Co@FePx-NCs material for alkaline solution hydrogen evolution as well as preparation method and application of Co@FePx-NCs material

A fepx-c2n4h4, hydrogen evolution technology, applied in the field of hydrogen energy, can solve the problems of high cost of electrolytic hydrogen desorption catalyst, complicated preparation method, etc., and achieve the effects of good coordination hydrogen activation energy, simple preparation method and high hydrogen evolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A Co@FeP x -NCs hydrogen evolution material, its preparation method is as follows:

[0042] 1) Mix 2mmol ferric chloride, 2mmol sodium hypophosphite, 16mmol dicyandiamide and 50ml ethanol and ultrasonically disperse for 30min to completely dissolve the solid to obtain a solution, then add 1mmol of cobalt acetate to the solution and ultrasonically disperse for 30min to completely dissolve the solid , to obtain a mixture;

[0043] 2) Put the mixed solution into an oil bath and heat and evaporate to dryness at 100°C to obtain CoP x / FeP x -C 2 N 4 h 4 mixture;

[0044] 3) Take 1g CoP x / FeP x -C 2 N 4 h 4 The mixture was soaked in 50mL of 0.33mol / L phosphoric acid solution and etched for 20h, then filtered, dried in vacuum at 60°C for 16h, and then calcined in a resistance furnace at 800°C for 2h under nitrogen atmosphere to obtain Co@FeP x -NCs hydrogen evolution material.

