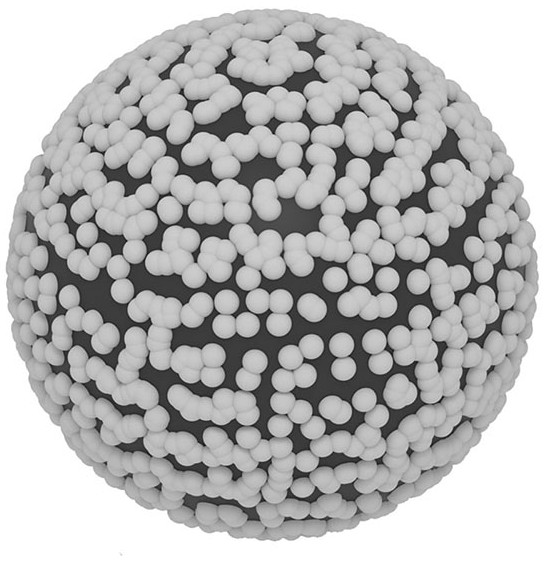

a kind of iro 2 @ir core-shell structure electrocatalytic oxygen evolution reaction catalyst

A technology of oxygen evolution reaction and core-shell structure, applied in the application field of electrocatalytic materials, can solve the problems of overpotential and high Tafel slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

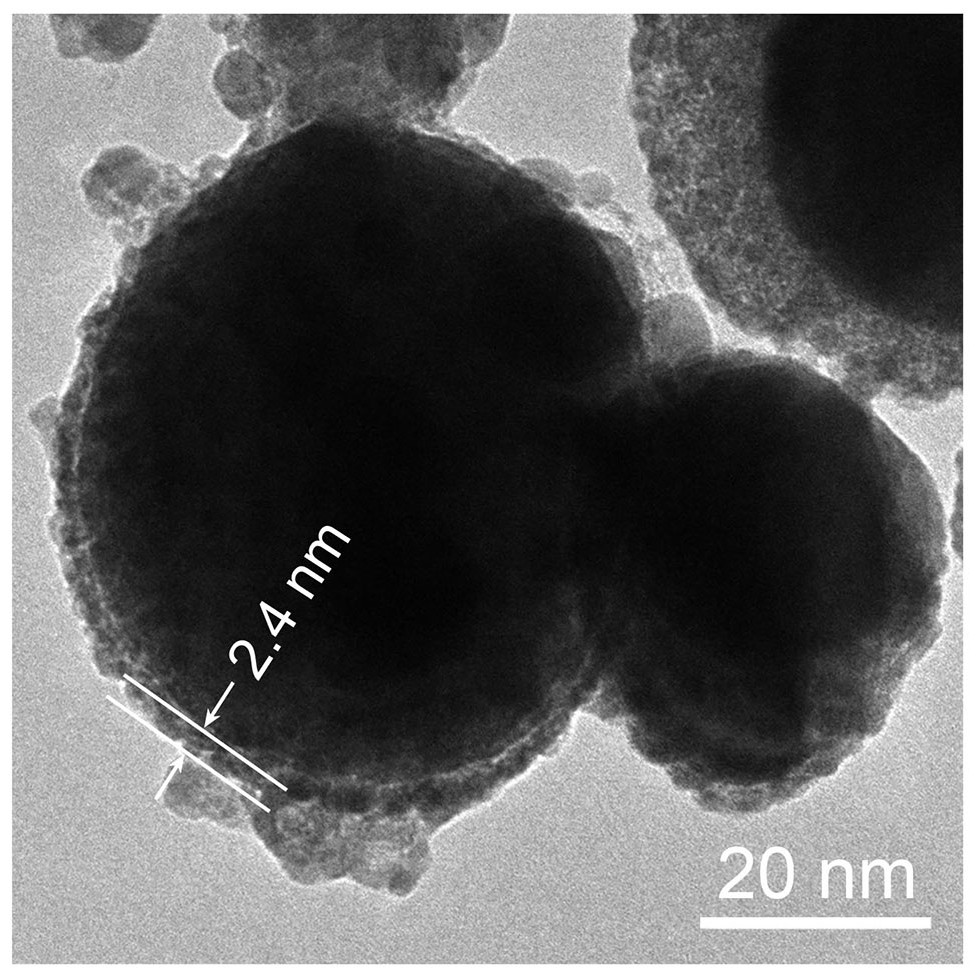

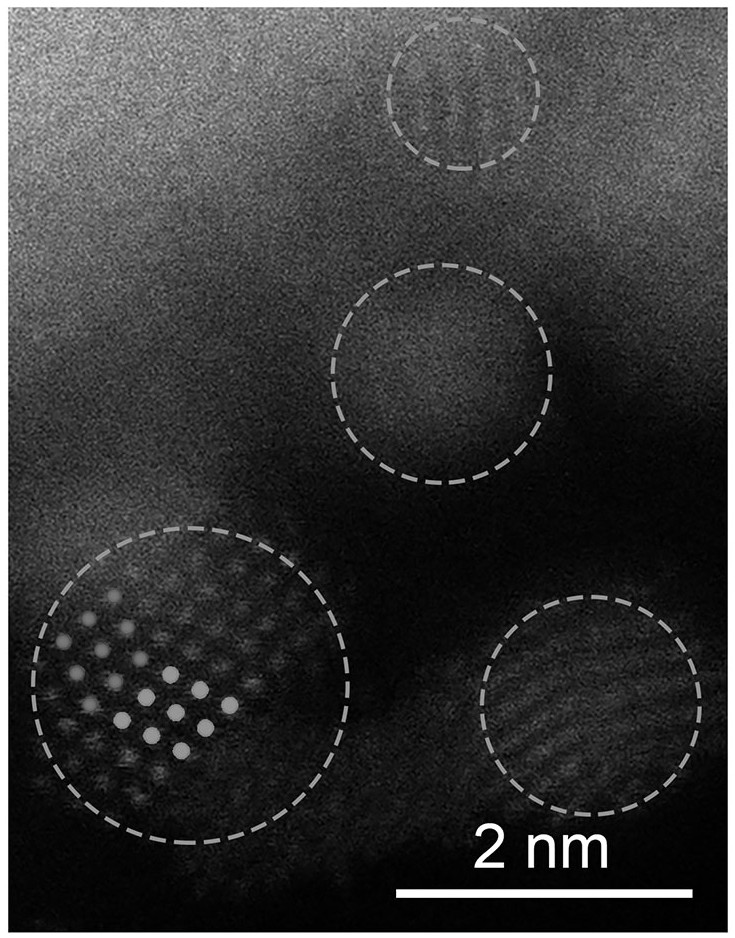

[0024] The implementation of the present invention will be described in detail below in conjunction with specific embodiments.

[0025] The concrete steps of this embodiment are as follows:

[0026] ① Material pretreatment: use IrO2 with a purity of 99.99%, and grind it into powder;

[0027] ② Weighing and dispersion: Weigh 3 grams of IrO2 powder, evenly disperse it on a 1 cm2 glass slide, press it tightly with a cover glass, so that the thickness of the sample is uniform everywhere, and the weighing error is ± 0.005 grams;

[0028] ③Laser treatment: use a nanosecond laser to irradiate the sample, the pulse time is 8-15 nanoseconds, the laser frequency is 10-25 kHz, and the irradiation time is 60 seconds;

[0029] ④Annealing: Anneal at 800 degrees Celsius for 2 hours.

[0030] In order to illustrate the technical effect of the present embodiment, prepare the sample according to the following steps as the comparative example of the present embodiment:

[0031] ① Material pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com