Patents

Literature

46results about "Discharge tube hollow cathodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

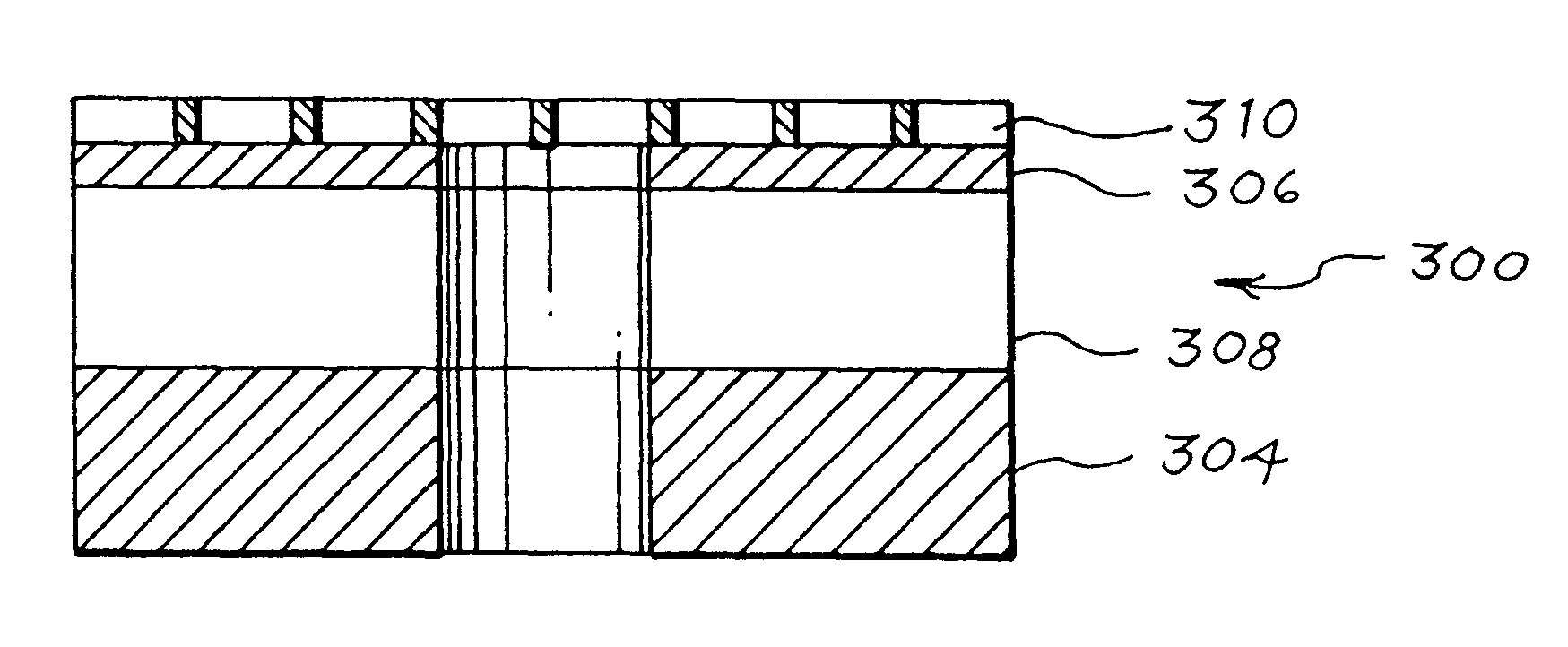

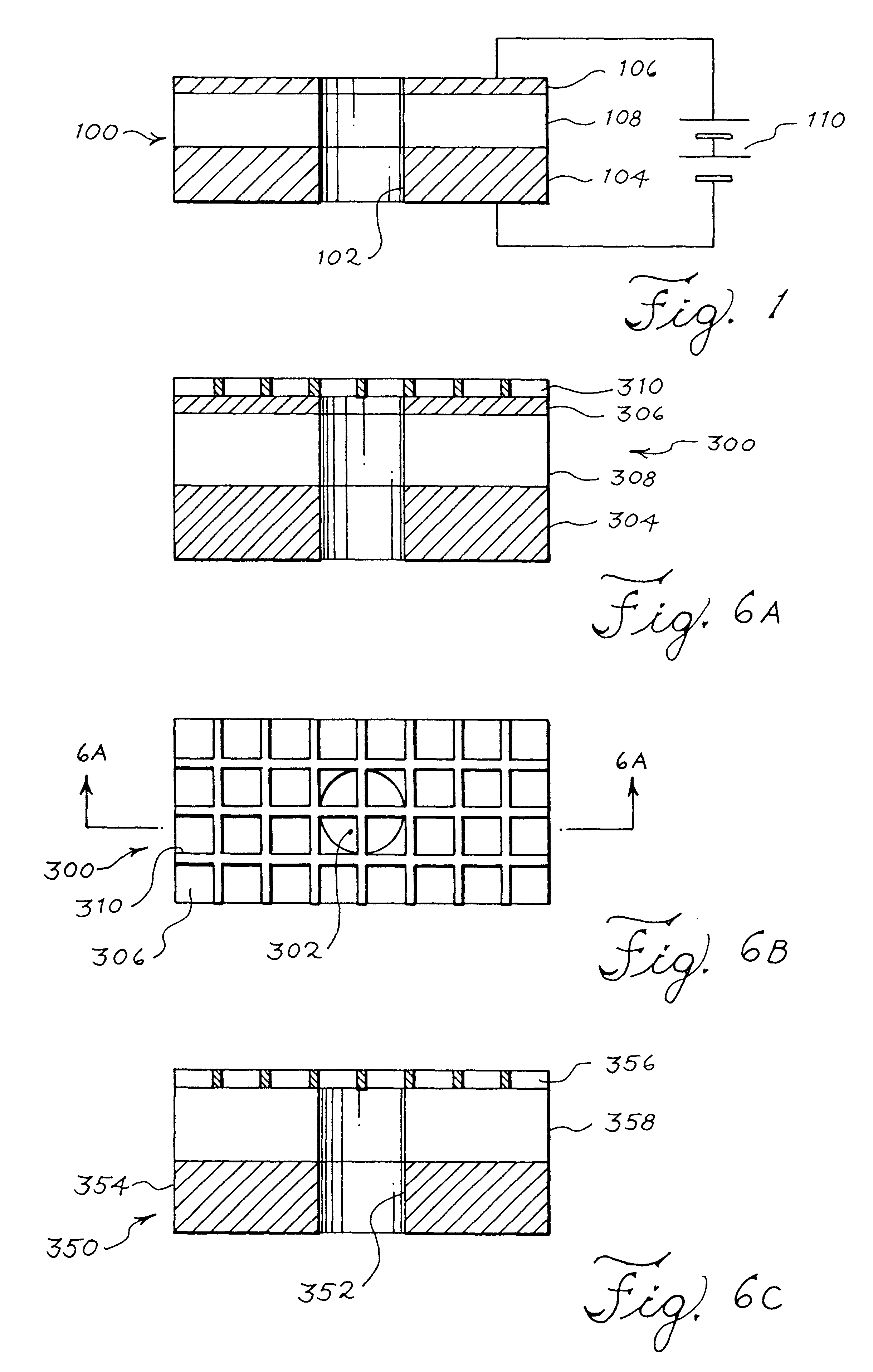

