Patents

Literature

65 results about "Tantalum foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum foil can be used as a vacuum blast furnace for heating components, heat insulation parts and loading vessels. In the chemical industry, it can be used as a boiler, heater, cooler, various utensils, etc. And it is widely used in aerospace and medical devices.

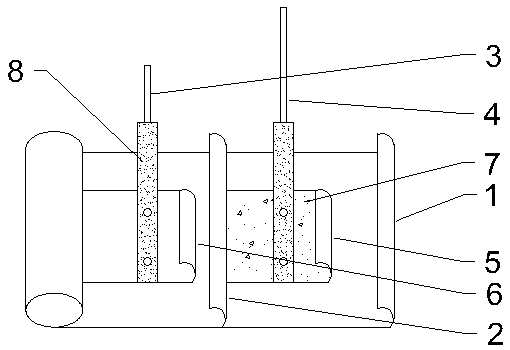

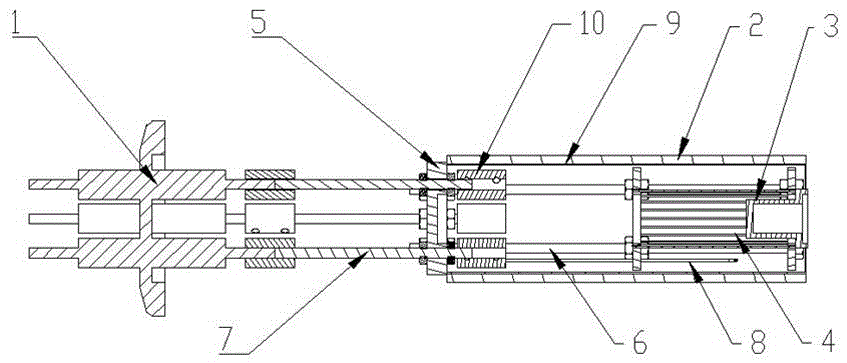

Industrial hollow cathode

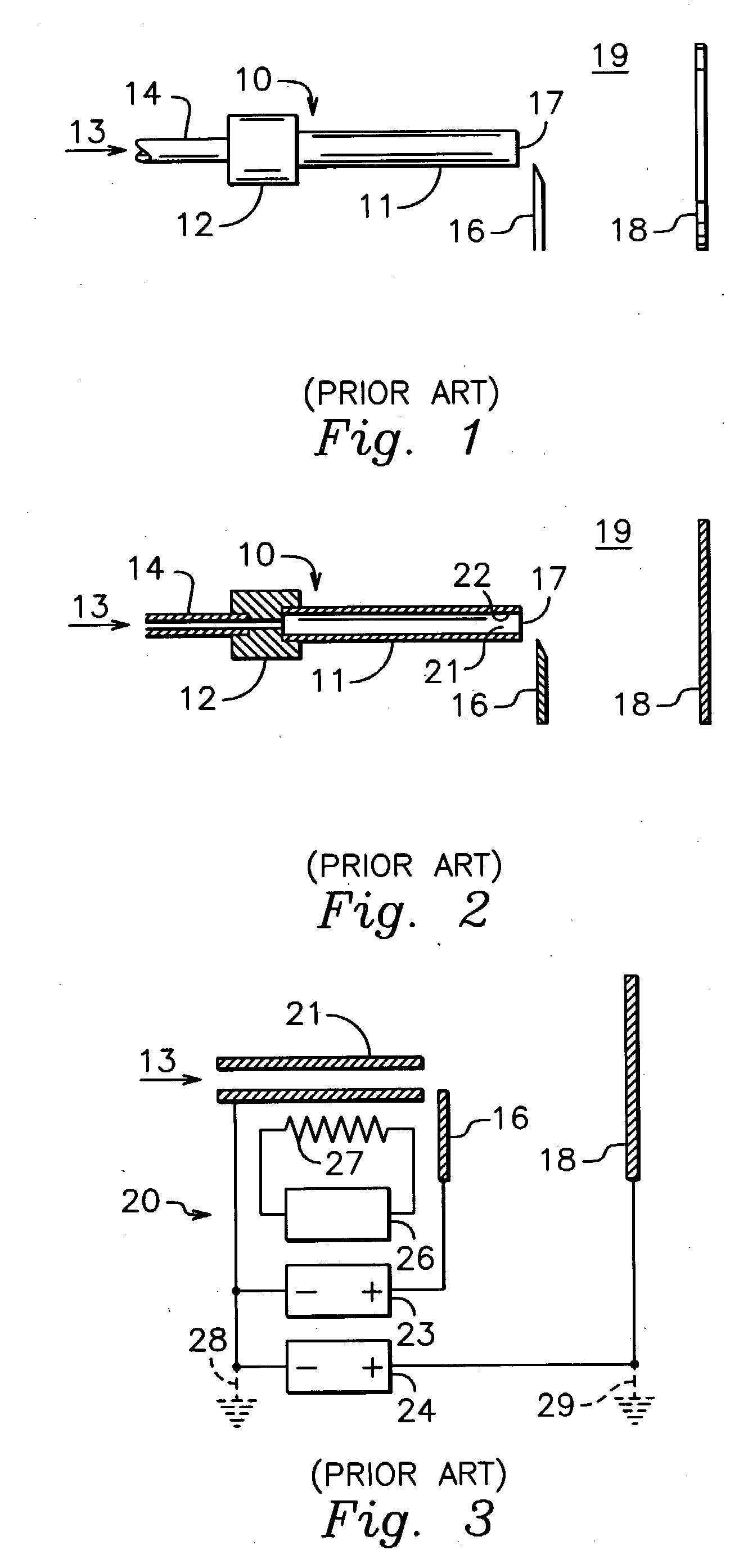

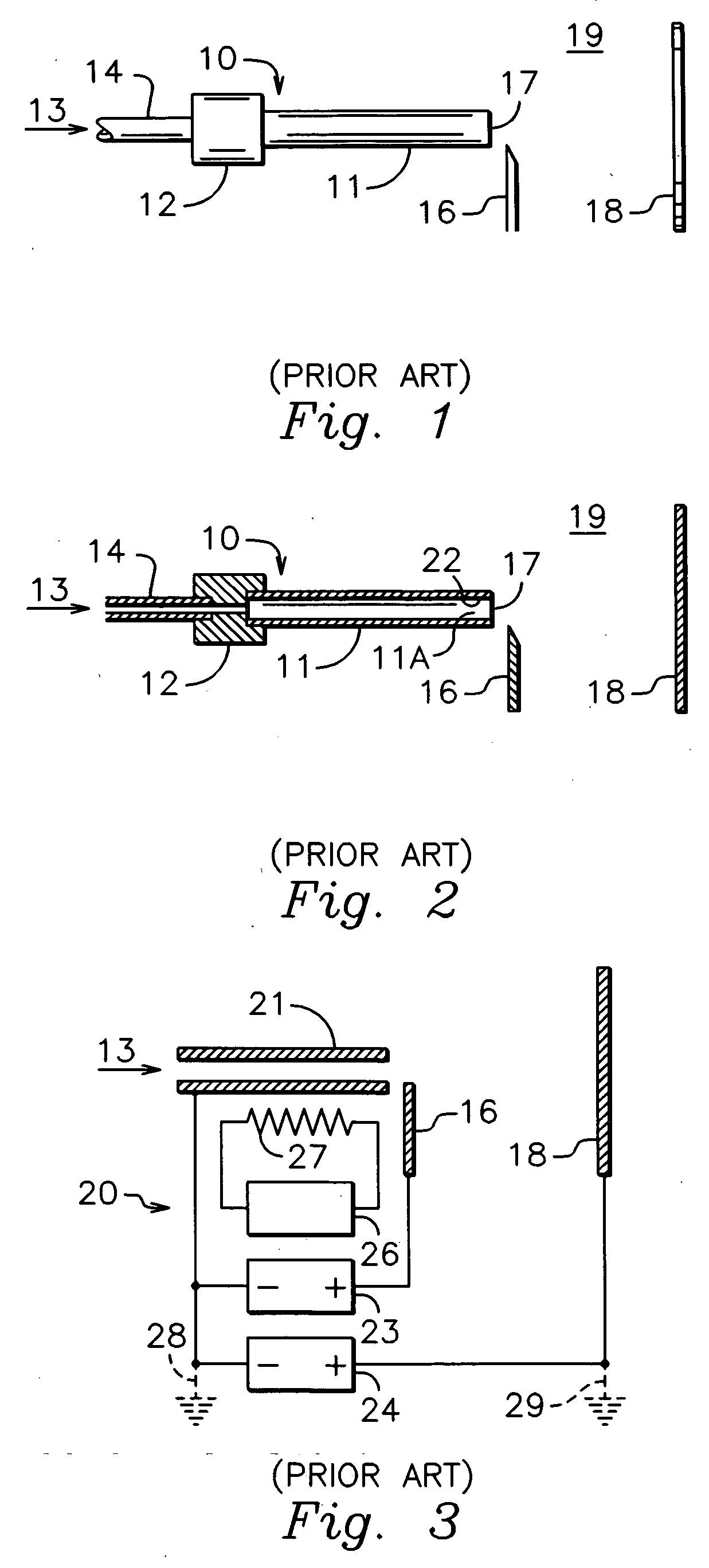

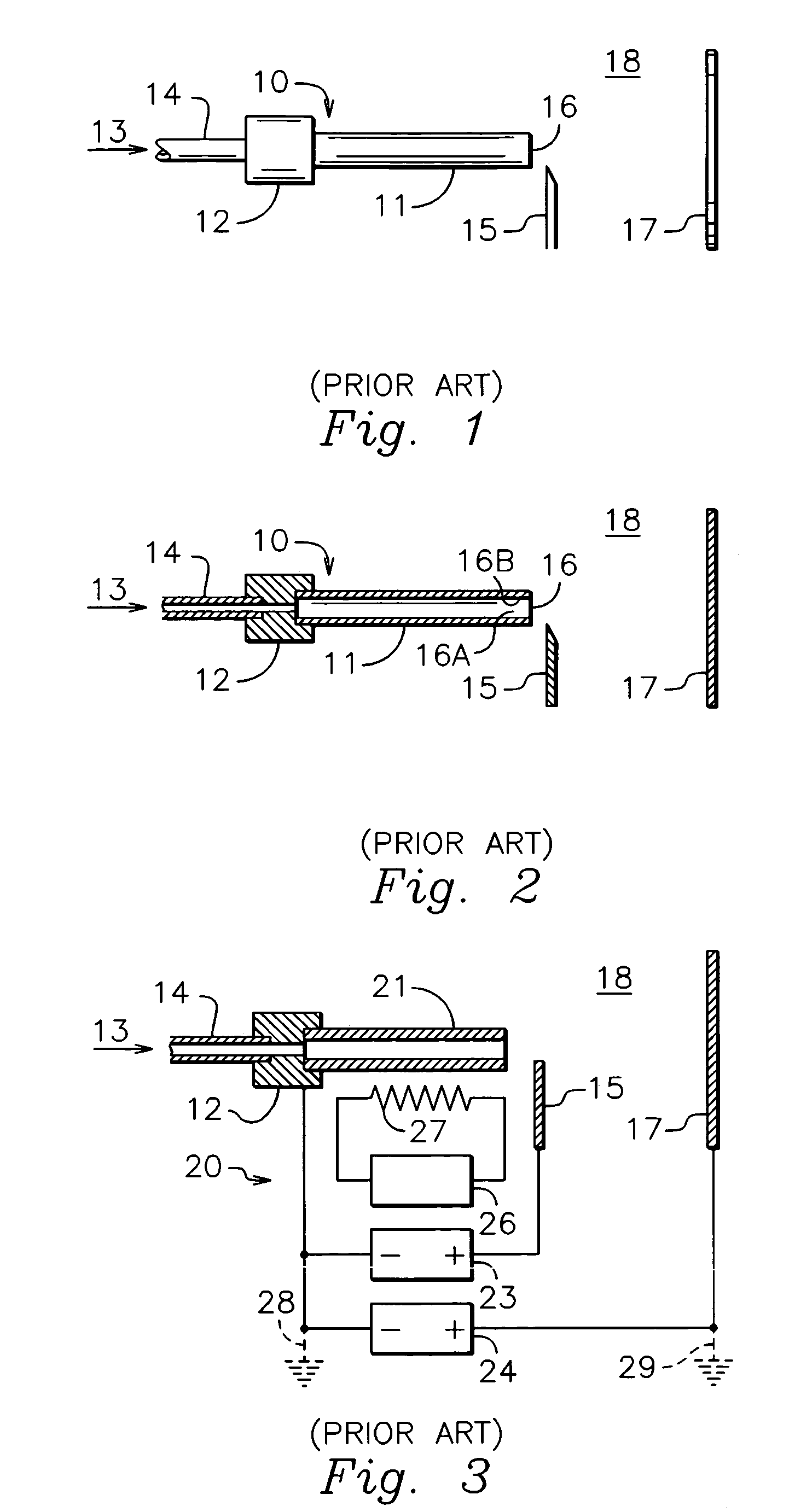

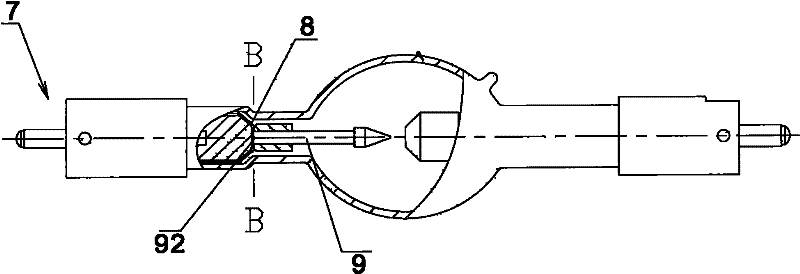

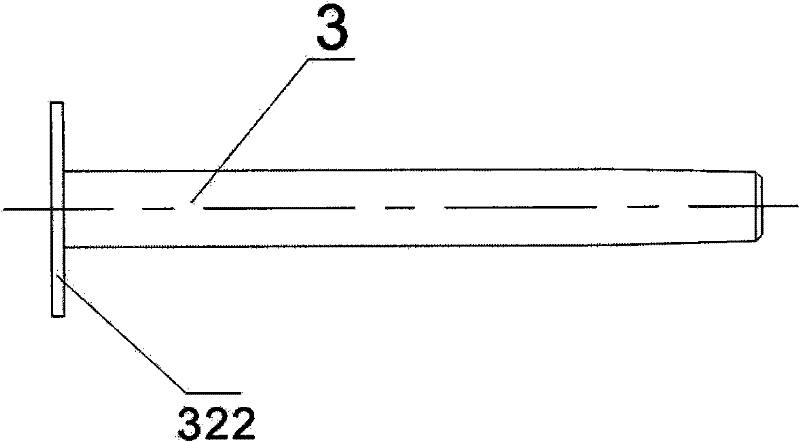

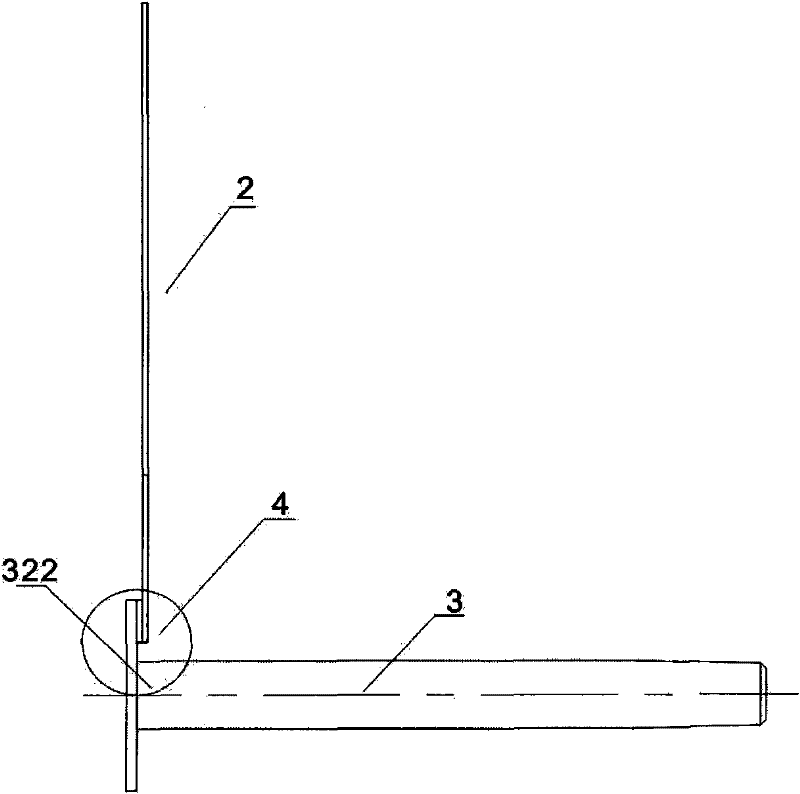

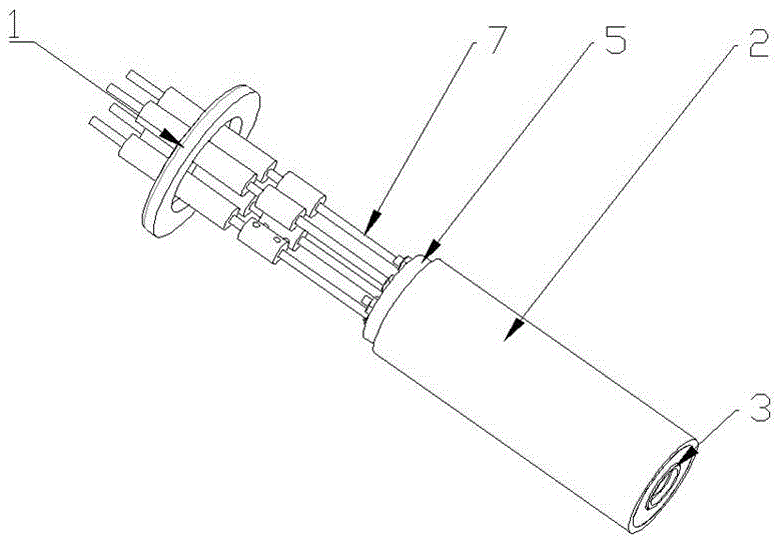

ActiveUS20070222358A1Simple to fabricateSimple to useLamp incadescent bodiesThermionic cathodesEngineeringOperating temperature

