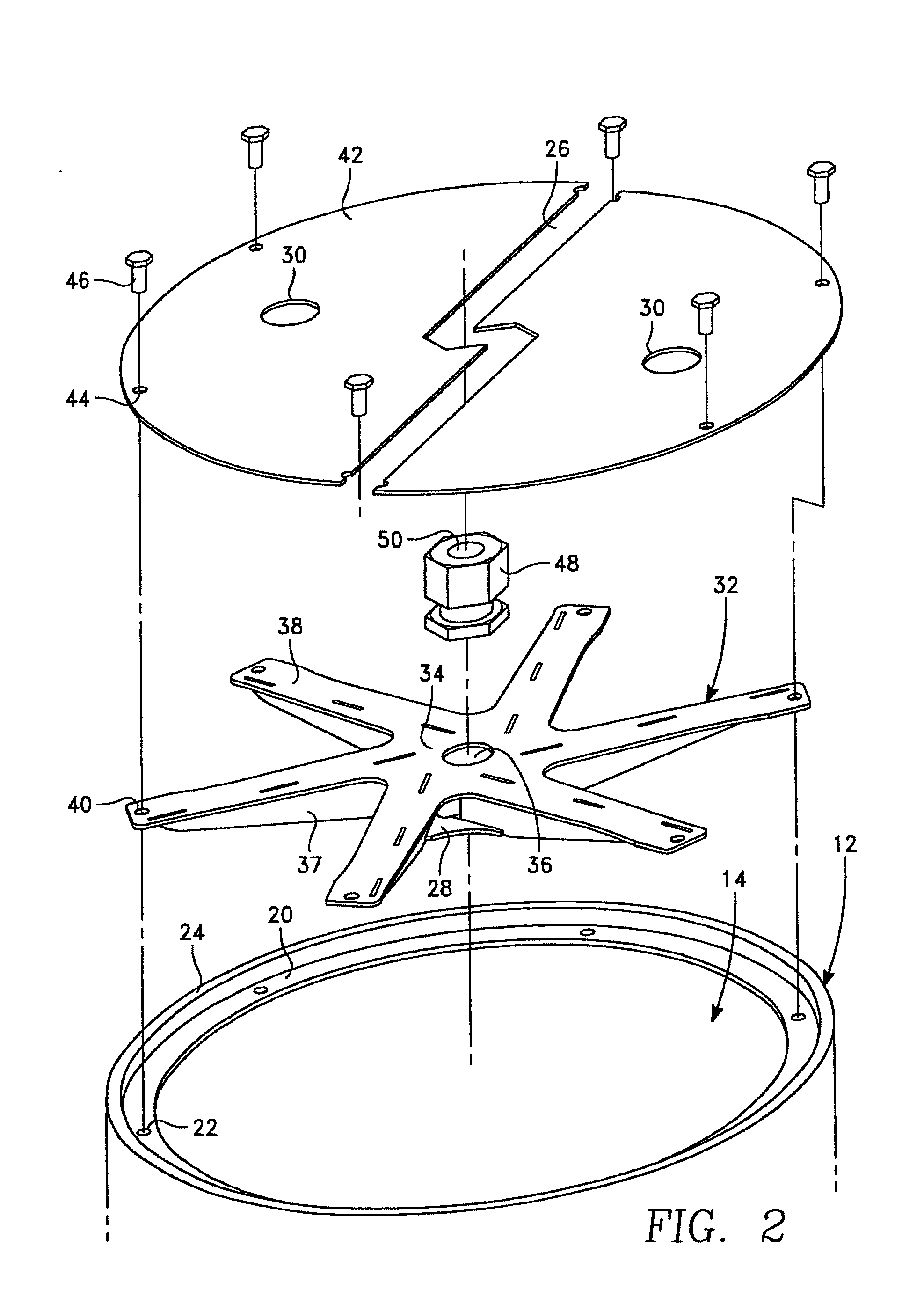

Support assembly for a core drill

InactiveUS20140334892A1Good structural supportImprove structural strengthTool workpiece connectionTransportation and packagingDrive shaftEngineering

A support assembly for a core drill which utilizes an improved high strength spoked reinforcer. The reinforcer may be removably mounted a core drill tube by fasteners. A drive connection is removably mounted and centrally located on an outer disc of a pair of discs. The drive connection is adapted to connect with a drive shaft to cause rotation of the tube. The assembly can also include a split in the disc when the high strength spoked reinforcer is not welded thereto, thereby providing a means of water control. The high strength spoked reinforcer can be a separate piece that is bolted to the disc or can be integrally formed as one piece therewith.