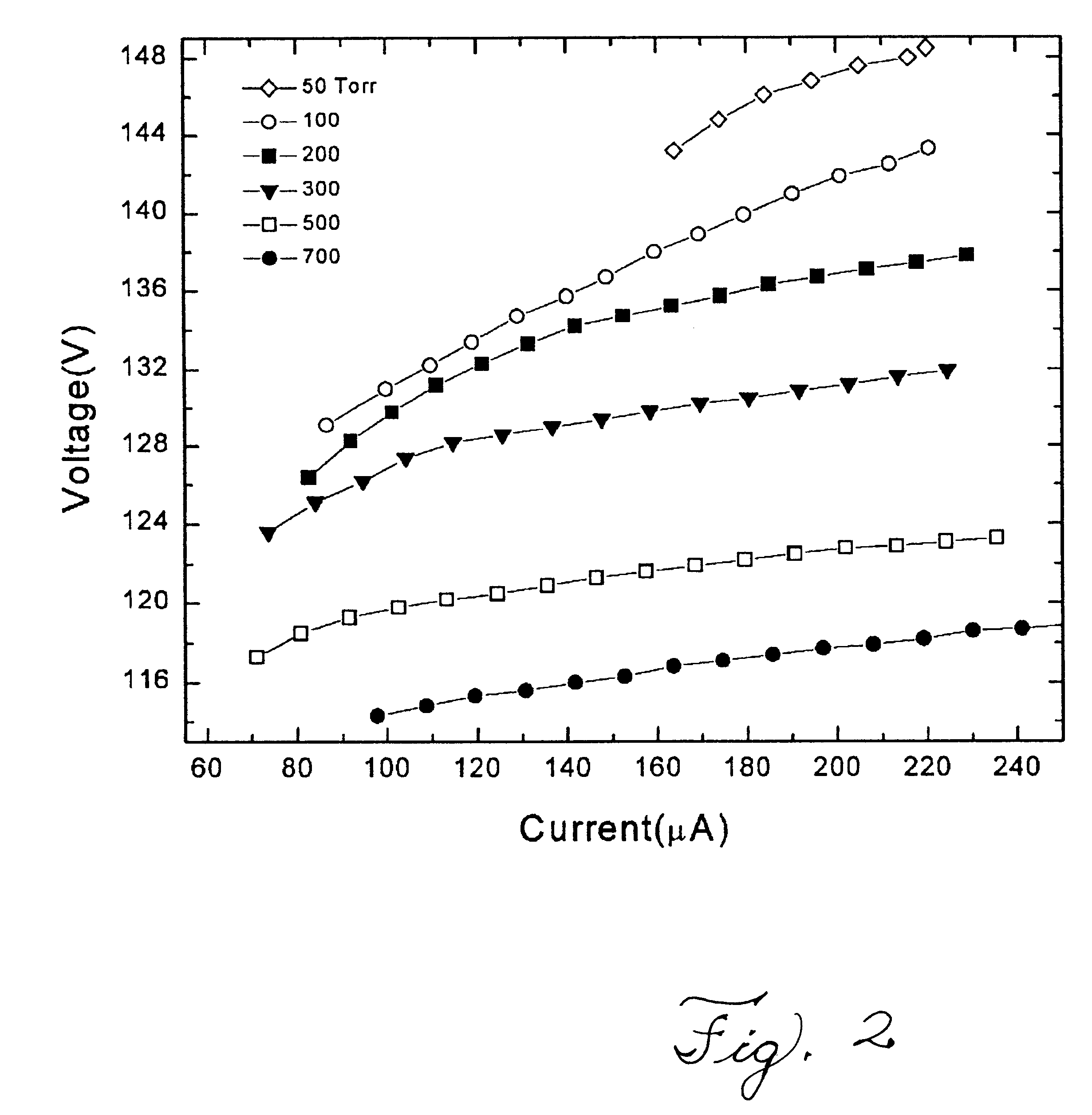

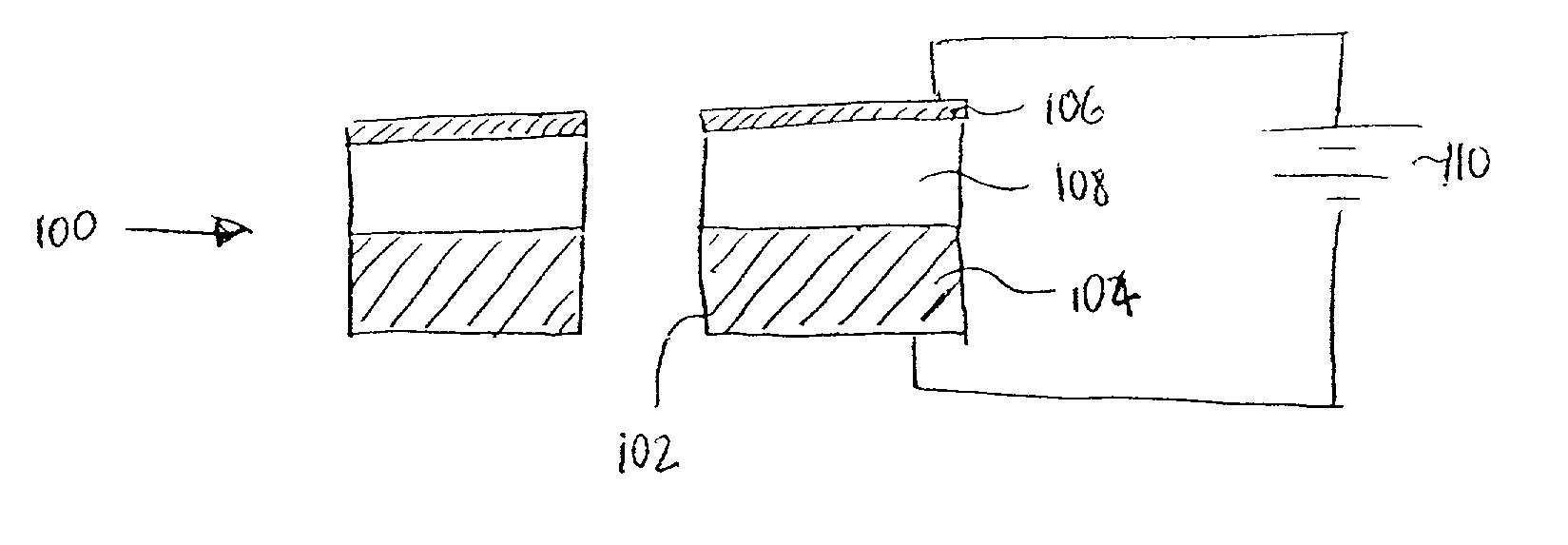