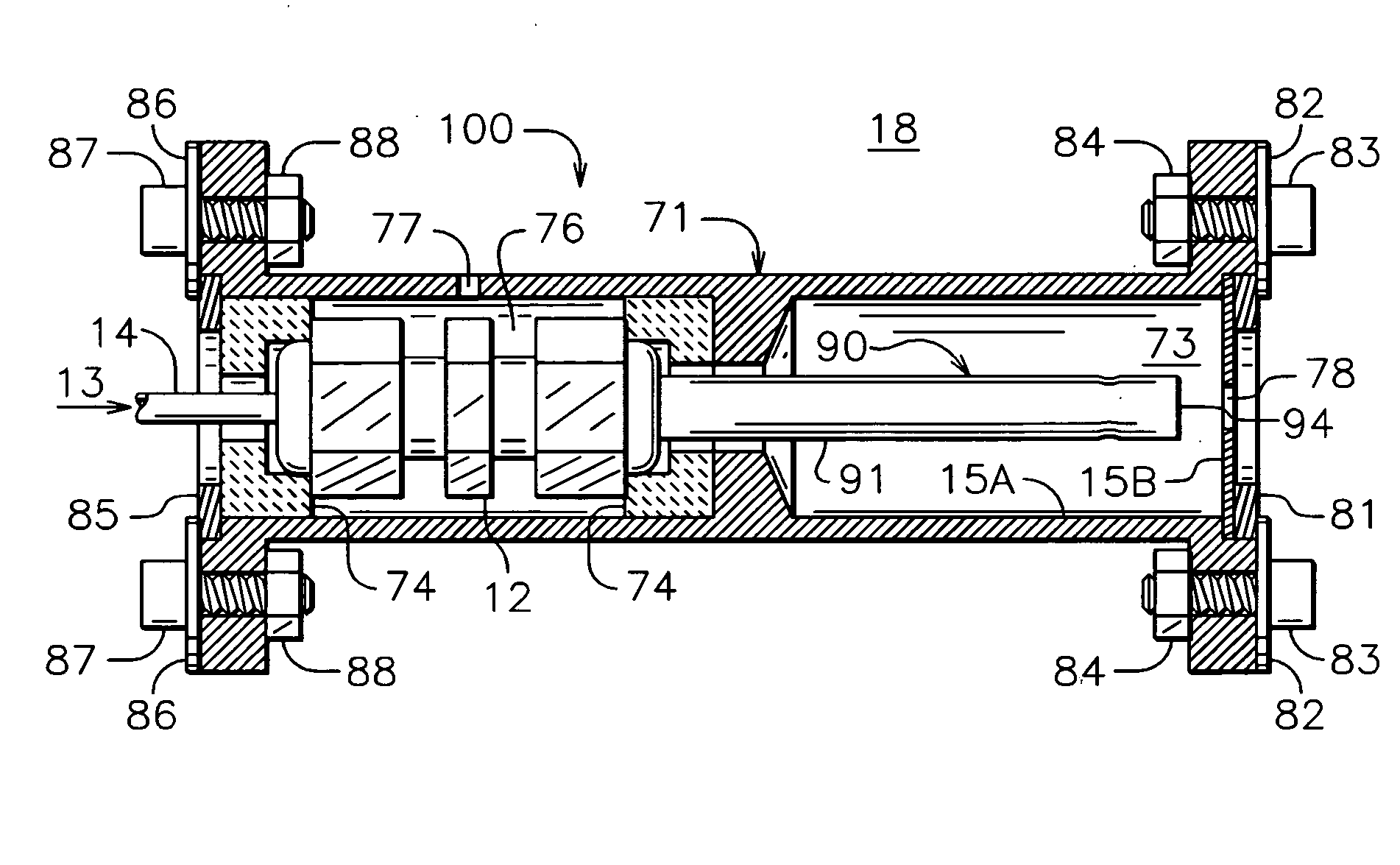

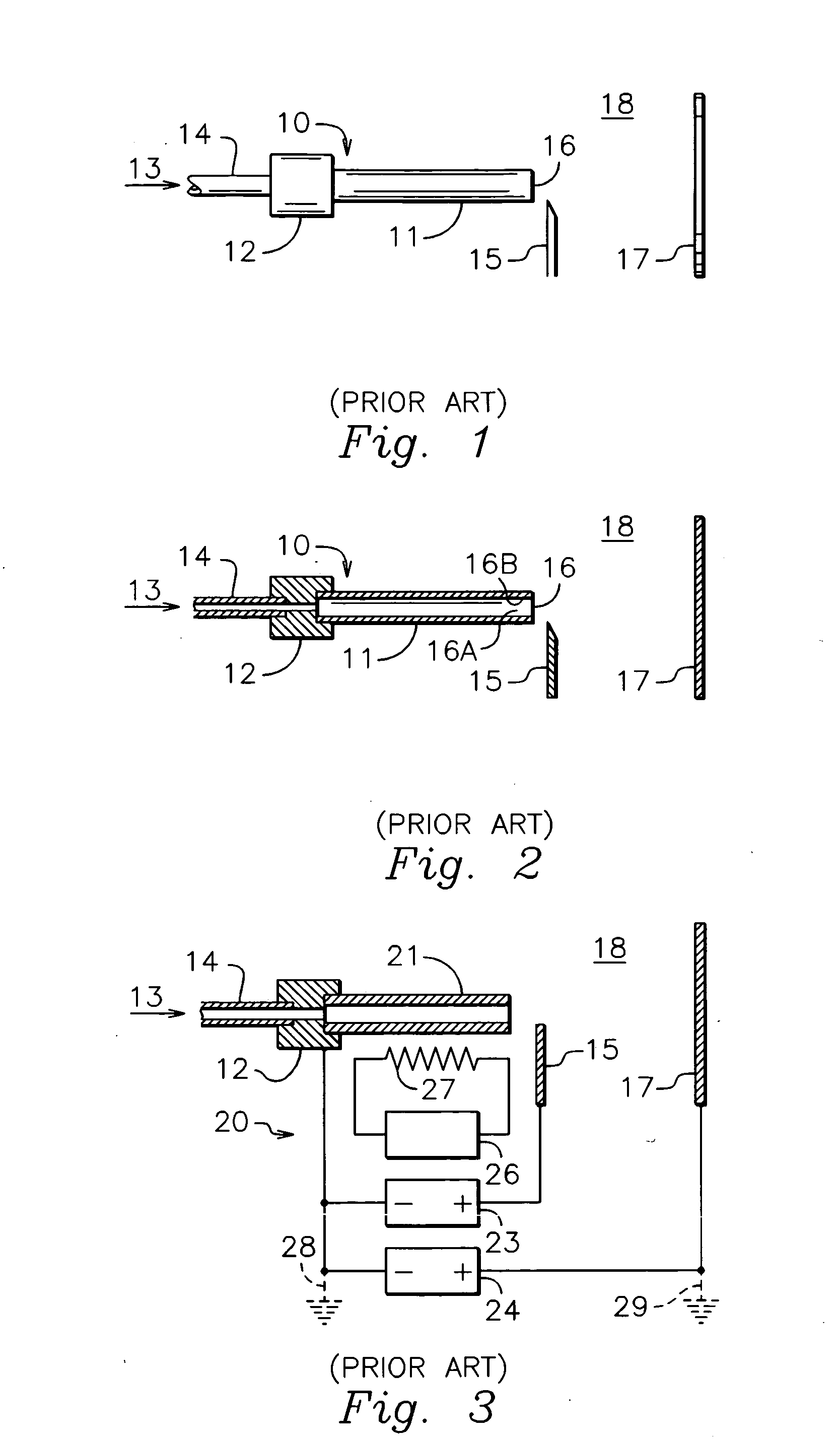

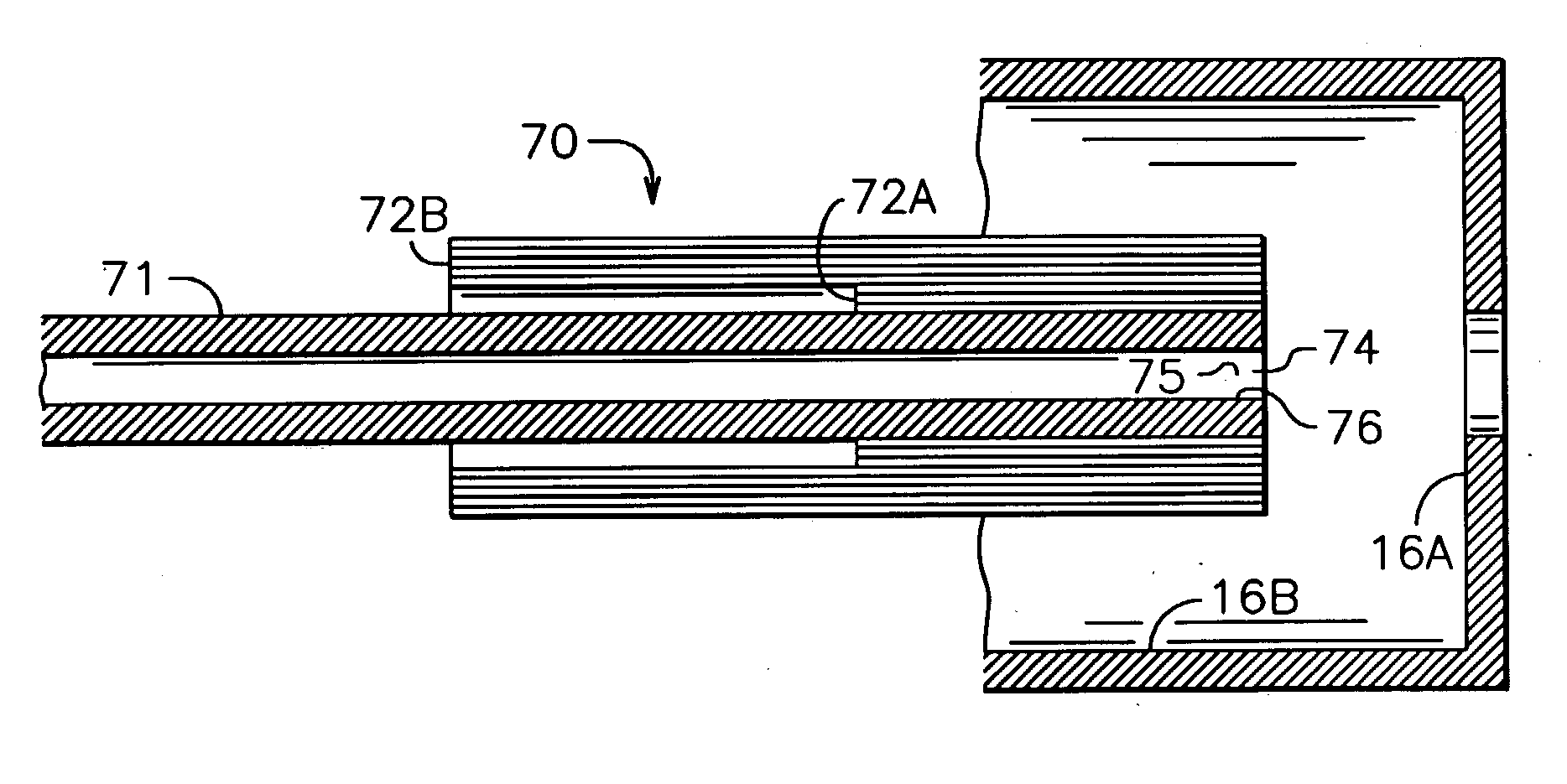

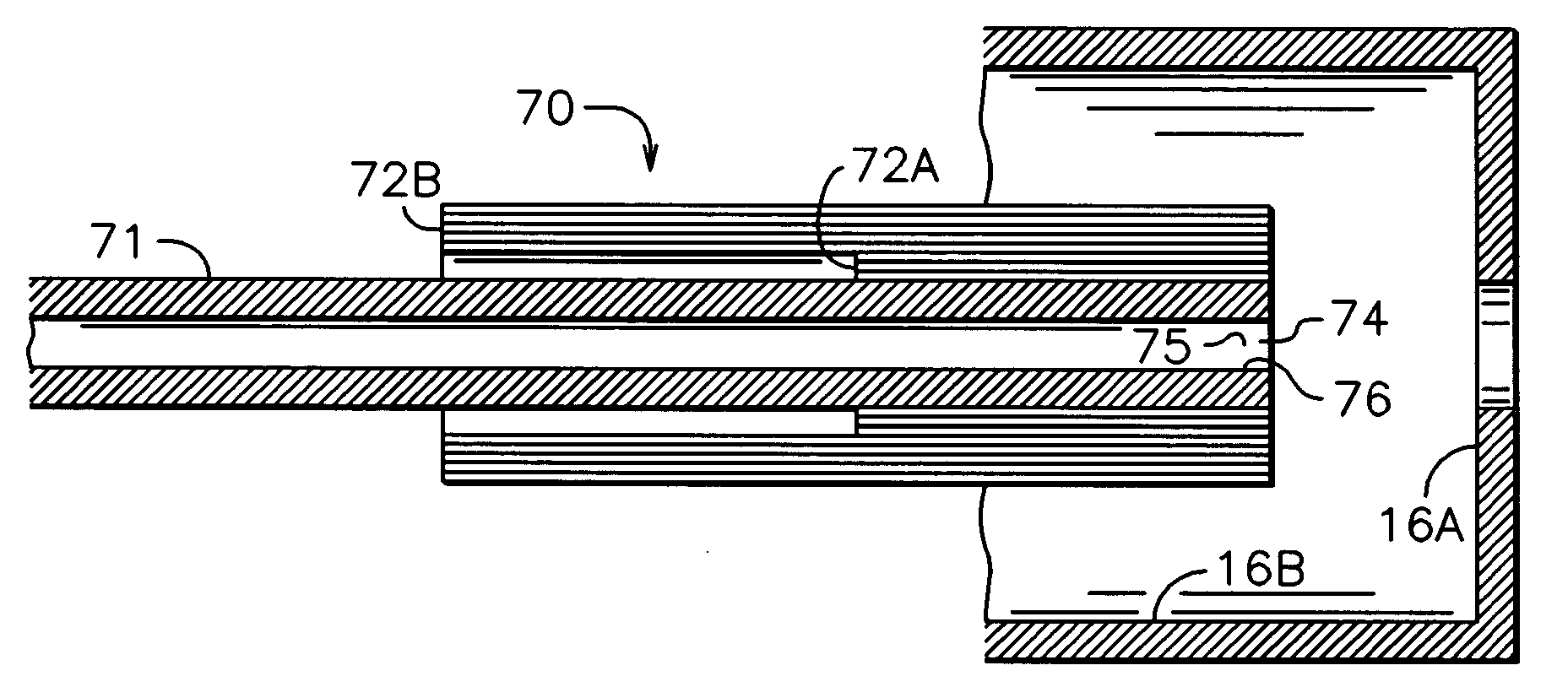

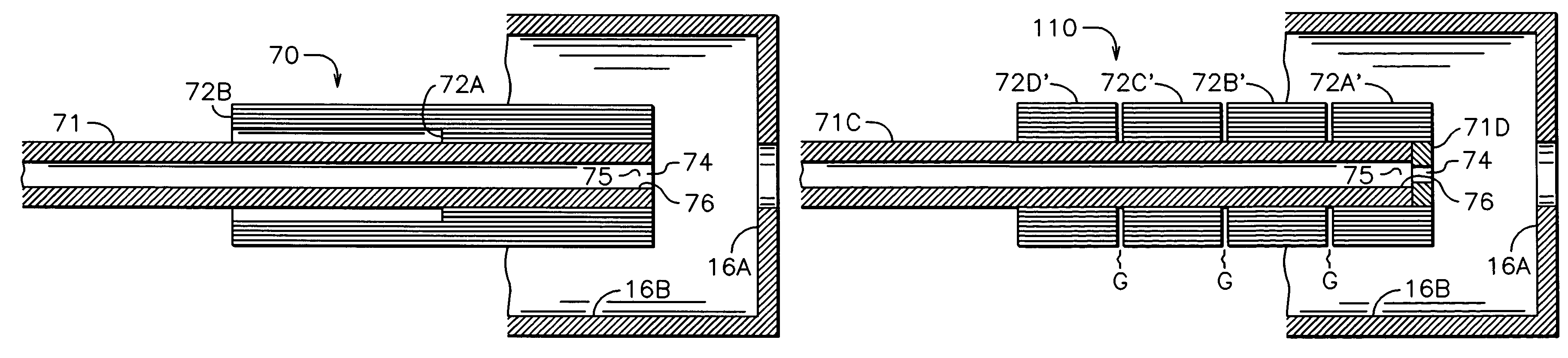

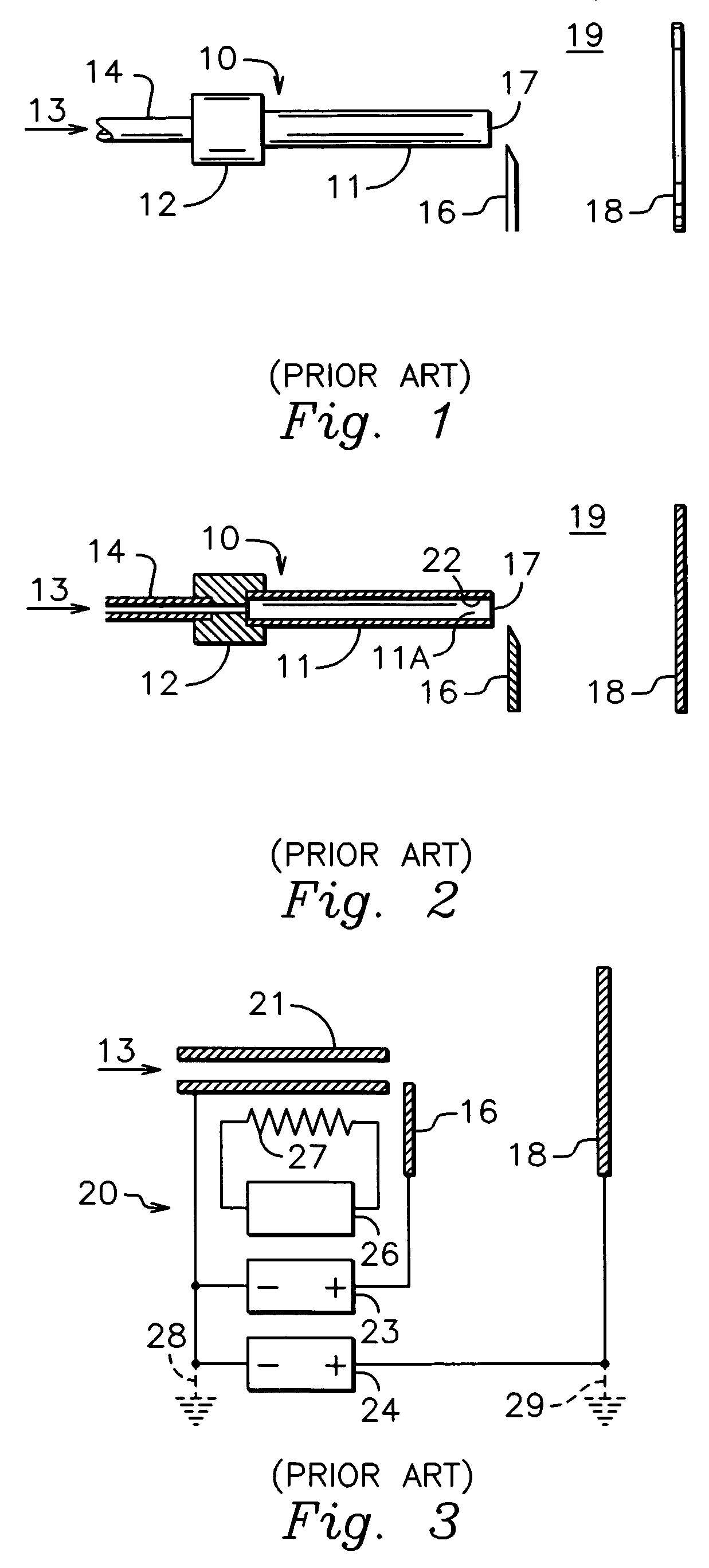

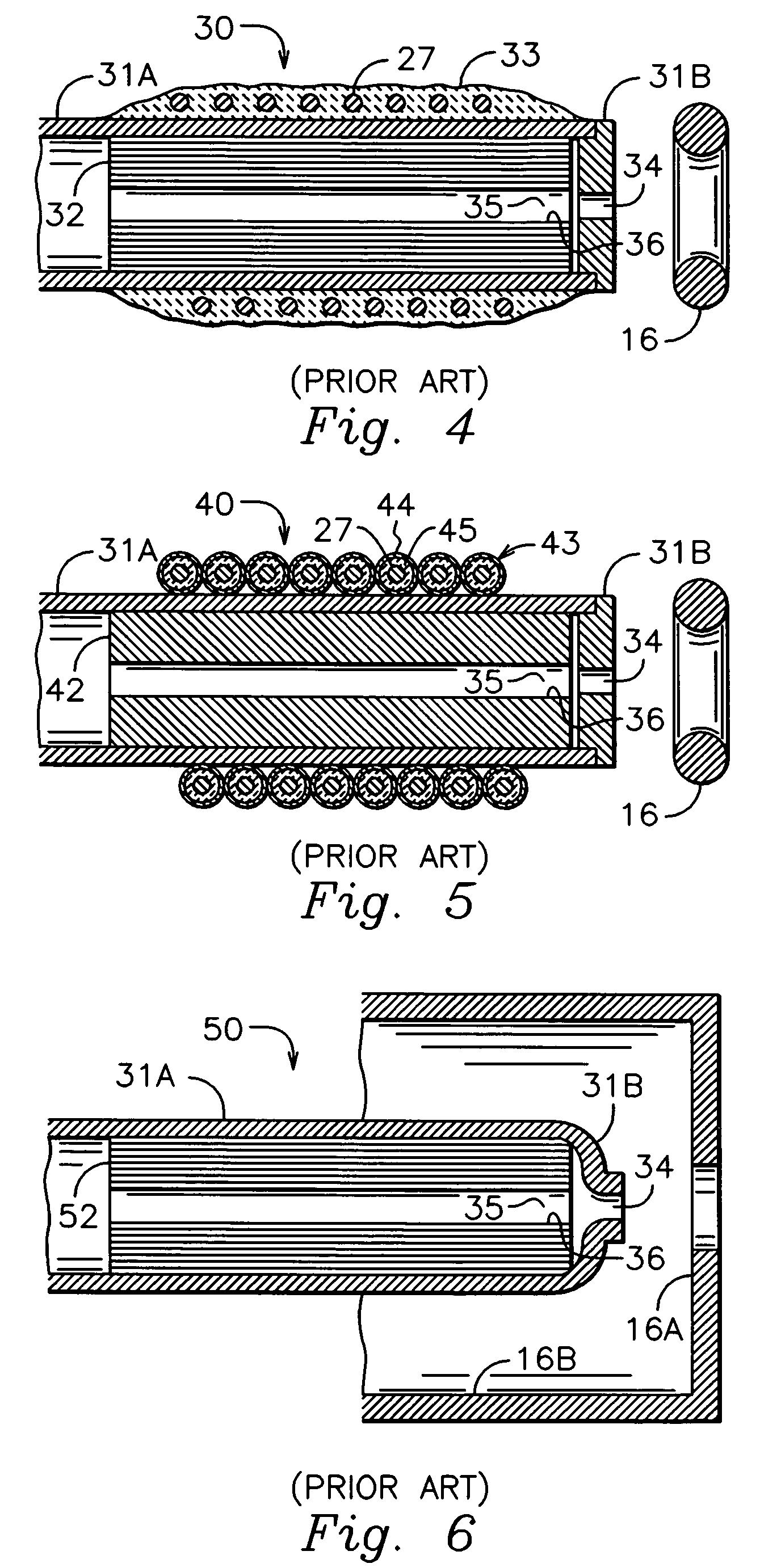

In accordance with one embodiment, the hollow cathode is comprised of a first tantalum tube, tantalum foil, and a second tantalum tube. The foil is in the form of a spiral winding around the outside of the first tube and is held in place by the second tube, which surrounds the foil. One end of the second tube is approximately flush with one end of the first tube. The other end of the second tube extends to a cathode support through which the working gas flows. To start the cathode, a flow of ionizable inert gas, usually argon, is initiated through the hollow cathode and out the open end of the first tube. An electrical discharge is then started between an external electrode and the first tube. When the first tube is heated to operating temperature, electrons are emitted from the open end of the first tube.

Owner:KAUFMAN & ROBINSTON

Industrial hollow cathode

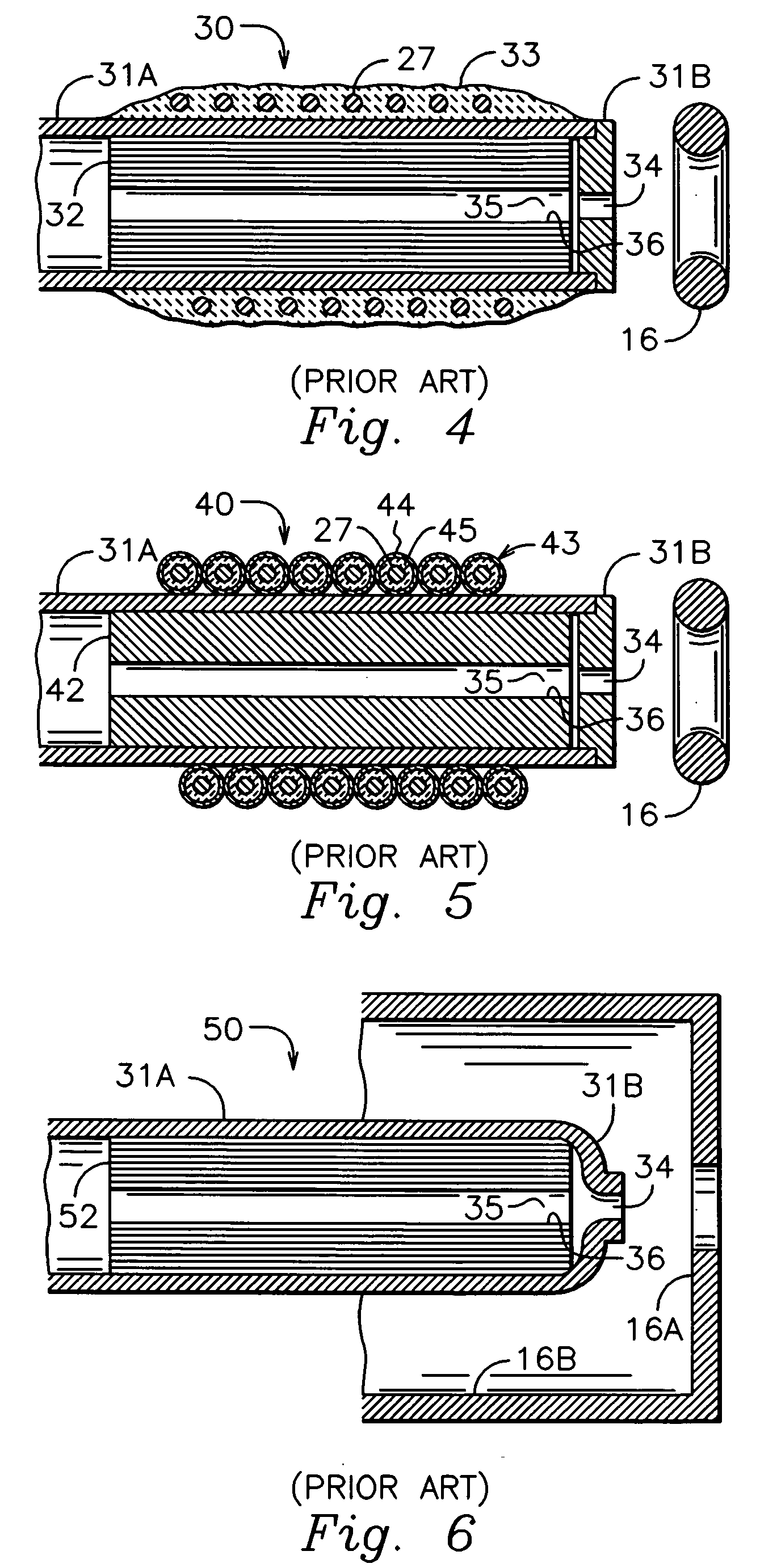

InactiveUS20040000853A1Simple to fabricateSimple to useThermionic cathodesDischarge tube solid thermionic cathodesEngineeringRadiation shield

