Cobalt phosphide hierarchical porous nanowire material as well as preparation and application thereof

A cobalt phosphide nanometer and hierarchical porous technology, which is applied in the field of electrocatalysis, can solve the problems of poor structural stability of the soft template method, easy collapse of the product structure, complex template method technology, etc., to achieve nano-effects, reduce hydrogen evolution overpotential, The effect of improving electrocatalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) 0.356g CoCl 2 ·6H 2 O and 0.068g urea were dissolved in 37mL deionized water, heated to 40°C and kept for 30min. Subsequently, 2.25 mL of oleylamine was preheated in an oven at 65° C., and added to the aforementioned solution under slow stirring. After stirring evenly, the solution was transferred to a 50mL hydrothermal reactor and heated to 185°C for 12h. After cooling to room temperature, the product was centrifuged, washed several times with water and ethanol, and freeze-dried to obtain basic cobalt carbonate nanowires Co(OH) x (CO 3 ) y , x>0, y>0, and x+2y=3;

[0029] (2) 0.02g basic cobalt carbonate nanowire obtained in step (1) and 0.4g NaH 2 PO 2 After mixing evenly, put it in a quartz tube furnace, heat to 400°C at a rate of 3°C / min under the protection of argon and keep it for 2h, cool to room temperature, wash the product several times with deionized water, and dry to obtain cobalt phosphide Hierarchically porous nanowires.

