A large-scale hot forging die with a fist-like bionic structure and its manufacturing method

A technology of hot forging die and manufacturing method, applied in manufacturing tools, forging/pressing/hammering machines, forging/pressing/hammer devices, etc., can solve the problems of cracking, easy deformation of the surface layer, difficulty, etc., and achieve good structural support effect, reduce surface cracks, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

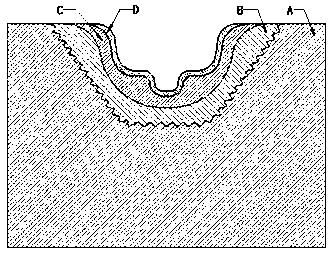

[0032] The large-scale hot forging die of the fist type bionic structure of the present invention comprises a die base body, a bone layer serving as structural support, and a skin layer capable of wear resistance and deformation resistance under high temperature and heavy load conditions. Through multi-material gradient additive manufacturing and metallurgical bonding, the bionic structure forging die is finally obtained. The design concept of the present invention is to use the forging die (the hardness of the surface layer of the die cavity to reach HRC50) As the "bone" of the "fist", it can play a good structural support role. Then, a layer of material with low strength and hardness (about HRC30-35) at room temperature (such as cobalt-based or nickel-based superalloy soft material) is added by arc fuse as the skin layer of the "fist". When the strength and hardness are not significantly reduced, it can play a good role in high temperature wear resistance and deformation re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com