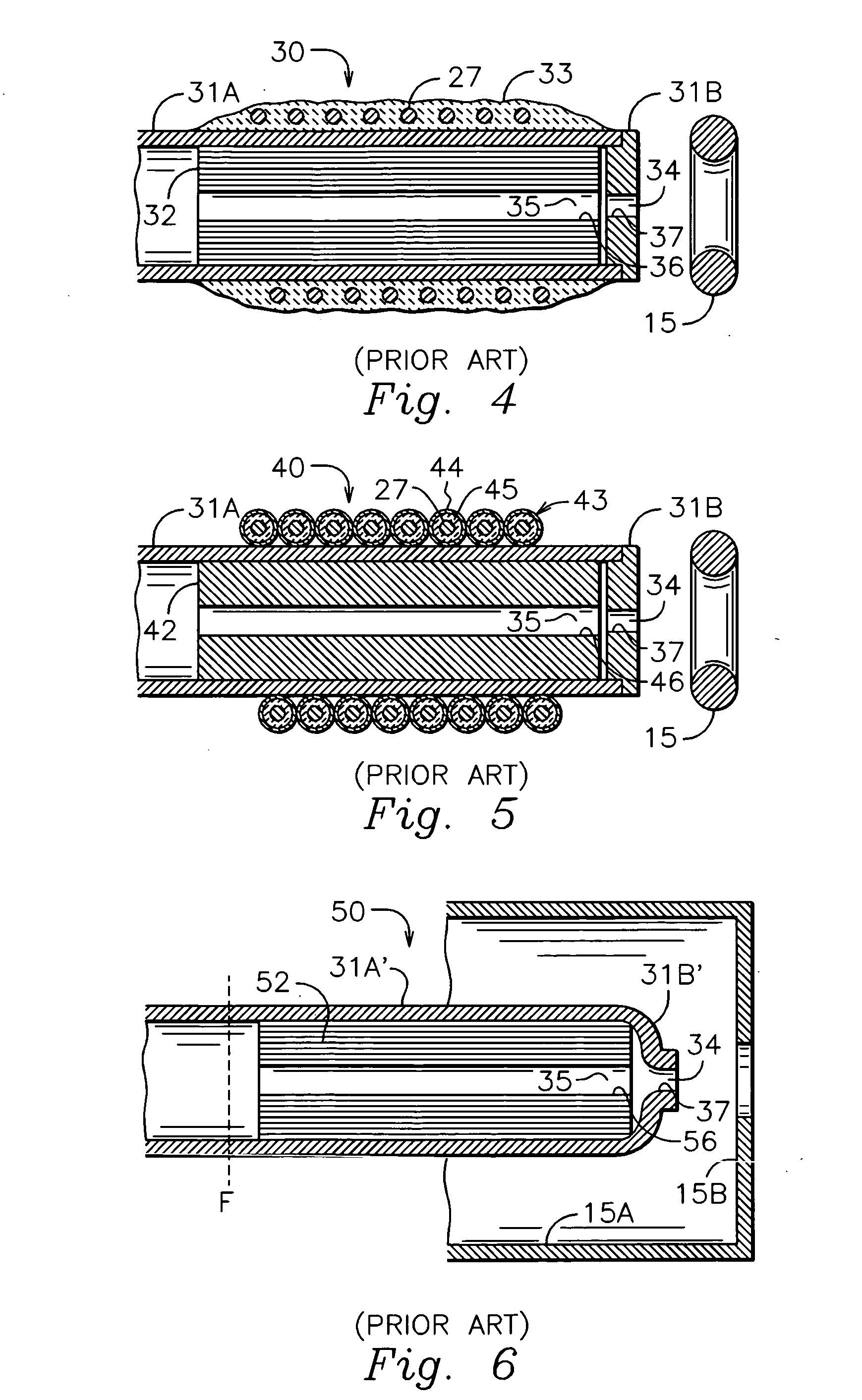

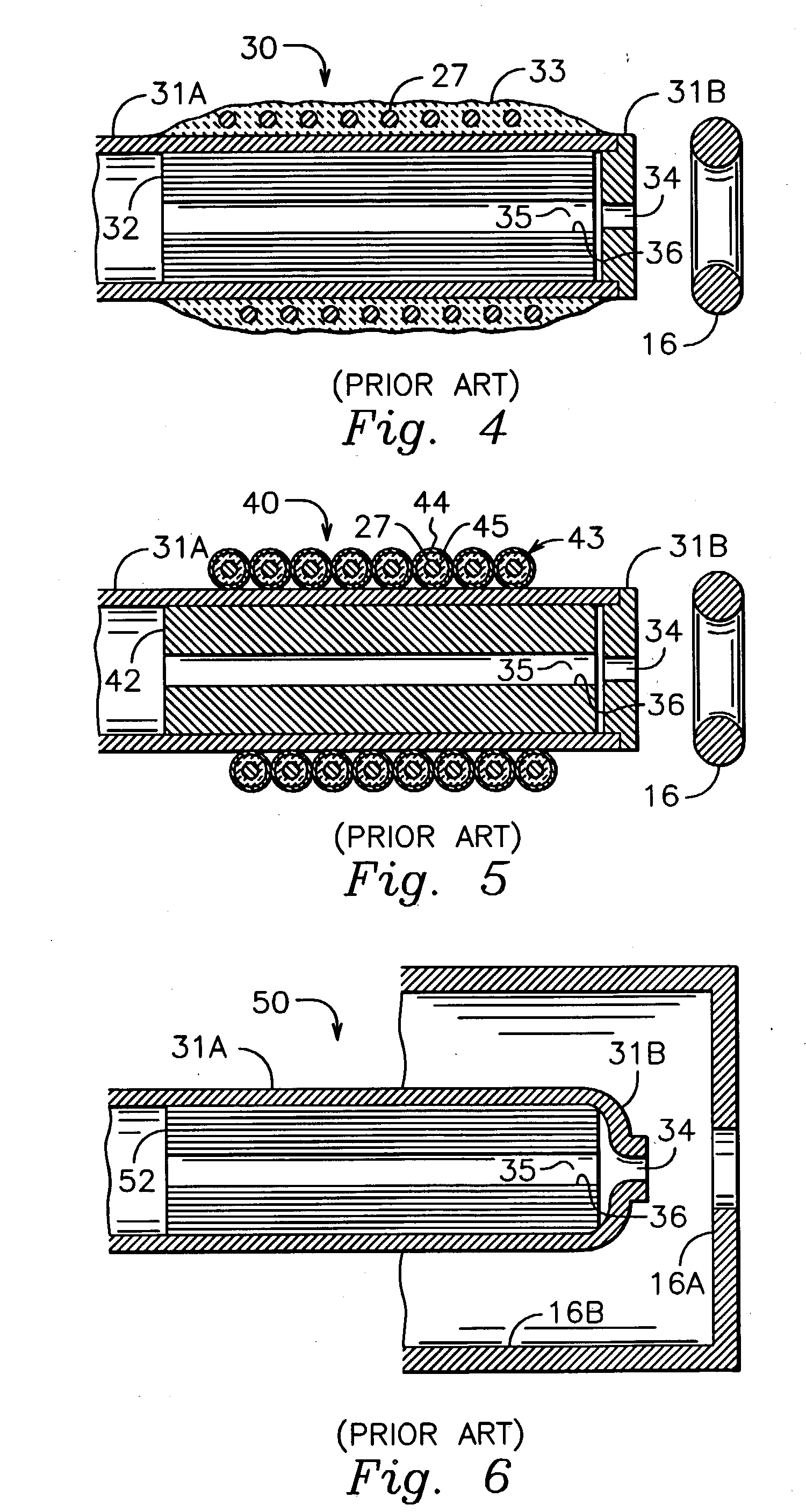

In accordance with one embodiment of the present invention, the hollow-cathode apparatus comprises a small-diameter tantalum tube with a plurality of tantalum-foil radiation shields, wherein the plurality of shields in turn comprise one or more spiral windings external to that tube and approximately flush with the open end from which electron emission takes place. The axial length of at least one of the inner windings (closer to the tantalum tube) is equal to or less than approximately half the length of the tantalum tube. An enclosed keeper surrounds the cathode. To start the cathode, a flow of ionizable inert gas, usually argon, is initiated through the cathode and out the open end. An electrical discharge is then started between the keeper and the hollow cathode. When heated to operating temperature, electrons exit from the open end of the hollow cathode.

Owner:KAUFMAN & ROBINSON

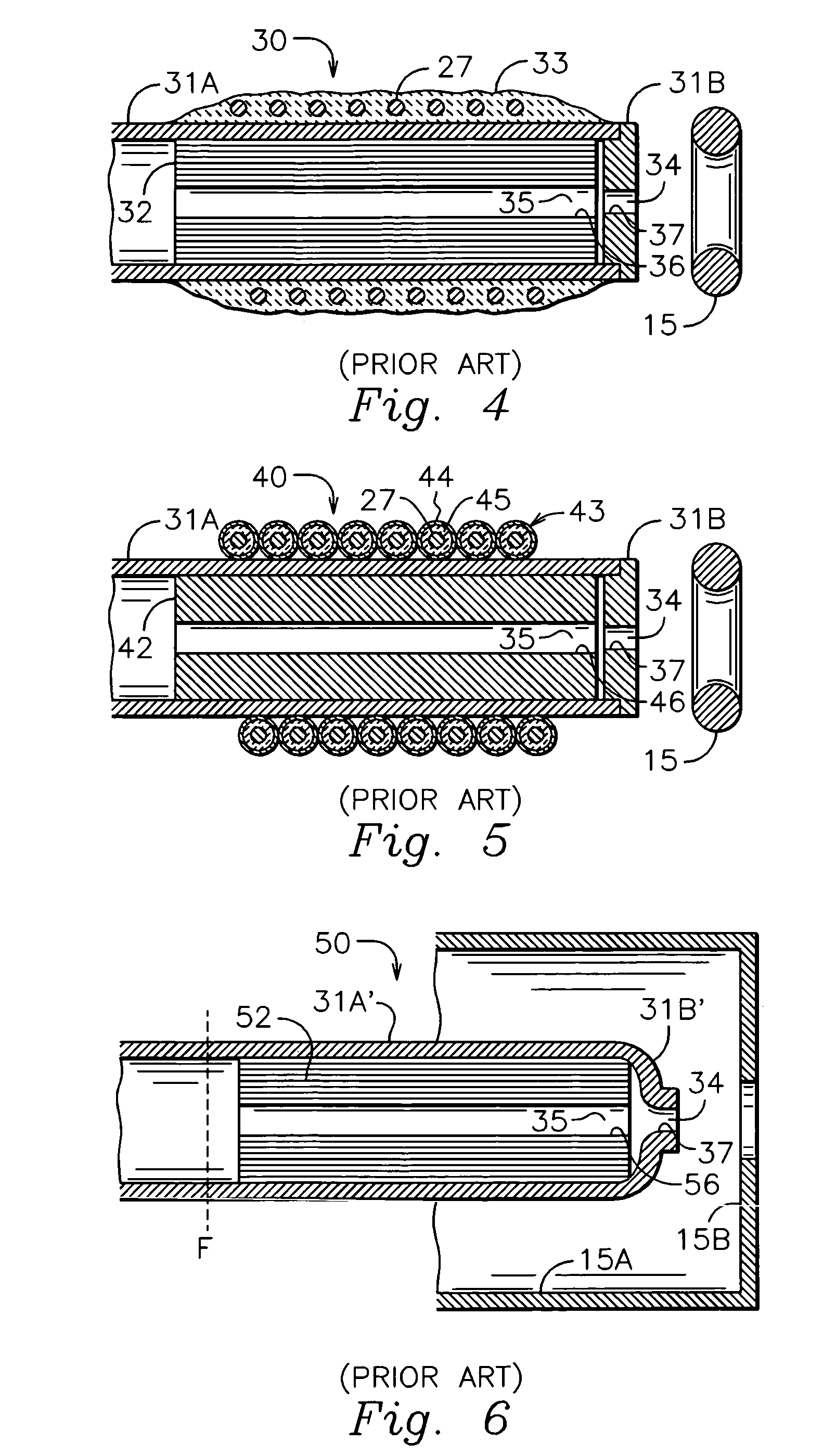

Industrial hollow cathode with radiation shield structure

ActiveUS20060132017A1Simple to fabricateSimple to useThermionic cathodesMachines/enginesConductor CoilOperating temperature

In accordance with one embodiment of the present invention, the hollow-cathode apparatus comprises a small-diameter tantalum tube with a plurality of tantalum-foil radiation shields, wherein the plurality of shields in turn comprise one or more spiral windings external to that tube and approximately flush with the open end from which electron emission takes place. The axial length of at least one of the inner windings (closer to the tantalum tube) is equal to or less than approximately half the length of the tantalum tube. An enclosed keeper surrounds the cathode. To start the cathode, a flow of ionizable inert gas, usually argon, is initiated through the cathode and out the open end. An electrical discharge is then started between the keeper and the hollow cathode. When heated to operating temperature, electrons exit from the open end of the hollow cathode.

Owner:KAUFMAN & ROBINSON

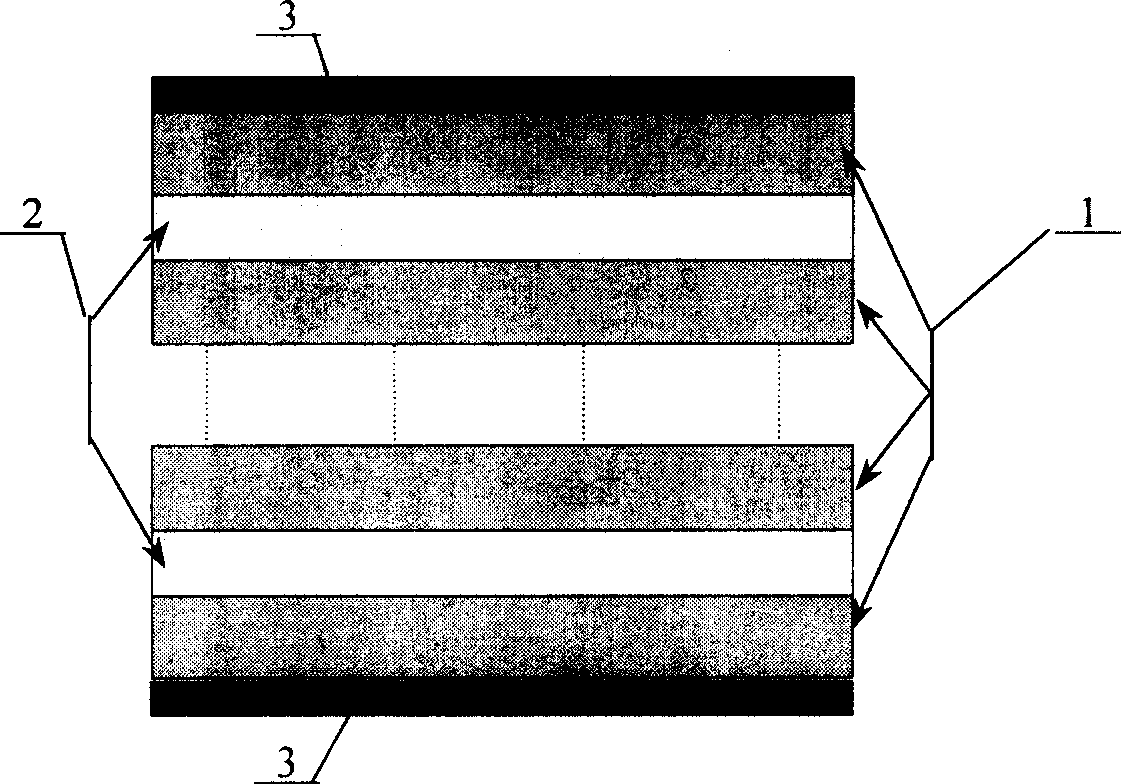

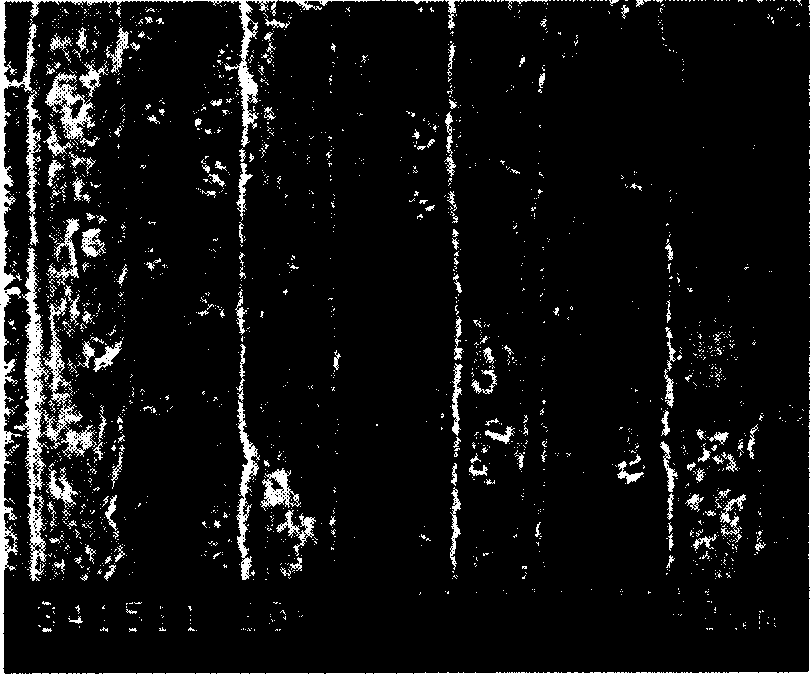

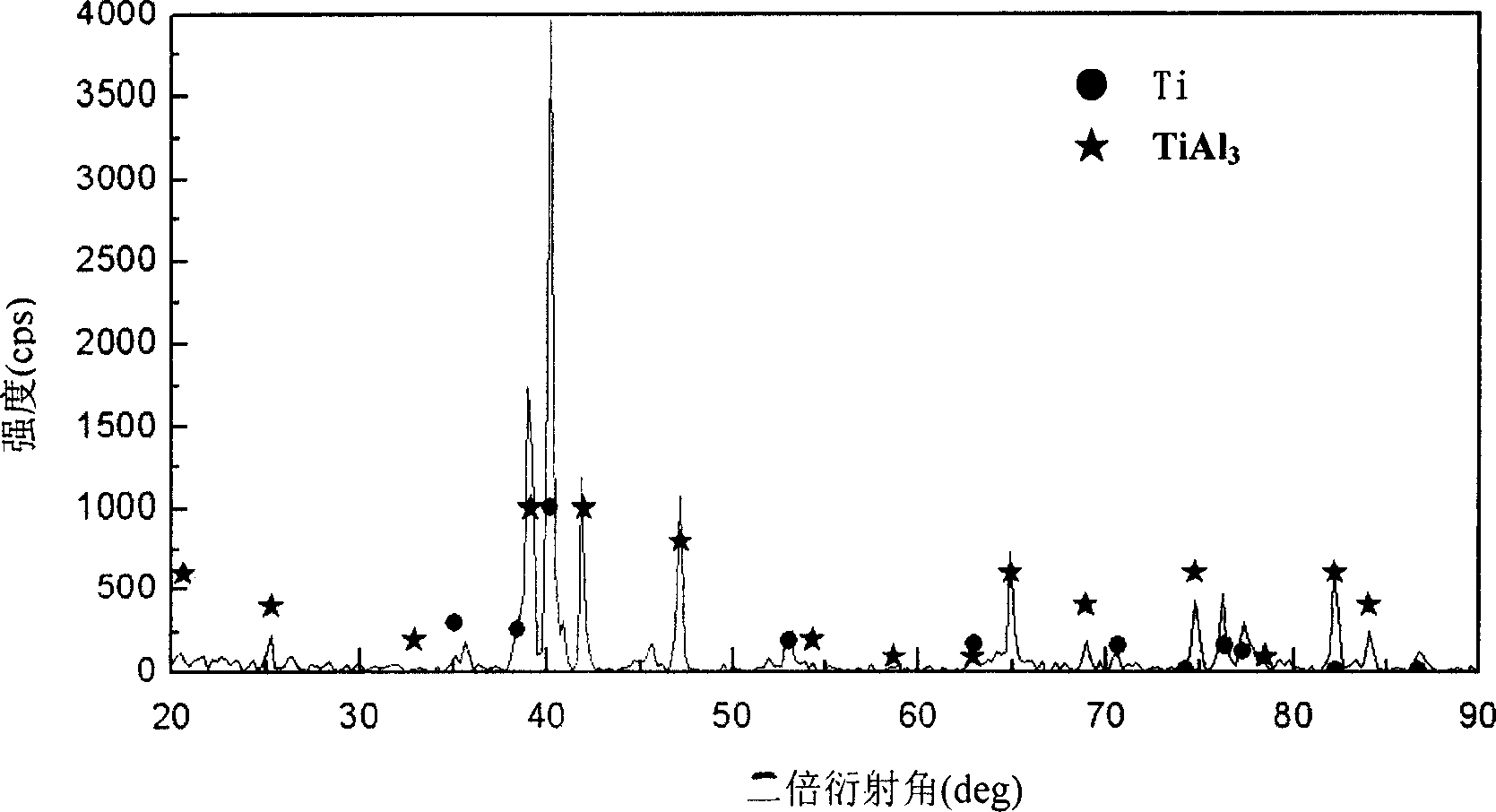

Method for preparing titanium aluminium alloy sheet material from foil element by hot pressing diffusion transformation synthesis

InactiveCN1730223AHigh strengthUniform and fine grain structureNon-electric welding apparatusTitanium alloyAluminum foil

The invention relates to a method for preparing alumino-titanium alloy sheet material by hot-pressed diffusion phase transformation, which pertains to metal heat treating domain. The invention comprises the following steps: (1) subjecting foil surface to chemical and mechanical treatment by titanium foil and aluminum foil; (2) folding titanium foil and aluminum foil by interval and wrapping the outer surface by tantalum foil; (3) subjecting it to continuous heat treatment on vacuum hot-pressing equipment; (4) cooling the plate blank; (5) grinding the surface of plate blank by grinder. The invention can produce alumino-titanium alloy board with highly dense chip histological structure and strength in the longitude direction.

