Coiled polymer tantalum capacitor

A technology of tantalum capacitors and polymers, applied in the field of winding polymer tantalum capacitors, can solve the problems of large change in resistivity of liquid electrolyte, low unit price, and liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

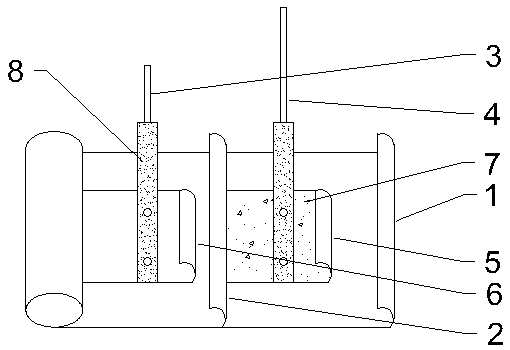

[0015] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , the winding polymer tantalum capacitor described in this embodiment, the purity of tantalum in the tantalum sheet material in the capacitor is controlled above 99.99%, and its production process includes the following steps:

[0016] 1) Among them, the hole expansion of positive tantalum foil is the core process, including electrochemical, chemical, and physical methods of hole expansion. Higher specific surface area and lower ESR can be produced by hole expansion. Electrochemical methods include constant current, constant voltage and other methods, chemical methods include corrosion of fluorine-containing compounds such as hydrofluoric acid, and physical methods include laser, mechanical perforation, etc. Reaming is a combination of one or several methods in order to achieve the best reaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com