Owner:WESTERN SAW MFR

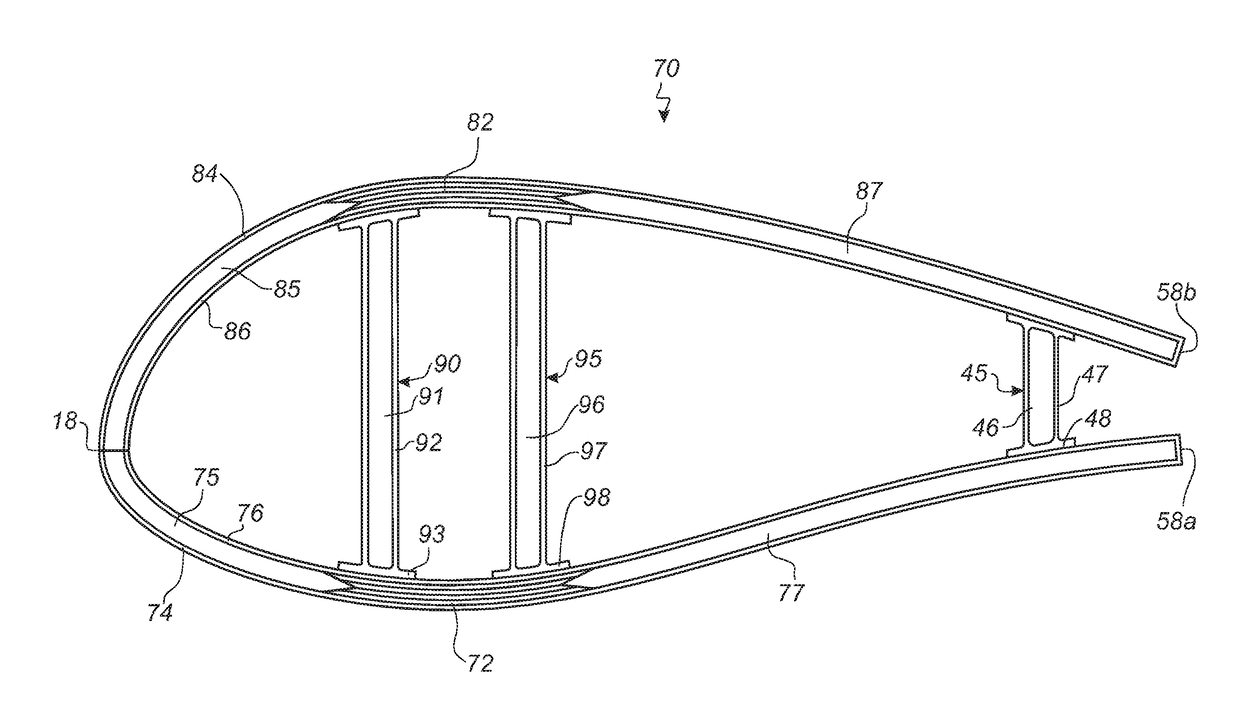

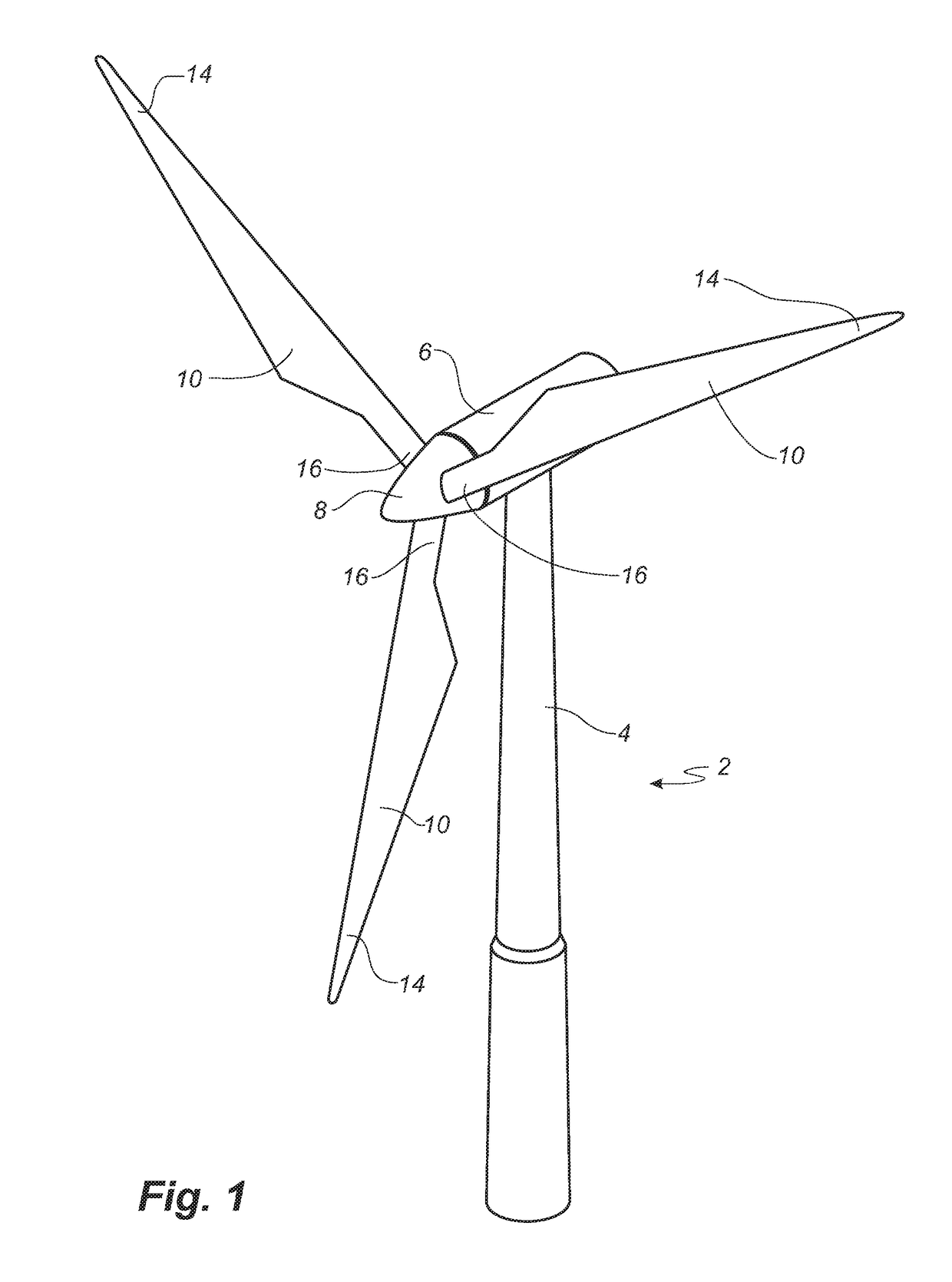

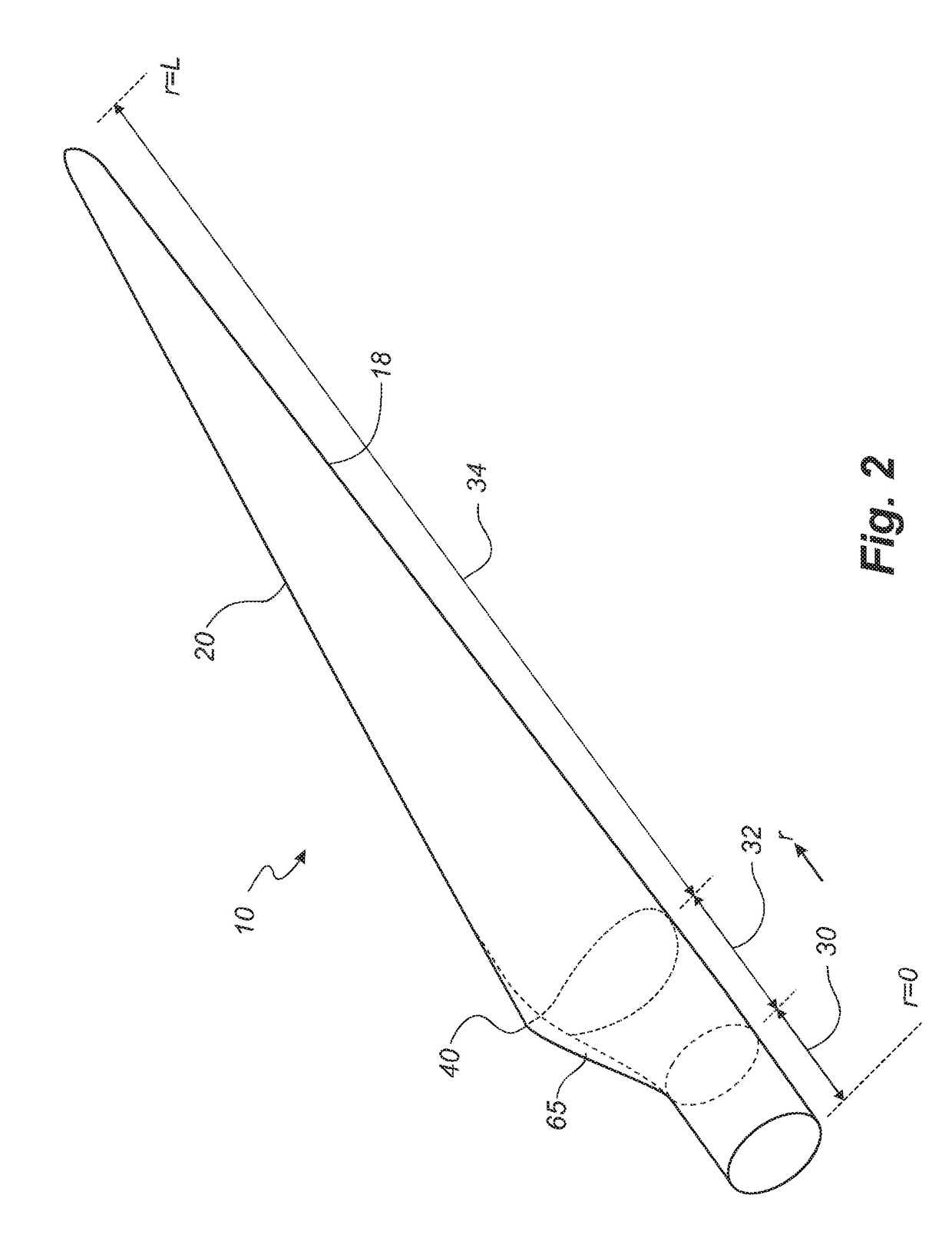

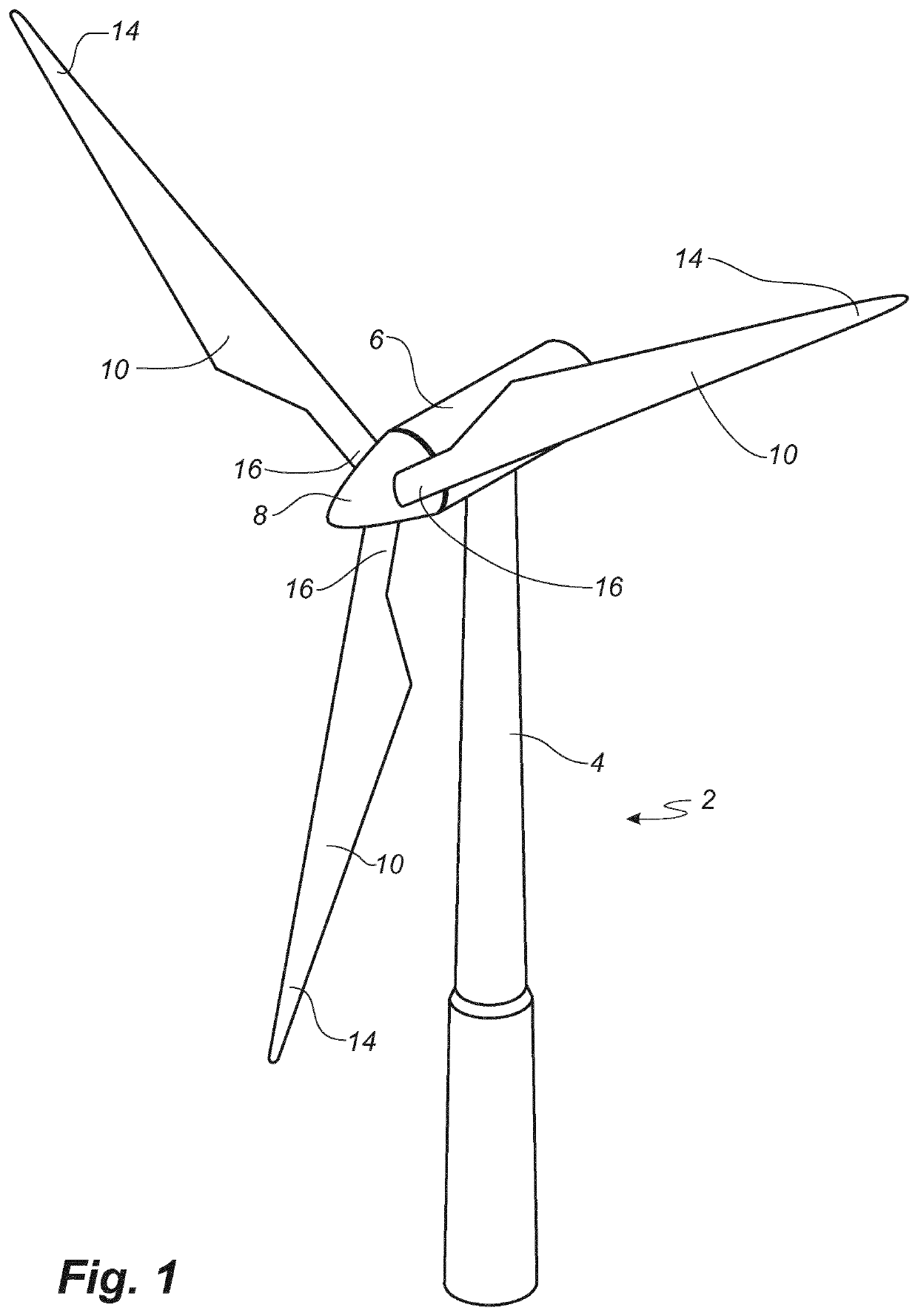

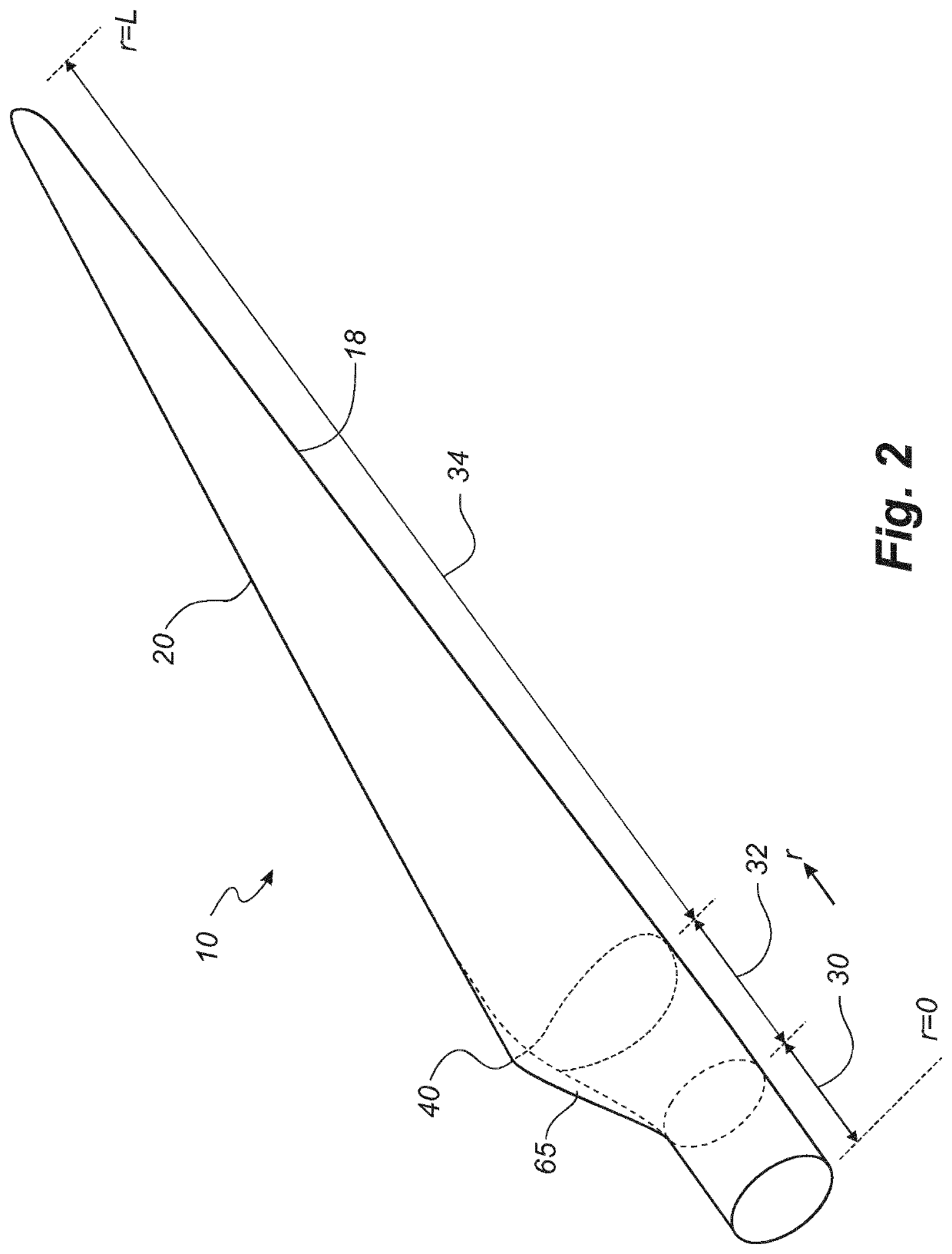

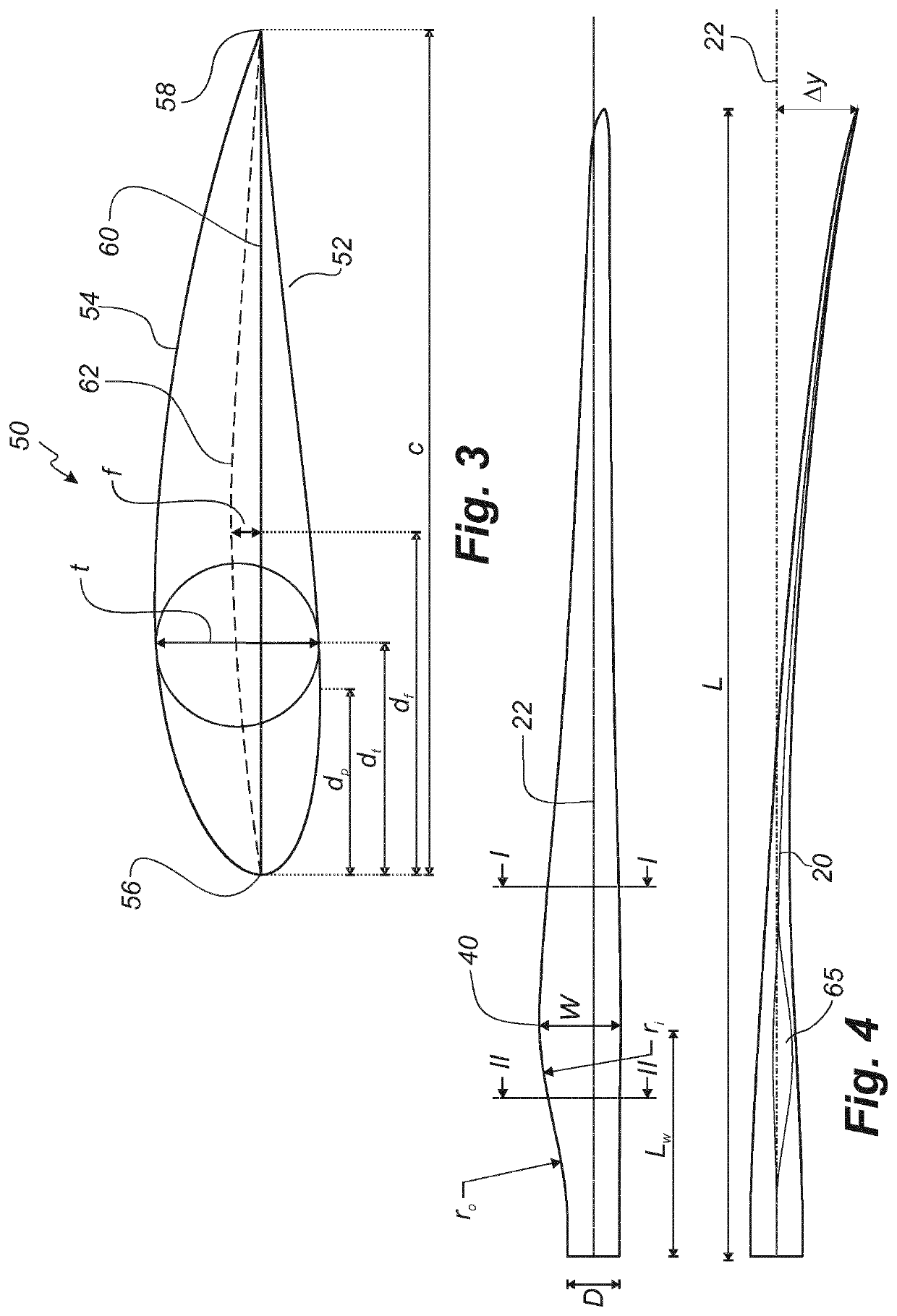

Wind turbine blade with a trailing edge spacing section

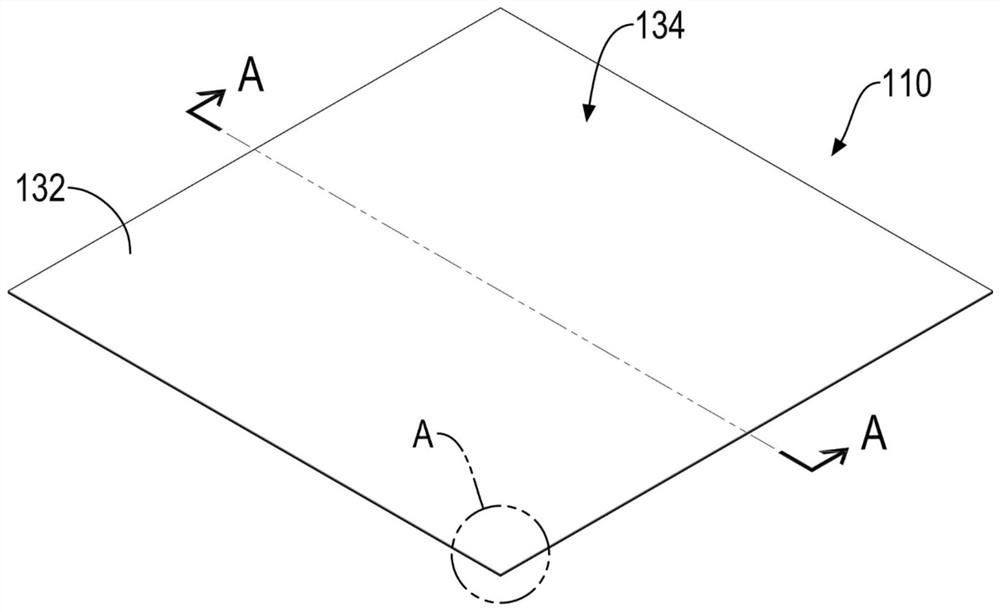

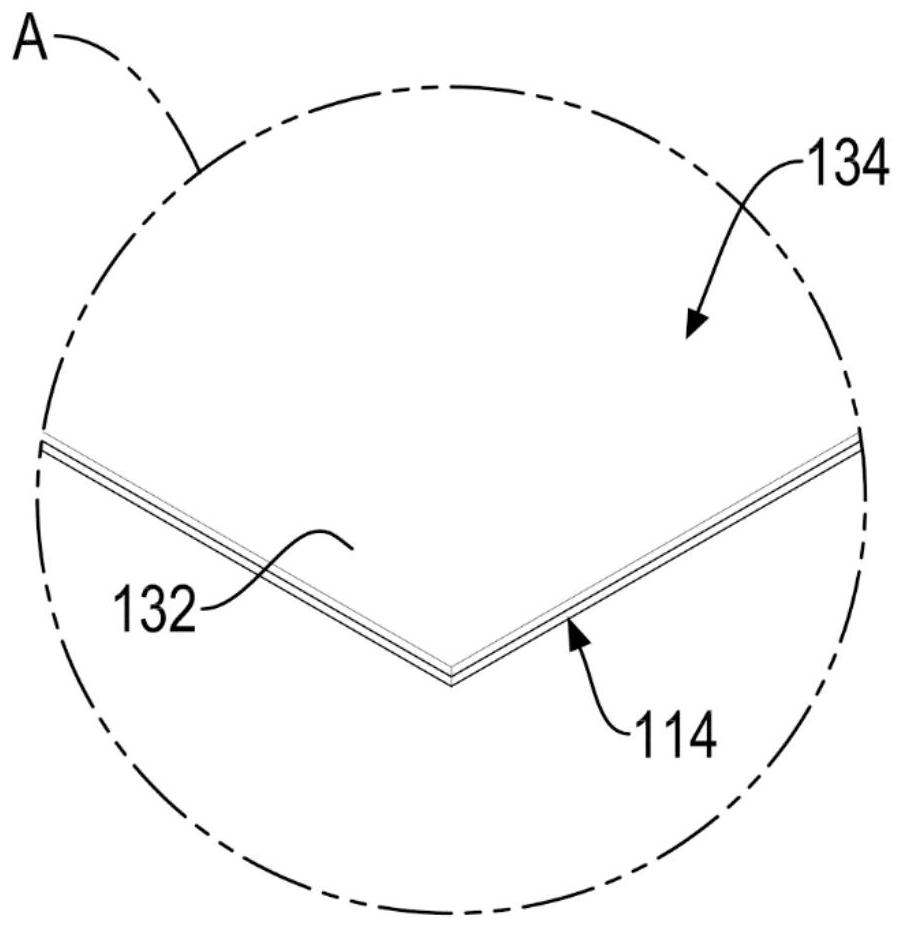

ActiveUS20180142670A1Improve structural stabilityGood structural supportFinal product manufactureMachines/enginesLeading edgeTurbine blade