Owner:HARBIN INST OF TECH

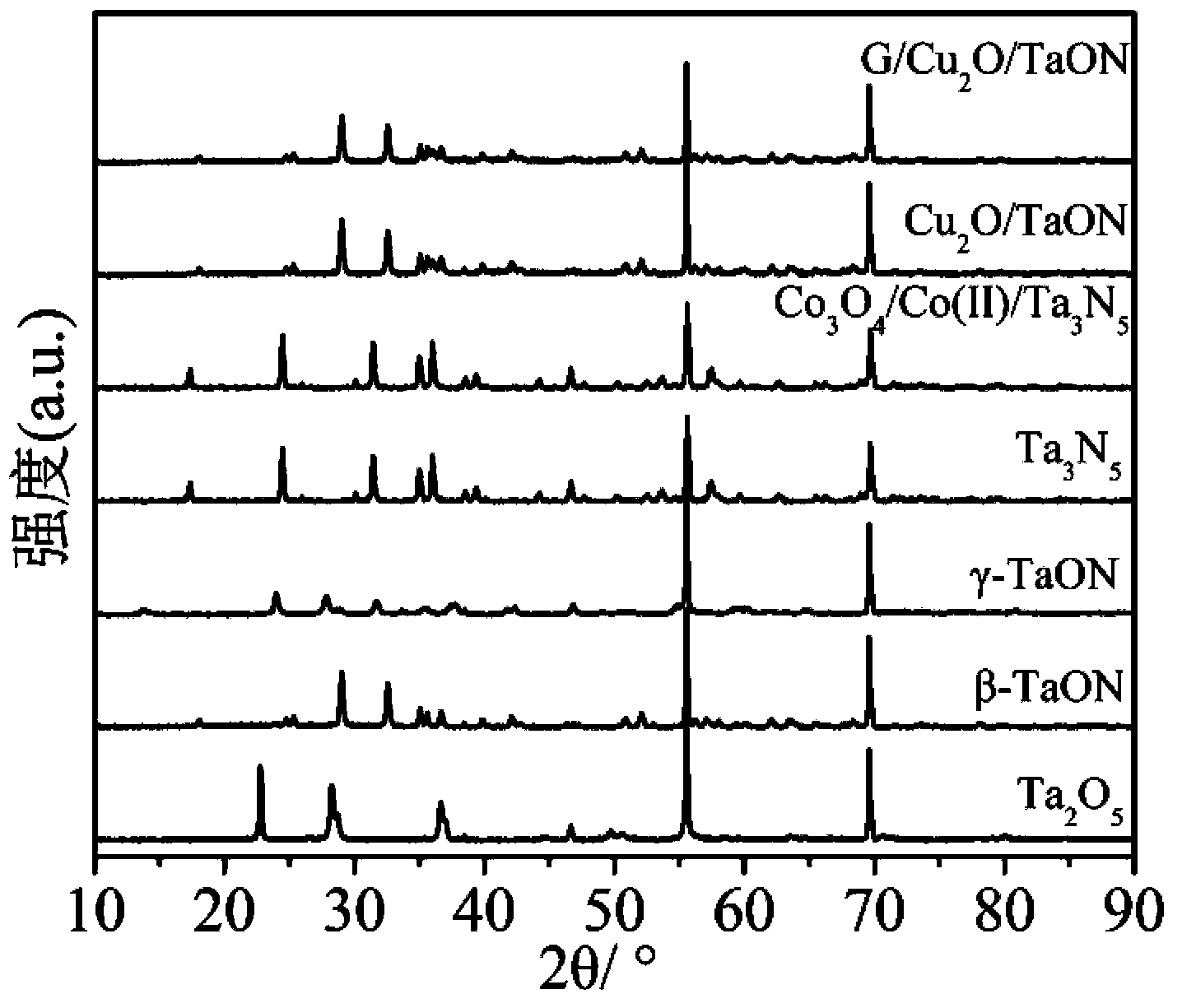

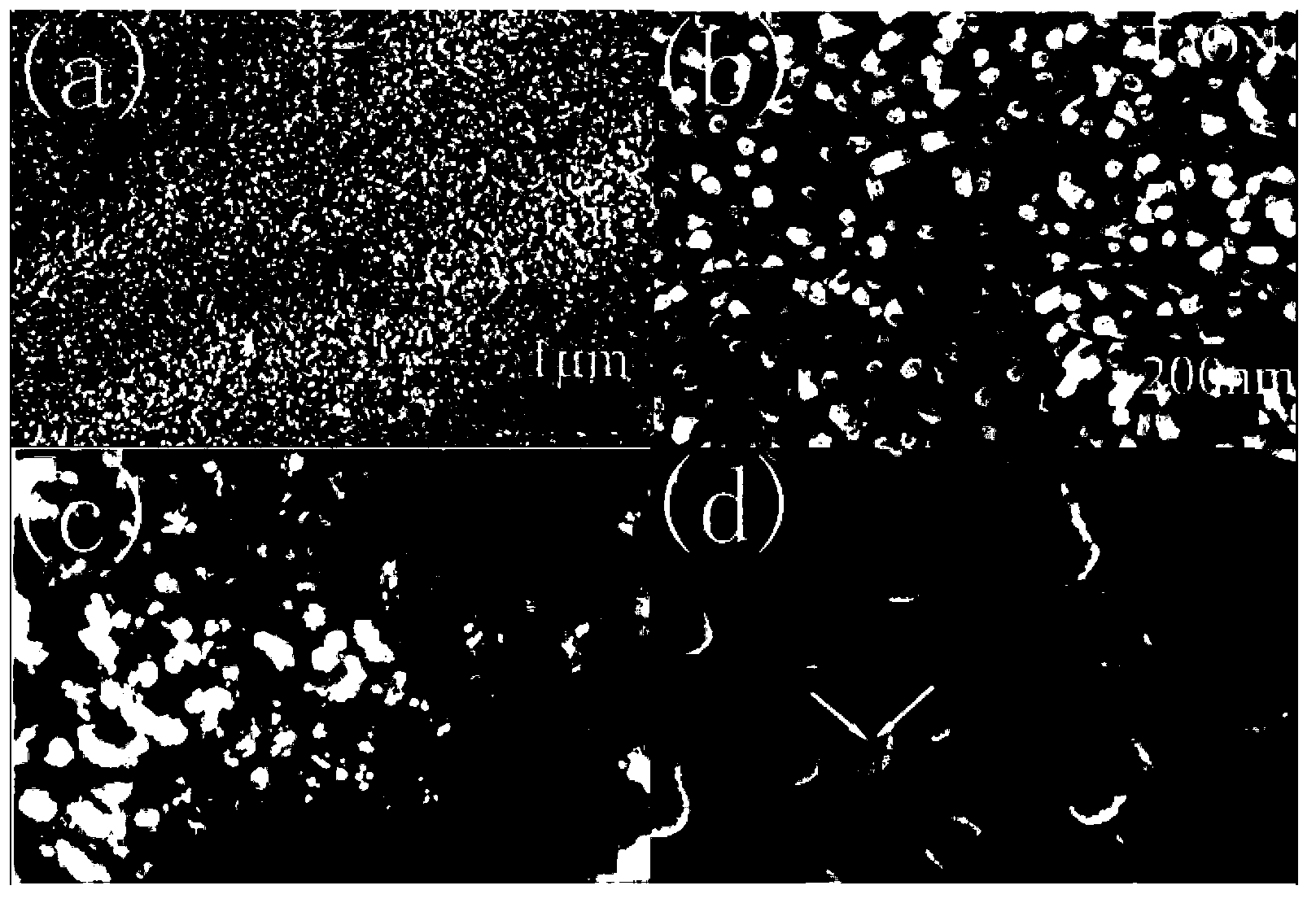

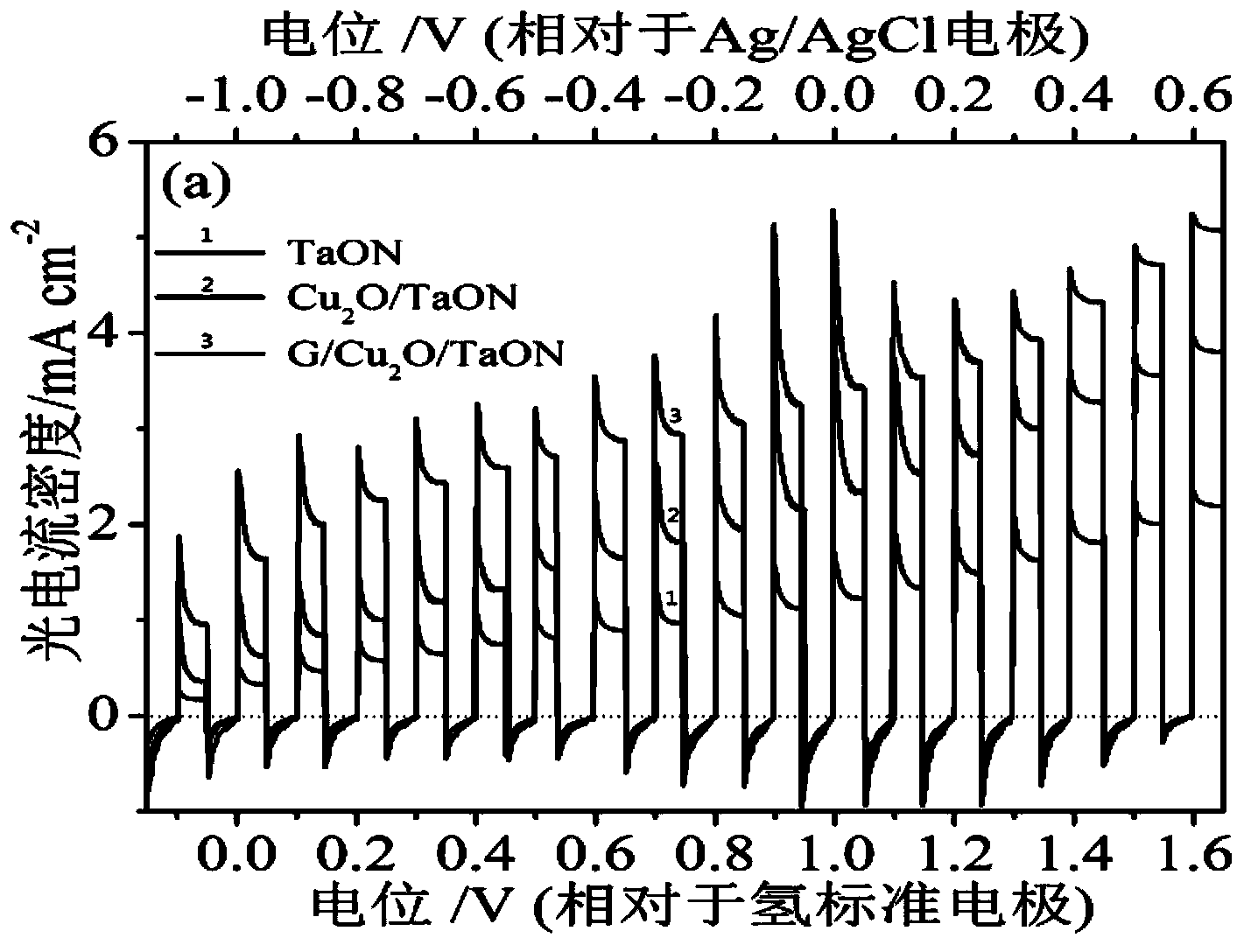

Preparation method of low-dimensional tantalum-based nano-array photo-electrode

InactiveCN103352211AHigh Oxygen Quantum EfficiencyElectrical apparatusEnergy inputWater vaporCuprate

The invention relates to a preparation method of a low-dimensional tantalum-based nano-array photo-electrode. The invention belongs to the field of solar energy, photo-catalyzing, and photochemical material. A metal tantalum foil is adopted as an initial raw material, and is mixed with hydrofluoric acid, hydrogen peroxide, cobaltate, cuprate, and the like; a constant-temperature reaction is carried out in an autoclave, such that a metal-oxide-loaded photo-electrode with the tantalum foil as a substrate and with a low-dimensional tantalum-based nano-array uniformly grown on the surface is obtained; the photo-electrode is washed by using ethanol and water, and is dried; the photo-electrode is further delivered into a heat treatment furnace, such that nitriding heat treatment is carried out; through the controlling over the ratio and flow rates of ammonia and water vapor, and through different periods of time, oxynitride and nitride array photo-electrodes with different nitrogen contents can be obtained; with a spin-coating method, graphene or nitrogen-doped graphene is uniformly covered on the surface of the nano-array. The photoelectric conversion efficiency of the tantalum-based composite nano-array photo-electrode is substantially improved. The visible-light-response tantalum-based composite nano-array photo-electrode provided by the invention has high Light-quantum conversion efficiency, and can be used in solar energy conversion and utilization.

Owner:UNIV OF SCI & TECH BEIJING

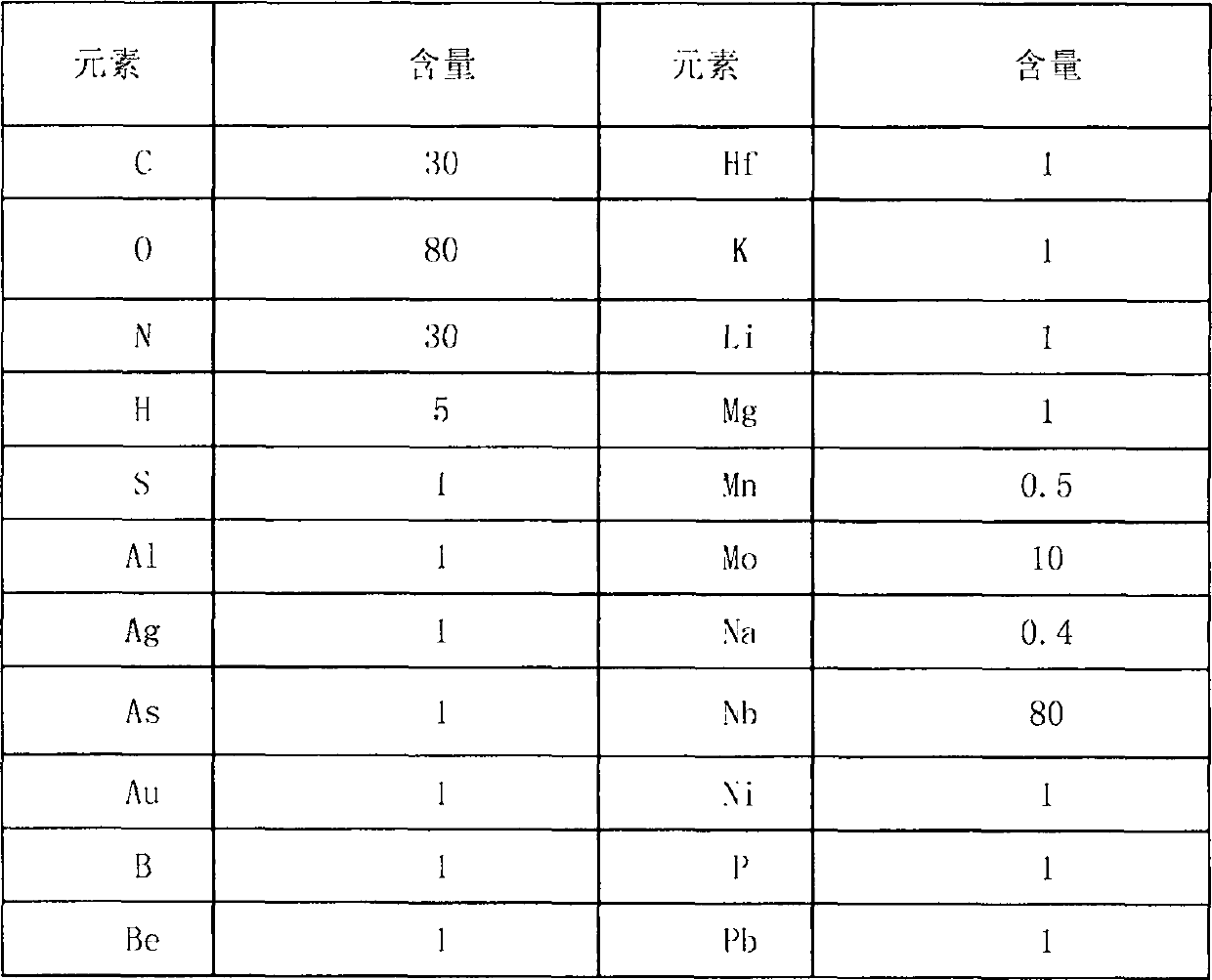

Preparation method for high purity tantalum foil for organic light emitting diode (OLED)

ActiveCN107619955ALow impurity contentReduce contentMetal rolling arrangementsEvaporationZone melting

The invention belongs to the manufacturing field of organic light emitting diodes (OLEDs) and relates to an evaporation boat which is used when depositing a metal electrode, in particular to a preparation method for a high purity tantalum foil evaporation boat for OLED. The preparation method includes the steps of material preparing, shove charging, first smelting, vacuum cooling, second smelting,cogging and rolling, tantalum ingot pickling, material preparing, vacuum annealing heat treatment and rolling. By adopting electron-beam smelting, zone melting purification and electromagnetic fieldpurification and controlling melting speed and time precisely, the fact that the tantalum foil is few in impurity content and high in purity is ensured; and through the process of rolling and by conducting high power rolling mill cogging directly, the technological process is simplified and work efficiency is improved. The tantalum foil manufactured by the method is few in structural defects, finein grain structure, high in uniformity and high in isotropy of internal mechanical properties of sheet materials.

Owner:BAOJI BOXIN METAL MATERIALS

Preparation method of pyrite electrode

The invention discloses a preparation method of a pyrite electrode. The preparation method comprises the following steps: selecting pyrite particles; washing and drying the selected pyrite particles for standby use; weighing 0.6-0.8 g of the dried pyrite, grinding the dried pyrite into powder with more than 200 meshes, pressing the powder into pyrite cylinders under the condition of 0.5 MPa in a powder pressing machine, and then packaging the pyrite cylinders with tantalum foils; grinding sodium chloride into powder with more than 200 meshes, putting in a drying oven for drying for 2 hours at the temperature of 150 DEG C; using the dried sodium chloride powder to prepare sodium chloride cylinders containing the pyrite cylinders; putting the sodium chloride cylinders containing the pyrite cylinders into high-pressure assembly blocks, and carrying out warming pressure sintering; and polishing a sample after sintering is completed to obtain the pyrite electrode. The preparation method solves the technical problems that an existing pyrite electrode is extremely difficult to process and prepare caused by the facts that pyrite is crisp and poor in ductility and pyrite is symbiotic with other sulfide minerals to influence electrochemical corrosion results of pyrite in the prior art.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

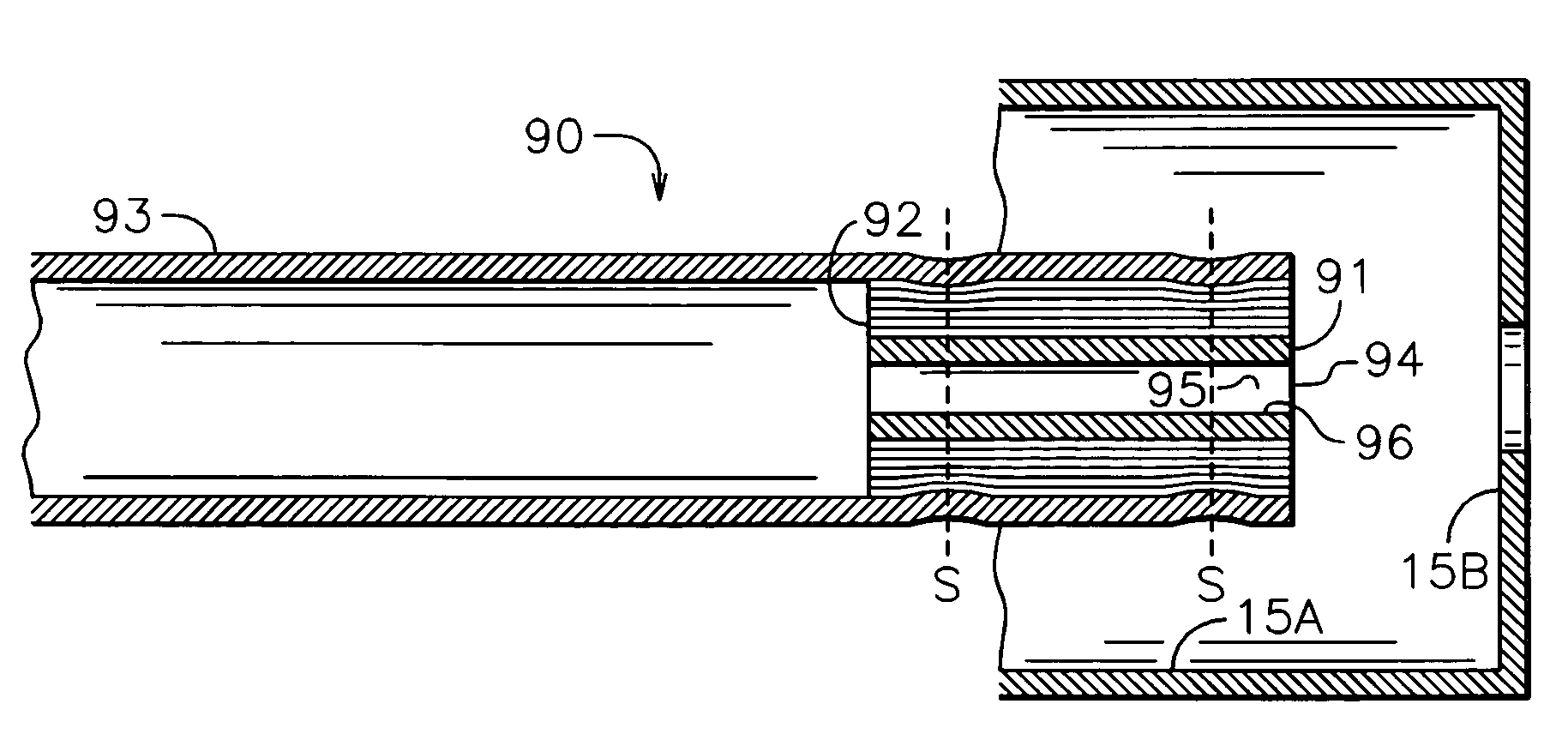

Industrial hollow cathode with radiation shield structure

In accordance with one embodiment of the present invention, the hollow-cathode apparatus comprises a small-diameter tantalum tube with a plurality of tantalum-foil radiation shields, wherein the plurality of shields in turn comprise one or more spiral windings external to that tube and approximately flush with the open end from which electron emission takes place. The axial length of at least one of the inner windings (closer to the tantalum tube) is equal to or less than approximately half the length of the tantalum tube. An enclosed keeper surrounds the cathode. To start the cathode, a flow of ionizable inert gas, usually argon, is initiated through the cathode and out the open end. An electrical discharge is then started between the keeper and the hollow cathode. When heated to operating temperature, electrons exit from the open end of the hollow cathode.

