Corrosion-resistant coating for bipolar plate of fuel cell and preparation method of corrosion-resistant coating

A fuel cell and bipolar plate technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of equipment with limited product size, difficult to guarantee the quality of the film layer, leakage of metal substrates, etc., to avoid contact with corrosive media, preparation The method is simple and efficient, and the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

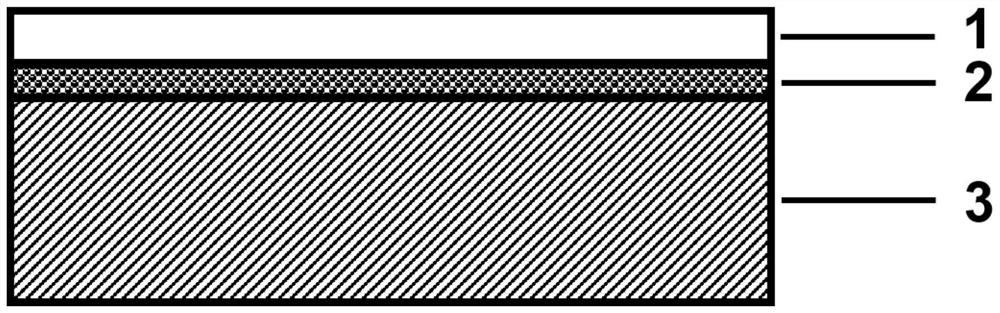

[0036] This embodiment provides a method for preparing a corrosion-resistant coating for a fuel cell bipolar plate, including:

[0037] 1) Pretreatment of the metal plate 1: cleaning the pure magnesium bipolar plate with ultrasonic vibration using acetone and absolute ethanol in sequence.

[0038] 2) Preparation of the conductive colloid layer 2: apply the conductive colloid layer 2 on the surface of the metal plate 1 with a scraper, and the coating thickness is 30 μm;

[0039] 3) Hydrophobic carbon fiber cloth layer: cut 40μm thick tantalum foil to 1cm 2 Attached to the surface of the conductive colloid layer 2 to form a tantalum foil layer 3 .

[0040] 4) Apply a pressure of 10-50N (20N in this embodiment) on the surface of the tantalum foil layer 3 to fully contact the conductive colloid layer 2 with the tantalum foil layer 3 .

[0041] 5) Put the metal pole plate 1 coated with anti-corrosion coating into a drying oven, set the temperature at 140-160°C (150°C in this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com