A wind turbine blade is provided with two shell parts each at least partly made of a sandwich structure including an inner skin (76), an outer skin (74), and an intermediate core material (75, 77), wherein the shell parts are bonded together at least along their respective leading edges (18). The blade also comprises a longitudinally extending spacing section in which the respective trailing edges (58a, 58b) of the pressure side shell part and the suction side shell part are spaced apart, wherein a trailing edge shear web (45) is arranged between and connected to the sandwich structure of the suction side shell part (84, 86, 87) and the sandwich structure of the pressure side shell part (74, 76, 77).

Owner:LM WP PATENT HLDG

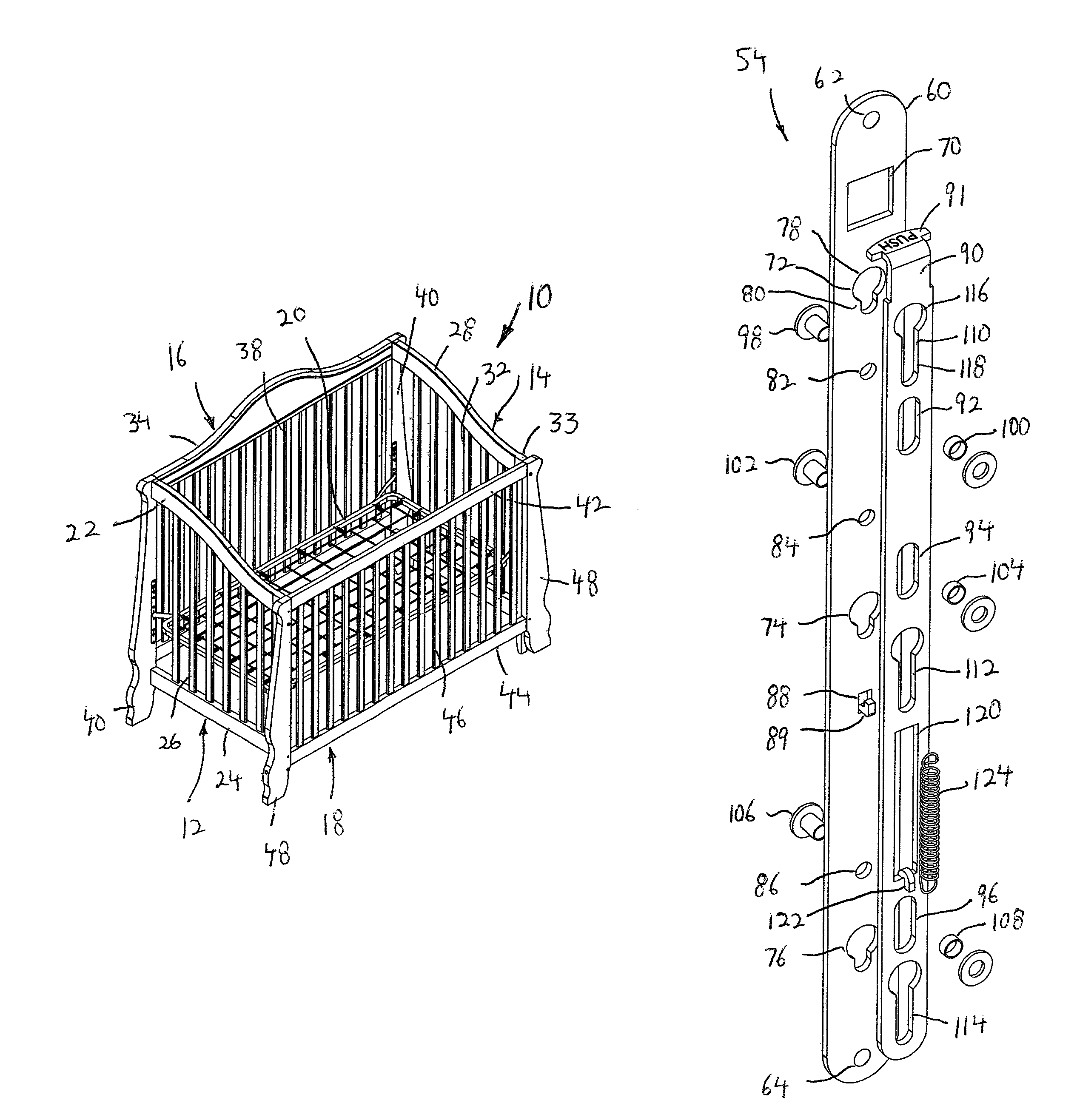

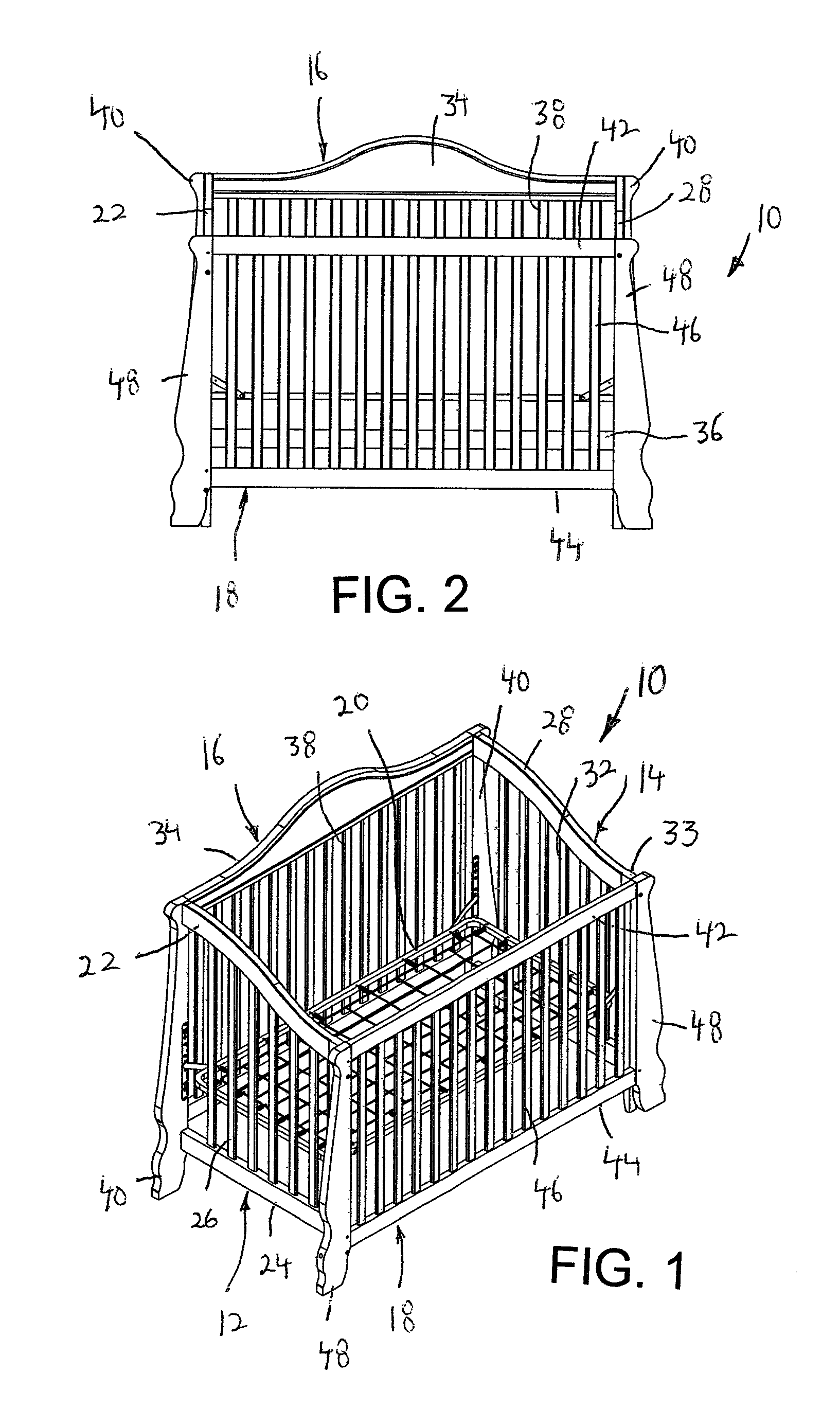

Connecting arrangement for spring deck holder for a crib mattress

A connecting arrangement for connecting a mattress support to supporting sides of a crib, includes stationary bars secured to the supporting sides, each having a first opening; slide bars, each having a second opening and mounted in sliding relation to a stationary bar between first and second positions in which the first and second openings are in or out of alignment with each other; a third opening in the slide bar and being in open communication with the second opening, the third opening being smaller than the second opening; and arms, each having one end connected to the mattress support and an opposite free end having a pin with an enlarged head for engagement within the first and second openings when the slide bar is moved to the first position and which is locked in the third opening when the slide bar is moved to the second position.

Owner:DELTA ENTERPRISE CORP

Biological iron-based alloy for promoting degradation by optimizing organization structure and preparation method thereof

ActiveCN110699607AReduced Corrosion ResistanceIncreased degradation rateAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingIron powder

The invention discloses a biological iron-based alloy for promoting degradation by optimizing an organization structure and a preparation method thereof, and belongs to the technical field of biomedical implant design and manufacturing. The biological iron-based alloy contains iron, manganese and silicon. The preparation method of the biological iron-based alloy comprises the following steps thatsilicon powder, manganese powder and iron powder are subjected to ball milling and mixing in proportion in the protective atmosphere; then and the biological iron-based alloy is prepared through a selective laser melting process. The biological iron-based alloy has the advantages that the solid solubility of manganese and silicon in an iron base is improved through the laser rapid solidification process, the alpha-ferrite single phase in pure iron is promoted to be converted into an epsilon-martensitic phase, especially a gamma-austenite phase, the characteristics that when an epsilon-martensite is compared with the gamma-austenite, the alpha-ferrite phase is lower in corrosion resistance, and compared with the epsilon-martensitic phase, the gamma-austenite is lower in electrical resistivity, the degradation rate of the biological iron-based alloy is increased. By means of the method for optimizing the microstructural structure of the iron base, the problem that the biological iron-based alloy is too slow in degradation is solved, and application of the iron-based alloy in bone repairing is promoted.

Owner:CENT SOUTH UNIV

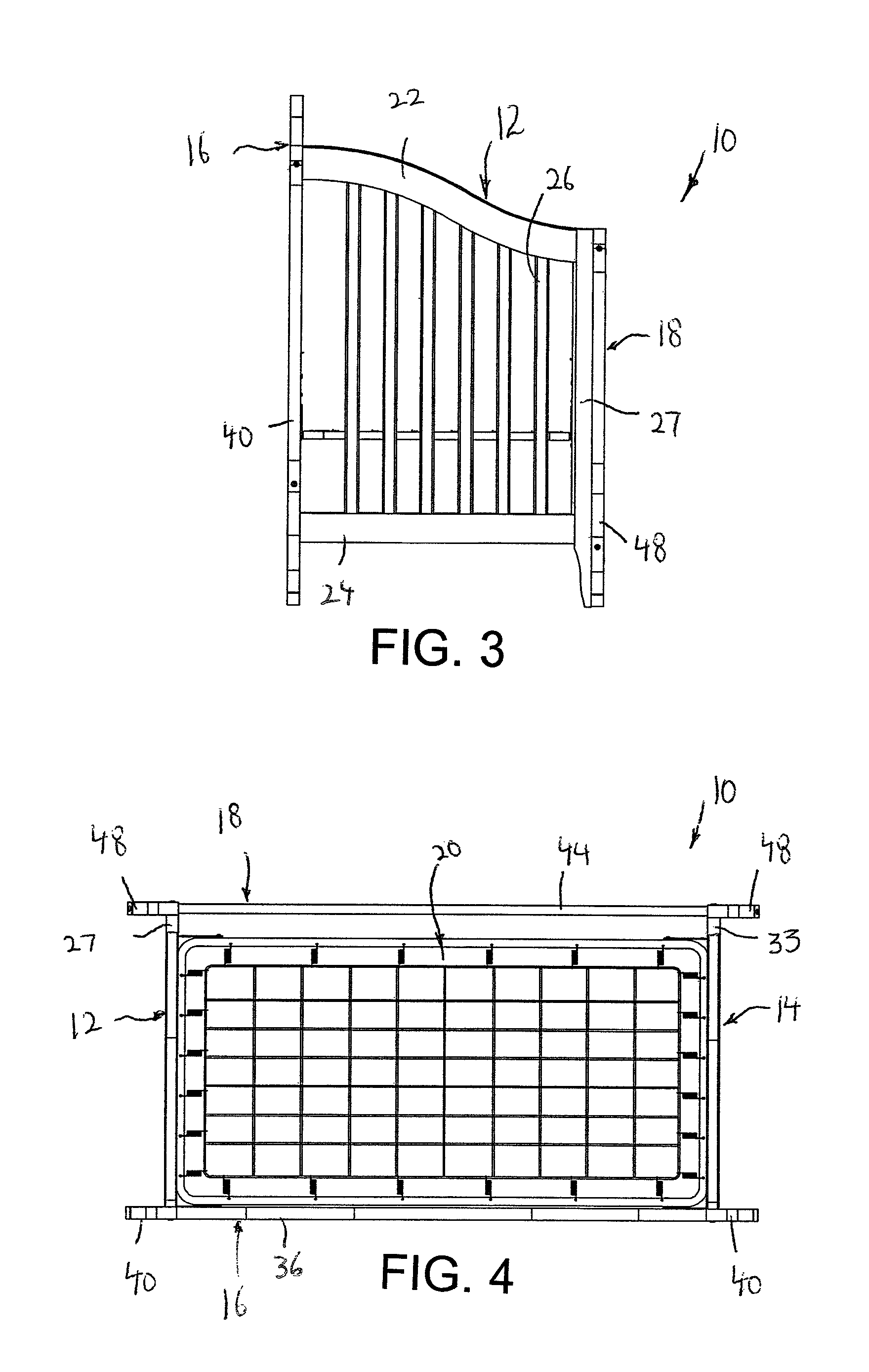

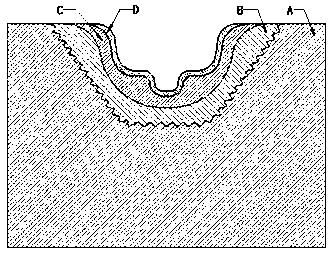

Fist type large-scale hot-forging die with bionic structure, and manufacturing method thereof