Owner:KAUFMAN & ROBINSON

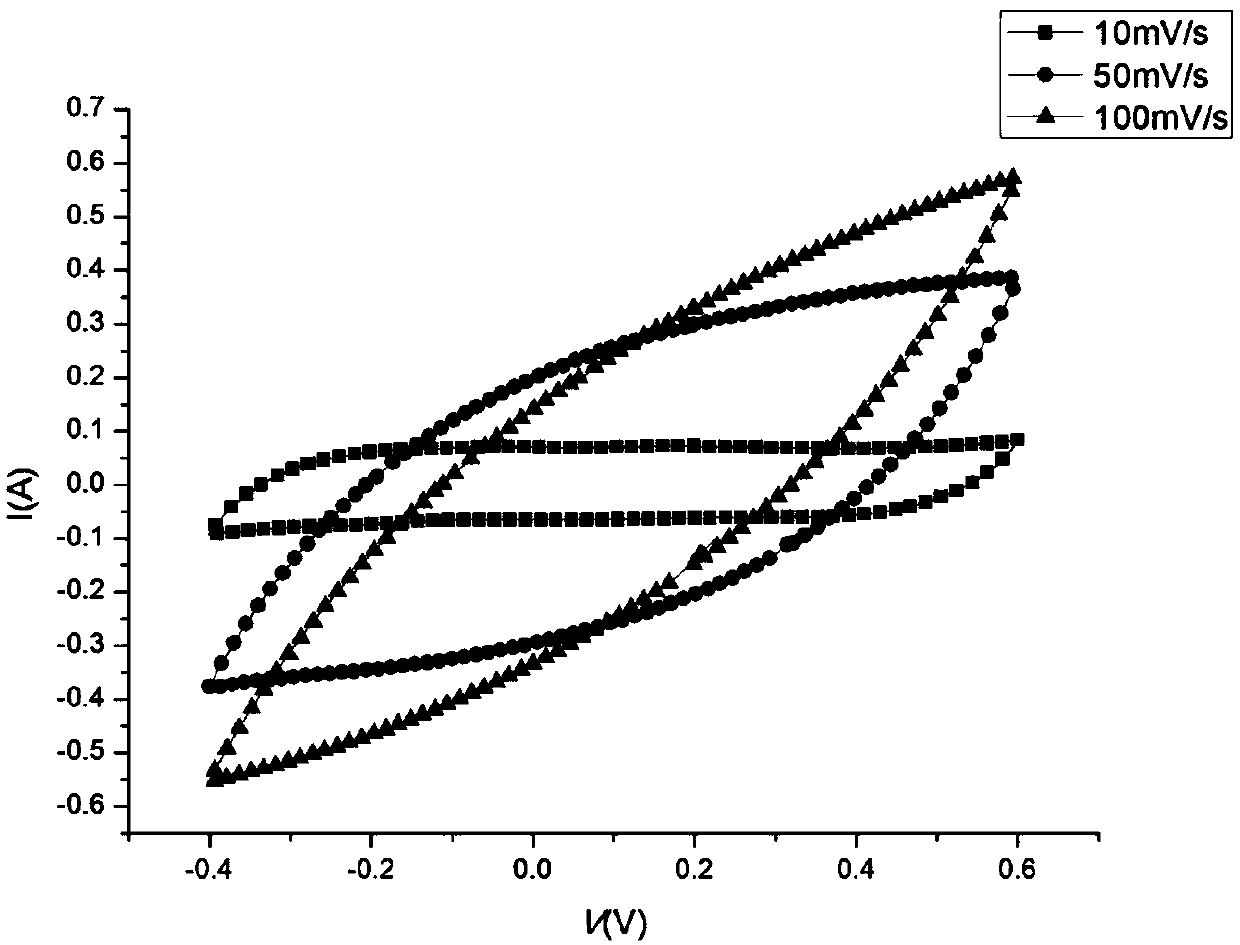

Cathode material used for high-energy tantalum mixed capacitor and preparation method thereof

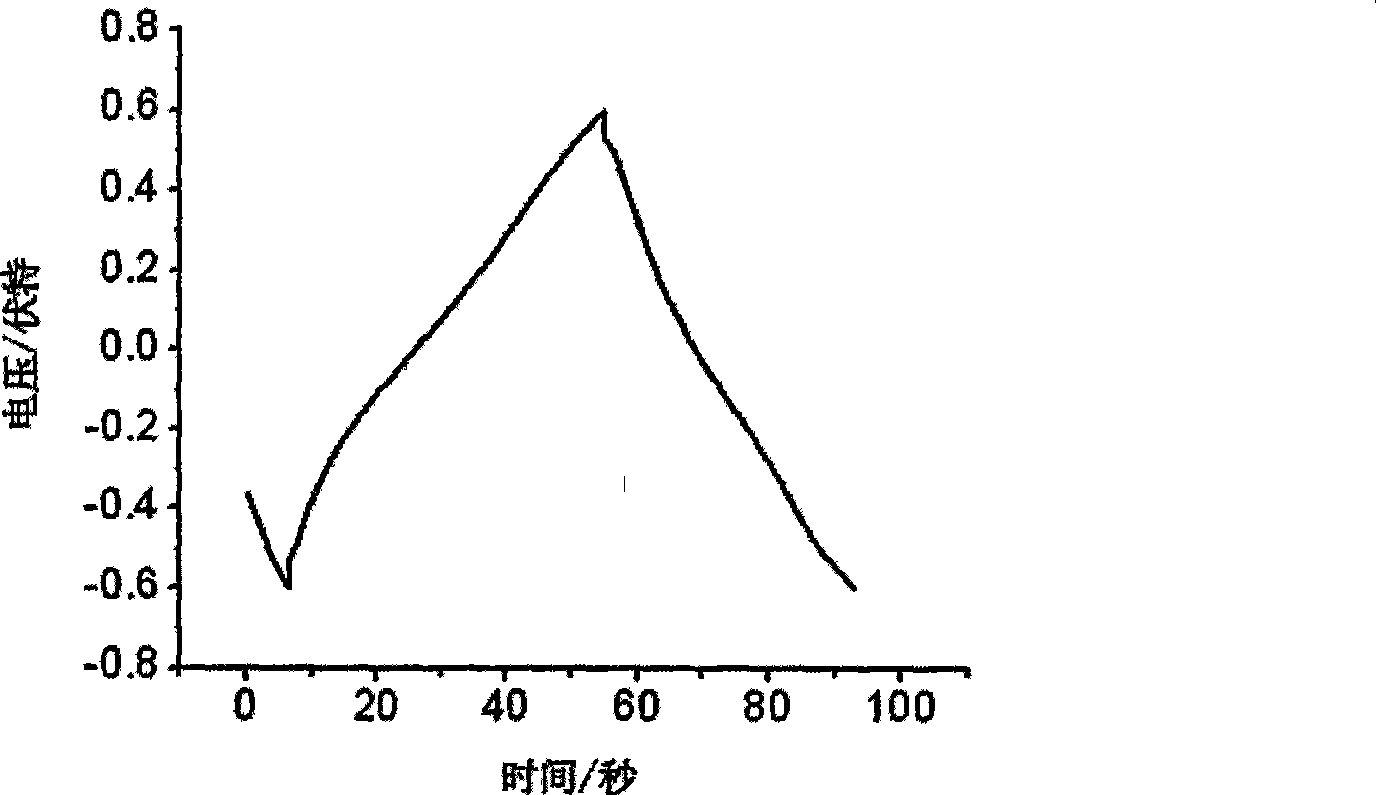

ActiveCN101533715AEnlarging the specific volume surface area of the cathodeEnsure super capacityCapacitor electrolytes/absorbentsCapacitor electrodesHigh energyUltra fine

The invention relates to a cathode material used for a high-energy tantalum mixed capacitor and a preparation method thereof; the cathode material comprises a cathode base material made of tantalum foil; the surface of the cathode material made of tantalum foil is coated with composite material of amorphous metal oxide and ultra-fine activated carbon powder; and an electrochemical capacitor is formed between the composite cathode material coated on the surface and injected electrolyte. The amorphous metal oxide coated on the tantalum foil is composite material; the composite material comprises the following substances: pyrrolidone substance is used as a solvent, homopolymer of vinyl fluoride is used as a bonding agent and various metal oxides and ultra-fine carbon powder form the composite material. The composite material comprises the following substances by weight percentage: 56 percent to 73 percent of pyrrolidone, 5 percent to 10 percent of polymer of vinyl fluoride, 2 percent to 5 percent of ultra-fine activated carbon powder and 20 percent to 29 percent of various metal oxides.

Owner:ZHUZHOU RIWANG ELECTRONICS TECH

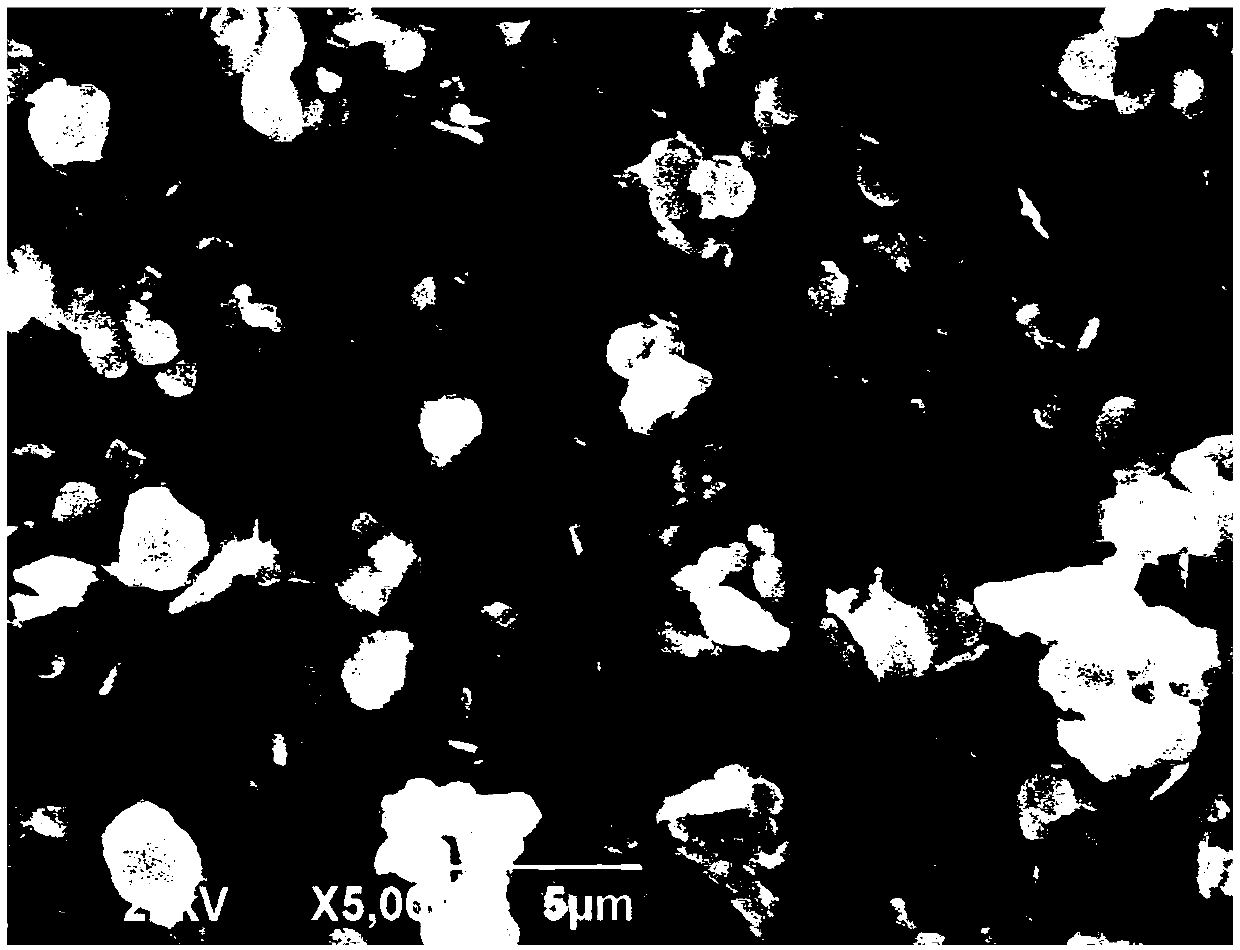

Production of high-purity tantalum flake powder

InactiveUS20080229880A1Reduce sizeTransportation and packagingMetal-working apparatusHydrogenTantalum foil

The present invention relates to a high-purity tantalum flake powder, produced by a hydride-dehydride process including: (a) cold working tantalum metal into a thin sheet; (b) hydriding the thin sheet, forming a brittle tantalum body, e.g., a foil or ribbon with an aspect ratio of greater than 5 to 1; (c) adjusting the tantalum body to a desired particle size; and (d) removing hydrogen from the tantalum body by vacuum sintering, forming a tantalum flake powder. In accordance with an embodiment of the present invention, tantalum flake is produced by sizing ultra-thin tantalum foil via the hydride-dehydride process. Tantalum is an extremely malleable metal and can be cold worked into extremely thin sheets less than 1 micron thick. Once hydrided, this foil is brittle, and can be easily sized by suitable milling processes. The hydrogen is removed by vacuum sintering, resulting in an extremely thin Ta metal flake.

Owner:READING ALLOYS

Fabrication method of pyrrhotite electrode

The invention discloses a fabrication method of a pyrrhotite electrode. The fabrication method comprises the following steps of picking out pyrrhotite particles; cleaning and drying the pyrrhotite particles; grinding 0.5-0.8g of pyrrhotite particles to powder with 200 meshes or over, pressing the pyrrhotite powder to a pyrrhotite cylinder with a pressure of 0.5MPa in a powder pressing machine, and wrapping the pyrrhotite cylinder with a tantalum foil; grinding sodium chloride to powder with 200 meshes or over, placing the powder in a baking oven, and drying the powder for 2 hours at a temperature of 150 DEG C; fabricating a sodium chloride cylinder internally provided with the pyrrhotite cylinder from the dried sodium chloride; placing the sodium chloride cylinder internally provided with the pyrrhotite cylinder in a high-voltage assembly block for sintering in a temperature raising and pressurizing way; and grinding and polishing the sintered sample, thereby obtaining the pyrrhotite electrode. By the fabrication method, the technical problems that the pyrrhotite electrode is brittle and is poor in extensibility, the pyrrhotite electrode and other sulfide minerals coexist, a chemical corrosion effect of the pyrrhotite electrode will be affected by an effect of an original battery among paragenetic minerals and the existing pyrrhotite electrode is difficult to process and prepare are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Method for preparing cathode of fully-sealed liquid mixed tantalum capacitor

The invention discloses a method for preparing a cathode of a fully-sealed liquid mixed tantalum capacitor, which comprises the following steps: pre-treating a tantalum foil to coarsen the surface of the tantalum foil; preparing solution containing a ruthenium compound and coating the solution on the tantalum foil to form a liquid membrane of which the thickness is 100 to 500 microns; preserving the temperature of the coated tantalum foil in a muffle furnace of which the temperature is 200 to 600 DEG C; and finally, boiling the tantalum foil in deionized water for 5 to 15min to remove undecomposed ruthenium compound and other byproducts in a ruthenium dioxide film, and drying the ruthenium dioxide film to obtain the cathode of the fully-sealed liquid mixed tantalum capacitor. The method for preparing the cathode of the fully-sealed liquid mixed tantalum capacitor of the invention adopts an acidic compound or an alkalic compound to substitute for a concentrated Hydrochloric acid, and has the advantages of low pollution in the whole preparation process, simple process and low time consumption. Because the ruthenium dioxide of the capacitor cathode prepared by the preparation method of the invention is firmly bonded on the tantalum foil and forms a coarse surface, the cathode has a high capacity. The preparation method of the invention needs no costly production equipment and is easy to realize industrial production.

Owner:西安华泰有色金属实业有限责任公司

Visible light response type photocatalytic material of tantalum nitride modified by cobalt and preparation method thereof

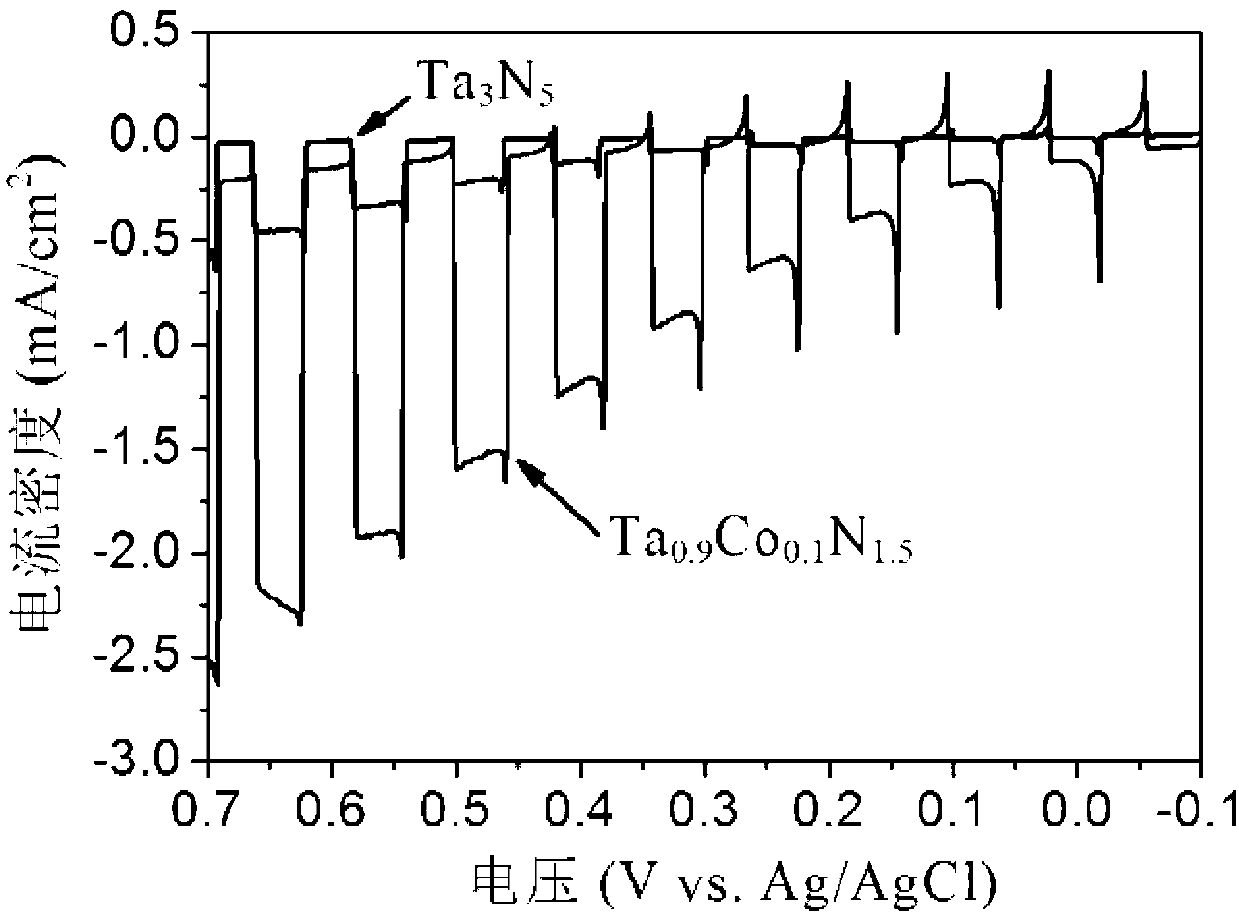

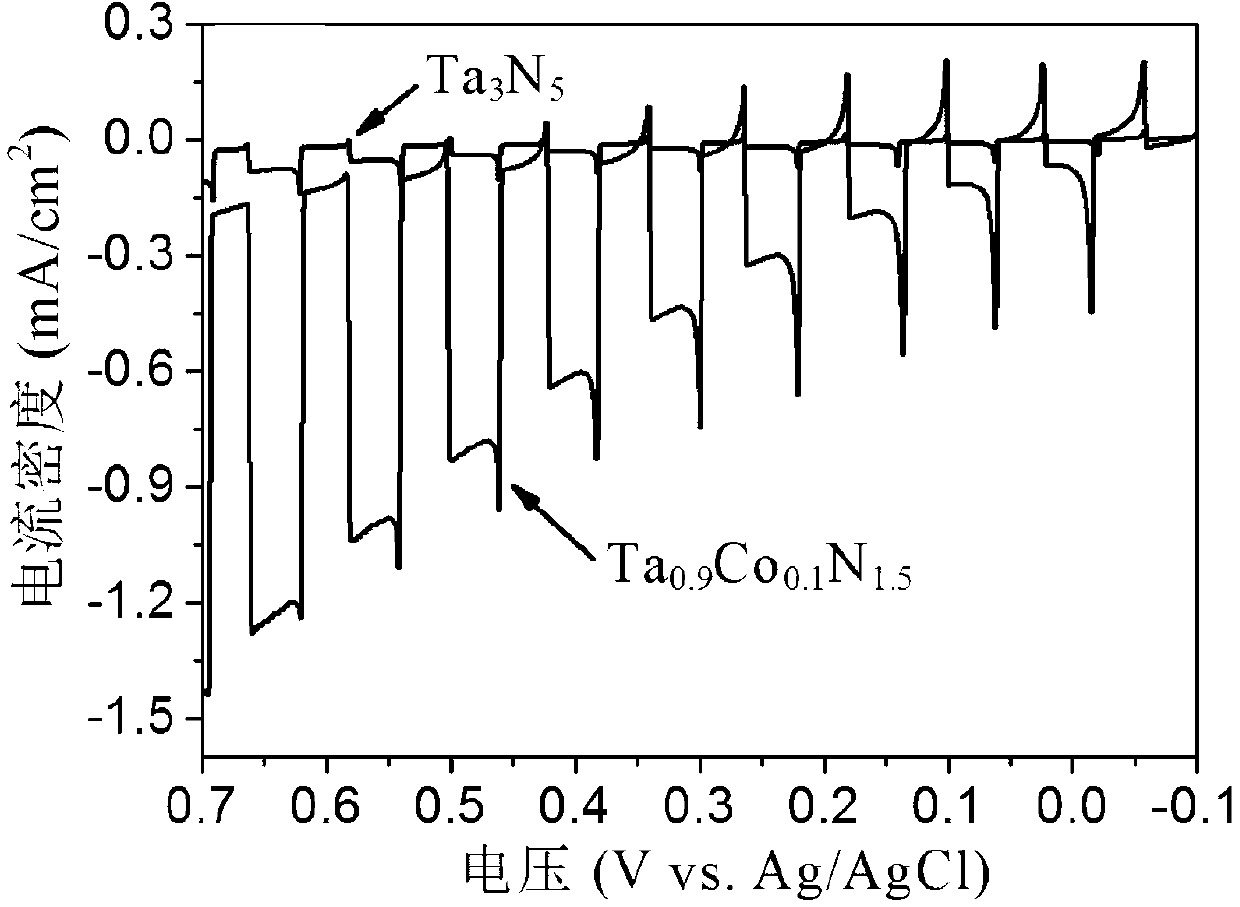

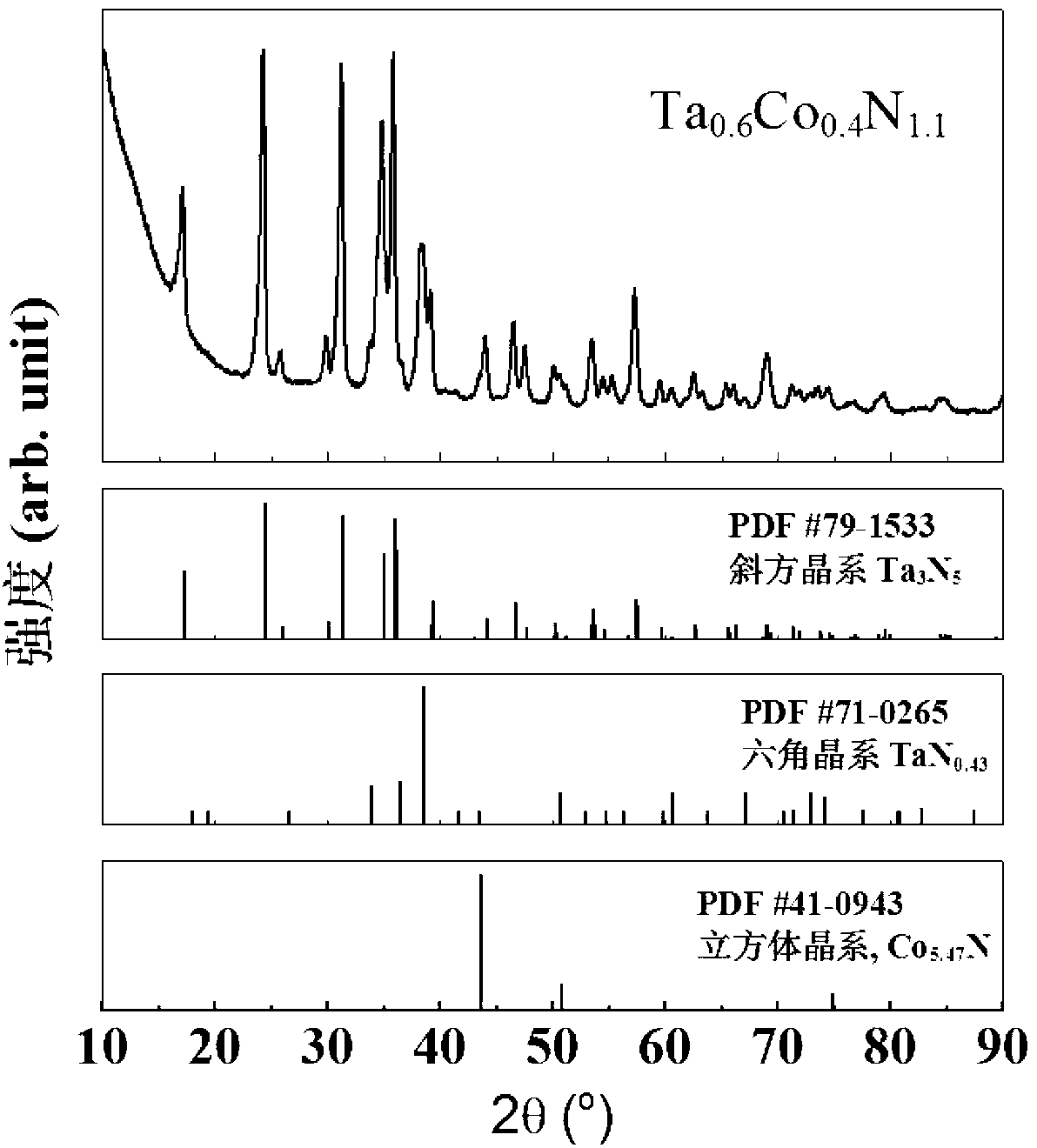

InactiveCN102784659AGood visible light photoelectrochemical performanceIncrease photocurrentPhysical/chemical process catalystsElectron transferLight response

