High-energy X-ray conversion targeting device

A light conversion, high-energy technology, applied in the direction of X-ray tube electrodes, X-ray tube parts, etc., can solve the problems affecting X-ray resolution and exposure, and achieve high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

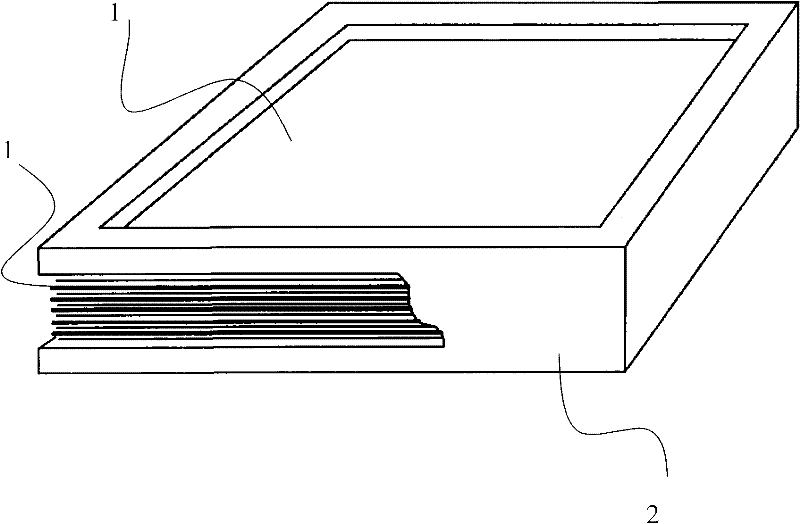

[0010] see figure 1 . figure 1 The part of is cut away to show the internal structure. In the state of use, the present invention is in a sealed state in order to keep the inside as a vacuum.

[0011] The present invention consists of dozens of layers of tantalum foils 1 superimposed on each other, with the same distance between the foils, and metal (generally stainless steel) materials are used around the tantalum foils to fix the entire target stacking device. The stacked target structure of the present invention has sufficient thickness as a whole, greatly increases the three-dimensional space of the entire target, can reduce the degree of damage to the target device when the electron beam acts on it, and can improve the intensity of X-rays and photographic resolution.

[0012] As an example, a stacked target device is composed of 24 layers of tantalum foil, the thickness of a single layer of tantalum foil is 0.05 mm, and the foil spacing is 0.5 mm. The tantalum foil is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com