Visible light response type photocatalytic material of tantalum nitride modified by cobalt and preparation method thereof

A catalytic material and visible light technology, applied in the field of photocatalytic materials, can solve the problems of reduced catalyst activity and stability, and achieve the effects of good visible light responsiveness, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Pure tantalum foil (2cm*2cm) was ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence; 5 Dissolve in methanol, make the precursor solution A that concentration is 10mM; Co(NO 3 ) 2 Dissolve in methanol to prepare precursor solution B with a concentration of 10 mM. Pipette 30 μL of precursor solution A onto the tantalum foil and air-dry at room temperature. After repeating 9 times, pipette 30 μL of precursor solution B onto the tantalum foil and air-dry at room temperature. The dripped sample was put into a tube furnace, and was annealed at 850°C in an anhydrous ammonia atmosphere with a flow rate of 80mL / min for 2h to obtain Ta 0.9 co 0.1 N 1.5 film.

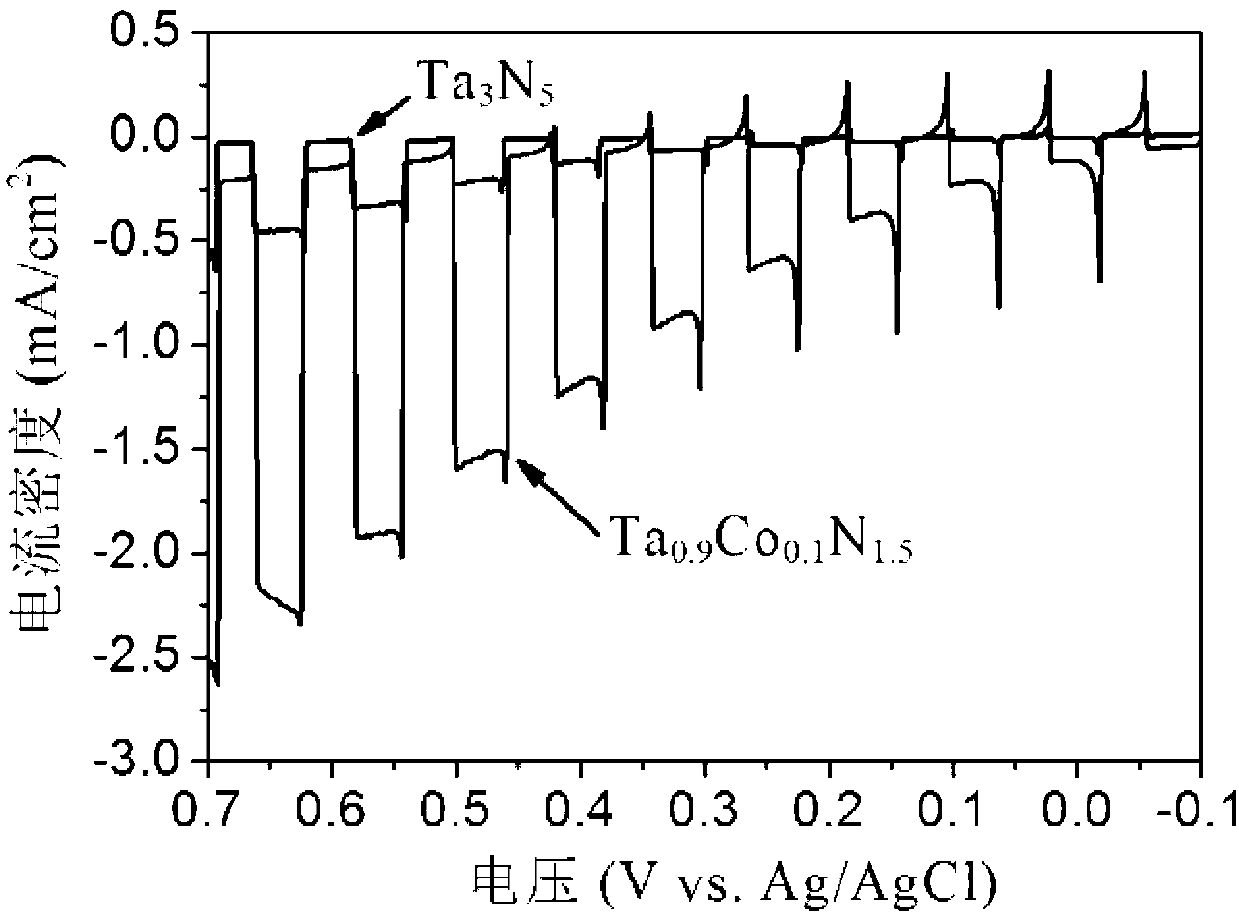

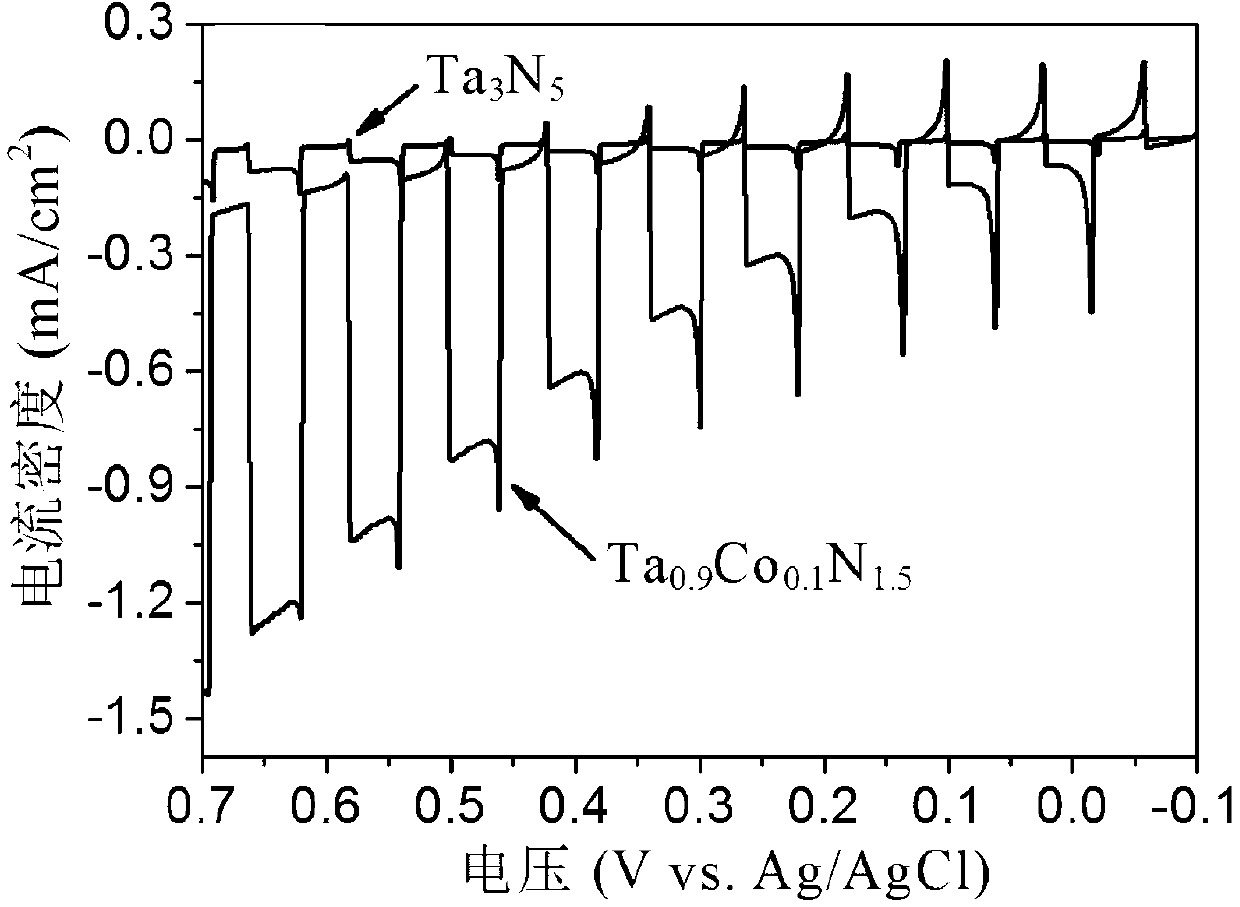

[0045] Figure 1a For Ta 3 N 5 and Ta 0.9 co 0.1 N 1.5 The linear scanning voltammetry curve of the film under the irradiation of ultraviolet and visible light; Figure 1b For Ta 3 N 5 and Ta 0.9 co 0.1 N 1.5 The linear scanning voltammetry curve of the thin film under visi...

Embodiment 2

[0047] Pure tantalum foil (2cm*2cm) was ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence; 5 Dissolve in methanol, make the precursor solution A that concentration is 10mM; Co(NO 3 ) 2 Dissolve in methanol to prepare precursor solution B with a concentration of 10mM. Pipette 30 μL of precursor solution A onto the tantalum foil, air-dry at room temperature, repeat 6 times, pipette 30 μL of precursor solution B onto the tantalum foil, repeat 4 times, and then air-dry at room temperature. The dripped sample was put into a tube furnace and annealed at 850 °C in an anhydrous ammonia atmosphere with a flow rate of 100 mL / min for 2 h to obtain Ta 0.6 co 0.4 N 1.1 film.