ActiveCN108213304AEasy to useGood structural supportGeometric CADForging/hammering/pressing machinesAlloyHigh surface

The invention discloses a fist type large-scale hot-forging die with a bionic structure, and a manufacturing method thereof. A transition layer, a strengthened layer and a skin layer are sequentiallyformed on a die matrix; the transition layer and the strengthened layer are jointly used as a bone layer to play a role in structure supporting; the skin layer is used as a die cavity surface layer contacting a forging piece and has wear resistance and deformation resistance under a high-temperature heavy load condition; at the normal temperature, the strength and the hardness of the die matrix, the transition layer and the strengthened layer are sequentially increased progressively, and the strength and the hardness of the skin layer are smaller than the strength and the hardness of the strengthened layer; and the strength and the hardness of the skin layer is not reduced obviously under a hot-forging working condition (below 650 DEG C). The skin layer is a cobalt-based or nickel-based high-temperature alloy welding material. According to the die, the occurrence of the problems such as surface layer cracks and difficulty in machining brought by high surface hardness are effectively reduced, meanwhile, a use performance of the large-scale forging die under the high-temperature heavy load working condition is further effectively improved, and the fist type large-scale hot-forging die with the bionic structure has favorable wear resistance and deformation resistance at the high temperature.

Owner:CHONGQING JIEPIN TECH +2

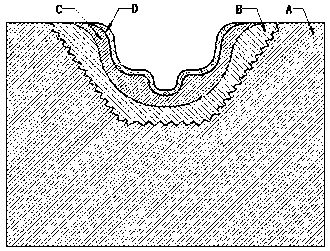

Methods of embedding thin-film capacitors into semiconductor packages using temporary carrier layers

ActiveUS20100270644A1Good structural supportMinimal distortionPrinted circuit aspectsSolid-state devicesDielectricSemiconductor package

Disclosed are methods of making a semiconductor package comprising at least one thin-film capacitor embedded into at least one build-up layer of said semiconductor package. A thin-film capacitor is provided wherein the thin-film capacitor has a first electrode and a second electrode separated by a dielectric. A temporary carrier layer is applied to the first electrode and the second electrode is patterned. A PWB core and a build-up material are provided, and the build-up material is placed between the PWB core and the patterned second electrode of said thin-film capacitor. The patterned electrode side of the thin-film capacitor is laminated to the PWB core by way of the build-up material, the temporary carrier layer is removed, and the first electrode is patterned.

Owner:CHEMTRON RES

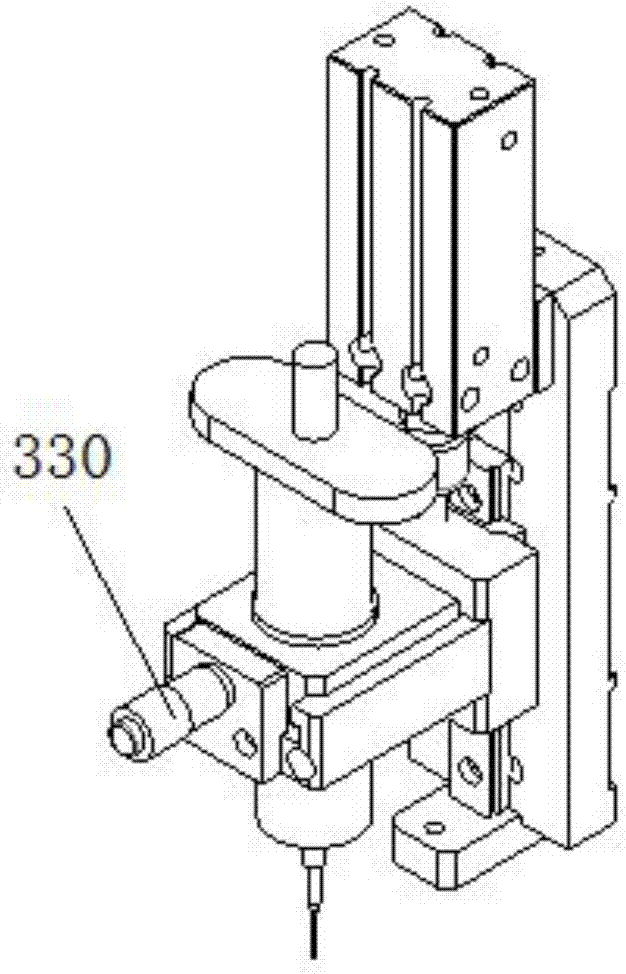

Glue dispensing device of hollow cup motor rotor

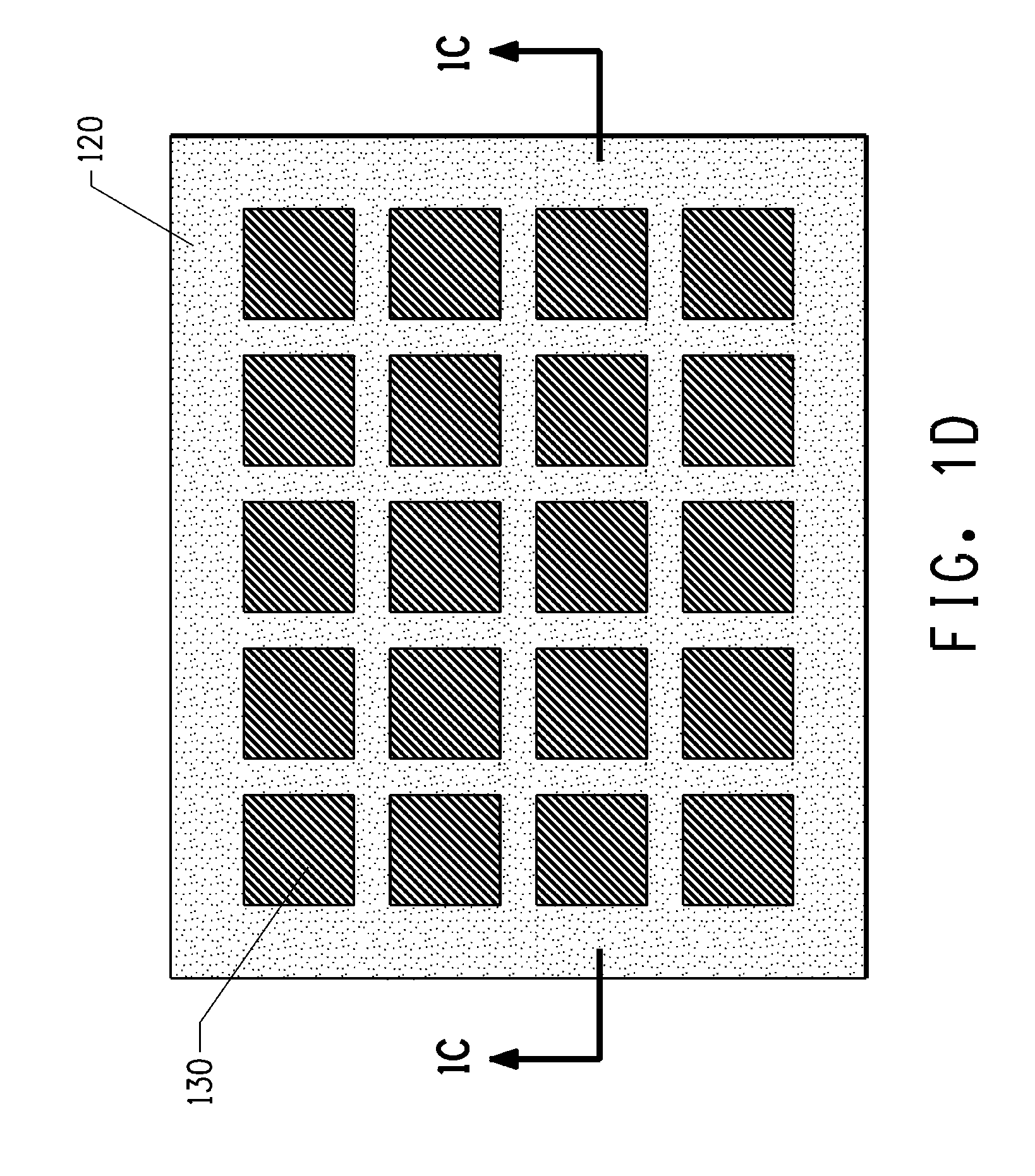

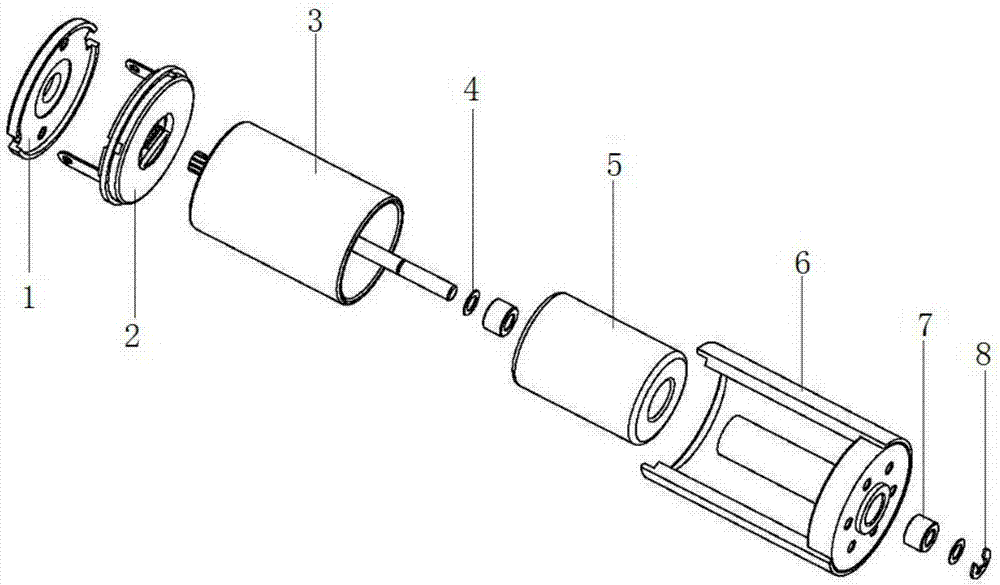

ActiveCN107029942AEasy to passEasy to rotate freelyLiquid surface applicatorsCoatingsDegrees of freedomEngineering

The invention discloses a glue dispensing device of a hollow cup motor rotor with the advantages of simple structure, automatic glue dispensing and high glue dispensing efficiency. The device comprises a servo translation mechanism, a hollow cup motor rotor rotating mechanism and an automatic glue dispensing device; the servo translation mechanism is provided with a movable slide block and a servo driving device; the movable slide block has translation motion degrees of freedom in the horizontal direction and / or the vertical direction under the effect of the servo driving device; the automatic glue dispensing device is fixedly arranged on the movable slide block; the hollow cup motor rotor rotating mechanism is fixedly arranged below the servo translation mechanism; the hollow cup motor rotor rotating mechanism comprises a glue dispensing tool, a power device for driving the glue dispensing tool to rotate, and a limiting device; the glue dispensing tool is provided with a strip groove with the width matched with the outer diameter of the hollow cup motor rotor; the limiting device is provided with an actuation end for limiting rotation of the hollow cup motor rotor on the glue dispensing tool; and the actuation end is positioned in the strip groove. The device can realize full-automatic glue dispensing.

Owner:ONCE TOP MOTOR MFG

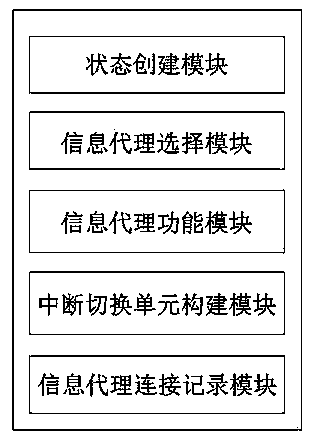

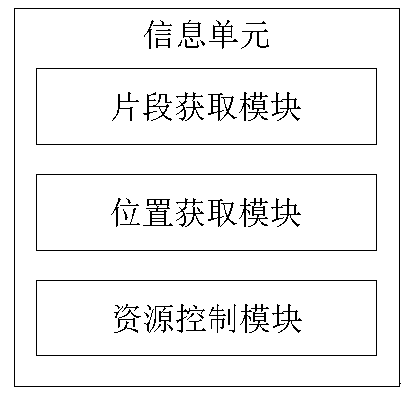

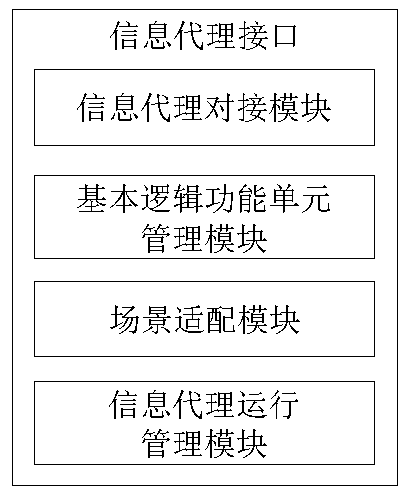

Information agent interface and application system based on information agent interface

ActiveCN104462219AEasy to implement complex processingGood structural supportWeb data indexingSpecial data processing applicationsStructure of Management InformationHuman–computer interaction

The invention provides an information agent interface on the basis of information units. The capacity of calling a series of basic logic function units for information segmentations under various scene modes is provided, and a responding mechanism oriented to incidents of information-unit-oriented is provided, so that good structural support is provided for content utilization and function expansion of the information units. By means of the interface mechanism, complex processing with the information segments as target objects is easily achieved by an application under various scene modes, and finally various practical functions are provided for a user so that the user generating or having access to information segments can obtain more experience through the application.