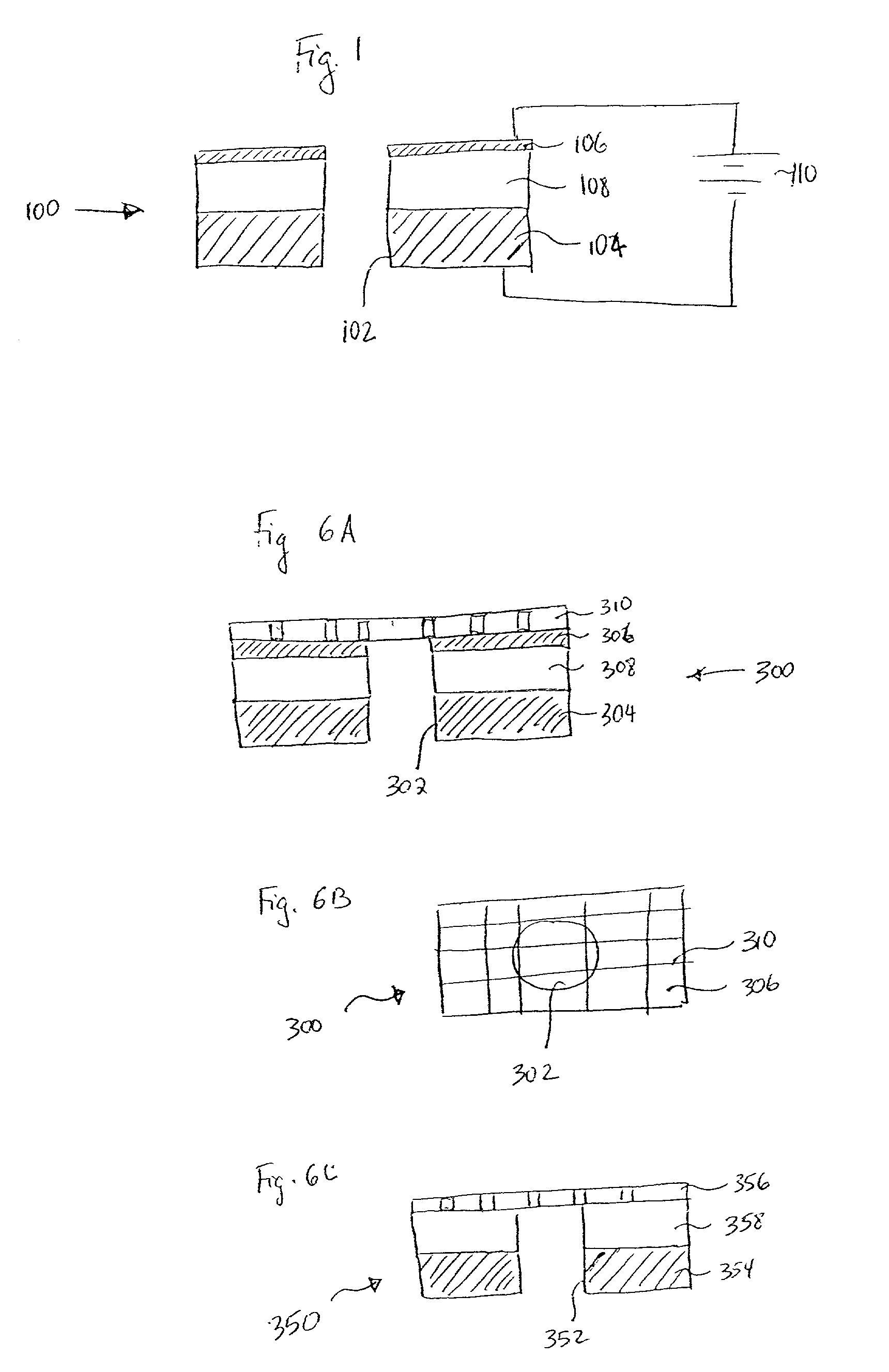