The invention discloses a visible light response type photocatalytic material of tantalum nitride modified by cobalt and a preparation method thereof. The preparation method includes cleanly washing a pure tantalum foil, using the pure tantalum foil as a substrate, dropping a precursor solution A containing Ta5+ onto the substrate, air drying at the room temperature to obtain a tantalum foil loaded with Ta5+, dropping a precursor solution B containing metal cobalt ions onto the tantalum foil loaded with Ta5+, air drying at the room temperature to obtain a tantalum foil loaded with Ta5+ and the metal cobalt ions, and subjecting the tantalum foil loaded with Ta5+ and the metal cobalt ions to a constant temperature calcination in a flowing anhydrous ammonia gas atmosphere to obtain the photocatalytic material. By means of the method, the prepared photocatalytic material has the advantages that the stability of Ta3N5 is effectively improved, the self oxidation of the Ta3N5 is inhibited, the electron transfer can be facilitated, the photoproduction electron-hole pair recombination is inhibited, and the photolysis efficiency is improved.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

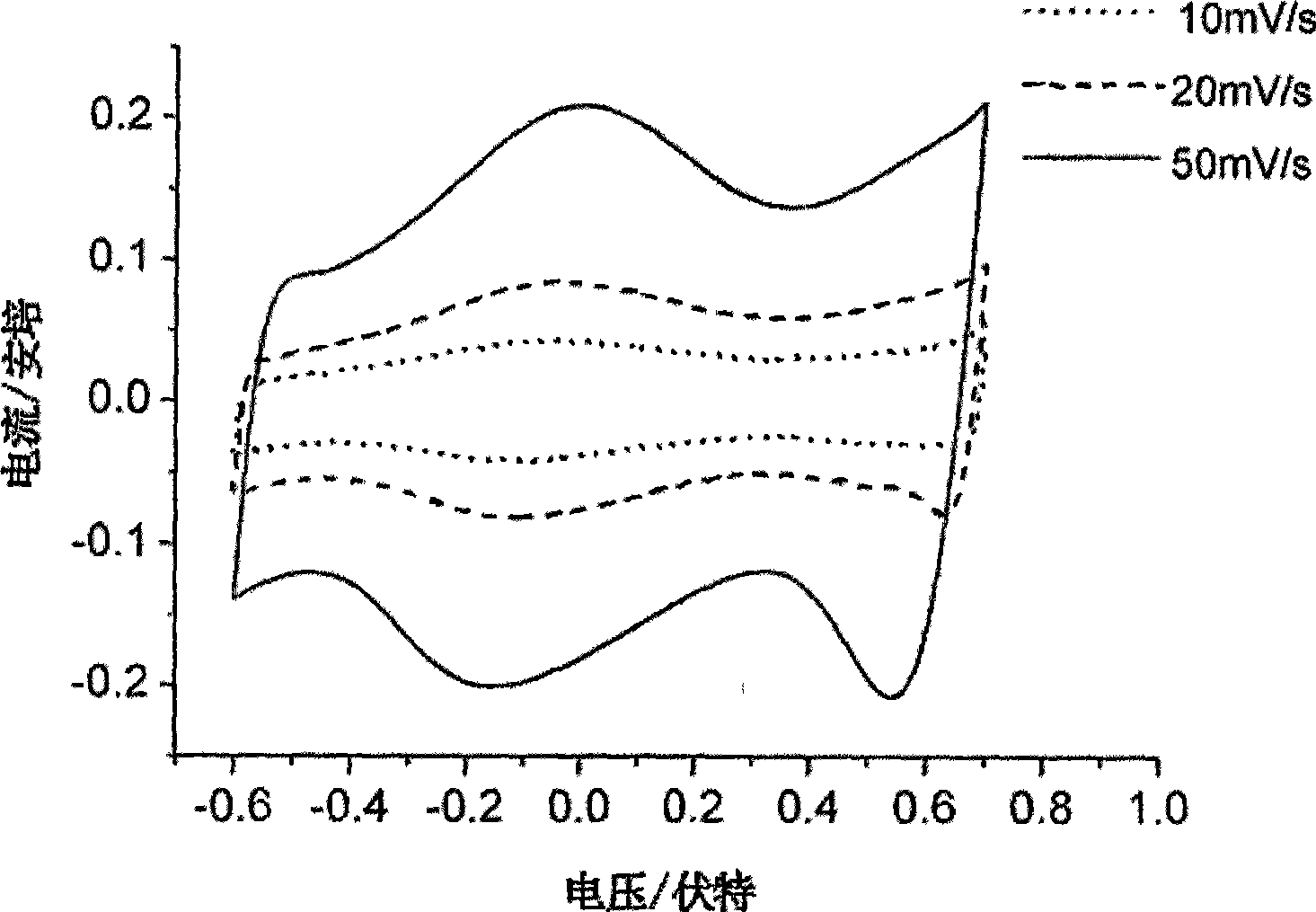

Preparation technique of composite film electrode used for a super capacitor

InactiveCN101533716ASolve power problemsSolve large capacityCapacitor electrodesCapacitancePolymer capacitor

The invention discloses a preparation technique of a composite film electrode used for a super capacitor; the preparation technique is characterized by comprising the following steps: pre-processing on high-purity metal tantalum foil with the purity of more than 99.95 percent: grinding and roughening, grinding and polishing, removing oil and cleaning to the metal tantalum foil; 2) electrodeposition technique; and 3) heat processing to the composite film electrode. The composite film electrode prepared by adopting the technique can reduce the using amount of noble metal ruthenium on the basis of guaranteeing capacitance characteristic, thus reducing the cost.

Owner:CENT SOUTH UNIV

Industrial hollow cathode

ActiveUS7728498B2Simple to fabricateSimple to useLamp incadescent bodiesThermionic cathodesOperating temperatureTantalum foil

Owner:KAUFMAN & ROBINSTON

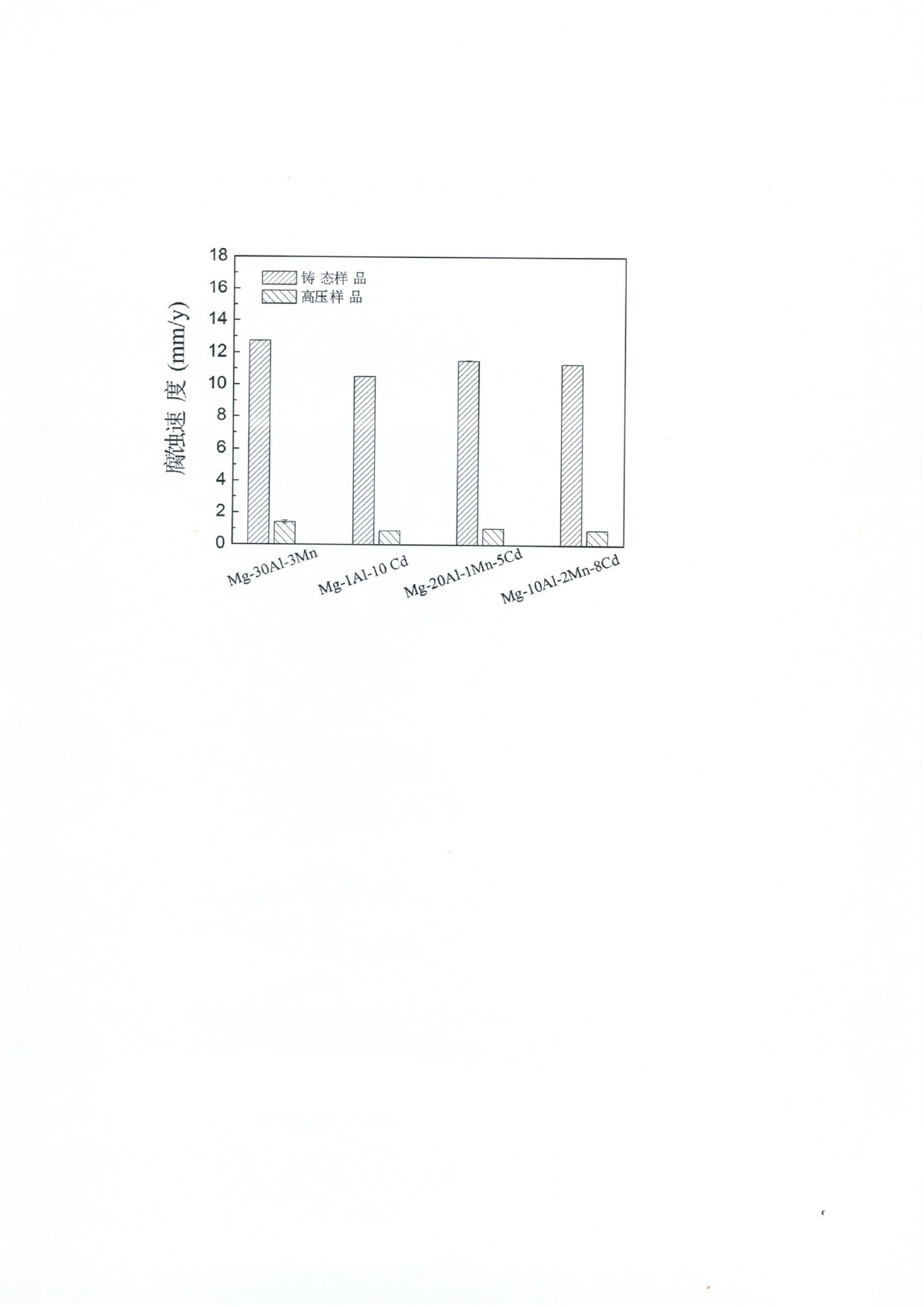

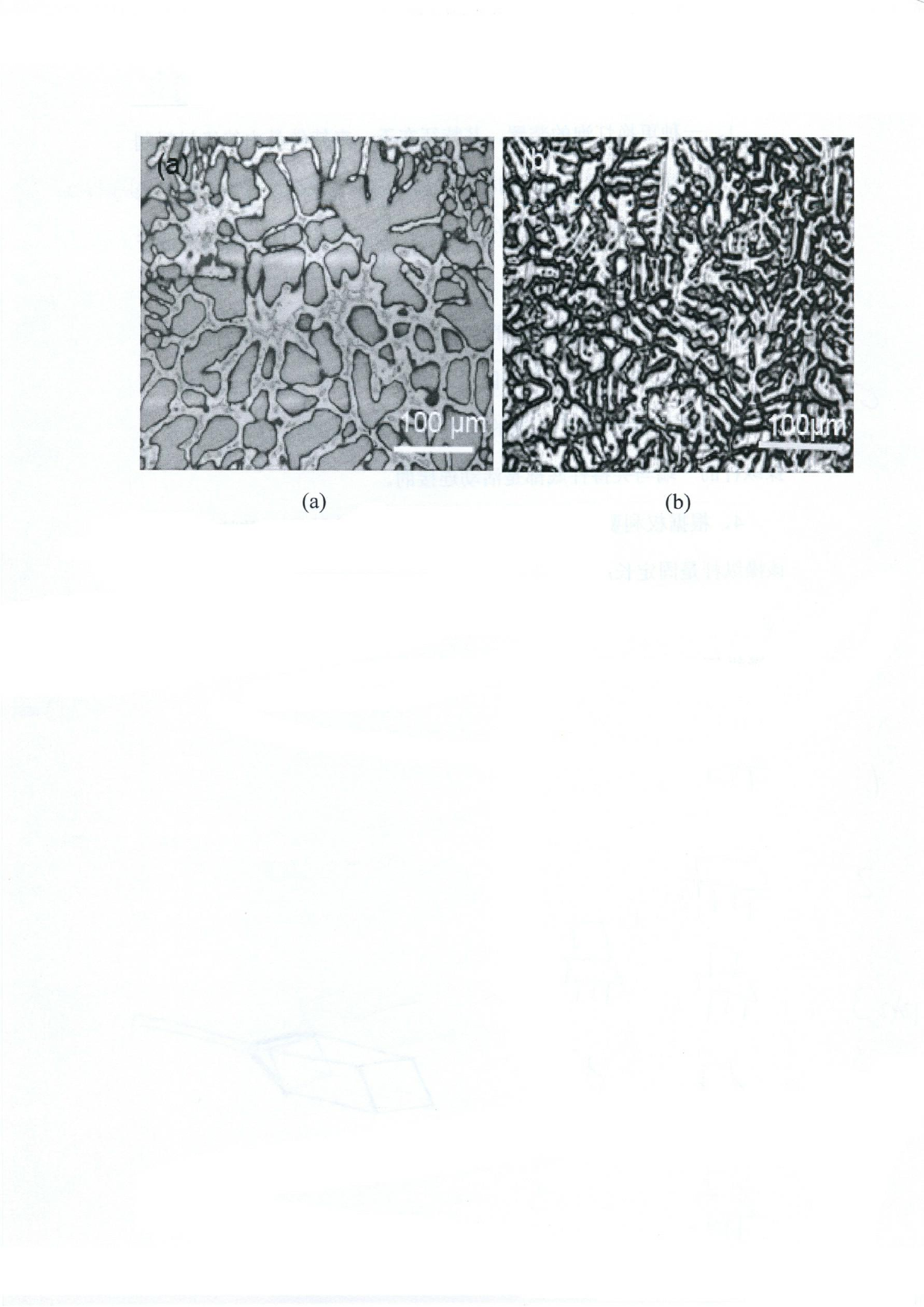

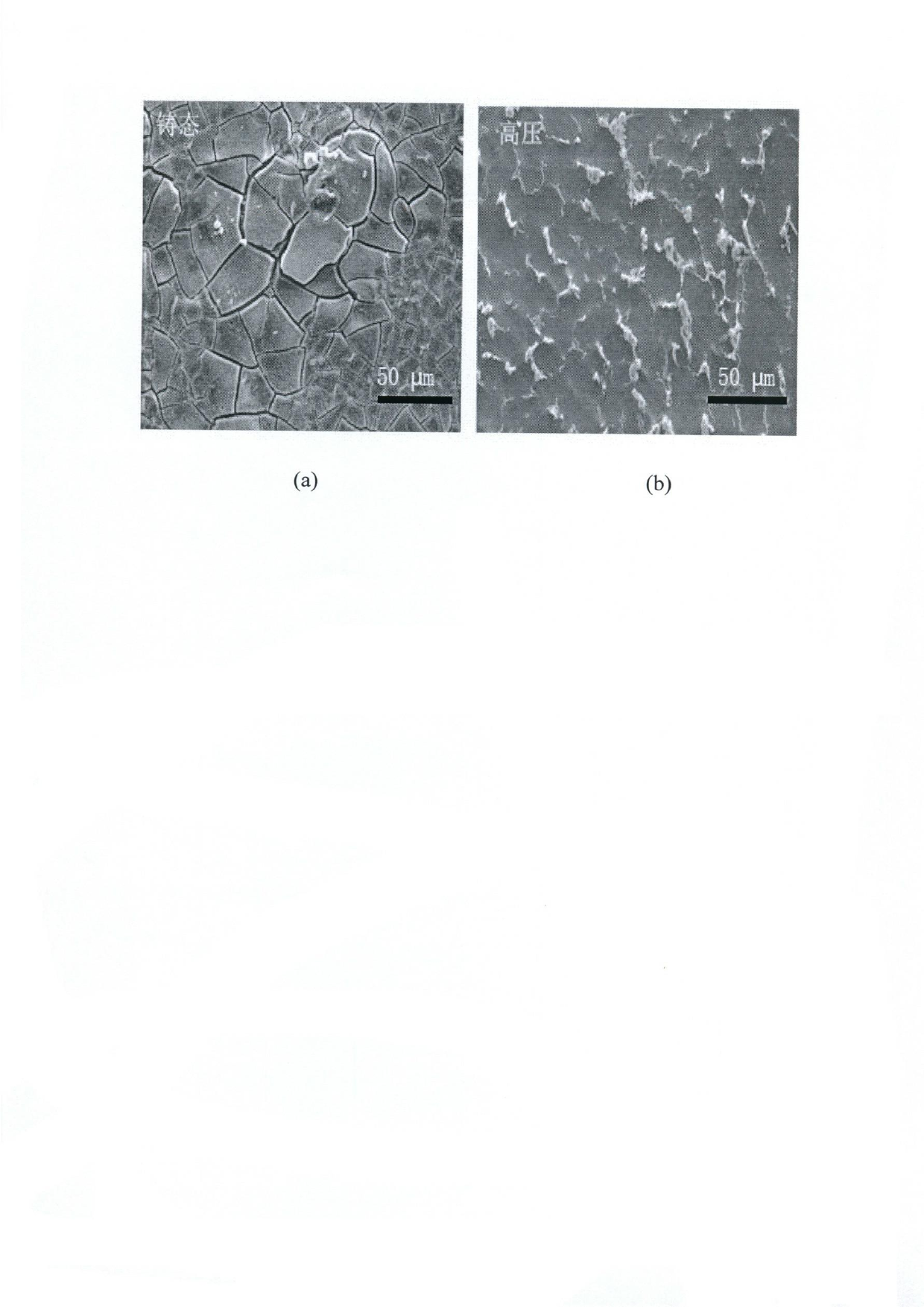

Anti-corrosion magnalium base alloy and preparation method thereof

The invention relates to an anti-corrosion magnalium base alloy of which the chemical composition is Mg-xAl-yMn-zCd, wherein x, y and z are mass fractions, x is 1-30%, y is 0-3%, and z is 0-10%. The preparation method comprises the steps that primary metal powder is pressed into blocks, plasma sintering is carried out for 5-10 minutes at the temperature of 400-520 DEG C and the pressure of 30MPa to obtain an alloy precursor; the alloy precursor is wrapped with tantalum foil and is fused at 2-10GPa and 1.1Tm (Tm is melting point), temperature is preserved for 30 minutes, and then nitrogen is blown for rapid solidification; and then at 0.1-0.2Tm, an magnesium alloy with high strength and outstanding corrosion resistance is obtained after 2-24 hours of aging. The magnalium base alloy and the preparation method thereof provided by the invention have the advantages that the process is simple, the cost is low, the corrosion resistance of the magnalium base alloy is improved by 10-12 times, the problem of surface layer destruction does not exist, and the application scope of the alloy is wider.

Owner:CITIC DICASTAL

High-temperature-resistant layered toughened tungsten-based composite material and preparation method thereof

ActiveCN108859318AImprove toughnessImprove performanceLamination ancillary operationsLaminationNiobiumBiological materials

The invention discloses a high-temperature-resistant layered toughened tungsten-based composite material and a preparation method thereof. The tungsten-based composite material comprises a plurality of stacked repeating units, wherein each repeating unit comprises a tungsten layer, a tantalum layer, a niobium layer, a tantalum layer and a tungsten layer which are sequentially stacked, and each twoadjacent repeating units share one tungsten layer. The preparation method comprises steps of (1) surface treatment, (2) molding, (3) sintering, and (4) demolding. The tungsten-based composite material has the advantages that a niobium foil and a tantalum foil form a toughening layer, a tungsten foil is arranged on both sides of the toughening layer as a base layer, toughening layers and base layers are alternately arranged like a biological material, and the toughness of the tungsten layer composite material is superior to that of pure tungsten; the layered toughened tungsten-based compositematerial has good comprehensive performance and has important practical significance for a first wall structure of a fusion reactor.