Owner:吴涛军

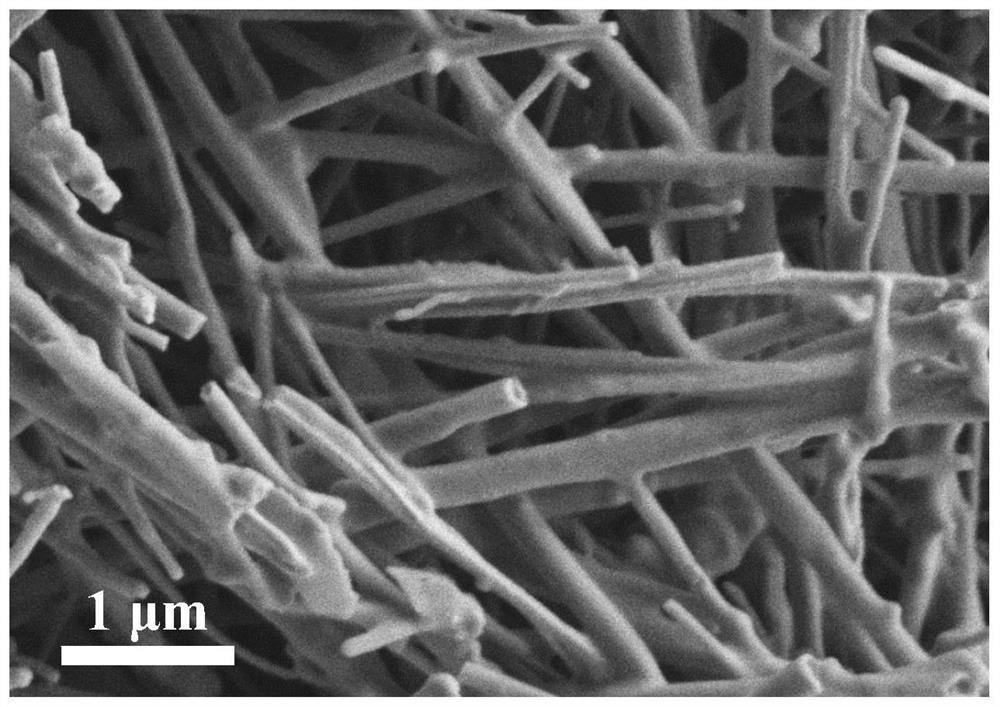

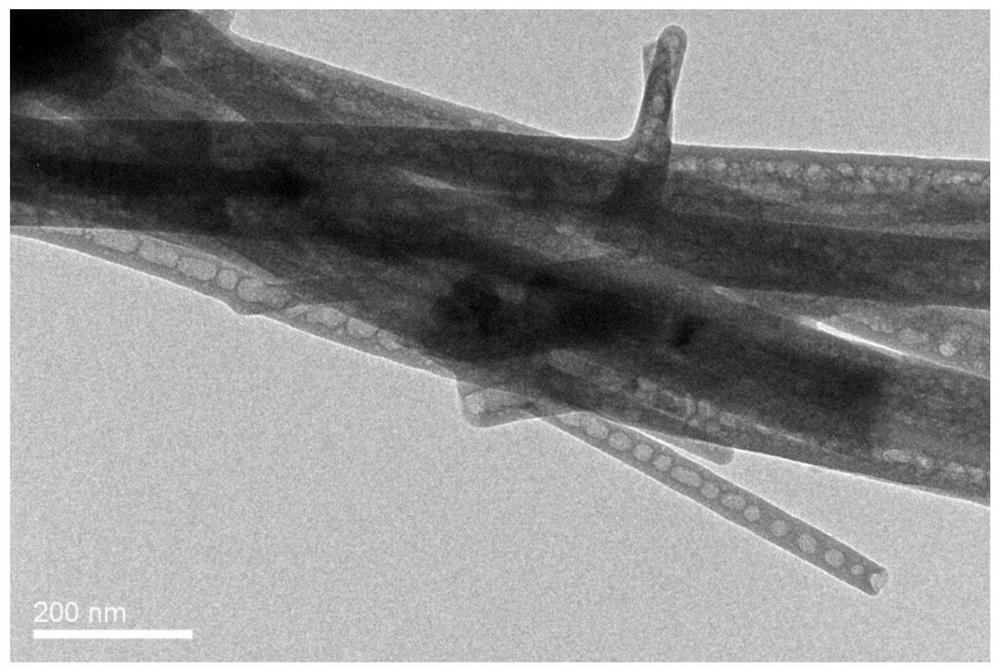

Cobalt phosphide hierarchical porous nanowire material as well as preparation and application thereof

PendingCN112246261AReduce hydrogen evolution overpotentialImprove electrocatalytic activityPhysical/chemical process catalystsNanotechnologyNanowireElectrolysis

The invention discloses a cobalt phosphide graded porous nanowire material, preparation thereof and an application thereof in water electrolysis hydrogen production reaction. In the cobalt phosphide hierarchical porous nanowire material, a large number of pores are distributed in the cobalt phosphide nanowire to form a hierarchical porous structure. The preparation method comprises the following steps: firstly, synthesizing basic cobalt carbonate nanowires, then carrying out controllable phosphorization, and simultaneously carrying out phosphorization and pore formation. According to the invention, the hydrogen evolution overpotential of cobalt phosphide can be reduced, and the electrocatalytic activity and stability are improved. The cobalt phosphide hierarchical porous nanowire has important application value as an electrocatalytic material, and the method is simple, efficient and capable of being used on a large scale.

Owner:CHINA JILIANG UNIV

Height specifiable plate system as replacement for molded vacuum support box

InactiveUS20190143488A1Facilitate manual handling and positioningGood structural supportGripping headsWork holdersShell moldingEngineering

A predetermined height specialized support plate and post structural assembly replaces the plastic injection molded box-shaped structure used in a conventional vacuum support. The support plates interfit and support a conventional rubber vacuum engagement body in a manner similar to but more strengthened than otherwise. Predetermined height is achieved by specifying the length of support posts that stabilize, make handling easier, and may also preferably provide a source of vacuum to oppositely oriented vacuum engagement bodies.

Owner:BLICK JOHN

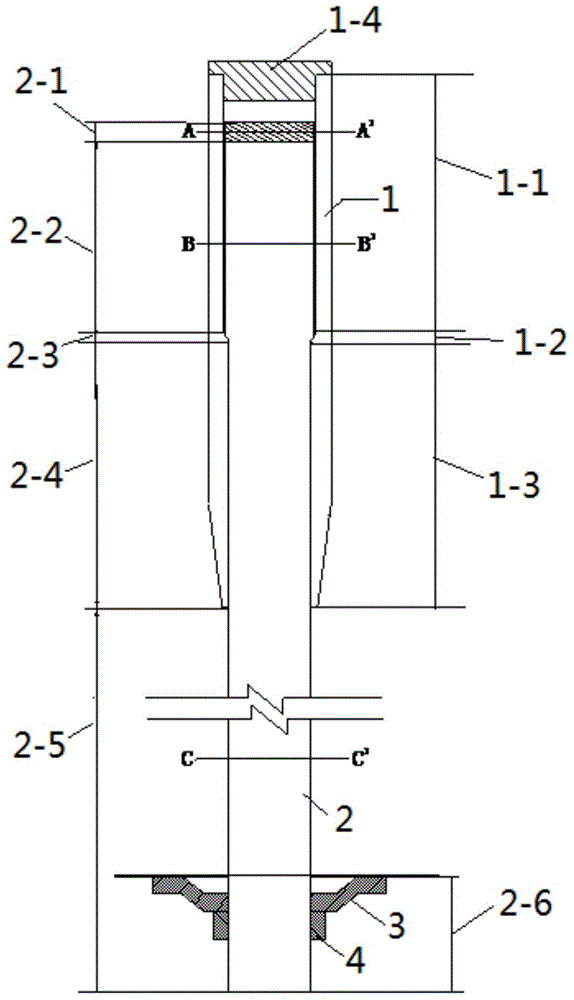

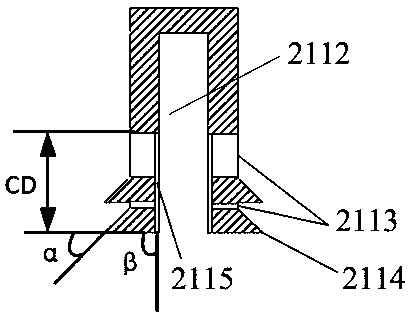

Pressing seam type friction type constant-resistance anchor rod

ActiveCN104453961AImprove work performanceSimple structureAnchoring boltsSolid structureStructural engineering

The invention relates to the technical field of engineering supporting, in particular to a pressing seam type friction type constant-resistance anchor rod. By means of the anchor rod, the technical problems that in the prior art, the ultimate tensile length of an anchor rod is small, function overload failure occurs easily, and the flexible supporting capacity is not achieved are solved. The anchor rod structurally comprises a sleeve, a rod body, a tray and a pressing block. The rod body comprises an entity segment, a constant-resistance segment, a conical segment, a friction resistance segment and a free segment from top to bottom. The entity segment is of a cylindrical solid structure. The side walls of the constant-resistance segment, the conical segment and the friction resistance segment are provided with gaps with the same width from top to bottom in the axial direction. The outer diameter of the constant-resistance segment is larger than that of the friction resistance segment. The outer diameter of the axial section of the rod body gradually diseases continuously and is in transition to the outer diameter of the friction resistance segment from the outer diameter of the constant-resistance segment in the axial direction through the conical segment The sleeve comprises a rough-hole segment, a conical-hole segment and a thin-hole segment and is matched with the rod body in inner diameter. The anchor rod is not damaged when a surrounding rock is greatly deformed, larger displacement of the rod body is allowed so as to adapt to deformation of the surrounding rock, the surrounding rock deformation energy can be continuously absorbed, and the stability of the surrounding rock is maintained.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