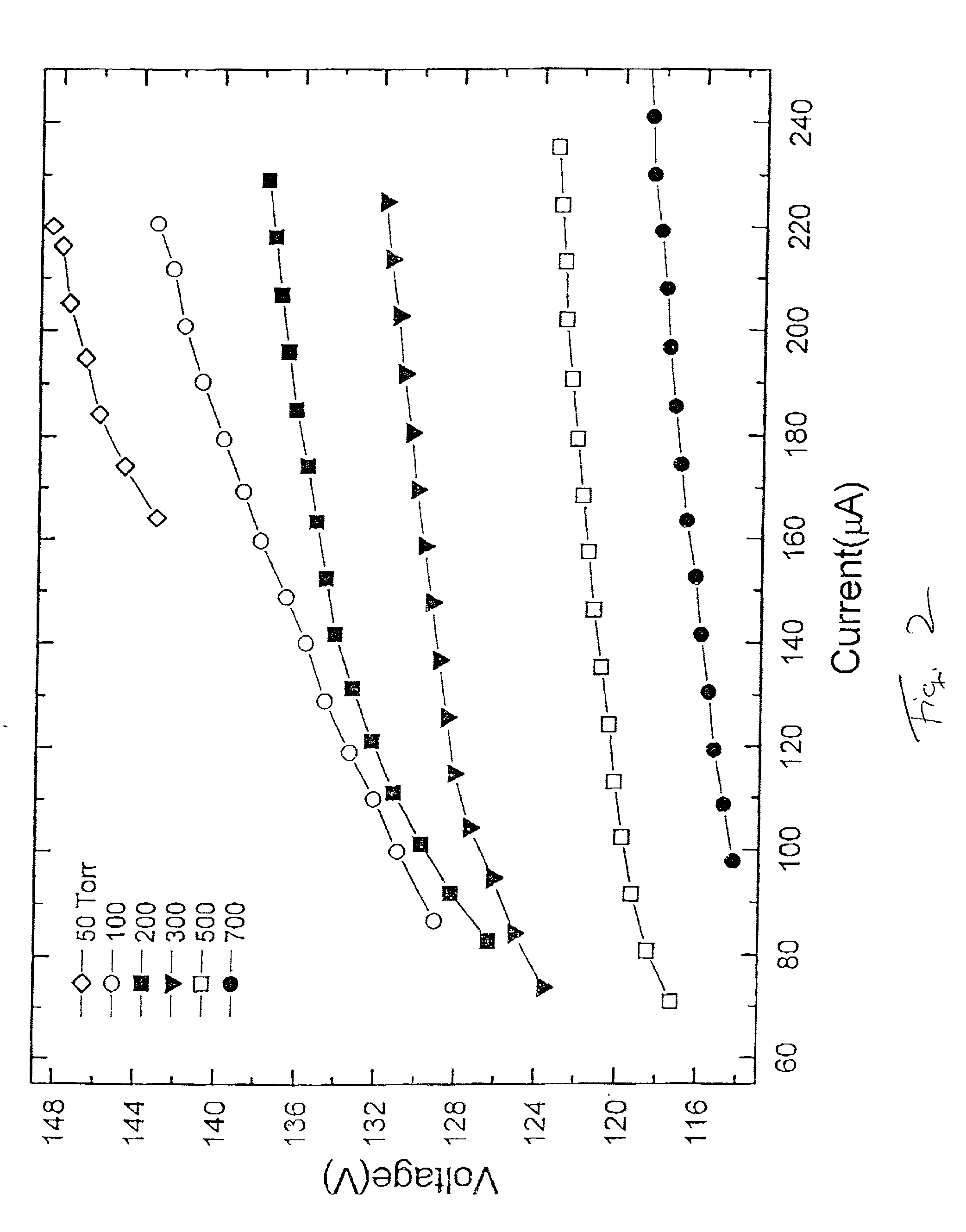

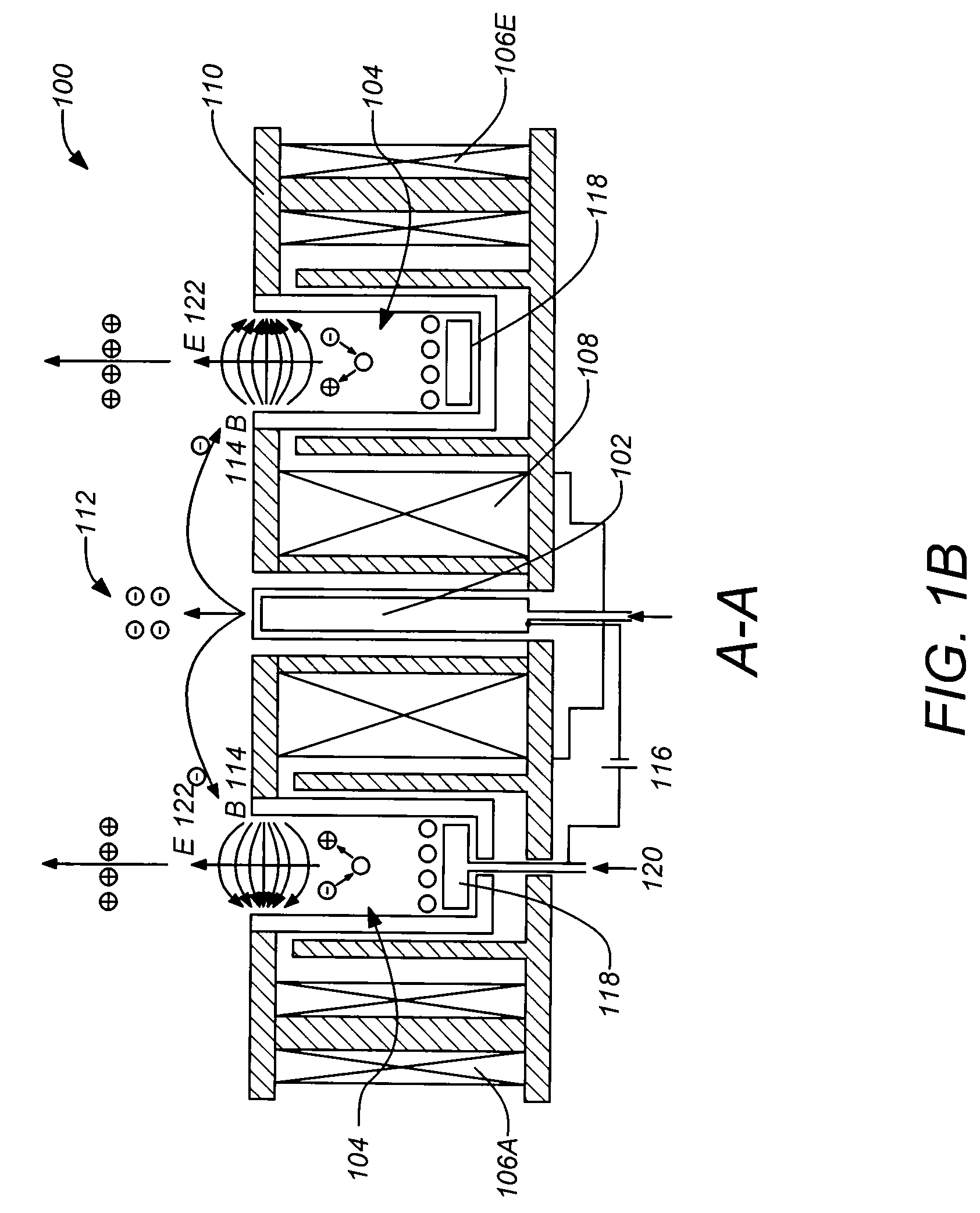