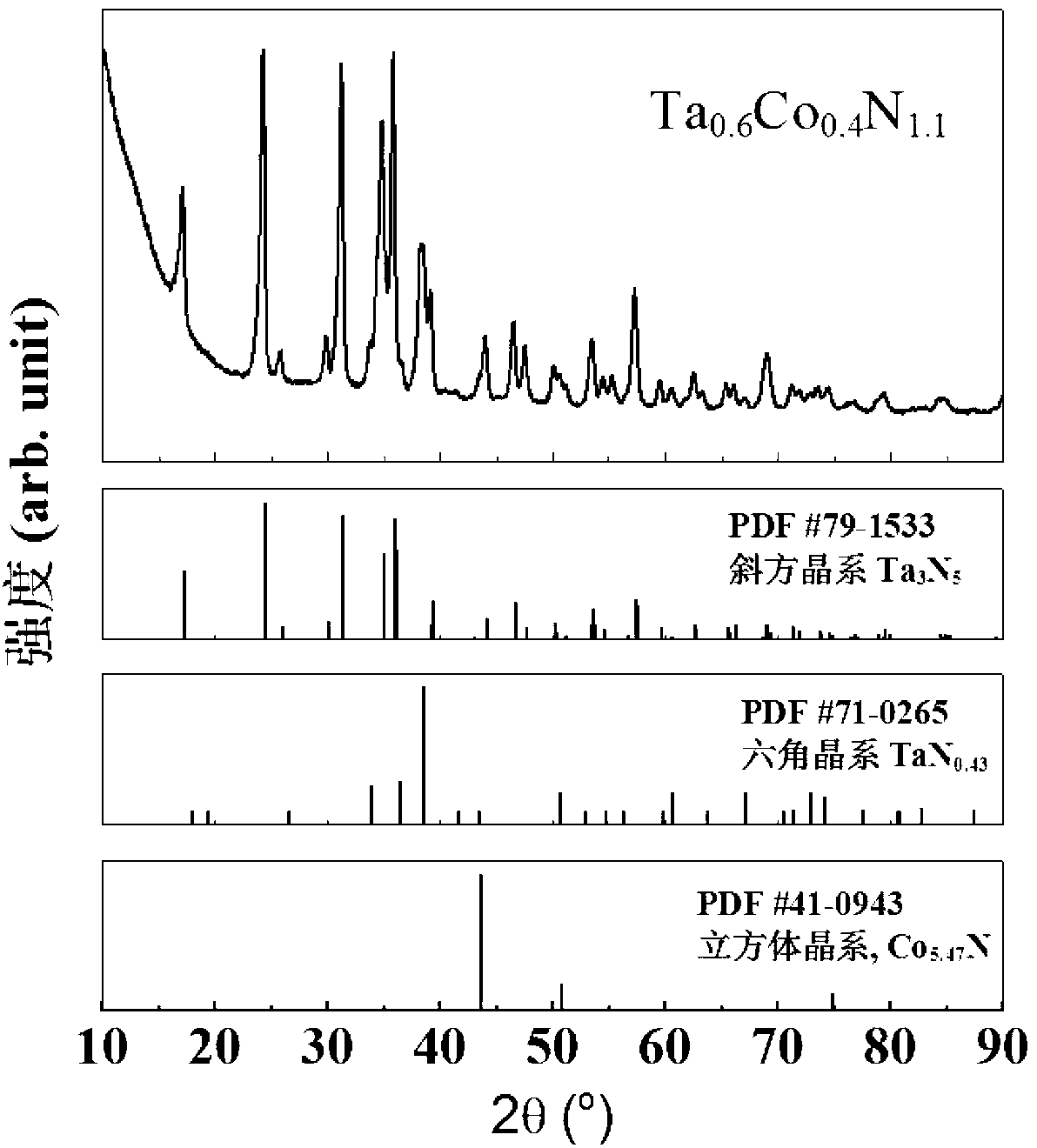

[0048] figure 2 For Ta 0.6 co 0.4 N 1.1 The GIXRD diagram of the film, given by figure 2 It can be seen that the main component of cobalt-modified tantalum nitride photocatalytic material is Ta 3 N 5 and Co 5.47 N, due to the use of tantalum foil as the substrate, am...

Embodiment 3

[0050] Pure tantalum foil (2cm*2cm) was ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence; 5 Dissolve in methanol, make the precursor solution A that concentration is 10mM; Co(NO 3 ) 2 Dissolve in methanol to prepare precursor solution B with a concentration of 10 mM. Pipette 30 μL of precursor solution A onto the tantalum foil, air-dry at room temperature, repeat 8 times, pipette 30 μL of precursor solution B onto the tantalum foil, repeat 2 times, and then air-dry at room temperature. The dripped sample was put into a tube furnace, and annealed at 800 °C in an anhydrous ammonia atmosphere with a flow rate of 100 mL / min for 4 h to obtain Ta 0.8 co 0.2 N 1.4 film.

[0051] Figure 4a for the same Ta 3 N 5 The linear scanning voltammetry curve repeated 3 times under the irradiation of ultraviolet-visible light; Figure 4b the same Ta 0.8 co 0.2 N 1.4 The linear scanning voltammetry curves of the film repeated three scans under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com