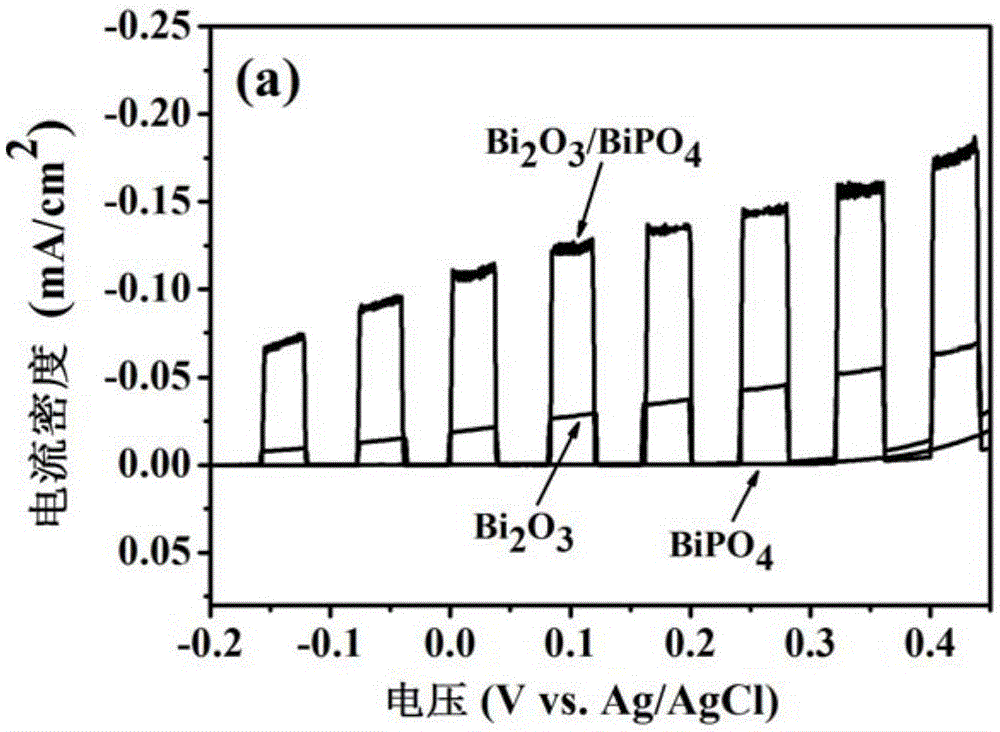

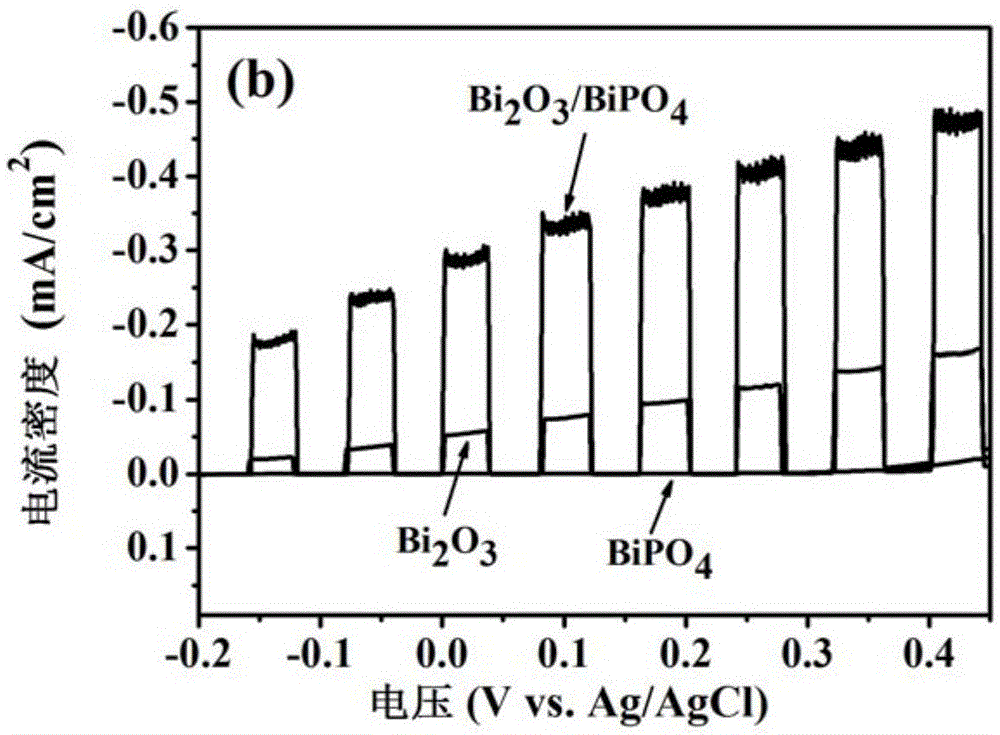

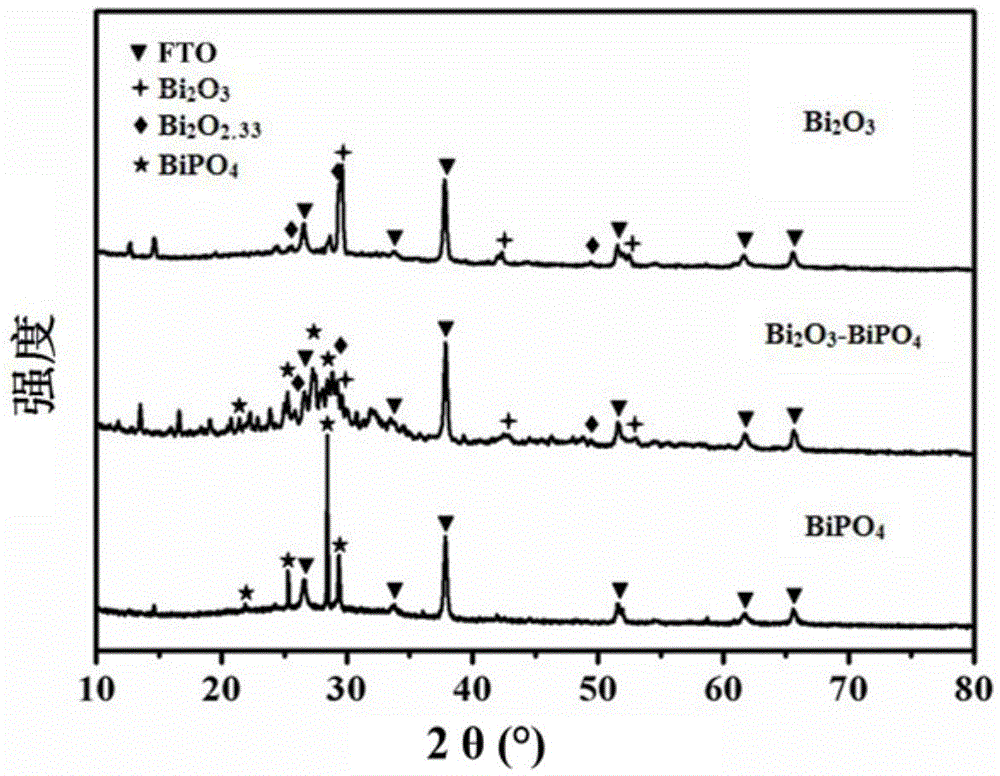

A p-n type bi 2 o 3 /bipo 4 Heterojunction visible light responsive photocatalytic thin film material and preparation method thereof

A thin film material, visible light technology, applied in the field of photocatalytic materials, can solve problems such as reducing the degree of electron-hole recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The FTO with a size of 10 mm × 50 mm × 2 mm was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 5 minutes in sequence, and then it was taken out to dry and placed flat for use.

[0059] (1) BiPO 4 Preparation of powder: 5ml containing 2mmol of Bi(NO 3 ) 3 with 2mmolNH 4 h 2 PO 4 The ethylene glycol solution was dissolved in 65 ml of distilled water. A homogeneous solution A was formed by magnetic stirring, and placed in air for 12h. After precipitation, cleaning, drying, calcination at 900°C for 2 hours, and grinding, the white BiPO 4 powder.

[0060] (2) Precursor BiPO 4 Preparation of thin film: mix 12mgKI with 48mgBiPO 4 The powder was dissolved in 30ml of acetone, and after stirring and ultrasonication, a uniform colloidal solution B was formed as the electrolyte solution. After the conductive substrate was cleaned and dried, it was used as the cathode and the anode respectively, and electrophoretic deposition was carried out ...

Embodiment 2

[0072] Repeat the operation steps of embodiment 1, difference is that Bi 2 o 3 / BiPO 4 The electrodeposition time in solution C was reduced to 5 min during the preparation of the thin film.

[0073] Bi prepared under the conditions of this example 2 o 3 / BiPO 4 The RhB decolorization rate of the film was 60%.

Embodiment 3

[0075] Repeat the operation steps of embodiment 1, difference is that Bi 2 o 3 / BiPO 4 The electrodeposition time in solution C was reduced to 1 min during the film preparation.

[0076] Bi prepared under the conditions of this example 2 o 3 / BiPO 4 The RhB decolorization rate of the film was 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com