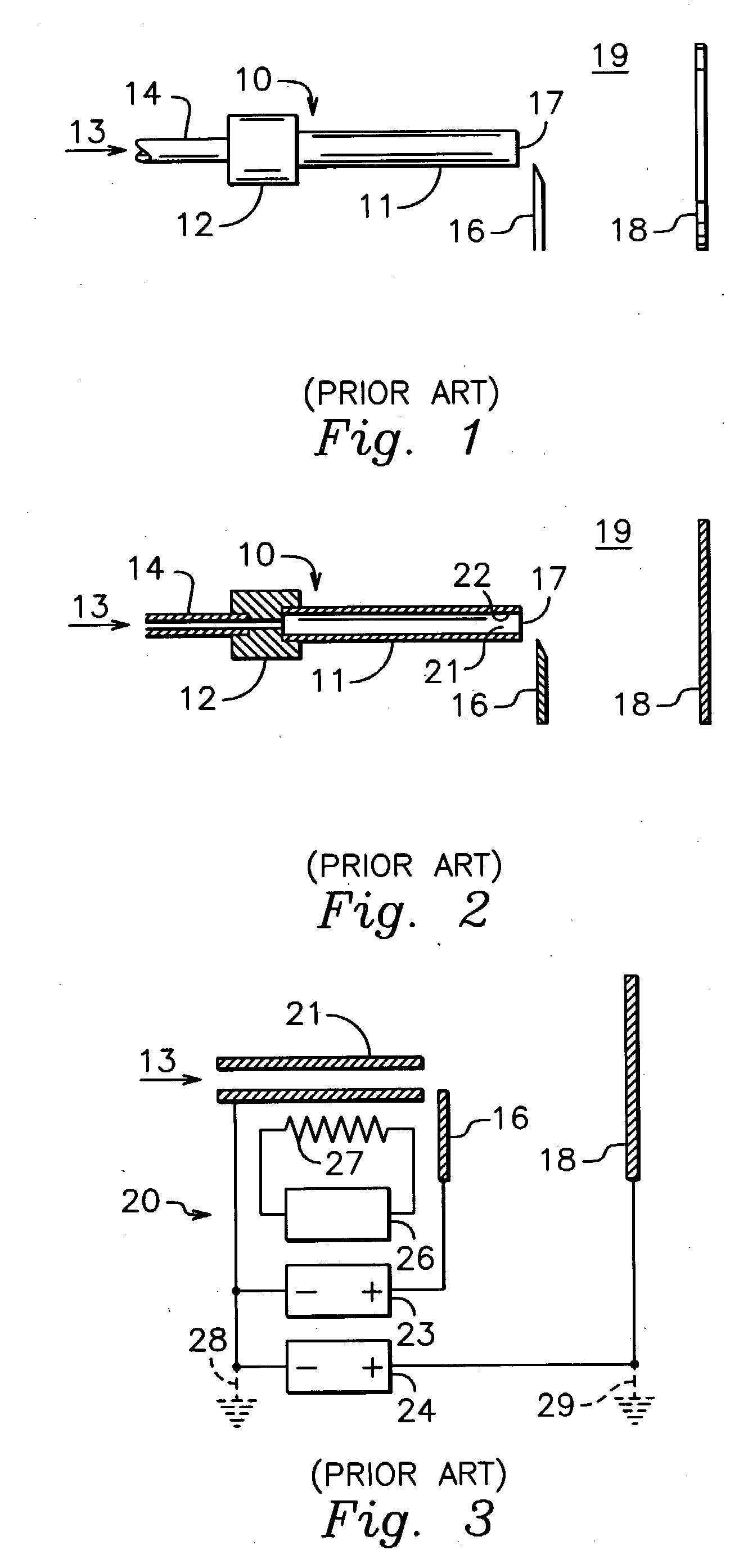