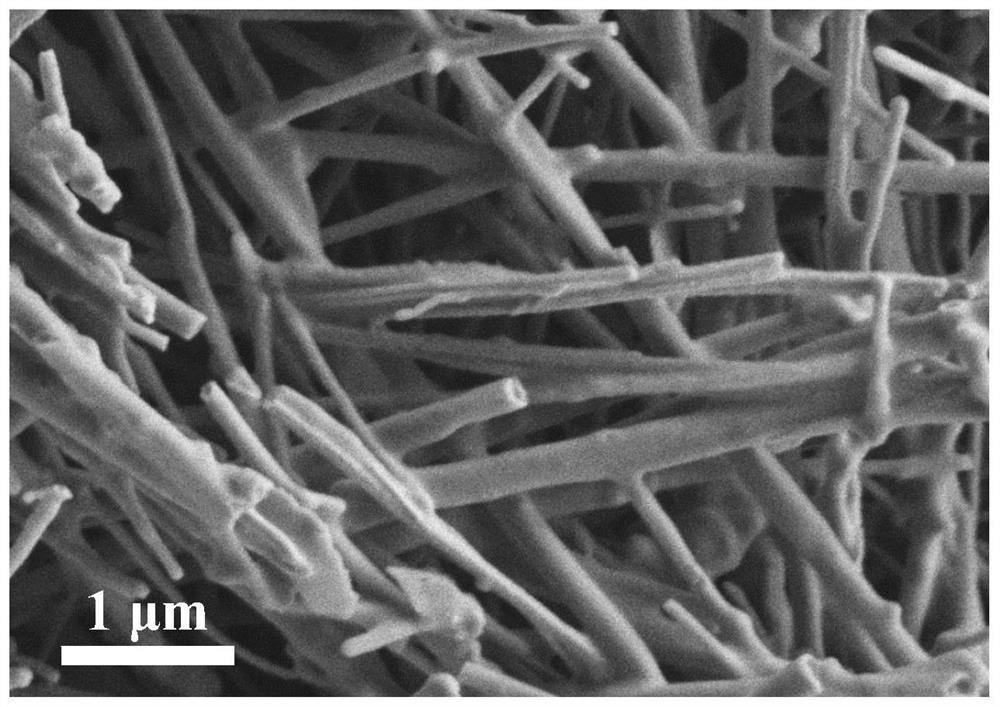

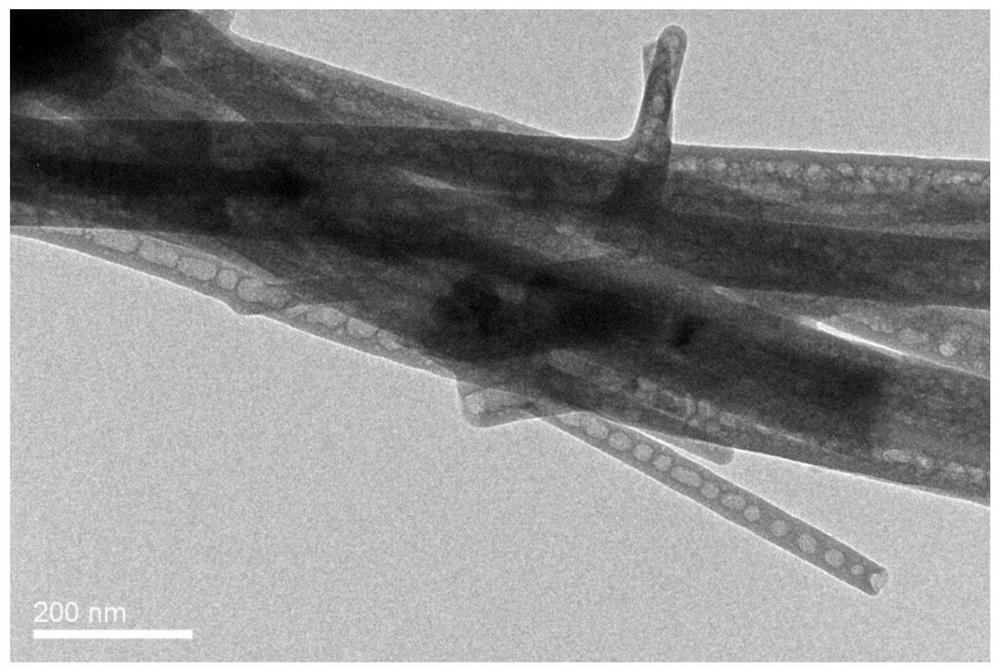

[0030] figure 1 is ...

Embodiment 2

[0034] (1) 0.356g CoCl 2 ·6H 2O and 0.068g urea were dissolved in 37mL deionized water, heated to 40°C and kept for 30min. Subsequently, 2.25 mL of oleylamine was preheated in an oven at 65° C., and added to the aforementioned solution under slow stirring. After stirring evenly, the solution was transferred to a 50mL hydrothermal reactor and heated to 190°C for 20h. After cooling to room temperature, the product was centrifuged, washed several times with water and ethanol, and freeze-dried to obtain basic cobalt carbonate nanowires Co(OH) x (CO 3 ) y , x>0, y>0, and x+2y=3;

[0035] Subsequent process is identical with embodiment 1.

[0036] The microstructure of the product cobalt phosphide hierarchical porous nanowires is similar to that of Example 1, the main difference being that the nanowires become thicker, with a diameter of 100-250 nm.

[0037] Adopt the same method as embodiment 1 to carry out HER performance test, electrolyte is N 2 saturated 0.5M H 2 SO 4 ...

Embodiment 3

[0039] (1) 0.356g CoCl 2 ·6H 2 O and 0.068g urea were dissolved in 37mL deionized water, heated to 40°C and kept for 30min. Subsequently, 2.25 mL of oleylamine was preheated in an oven at 65° C., and added to the aforementioned solution under slow stirring. After stirring evenly, the solution was transferred to a 50mL hydrothermal reactor and heated to 200°C for 24h. After cooling to room temperature, the product was centrifuged, washed several times with water and ethanol, and freeze-dried to obtain basic cobalt carbonate nanowires Co(OH) x (CO 3 ) y , x>0, y>0, and x+2y=3;

[0040] Subsequent process is identical with embodiment 1.

[0041] The microstructure of the product cobalt phosphide hierarchical porous nanowires is similar to that of Example 1, the main difference being that the nanowires become thicker, with a diameter of 150-300 nm.

[0042] Adopt the same method as embodiment 1 to carry out HER performance test, electrolyte is N 2 saturated 0.5M H 2 SO 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com