Preparation method and application of iron-nickel-doped tantalum nitride carbon nano-film integrated electrode

A carbon nano-film and nano-film technology, applied in the direction of electrodes, electrolytic coatings, electrolytic processes, etc., can solve the problems of lack of good electrocatalytic performance, and achieve the effects of facilitating the conduction of electrons, increasing capacity, and high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

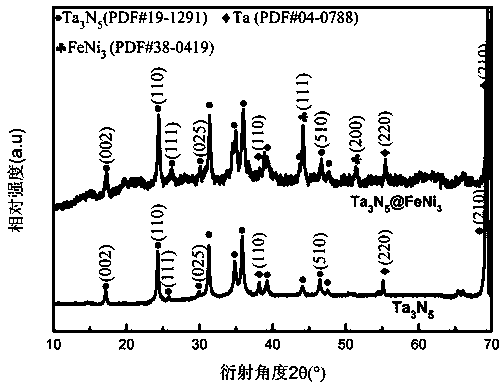

Embodiment 1

[0033] (1) Anode treatment: Ultrasonic cleaning of 1 square centimeter tantalum foil with acetone and ethanol, respectively, to remove organic matter on the surface, and blow dry with nitrogen; use a circular tantalum foil with an exposed surface diameter of 0.5 square centimeters and an area of 0.19625 square centimeters as Anode, 0.27mol / L NH 4 F and 15.89 mol / L H 2 SO 4 As the electrolyte, the platinum sheet was used as the cathode, and anodized at a voltage of 60 V for 15 minutes. After the reaction, the sample was rinsed with flowing distilled water and dried with nitrogen to obtain porous anodized tantalum oxide;

[0034] (2) Confined growth of iron oxide and nickel oxide in the channels of tantalum oxide nanoarrays: 0.028gNiCl 2 ·6H 2 O, 0.048gFe(NO 3 ) 3 9H2 O and 0.03gCO(NH 2 ) 2 dissolved in 4mlH 2 In O, sink the magnetic stirring bar to the bottom of the solvent, place the porous tantalum oxide obtained in step (1) in a cubic copper cage and suspend it in...

Embodiment 2

[0038] (1) Anode treatment: Ultrasonic cleaning of 1 square centimeter tantalum foil with acetone and ethanol, respectively, to remove organic matter on the surface, and blow dry with nitrogen gas; a circular tantalum foil with an exposed surface diameter of 0.5 square centimeters and an area of 0.19625 square centimeters was used as Anode, 0.27mol / L NH 4 F and 15.89 mol / L H 2 SO 4 Electrolyte, platinum sheet as cathode, anodized at 60 V for 15 min. After the reaction, the sample was rinsed with flowing distilled water and dried with nitrogen to obtain porous anodized tantalum oxide;

[0039] (2) Confined growth of iron oxide and nickel oxide in the channels of tantalum oxide nanoarrays: 0.028gNiCl 2 ·6H 2 O, 0.048gFe(NO 3 ) 3 9H 2 O and 0.03gCO(NH 2 ) 2 dissolved in 4mlH 2 In O, sink the magnetic stirring bar to the bottom of the solvent, place the porous tantalum oxide obtained in step (1) in a cubic copper cage and suspend it in the upper part of the solvent, mi...

Embodiment 3

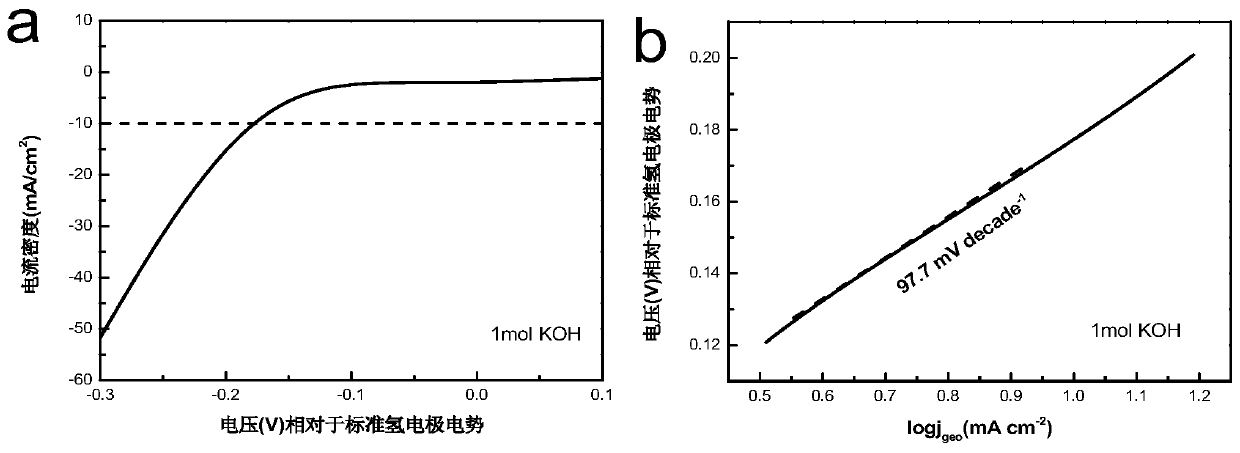

[0042] Example 3: Application

[0043] (1) Anode treatment: Ultrasonic cleaning of 1 square centimeter tantalum foil with acetone and ethanol, respectively, to remove organic matter on the surface, and blow dry with nitrogen gas; a circular tantalum foil with an exposed surface diameter of 0.5 square centimeters and an area of 0.19625 square centimeters was used as Anode, 0.27mol / L NH 4 F and 15.89 mol / L H 2 SO 4 Electrolyte, platinum sheet as cathode, anodized at 60 V for 15 min. After the reaction, the sample was rinsed with flowing distilled water and dried with nitrogen to obtain porous anodized tantalum oxide;

[0044] (2) Confined growth of iron oxide and nickel oxide in the channels of tantalum oxide nanoarrays: 0.028gNiCl 2 ·6H 2 O, 0.048gFe(NO 3 ) 3 9H 2 O and 0.03gCO(NH 2 ) 2 dissolved in 4mlH 2 In O, sink the magnetic stirring bar to the bottom of the solvent, place the porous tantalum oxide obtained in step (1) in a cubic copper cage and suspend it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com