Owner:HEFEI UNIV OF TECH

Method for preparing multilayer nano composite material and super capacitor electrode sheet

InactiveCN107622877AIncrease contact areaHigh capacity densityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceThiourea

The invention provides a method for preparing a multilayer nano composite material and a super capacitor electrode sheet, which includes the following steps: first, mixing and adding molybdenum powderand hydrogen peroxide to thiourea solution and carrying out hydrothermal reaction to prepare a few layers of MoS2 nano material; then, mixing the MoS2 nano material and ruthenium-containing precursorat a specific ratio, and getting a MoS2 / RuO2 nano composite material for super capacitors after hydrothermal reaction; and finally, hot-pressing the composite nano material on an electrode made of tantalum foil. The nano composite material of the super capacitor electrode sheet is prepared by making use of the large specific surface area and excellent electrical conductivity of the nano MoS2 two-dimensional (2D) layered structure. The amount of ruthenium oxide used can be reduced. The disadvantages of high cost and poor cycle performance of electrode are overcome. The contact area between theelectrode material and electrolyte is increased, and therefore, the specific capacitance and power density of the super capacitor electrode are improved. Moreover, the method is simple to operate, does not require any complicated preparation device, and is suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-energy X-ray conversion targeting device

The invention provides a high-energy X-ray conversion targeting device which relates to high-energy physical technology. The device of the invention comprises multiple layers of tantalum foil and a fixing device, wherein the multiple layers of tantalum foil are arranged in parallel, each layer of tantalum foil is fixedly installed on the fixing device, and the space between every two layers of tantalum foil is vacuum. The invention has the beneficial effect that after pulse electron beams with strong current (kA), high power and MeV energy act with X-ray conversion targets, the generated pulse X-rays have strong irradiation dose (greater than 300 roentgens) and simultaneously have high resolution of mm order of magnitude.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

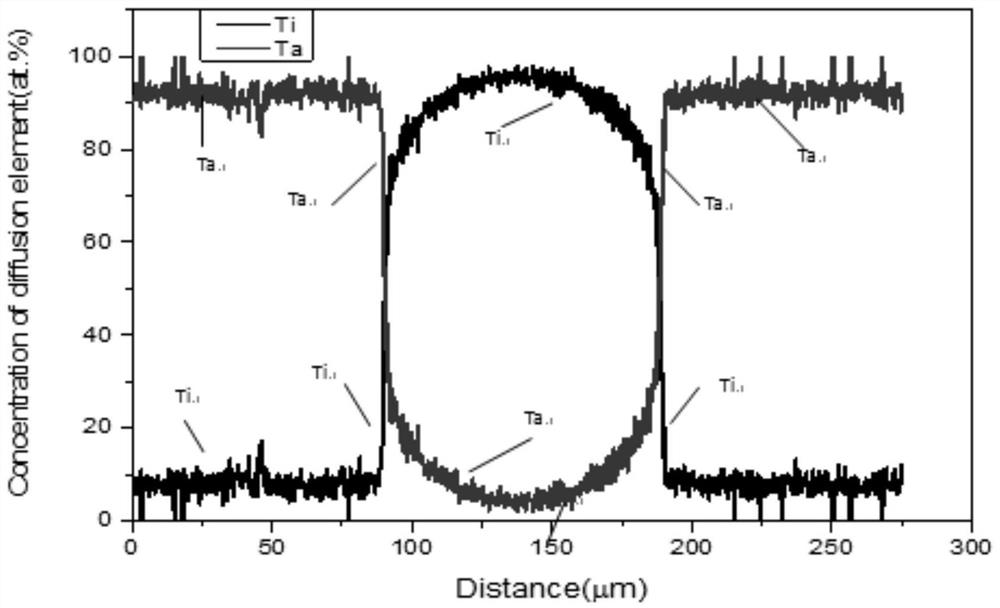

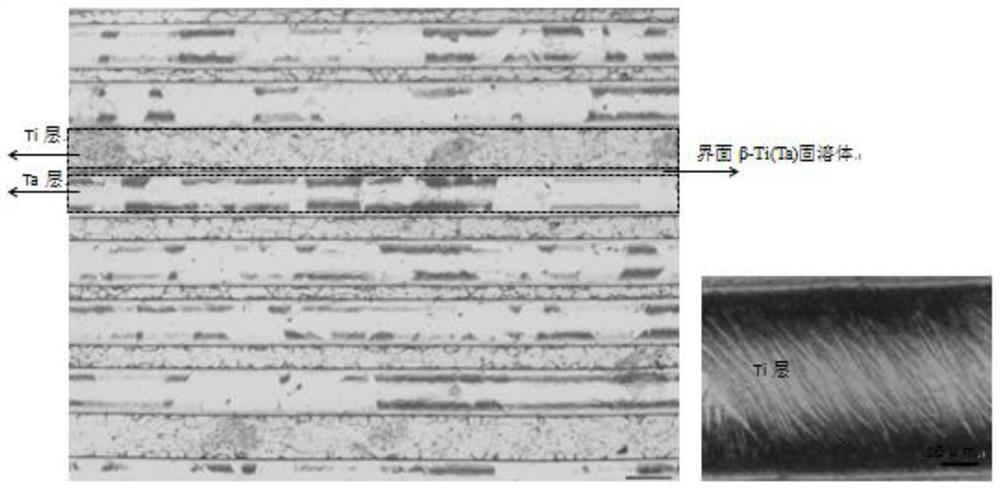

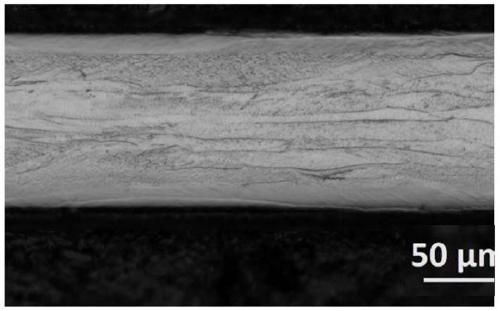

Gradient isomeric titanium-tantalum layered composite material and preparation method and application thereof

ActiveCN113183562AFix interface issuesGood mechanical propertiesLamination ancillary operationsLaminationAlloyUltimate tensile strength

The invention relates to the technical field of biomedical materials, in particular to a gradient isomerous titanium-tantalum layered composite material and a preparation method and application thereof. According to the titanium-tantalum layered composite material, by changing the thickness ratio of a titanium layer to a tantalum layer, component gradient distribution in the layered composite material is achieved, the tissue and performance of the layered composite material can be regulated, and a multi-layer layered structure with different structures is formed in the composite material, so that the strength and the toughness of the material are improved, and the elastic modulus is reduced. The specific method comprises the steps that: titanium foils and tantalum foils with different thicknesses are selected, titanium layers and tantalum layers are alternately stacked, the titanium foils and the tantalum foils with different thicknesses are connected through a diffusion connection method, the gradient isomeric titanium / tantalum layered composite material is prepared, the comprehensive mechanical property of the titanium-tantalum alloy is effectively improved, and meanwhile, the ductility can reach 28%. The preparation method can be used for regulating and controlling the structure and performance of the layered composite material, and has guidance meaning for improving and regulating and controlling the performance of the titanium-tantalum alloy used in the biomedical field.

Owner:HEFEI UNIV OF TECH

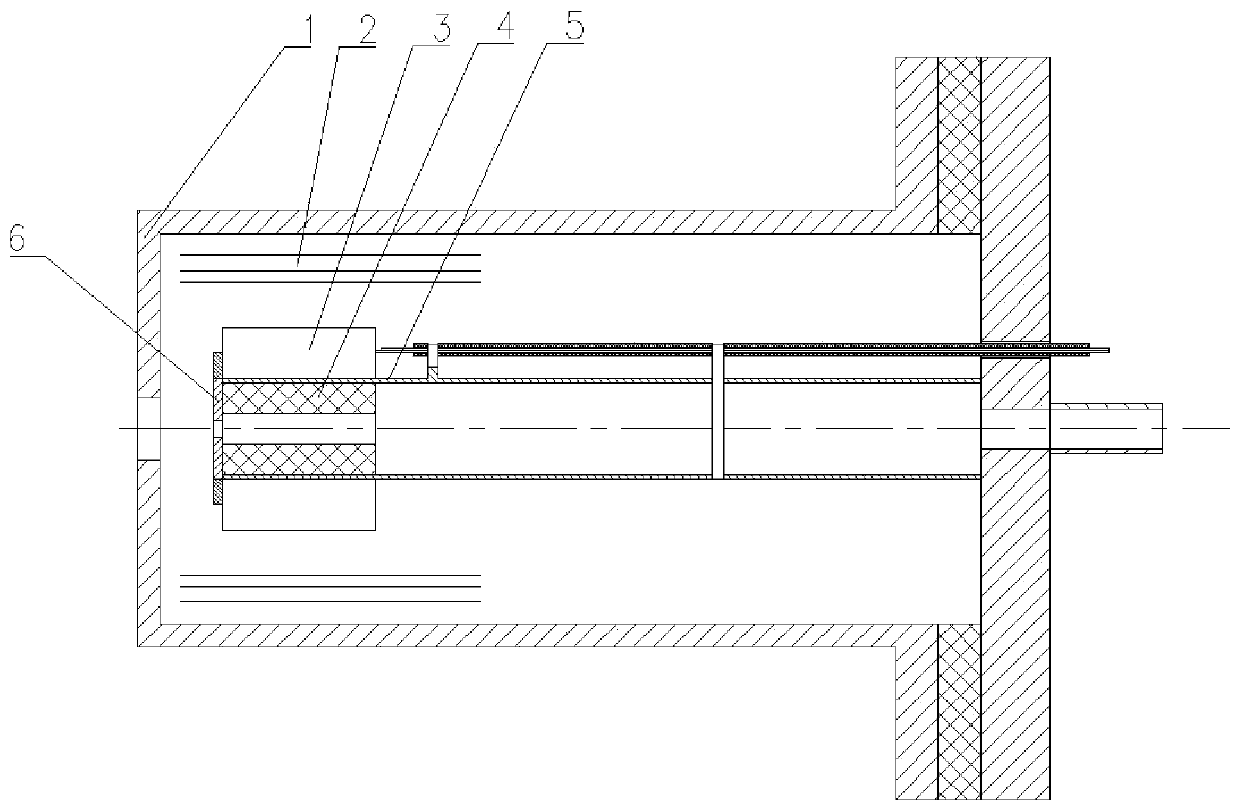

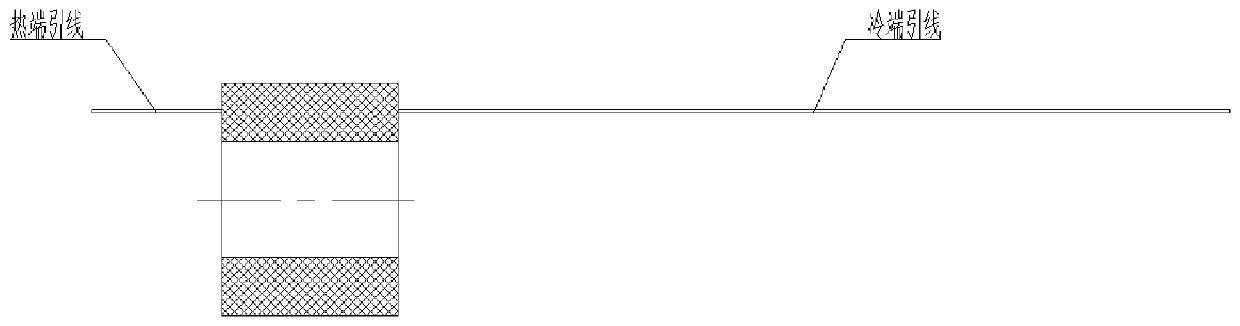

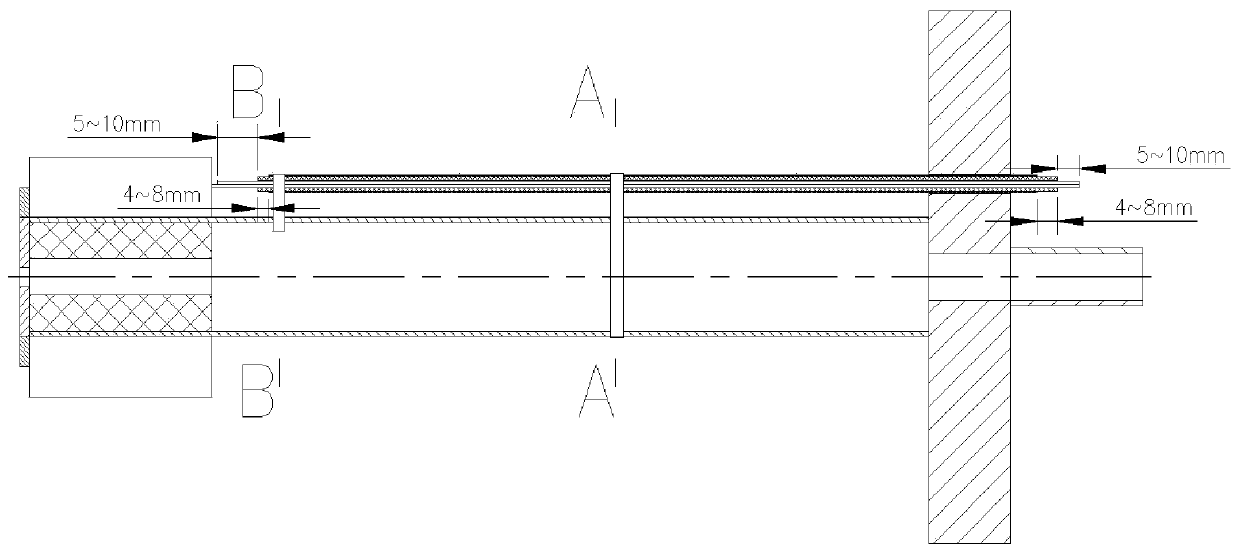

Lanthanum hexaboride hollow cathode heater heating wire cold end leading-out method

ActiveCN110335794AIncrease the equivalent conductive cross sectionLower resistanceMounting/support/spacing/insulation of electrode assembliesDischarge tube hollow cathodesSpot weldingLanthanum hexaboride

The invention provides a lanthanum hexaboride hollow cathode heater heating wire cold end leading-out method, which comprises the following steps: 1) at the heater heating wire cold end leading-out section, a plurality of metal wires and a heater heating wire are closely arranged side by side; 2) the metal wires arranged in parallel serve as a whole, and the outer surface of the metal wires is closely wrapped with multiple layers of tantalum foil, wherein the diameter obtained after wrapping of the tantalum foil is uniform, and the multiple layers of tantalum foil are fixed through spot welding; 3) the tantalum foil is coated with a single single-hole ceramic tube, wherein the ceramic tube cannot slide out freely; 4) the ceramic tube is externally sleeved by multiple layers of tantalum foil, wherein one part at each of the two ends of the ceramic tube is not wrapped with the tantalum foil, and the two layers of tantalum foil are fixed through spot welding; and 5) the cold end leading-out section is tightened and fixed to a cathode tube by utilizing a long-strip tantalum foil. The method can effectively reduce the power of the cold end leading-out section and reduce the temperatureof the cold end leading-out section, thereby preventing the heat from returning to the cold end, ensuring anti-mechanical properties of the cold end and preventing cold end leading-out wires from being broken in the satellite emission process.

Owner:BEIJING INST OF CONTROL ENG

Coiled polymer tantalum capacitor

PendingCN108597880AImprove securityGood temperature characteristicsSolid electrolytic capacitorsPolymer scienceChemical reaction

The invention provides a coiled polymer tantalum capacitor. The coiled polymer tantalum capacitor is prepared from the following steps of A. broaching on tantalum positive foil; B. cutting: first, cutting the broached and polished tantalum positive foil, second, cutting aluminum negative foil; and third, cutting electrolytic paper; C. connecting through a nail or winding: leading out positive andnegative poles; D. energizing: soaking, through applying DC voltage and current, in an energizing solution of certain temperature, such as phosphoric acid, and repairing a tantalum pentoxide layer; E.polymerizing a polymer cathode: soaking monomer and oxidant in the broached and polished tantalum sheet circularly, performing chemical reactions constantly under the conditions of constant humidityand constant temperature, so as to form a polymer cathode polymer layer; F. assembling: first, assembling a rubber tube, second, assembling a rubber cover, and third, assembling an aluminum shell; andG. charging and sorting. The coiled polymer tantalum capacitor has safer and more reliable performance, does not burn, and has lower equivalent serial resistance.

Owner:ZHUZHOU HONGDA ELECTRONICS

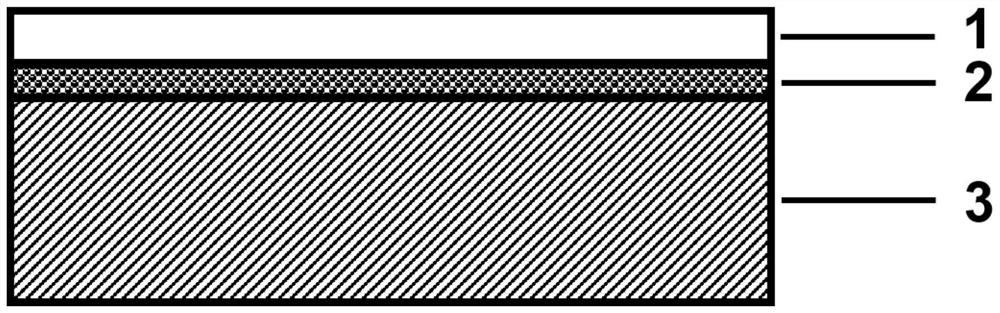

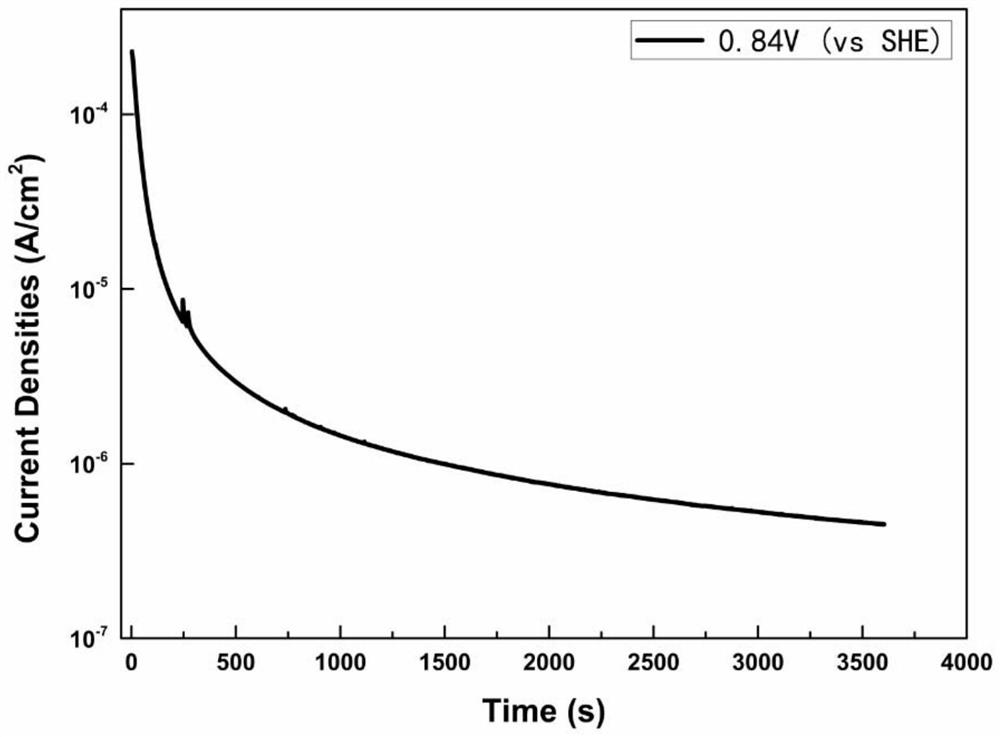

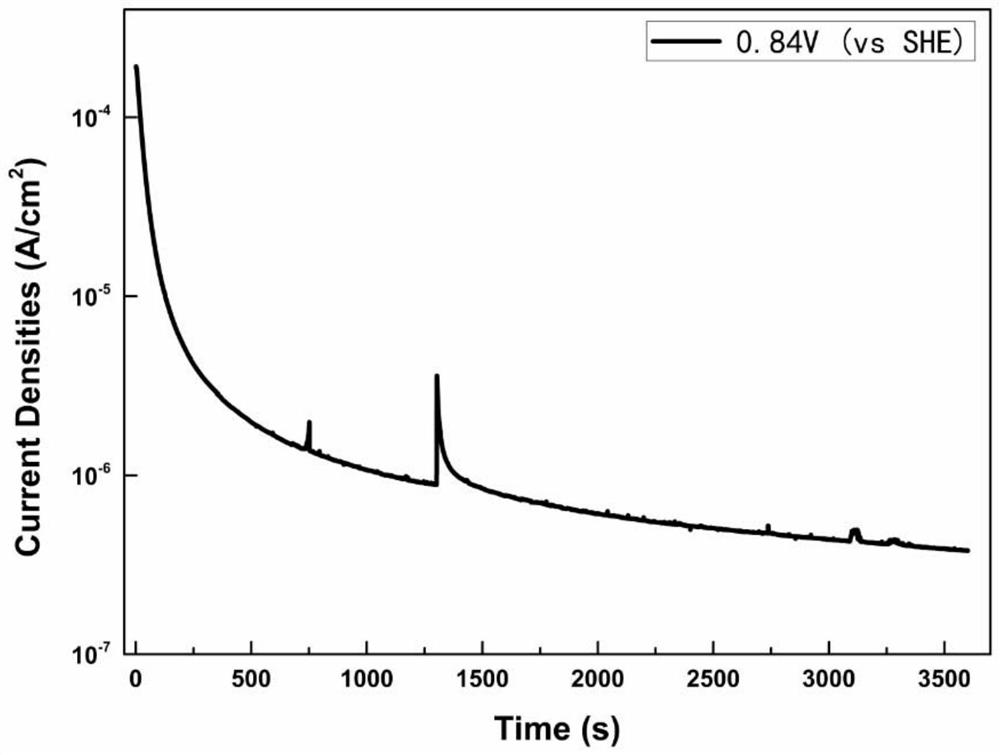

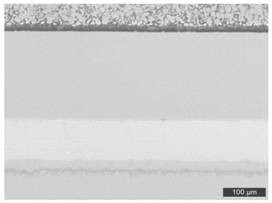

Corrosion-resistant coating for bipolar plate of fuel cell and preparation method of corrosion-resistant coating

ActiveCN112310429AGuarantee normal performanceReduce corrosion rateFuel cellsFuel cellsTantalum foil

The invention relates to a corrosion-resistant coating for a bipolar plate of a fuel cell and a preparation method of the corrosion-resistant coating. The corrosion-resistant coating comprises a conductive colloid layer coating the surface of a metal polar plate, and a tantalum foil layer arranged on the conductive colloid layer. Compared with the prior art, the tantalum foil is used for preventing the metal bipolar plate from being in contact with a corrosive medium in a battery environment, so the polar plate is effectively protected, and a corrosion speed in the battery environment can be reduced to 10<-8>-10<-7>A / cm<2>; and meanwhile, by utilizing the excellent conductivity of the conductive colloid and tantalum metal, the contact resistance is about 5-30 m omega cm<2> under 1.4 Mpa, and the performance of the bipolar plate of the fuel cell is ensured to be exerted. The preparation method is simple and efficient.