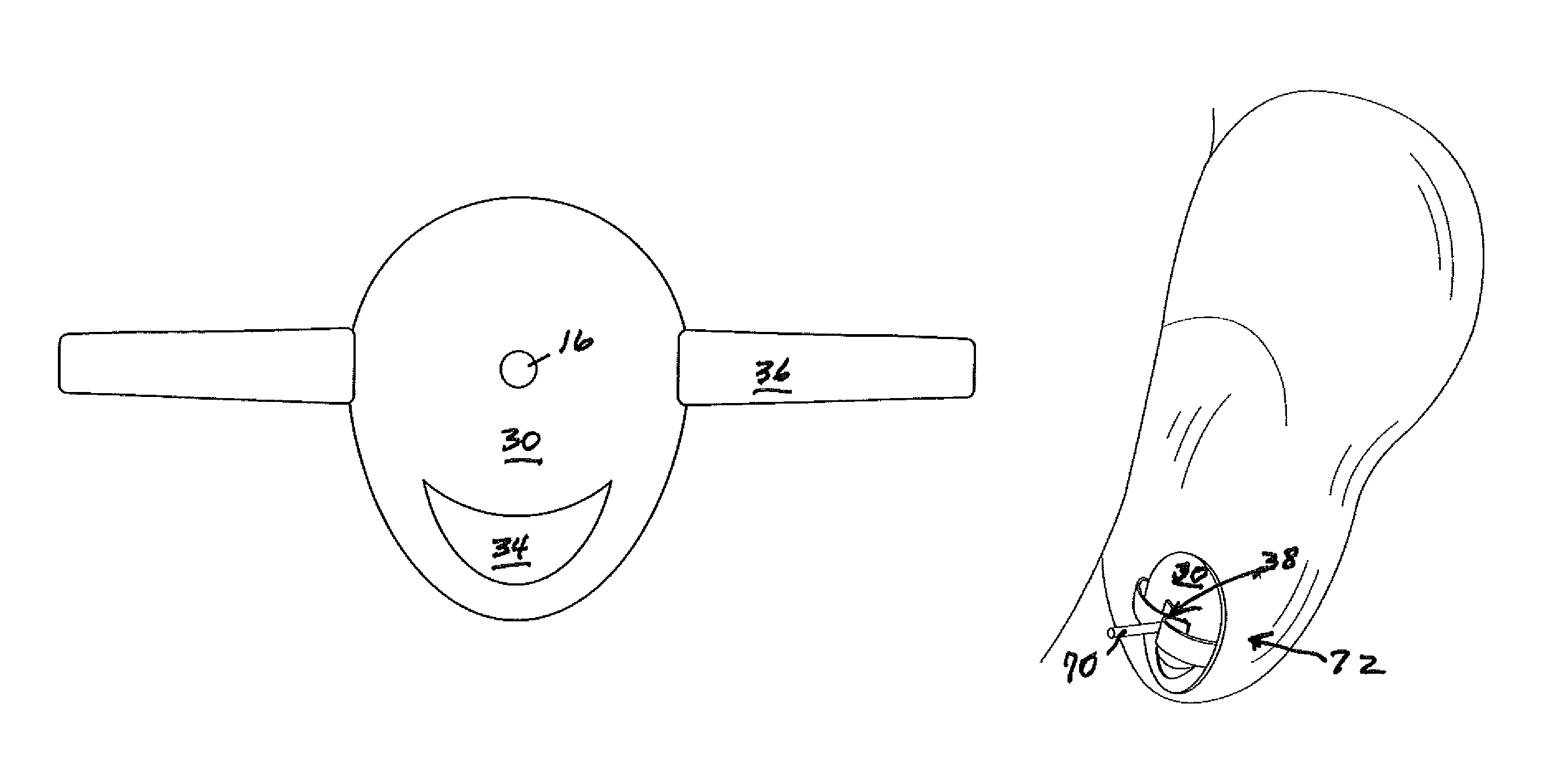

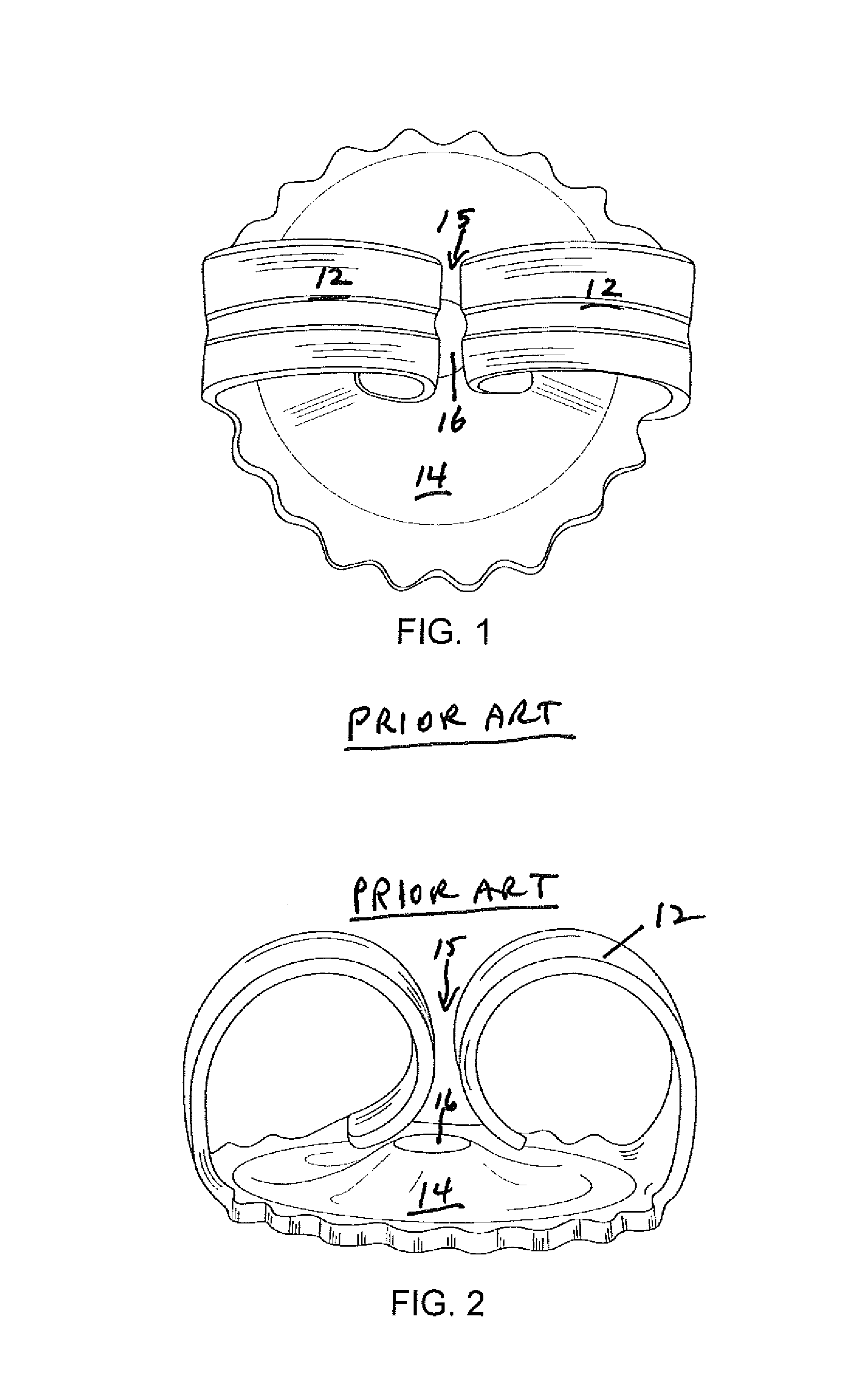

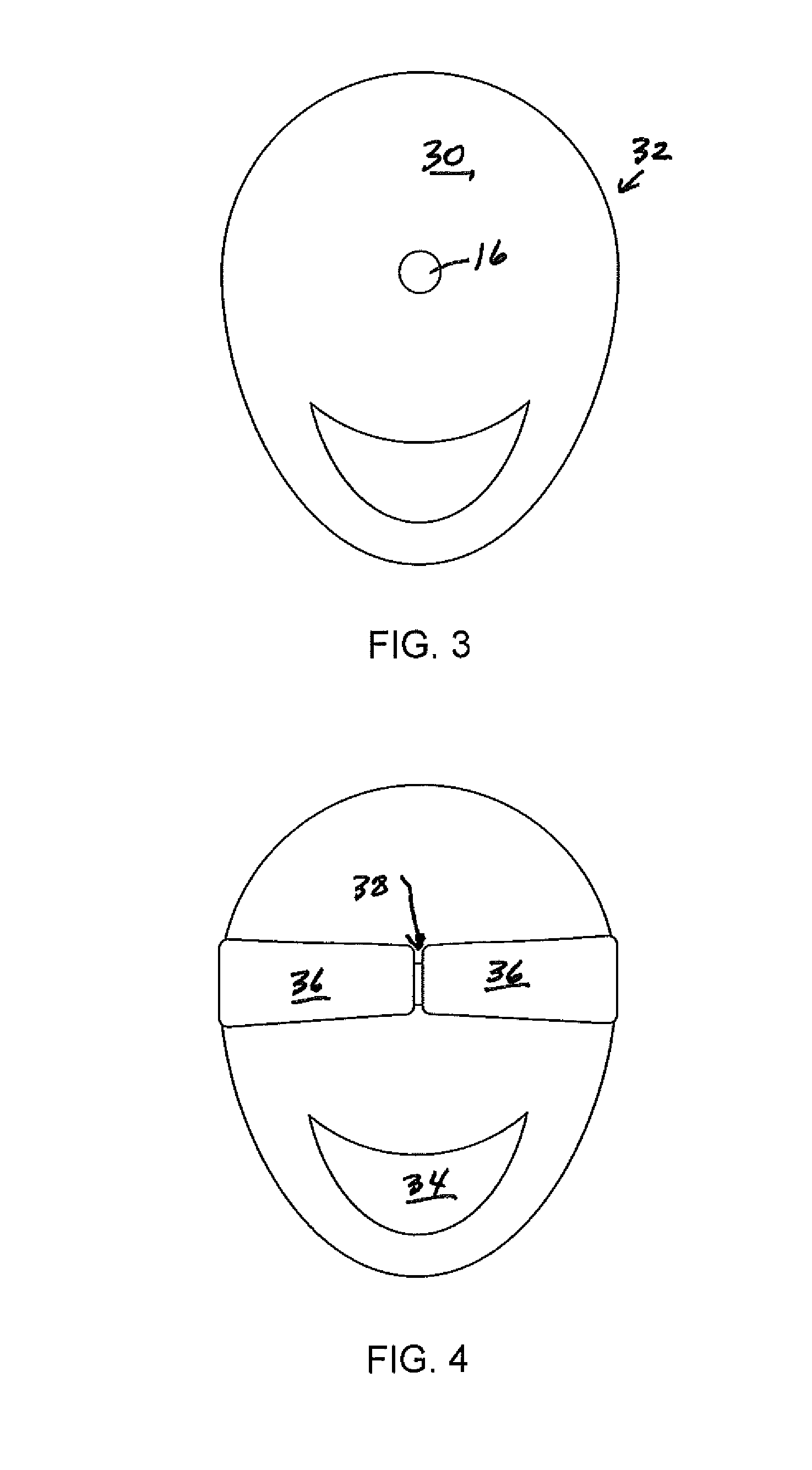

Nut plate for pierced earrings

A novel pierced earring for pierced ears which includes a rear plate attached to the pin, the rear plate forming the nut and having a peripheral shape approximating that of the rear portion of the lobe of the ear to provide substantial bearing surface against the rear of the lobe.