Embodiment 2

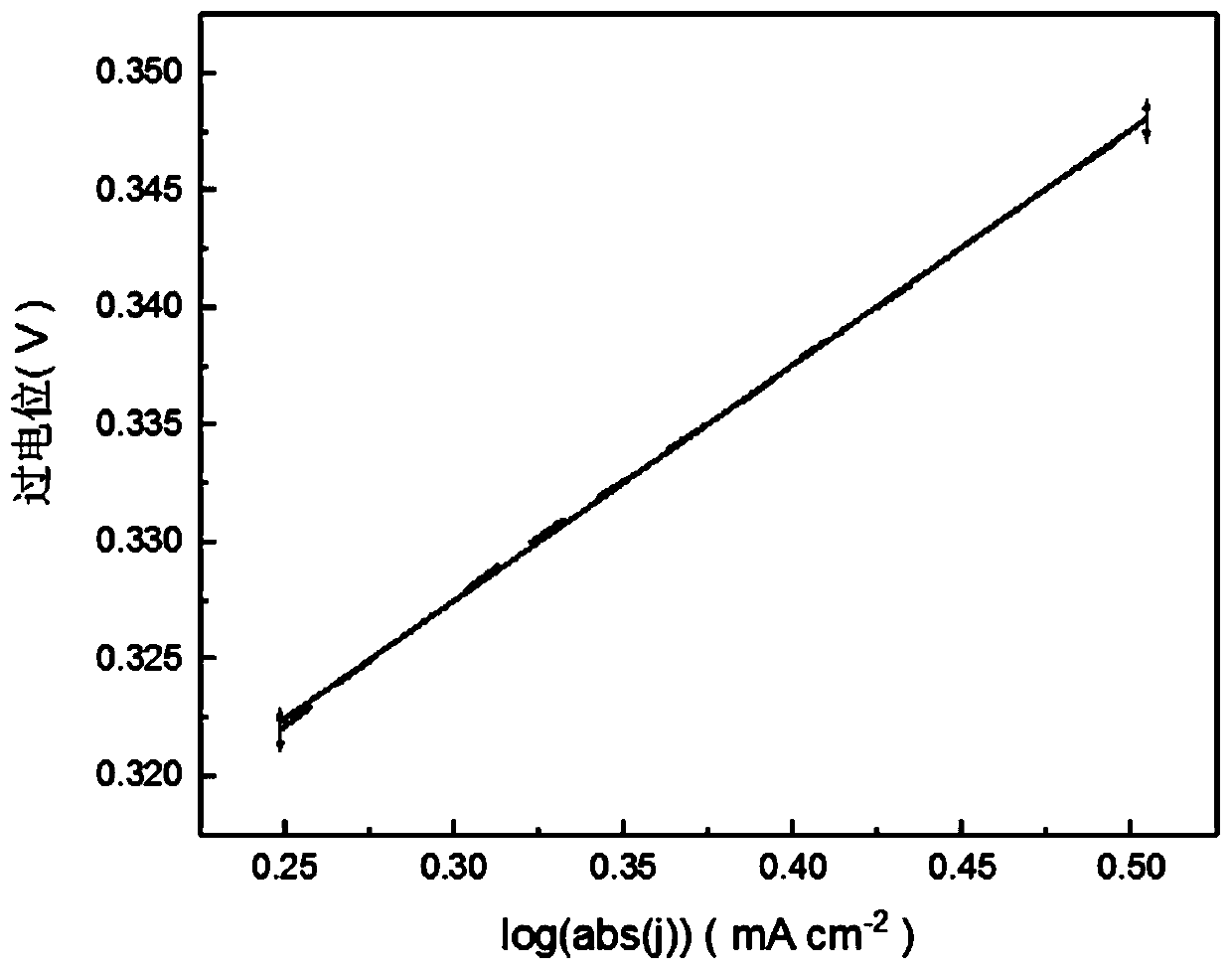

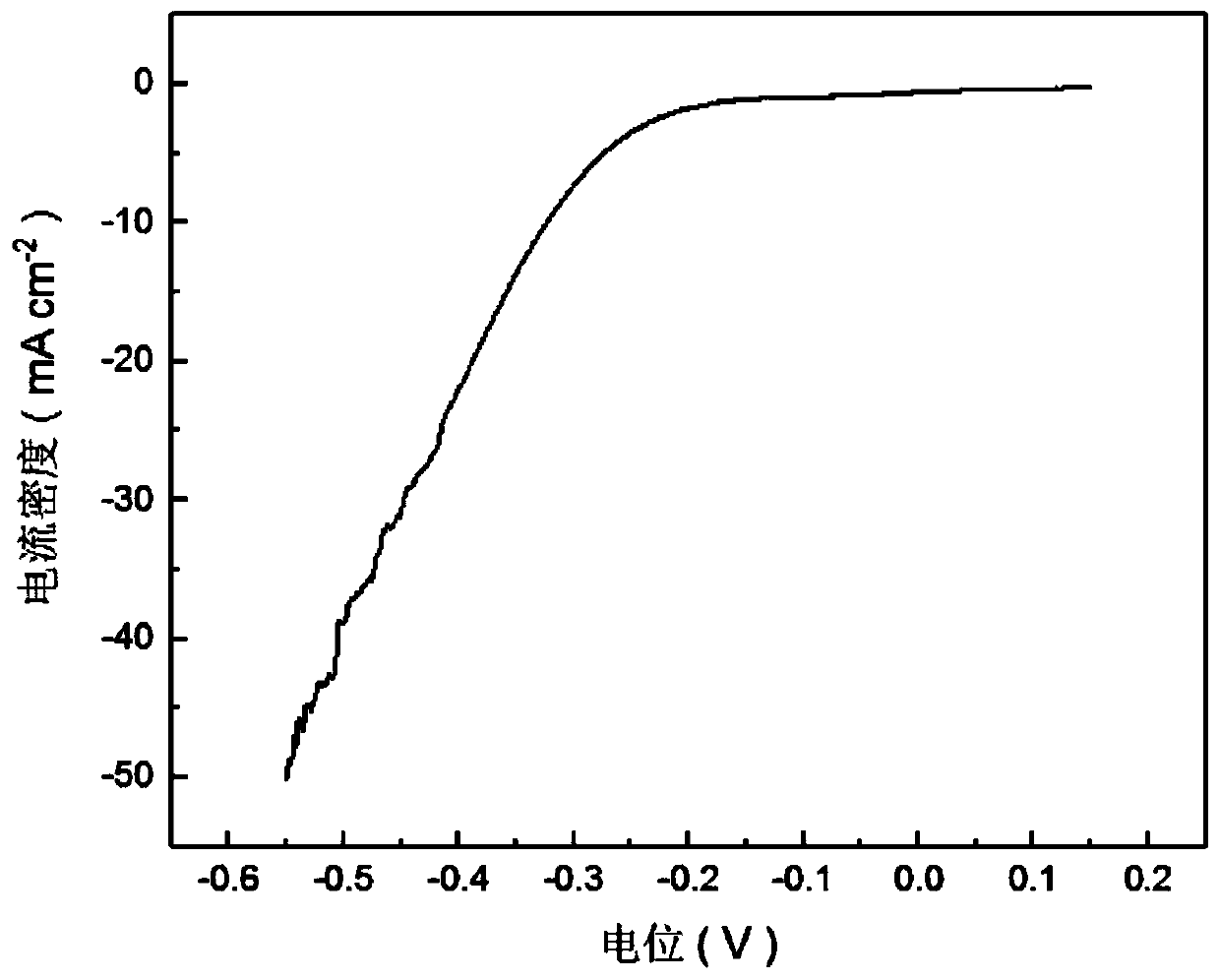

[0046] In this example, the Co@FeP prepared in Example 1 x -NCs hydrogen evolution material for electrocatalytic hydrogen evolution reaction, which specifically includes the following steps:

[0047] 1) Co@FeP prepared in Example 1 x -Grind the NCs hydrogen evolution material, and grind the surface of the glassy carbon electrode with 0.05 μm alumina to remove the residual sample, and rinse the glassy carbon electrode with ethanol and water in turn, and dry it;

[0048] 2) Prepare 1.0M potassium hydroxide solution, and feed nitrogen into the potassium hydroxide solution for 30 minutes to remove the air in the electrolyte, and obtain the electrolyte;

[0049] 3) Mix 0.5wt% Nafion solution with anhydrous methanol, weigh 1mg Co@FeP x - NCs hydrogen evolution material is dissolved in 100 μL Nafion solution and ultrasonically dispersed for two hours to obtain a hydrogen evolution solution, then absorb 12 μL hydrogen evolution solution and drop-coat it on the glassy carbon electrod...

Embodiment 3

[0053] A Co@FeP x -NCs hydrogen evolution material, its preparation method is as follows:

[0054] 1) Mix 2mmol ferric chloride, 5mmol sodium hypophosphite, 12mmol dicyandiamide and 60ml ethanol and ultrasonically disperse for 20min to completely dissolve the solid to obtain a solution, then add 0.75mmol cobalt acetate to the solution and ultrasonically disperse for 20min to completely dissolve the solid Dissolved to obtain a mixed solution;

[0055] 2) Put the mixed solution into an oil bath and heat and evaporate to dryness at 80°C to obtain CoP x / FeP x -C 2 N 4 h 4 mixture;

[0056] 3) Take 1g CoP x / FeP x -C 2 N 4 h 4 The mixture was soaked in 30mL of 1mol / L phosphoric acid solution and etched for 16h, followed by filtration, vacuum drying at 60°C for 18h, and high-temperature calcination in a resistance furnace at 650°C for 4h under nitrogen atmosphere to obtain Co@FeP x -NCs hydrogen evolution material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com