Owner:SHANGHAI JIAO TONG UNIV

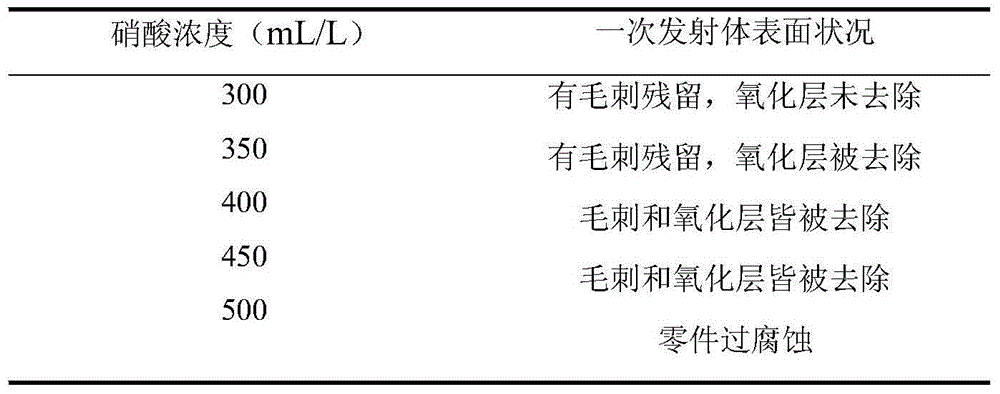

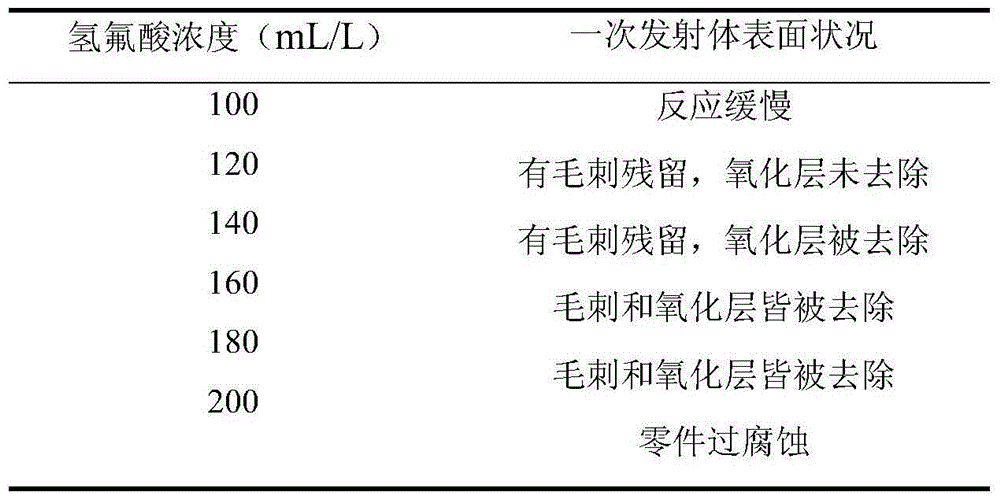

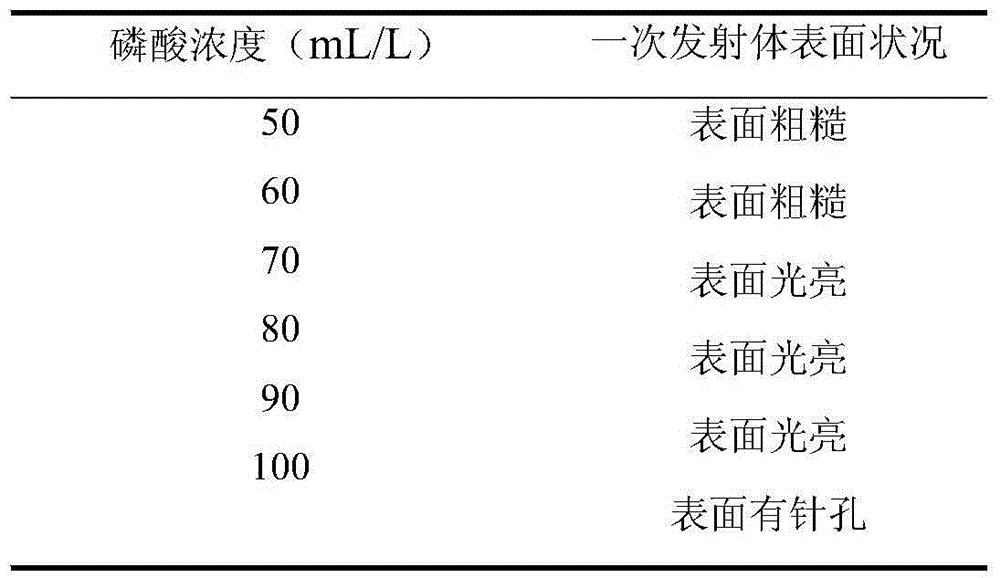

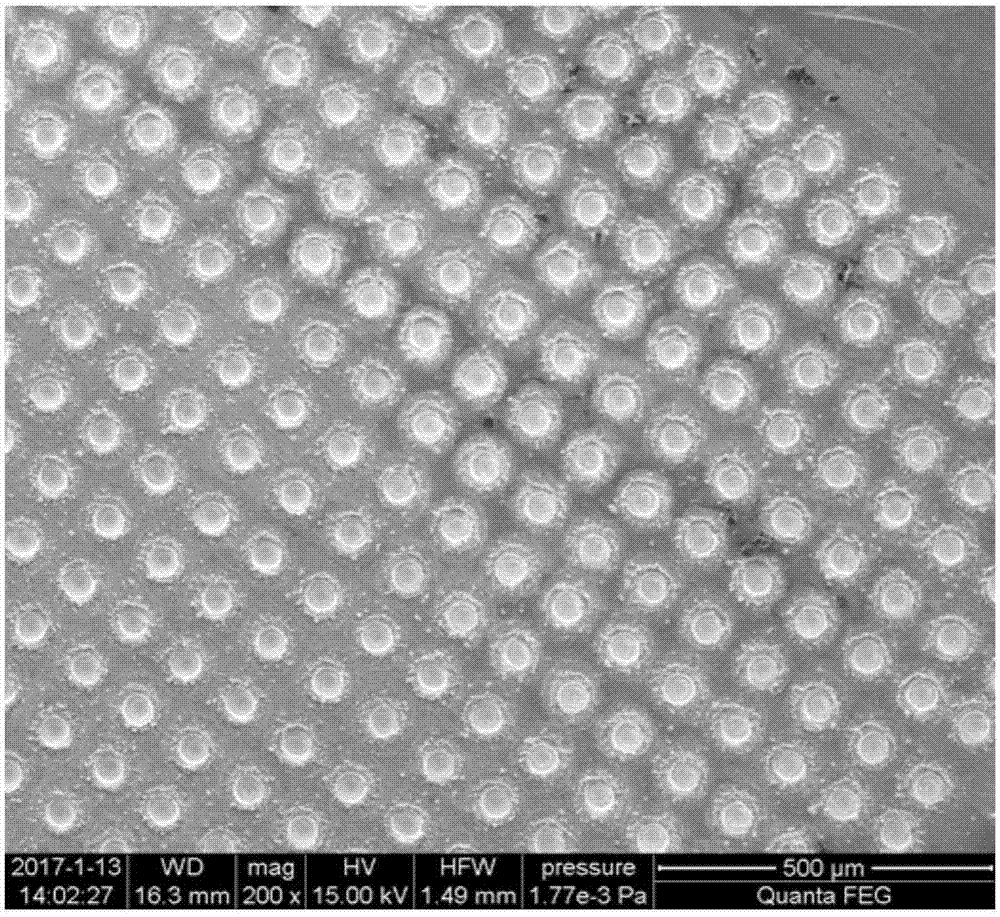

Solution for electrochemical deburring and oxide layer removal of tantalum-foil material primary emitter for magnetron and deburring method

The invention discloses a solution for electrochemical deburring and oxide layer removal of a tantalum-foil material primary emitter for a magnetron and a deburring method. The solution is prepared from the following raw materials: 400mL / L to 450mL / L of nitric acid, 160mL / L to 180mL / L of hydrofluoric acid, 70mL / L to 90mL / L of phosphoric acid, 10mL / L to 15mL / L of glycerol, and 0.3g / L-0.4g / L of lauryl sodium sulfate. According to the structural characteristic that the thickness of the tantalum-foil material primary emitter of the magnetron is only 10-20 microns, the composition and concentration of an electrolyte are screened by use of lots of experiments; the electrolyte is capable of well removing the burrs and oxide layers on the edges and surface of the tantalum-foil material primary emitter for the magnetron and capable of meeting the assembly requirements of the high-precision cathode emitter, and has an important application value; as a result, the defects of the prior art can be solved.

Owner:NANJING SANLE GROUP

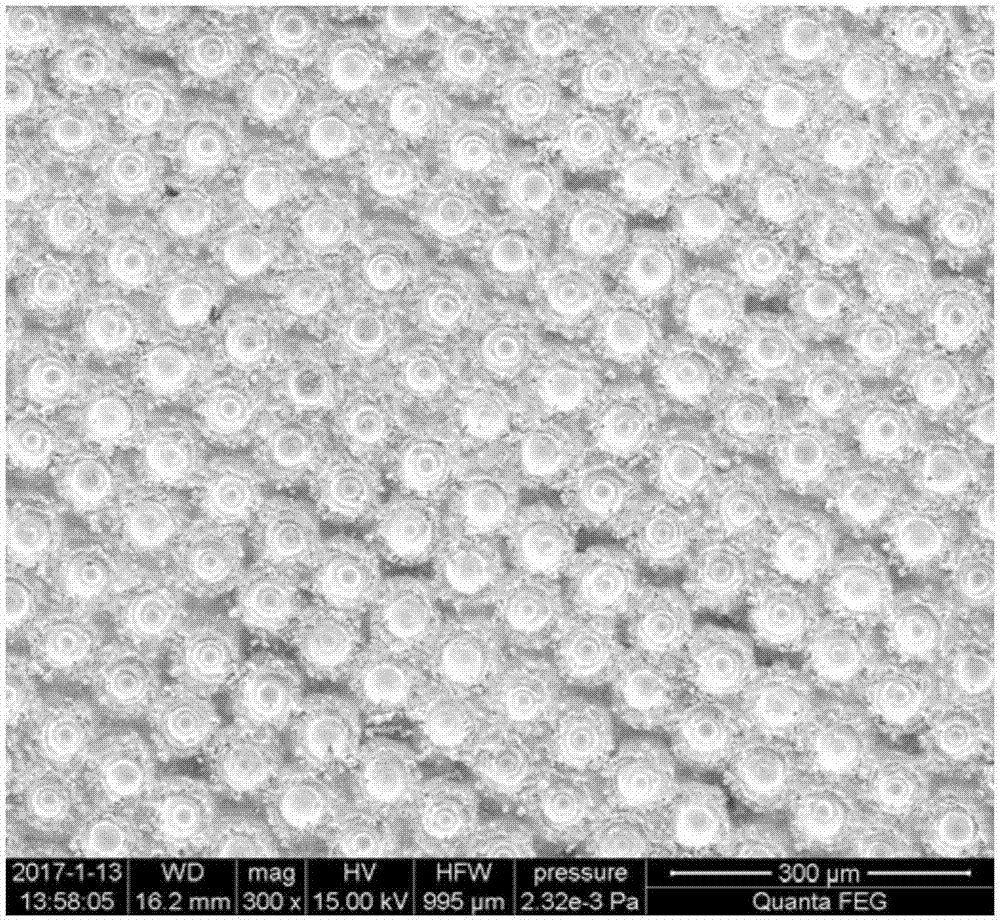

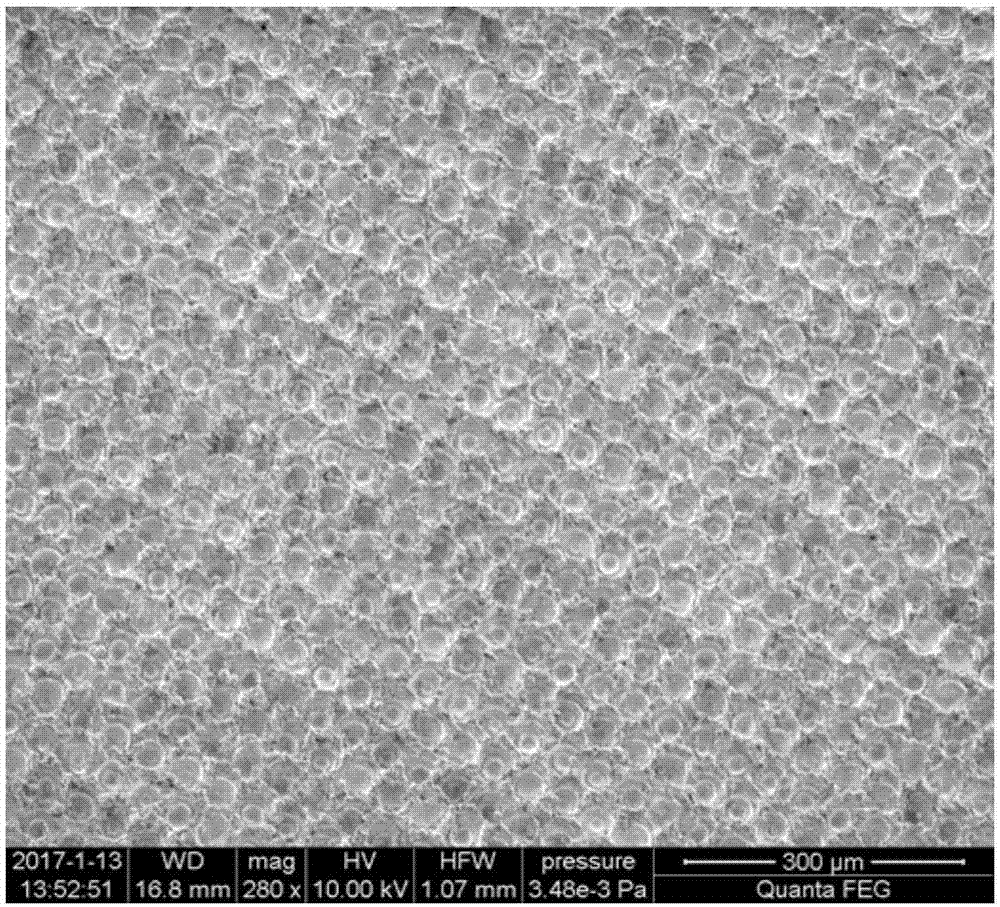

Ordered pore array anode tantalum foil for tantalum capacitors and preparation method thereof

InactiveCN106910635AIncrease capacityIncrease surface areaSolid electrolytic capacitorsTantalum capacitorHigh energy laser

The invention provides an ordered pore array anode tantalum foil for tantalum capacitors and a preparation method thereof. Tantalum sheets with different thickness as a main material are irradiated with high-energy laser, and an ordered pore array in uniform distribution is obtained very simply on the surface of tantalum. The surface area is increased greatly, and the capacity of tantalum capacitors prepared eventually will be greatly improved. The anode tantalum foil of the invention can be made into any shape such as sheet and coil, and better satisfies the requirement for thin and high-capacity components in modern times.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

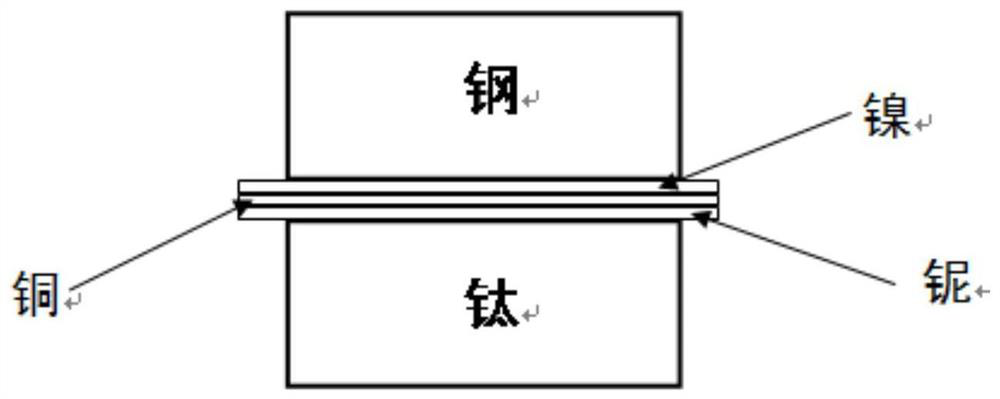

A kind of titanium-steel alloy high-strength diffusion joining method

ActiveCN110238504BHigh strengthReduce distortionWelding/soldering/cutting articlesNon-electric welding apparatusManufacturing technologyTitanium

The invention relates to a titanium-steel alloy high-strength diffusion connection method, which belongs to the field of welding technology. The method of the present invention includes: adding a composite intermediate layer between the welding surfaces of the titanium alloy weldment and the steel alloy weldment, and then placing it in a vacuum diffusion furnace for diffusion connection, so that the titanium alloy weldment and the steel alloy weld The components are connected into an integral structure through a composite intermediate layer, wherein the composite intermediate layer is made of nickel foil, copper foil and niobium foil. By using nickel, copper, and niobium as the composite intermediate layer for diffusion connection with titanium alloy and steel alloy, the connection strength between titanium alloy and steel alloy is improved, and it can meet the manufacturing technical requirements of aviation, aerospace and other high-end equipment fields.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

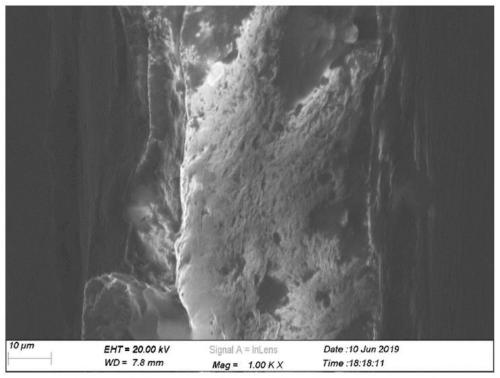

Preparation method of copper-tantalum composite wire with high strength and high conductivity

The invention discloses a preparation method of a copper-tantalum composite wire with high strength and high conductivity. The method comprises the steps of (1) overlapping a pure tantalum foil and ananaerobic copper foil, jointly winding on a central copper rod, and forming a densely arranged winding copper foil-tantalum foil composite; (2) loading the copper foil-tantalum foil composite into acopper sleeve body, vacuum seal welding, and carrying out isostatic cool pressing treatment and hot extrusion processing, so as to obtain an extrusion composite rod; (3) drawing to obtain a compositecore rod; (4) after sizing and cutting, straightening and acid pickling, loading a multi-core bundle into a copper pipe, carrying out hot extrusion and drawing processing, and cooperating with intermediate annealing, so as to obtain the copper-tantalum composite wire with high strength and high conductivity. According to the preparation method of the copper-tantalum composite wire with high strength and high conductivity provided by the invention, the copper foil and the tantalum foil are selected as raw materials, so that the plastic deformation degree of tantalum is greatly reduced, a Cu / Tainterface is remarkably increased, the advantages of the high shear modulus and the high strength of the tantalum are fully played, the mechanical property of the wire is further improved, and the copper-tantalum composite wire with high strength and high conductivity can be applicable to a high field pulse magnet.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Welding method of super-high voltage short arc mercury conductive molybdenum foil and super-high voltage short arc mercury lamp

InactiveCN102237232AAvoid safety hazardsExtend your lifeGas discharge lampsElectrode assembly manufactureNiobiumUltra high voltage

The embodiment of the invention discloses a welding method of a super-high voltage short arc mercury conductive molybdenum foil. In the method, the molybdenum foil is welded and connected with a metal rod including a gasket or a molybdenum cup; the method comprises the following steps of: fixing the gasket or the molybdenum cup on the metal rod and fixing the molybdenum foil on the gasket or the molybdenum cup by using a welding material, wherein the welding material at least comprises one of a tantalum foil or niobium. The embodiment of the invention also discloses a super-high voltage short arc mercury lamp. According to the welding method for connecting the super-high voltage short arc mercury conductive molybdenum foil with an electrode and the super-high voltage short arc mercury lamp, provided by the embodiment of the invention, by using the welding material tantalum foil or niobium, the conductive molybdenum foil is firmly connected with the gasket or the molybdenum cup through spot welding or other means so that the current can be conducted to the electrode in the lamp from outside of the lamp through the conductive molybdenum foil; simple process structure is obtained, the reliability of a welding part is assured and the service life of the product and the safety in use are improved.

Owner:ORC ADVANCED SPECIALTY LIGHTING SHENZHEN

Metal evaporation device applied to evaporation coatings

InactiveCN105624612AIncrease temperatureImprove efficiencyVacuum evaporation coatingSputtering coatingTantalum foilCoating

The invention discloses a metal evaporation device applied to evaporation coatings. The metal evaporation device comprises a ceramic sealing electrode and a main metal evaporation body, the main metal evaporation body comprises a main body support formed by penetrating through three or more aluminum oxide ceramic wafers through a plurality of supporting screw rods, a ceramic pipe is arranged outside the main body support in a sleeving mode, electrode columns are arranged on one aluminum oxide ceramic wafer of the main body support in a penetrating mode, a crucible is arranged on another aluminum oxide ceramic wafer of the main body support, heating wires are wound between two adjacent aluminum oxide ceramic wafers and axially surround the outer wall of the crucible, and the ceramic sealing electrode is connected to the electrode columns in a communication mode. According to the device, the tantalum heating wires or the tungsten heating wires are adopted as heating media, high temperature can be realized, the heating speed is high, and the energy consumption is small; a thermocouple is additionally arranged, the temperature can be visually monitored in the heating process, and material evaporation can be well controlled; evaporation material in the crucible does not make contact with the heating wires, so that the service life is prolonged; a tantalum foil layer is arranged, has the heat preservation and heat insulation effect and can lower the heat energy loss in the heating process.

Owner:SUZHOU FANGSHENG OPTOELECTRONICS CO LTD

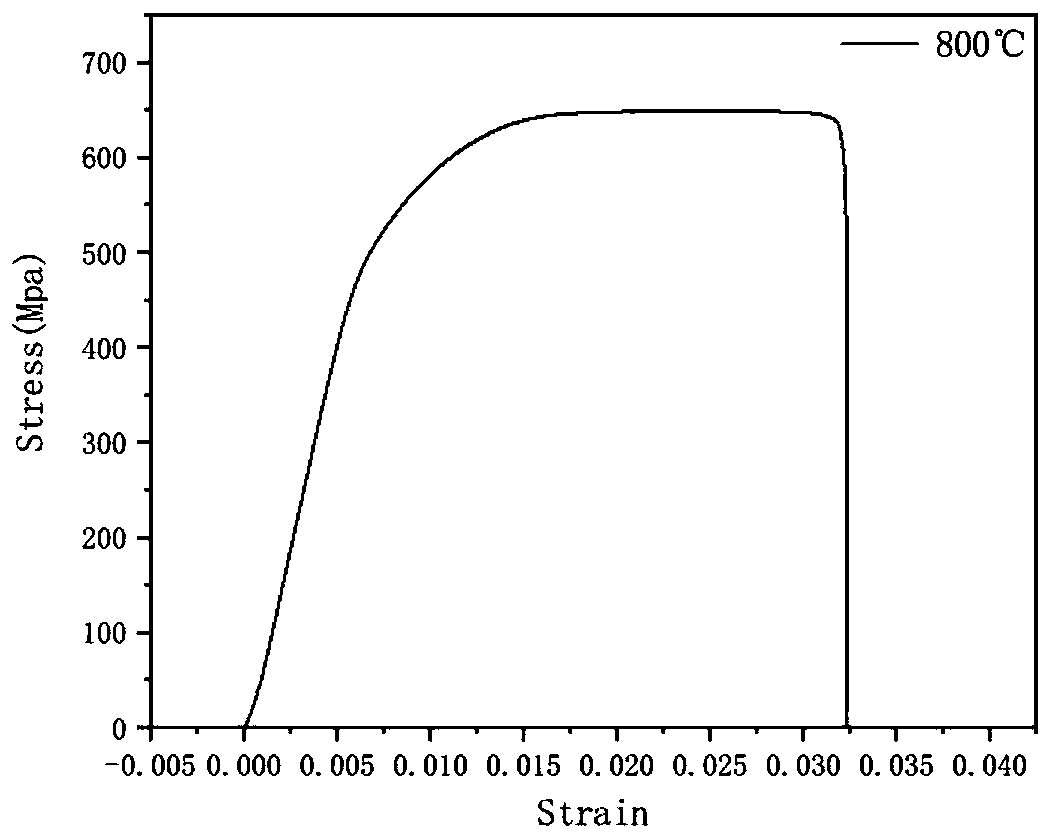

Annealing and strengthening technological method for rolled pure tantalum foil

ActiveCN111440938AHigh tensile strengthImprove plastic deformationFurnace typesHeat treatment furnacesMetallurgyTantalum foil

The invention discloses an annealing and strengthening technological method for a rolled pure tantalum foil. The method comprises: surface treatment; vacuum packaging; and vacuum annealing treatment of rolled pure tantalum foil, wherein the rolling deformation of the rolled pure tantalum foil is not less than 50%, an annealing temperature is 700 DEG C-850 DEG C, holding time is 1 h-1.5 h, and aircooling is performed after the heat preservation is completed. The annealing method of rolled tantalum foil disclosed by the present invention can significantly improve the tensile strength of rolledpure tantalum foil and the plastic deformation, indicating that mechanical properties of the rolled tantalum foil can be improved through an annealing process of the present invention.

Owner:HEFEI UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com