Owner:RICHLINE GRP

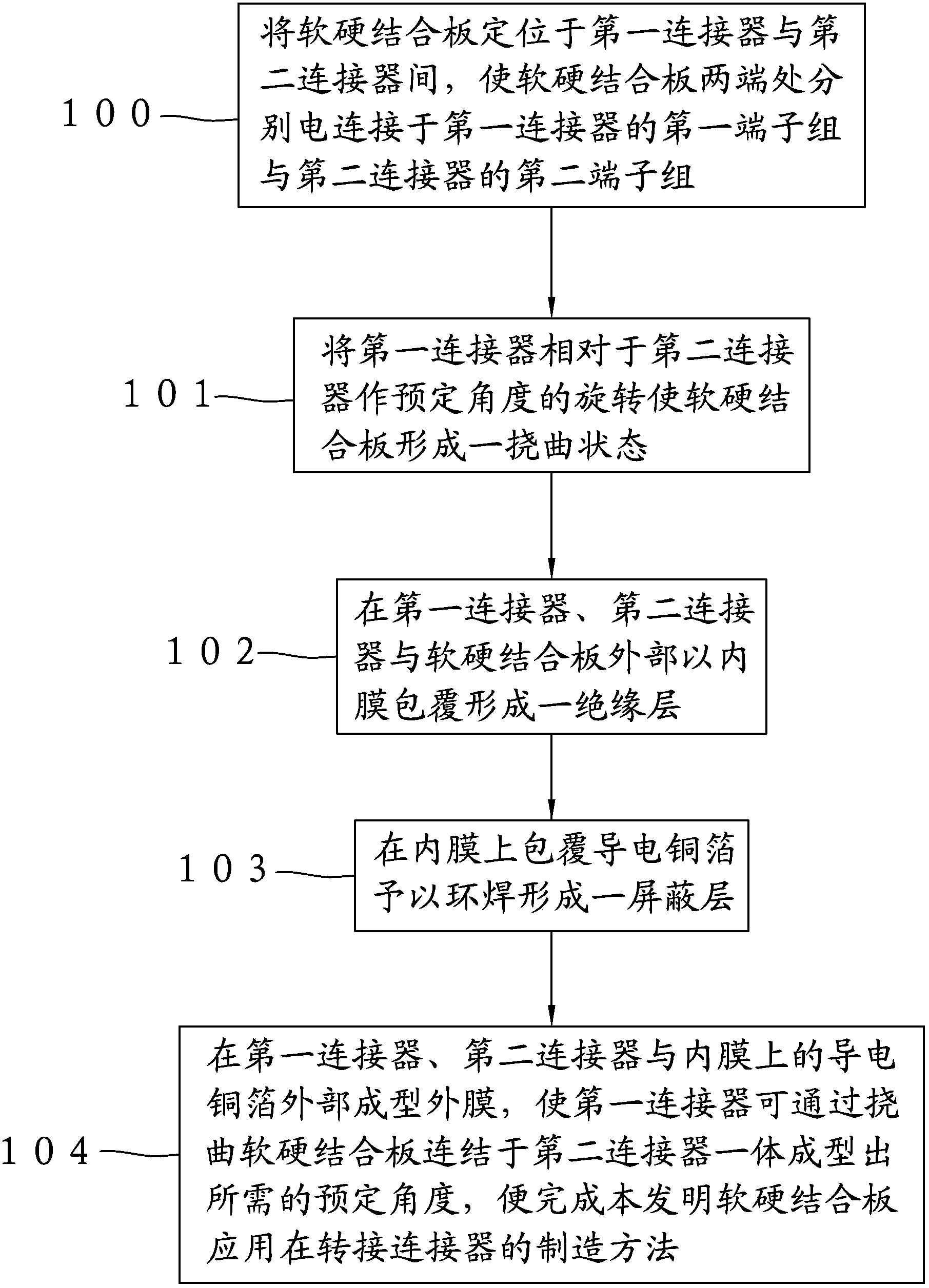

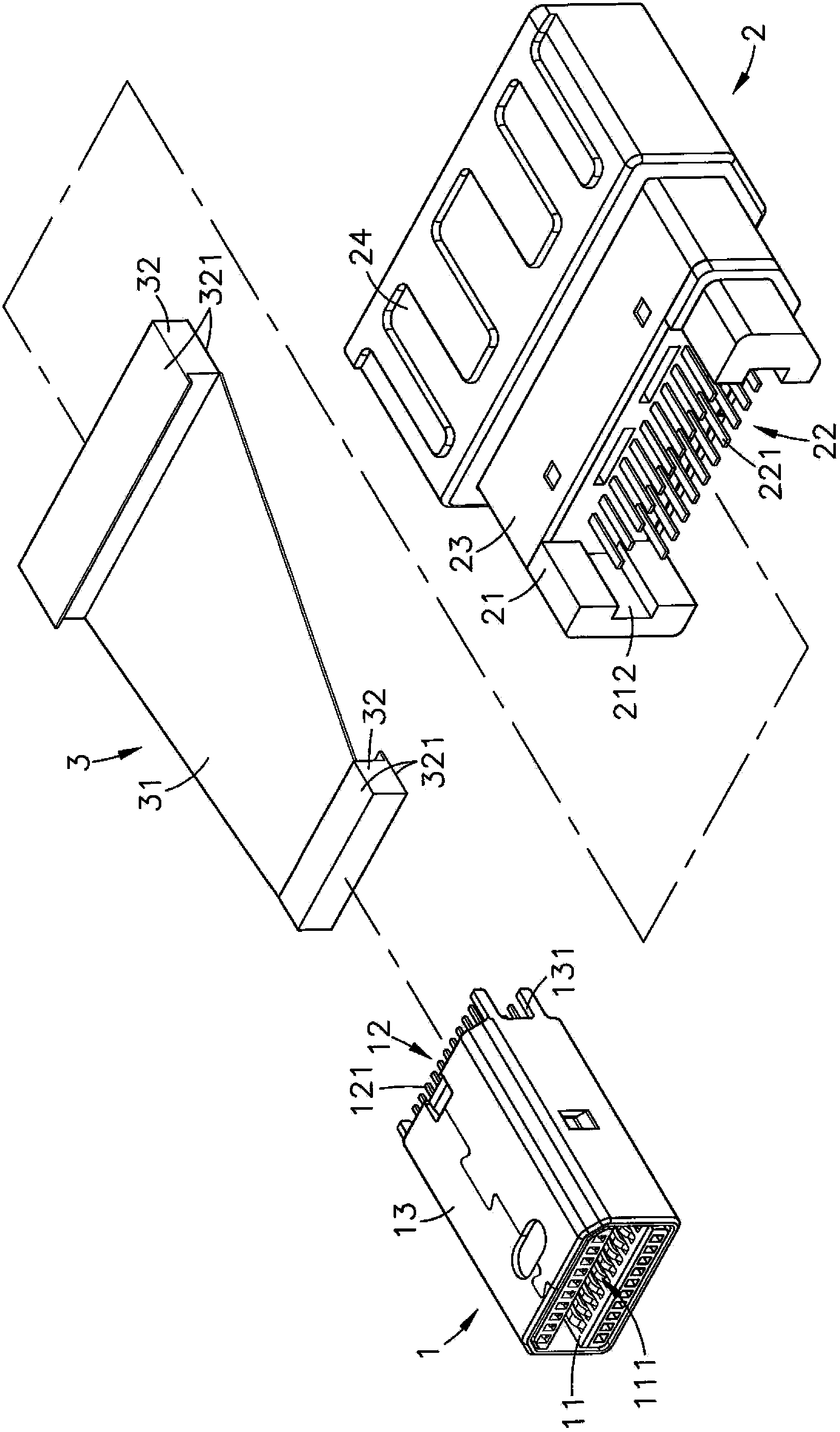

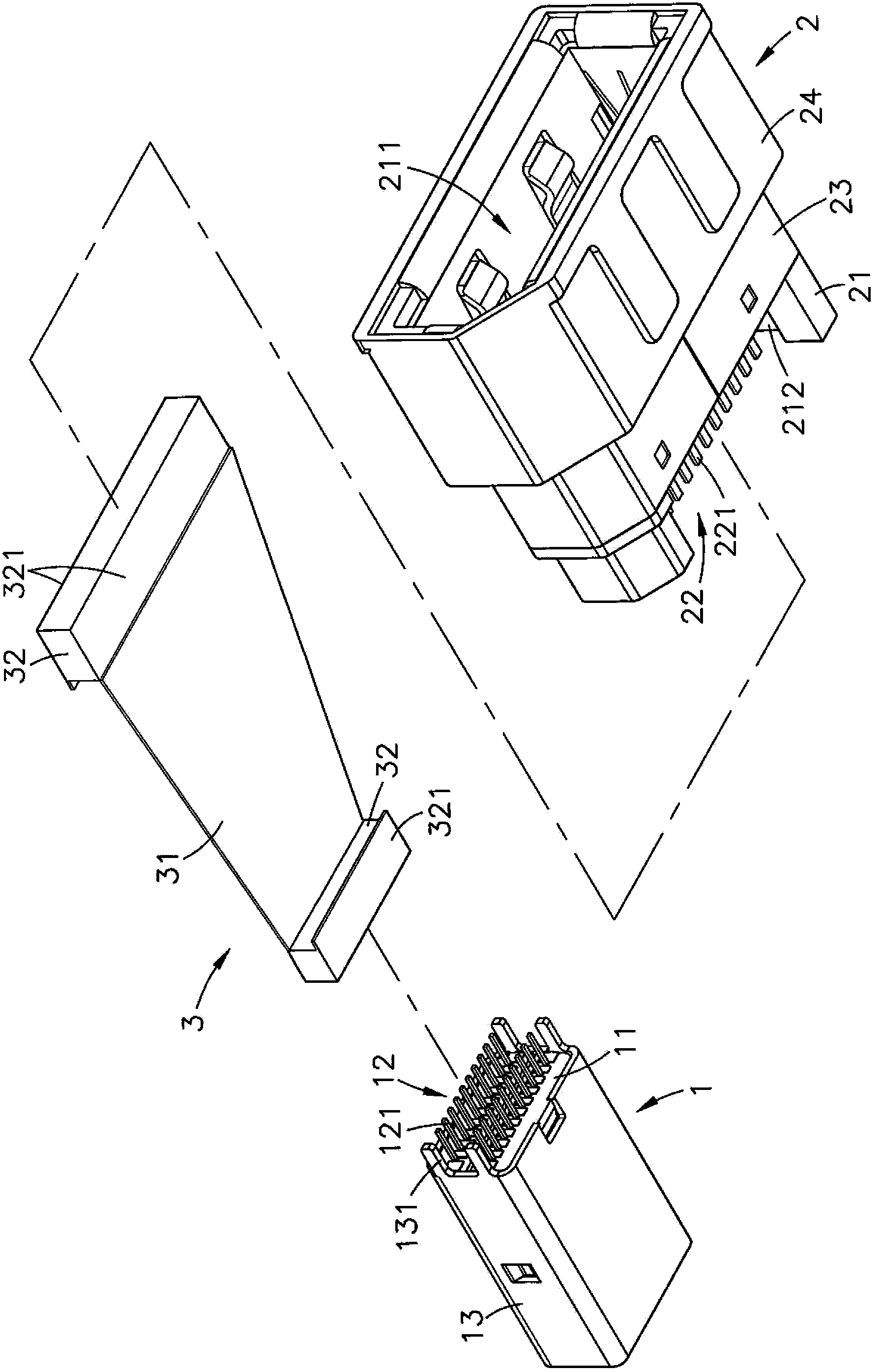

Manufacturing method for applying soft and hard combined plate to adaptor connector

InactiveCN103490266AAvoid connectivityAvoid the situationCoupling device engaging/disengagingElectricityAdaptor/connector

The invention relates to a manufacturing method for applying a soft and hard combined plate to an adaptor connector. The manufacturing method is characterized in that the two ends of the soft and hard combined plate are respectively provided with a first terminal set electrically connected to a first connector body a second terminal set electrically connected to a second connector body, the first connector body rotates by a preset angle relative to the second connector body to enable the soft and hard combined plate to form a deflection state, an insulating layer can be conveniently formed through inner film wrapping, an inner film is wrapped with an electric conduction copper foil to form a shielding layer in a ring welding mode, outer films are molded on the exterior of the first connector body, the exterior of the second connector body and the exterior of the electric conduction copper foil, the first connector body is connected to the second connector body through the deflection soft and hard combined plate to integrally mould a needed preset angle, the situation that the second connector body with wide width shields an connecting port of an adjacent electronic device so that inserting connection cannot be achieved after the first connector body is inserted in the second connector body in a connected mode is avoided, the good structural supporting performance is achieved, the wire arrangement is not required, and the whole operation is easy to achieve.

Owner:HUAGUO ELECTRONICS DONGGUAN

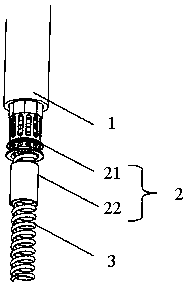

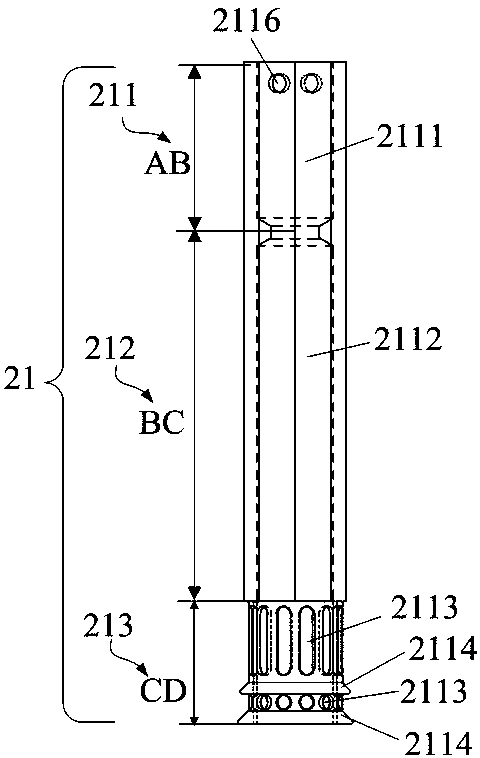

Supporting structure, prosthesis and prosthesis system

ActiveCN108261269AImprove structural supportThe extension function is stable and effectiveBone implantProsthesisEngineering

The invention provides a supporting structure, a prosthesis and a prosthesis system. The supporting structure can improve a supporting force for the prosthesis and enables the extension function of the prosthesis to be stable and effective. The supporting structure comprises an extension part and a blocking part, wherein the extension part comprises a body and a plurality of brim structures positioned at the near end of the body; the plurality of brim structures extend outwards along the radial direction of the body so as to extend into a limiting part; furthermore, the plurality of brim structures are also arranged along the axial direction of the body; the body is provided with an inner cavity with a closed end, and is provided with a hollowed-out structure at the part close to the plurality of brim structures; the blocking part has a hollow structure with two opened ends, is arranged in the inner cavity, and is used for covering the hollowed-out structure; when the plurality of brimstructures emit heat, the parts, contacted with the plurality of brim structures, of the limiting part are melted, so that the limiting of the limiting part for the supporting structure is removed.

Owner:MICROPORT SINICA CO LTD

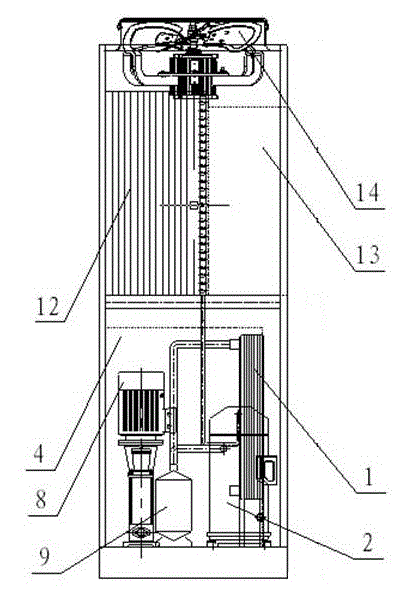

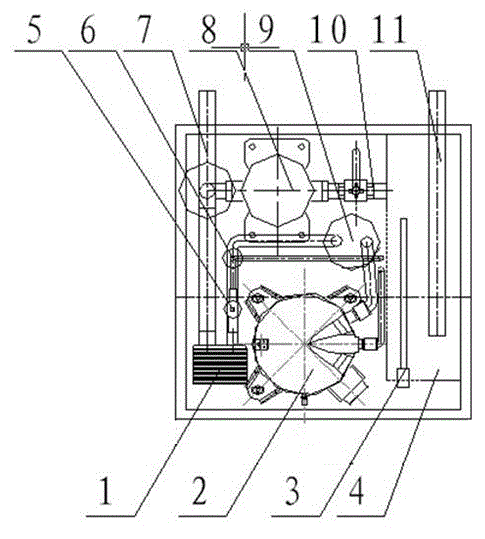

Integrally-sealed central air conditioner outdoor unit

InactiveCN102721121AReduce weightGood structural supportLighting and heating apparatusNoise suppressionVapor–liquid separatorEngineering

The invention relates to an air-conditioning unit and discloses an integrally-sealed central air conditioner outdoor unit. The integrally-sealed central air conditioner outdoor unit comprises a cabinet, wherein inside the cabinet, a scroll compressor 2, a U-shaped condenser 12, a dry filter 6, a thermostatic expansion valve 5, a brazing-type plate evaporator 1 and a gas-liquid separator 9 are orderly connected through a pipeline; the gas-liquid separator 9 is connected to the scroll compressor 2 again to form a refrigerant circulating pipeline; a water return master pipe 11, a frozen water tank 4, a circulating pump 8, the brazing-type plate evaporator 1 and a water outlet master pipe 7 are orderly connected through the pipeline to form a waterway circulating pipeline; an electric appliance control box 13 is arranged on the upper part of the cabinet; a condensate fan 14 is arranged on the top of the cabinet; and the connection position of the condensate fan 14 and the cabinet adopts a sealing structure, and a sealed partition plate for partitioning the cabinet to form an upper and lower layered structure is arranged at the bottom of the electric appliance control box 13. According to the integrally-sealed central air conditioner outdoor unit, by adopting the layered structure, the noise is effectively reduced, and the integrally-sealed central air conditioner outdoor unit is more suitable for household use.

Owner:CHANGZHOU CHILLTECH AIR CONDITIONING & REFRIGERATING PROD

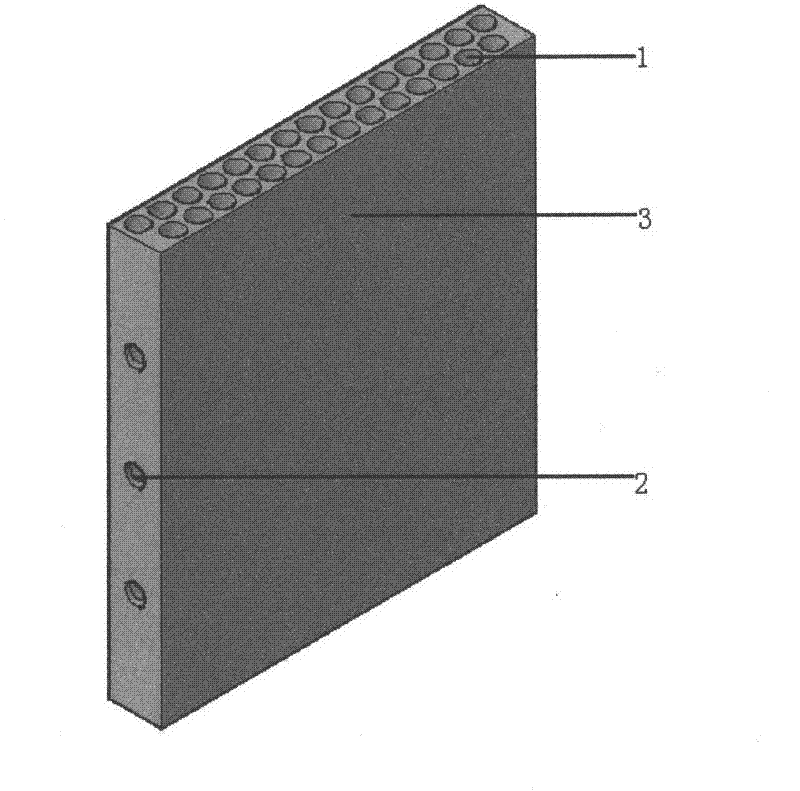

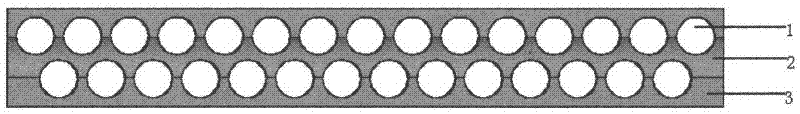

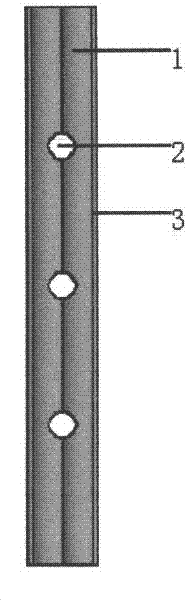

Honeycomb panel-type radiator

InactiveCN102692141AImprove structural strengthNo noiseStationary conduit assembliesEngineeringHoneycomb like

A honeycomb panel-type radiator is provided. The radiator has a honeycomb-like structure having vertical holes for enhancing convection intensity and increasing heat exchange area, thereby improving heat radiation efficiency. By the good intensity of the honeycomb structure, the panel-type radiator provides a better structural support and protection for heat-producing equipment.

Owner:FLEX TIANJIN TECH

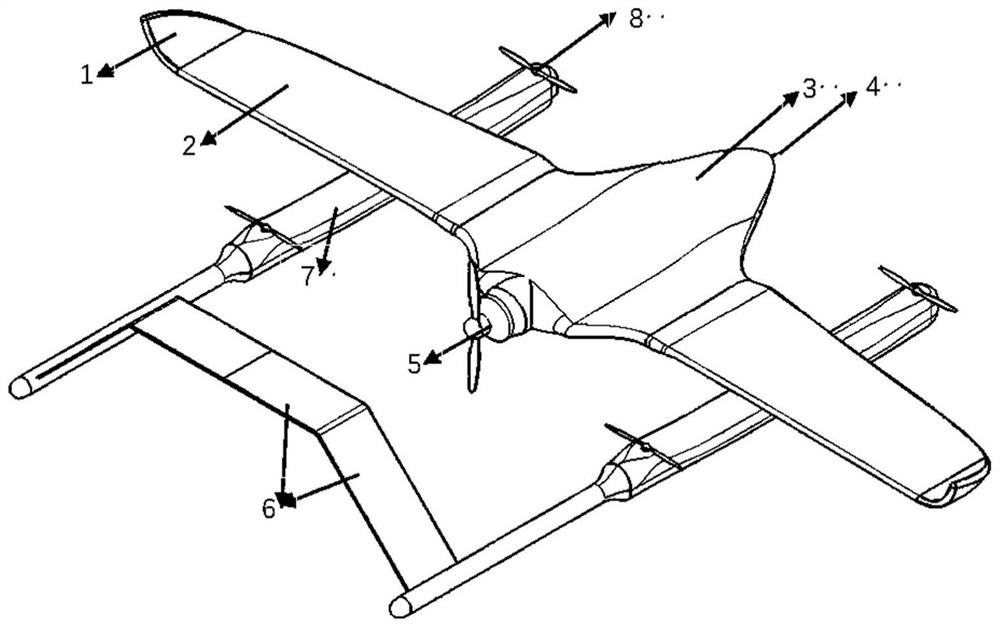

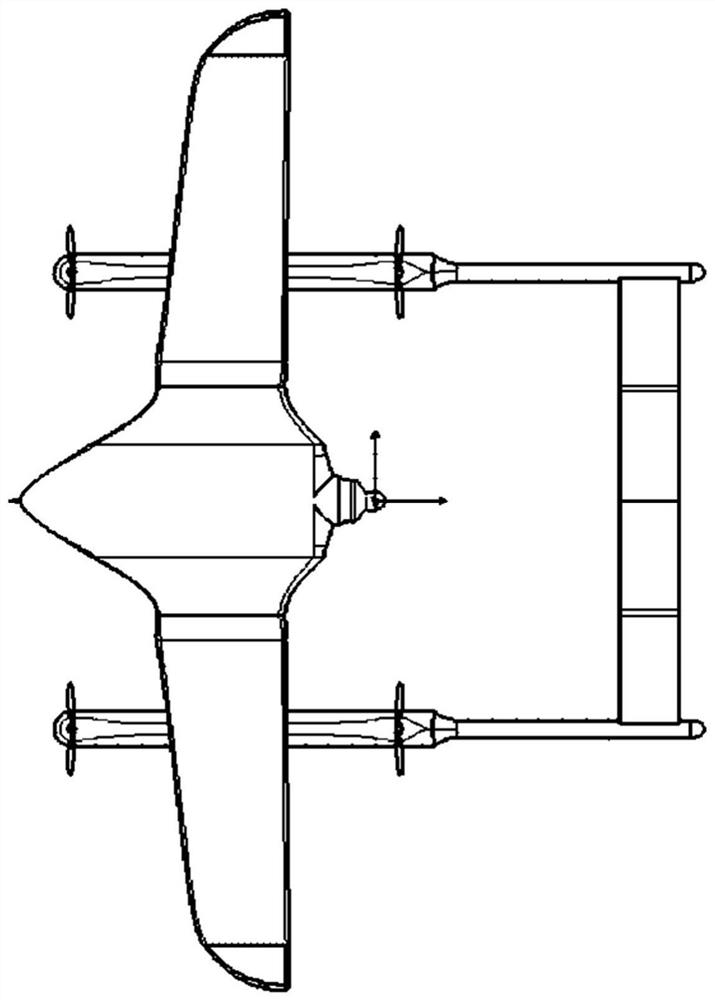

Combined type vertical take-off and landing long-endurance electric unmanned aerial vehicle

PendingCN112810812AReduce frictional resistanceImprove the lift-to-drag ratioWing shapesEfficient propulsion technologiesWetted areaMarine engineering

The invention discloses a combined type vertical take-off and landing long-endurance electric unmanned aerial vehicle, which belongs to the field of unmanned aerial vehicles. According to the combined type vertical take-off and landing long-endurance electric unmanned aerial vehicle, the fuselage adopts the wing body fusion body, the wetted area of the unmanned aerial vehicle can be reduced by removing unnecessary exposed parts of the fuselage, so that the frictional resistance is reduced, and the lift-drag ratio of the unmanned aerial vehicle is increased by reducing parts irrelevant to lift force in the wing body fusion layout. The winglet is adopted, the end plate effect of the winglet is utilized, and the equivalent aspect ratio of the aircraft is increased under the condition that the wingspan increase is small. The double-tail-boom empennage layout is adopted, the lateral stability of the unmanned aerial vehicle can be improved, and the structural support is good. The lift-drag ratio aerodynamic layout is improved through the structural design of the unmanned aerial vehicle, so that the endurance performance of the aircraft is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

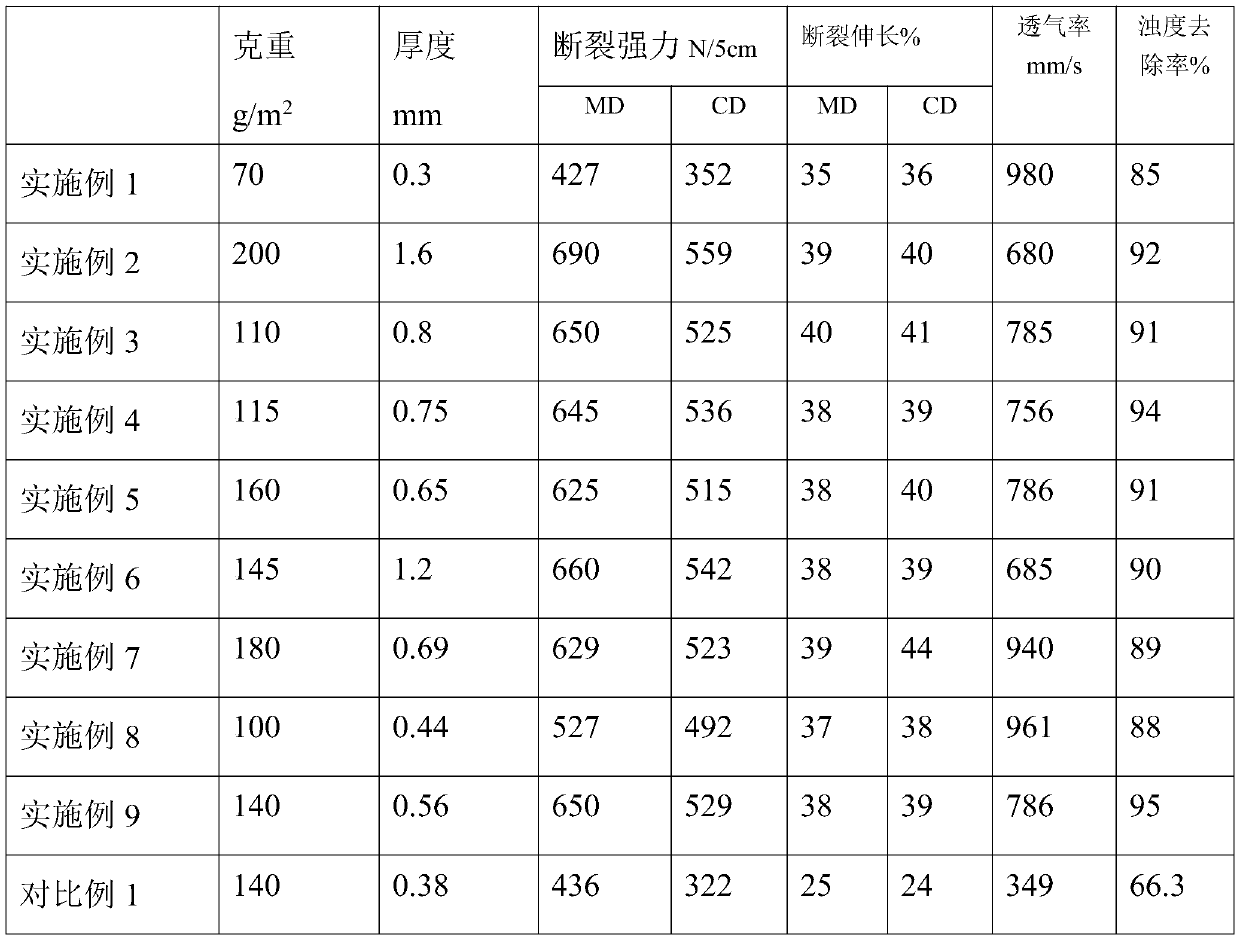

A kind of non-woven fabric with two-component gradient structure for water filtration and its preparation method and application

ActiveCN106521811BExtended service lifeLarge non-rolling pointFiltration separationNon-woven fabricsPolymer scienceFiltration

The invention discloses a two-component gradient structure non-woven fabric for water filtering and a preparation method thereof. The non-woven fabric is composed of a first-layer fiber web and a second-layer fiber web which are bonded together, wherein the first-layer fiber web and the second-layer fiber web are each composed of trefoil PET filament fibers and circular COPET filament fibers which have different finenesses. The preparation method comprises the steps that PET slices and COPET slices which are subjected to pre-crystallization are fully dried; fusion overstocking, spinning, cooling, drafting and separation lapping are conducted through two groups of different spinning assemblies, then the obtained two layers of fiber webs are overlapped to form a composite fiber web, and finally the composite fiber web is subjected to hot air bonding and melting to be reinforced into a whole. According to the two-component gradient structure non-woven fabric for water filtering, the advantages of different fineness filtering in a filter material can be fully exerted, the filtering efficiency is guaranteed, the service life is effectively prolonged, and pressure drop is controlled within a reasonable range; accordingly, the non-woven fabric has the advantages of being free of rolling points, high in ventilation property and filtering precision, low in pressure drop and long in service life.

Owner:SHANDONG TAIPENG ENVIRONMENTAL PROTECTION MATERIAL

Vitrified dilatant polymer foam hybrid material

The invention discloses a vitrified dilatant polymer foam hybrid material. The hybrid material is characterized by comprising a dilatant polymer and polymer foam particles, wherein the dilatant polymer is at least selected from a vitrified dilatant polymer; the polymer foam particles are compounded with the dilatant polymer and other optional components to form the hybrid material. The hybrid material has the characteristics of low density, heat insulation, sound insulation, buffering, shock absorption, dilatancy, slow resilience and the like, and can be widely applied to manufacturing of packaging materials, building materials, impact-resistant protective materials, shock absorption materials, buffering materials, silencing materials, heat preservation materials, shape memory materials, electronic and electric appliance materials, medical supplies and the like.

Owner:厦门天策材料科技有限公司

Vapor chamber and manufacturing method for the same

ActiveCN112033197AIncrease return speedImprove cooling effectHeat exhanger conduitsIndirect heat exchangersThermodynamicsMechanical engineering

Owner:COOLER MASTER CO LTD

A large-scale hot forging die with a fist-like bionic structure and its manufacturing method

ActiveCN108213304BEasy to useGood structural supportGeometric CADForging/hammering/pressing machinesAlloyHigh surface

The invention discloses a fist type large-scale hot-forging die with a bionic structure, and a manufacturing method thereof. A transition layer, a strengthened layer and a skin layer are sequentiallyformed on a die matrix; the transition layer and the strengthened layer are jointly used as a bone layer to play a role in structure supporting; the skin layer is used as a die cavity surface layer contacting a forging piece and has wear resistance and deformation resistance under a high-temperature heavy load condition; at the normal temperature, the strength and the hardness of the die matrix, the transition layer and the strengthened layer are sequentially increased progressively, and the strength and the hardness of the skin layer are smaller than the strength and the hardness of the strengthened layer; and the strength and the hardness of the skin layer is not reduced obviously under a hot-forging working condition (below 650 DEG C). The skin layer is a cobalt-based or nickel-based high-temperature alloy welding material. According to the die, the occurrence of the problems such as surface layer cracks and difficulty in machining brought by high surface hardness are effectively reduced, meanwhile, a use performance of the large-scale forging die under the high-temperature heavy load working condition is further effectively improved, and the fist type large-scale hot-forging die with the bionic structure has favorable wear resistance and deformation resistance at the high temperature.

Owner:CHONGQING JIEPIN TECH +2

Wind turbine blade with a trailing edge spacing section

ActiveUS11028824B2Good structural supportLess-prone to buckling effectFinal product manufactureMachines/enginesLeading edgeSuction force

A wind turbine blade is provided with two shell parts each at least partly made of a sandwich structure including an inner skin (76), an outer skin (74), and an intermediate core material (75, 77), wherein the shell parts are bonded together at least along their respective leading edges (18). The blade also comprises a longitudinally extending spacing section in which the respective trailing edges (58a, 58b) of the pressure side shell part and the suction side shell part are spaced apart, wherein a trailing edge shear web (45) is arranged between and connected to the sandwich structure of the suction side shell part (84, 86, 87) and the sandwich structure of the pressure side shell part (74, 76, 77).

Owner:LM WP PATENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com