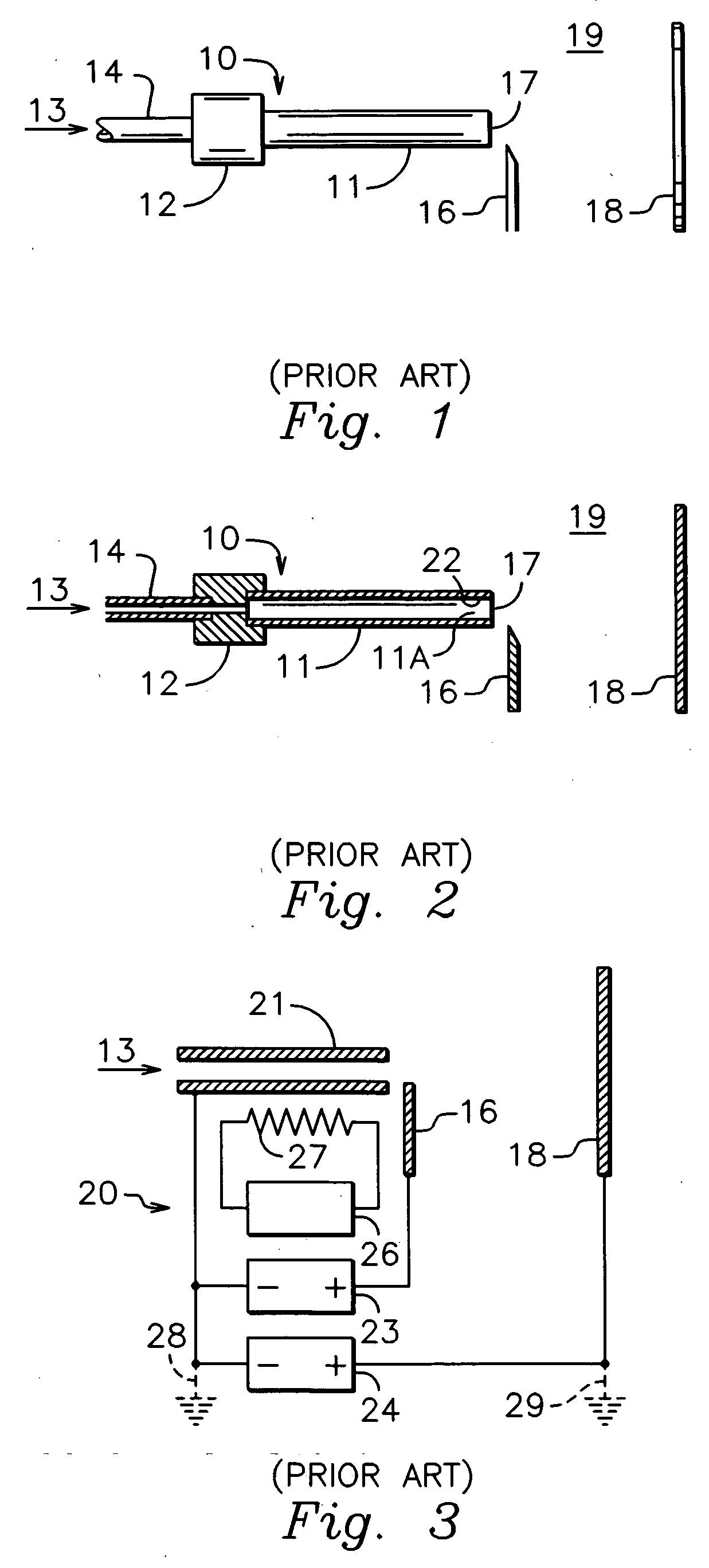

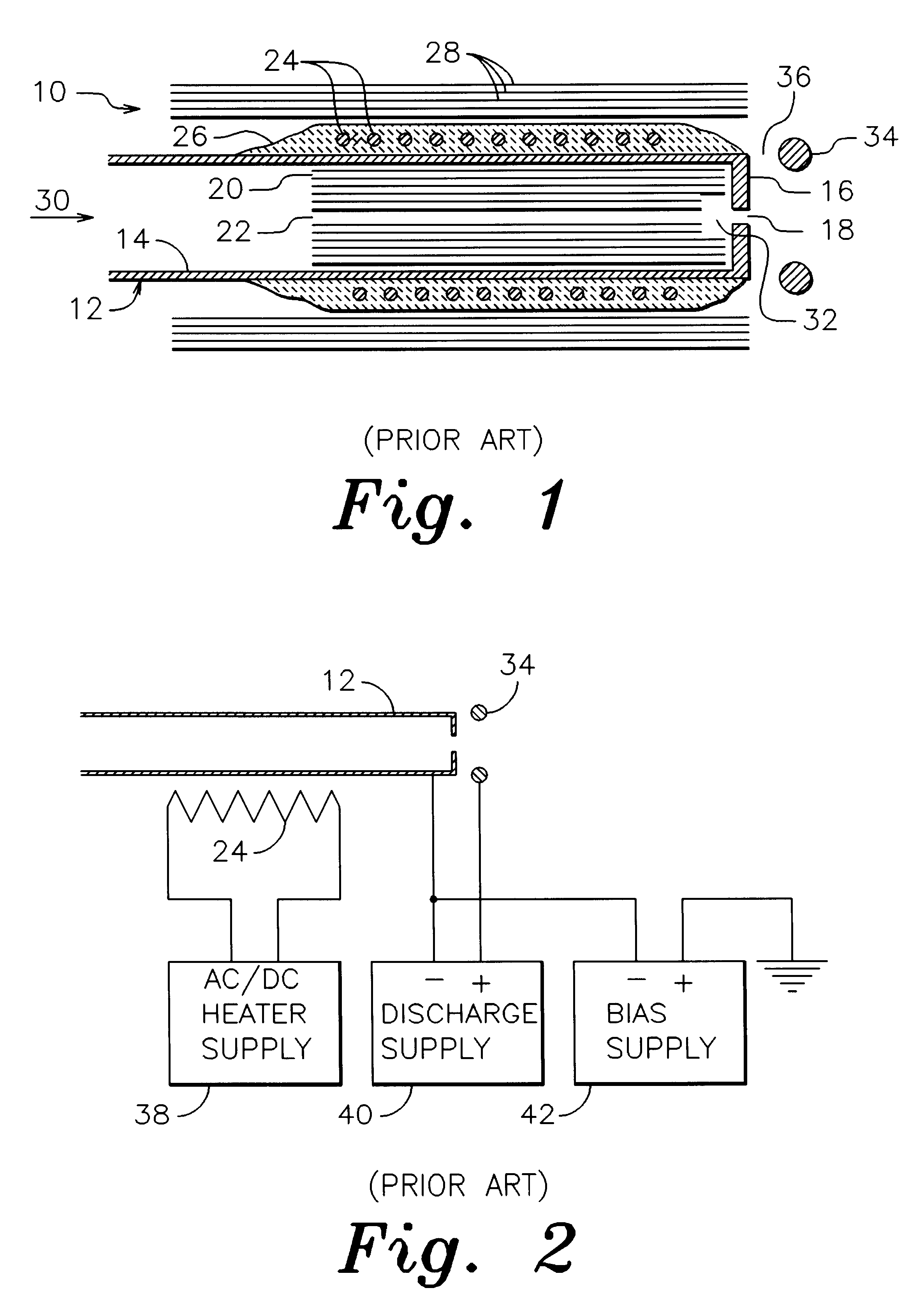

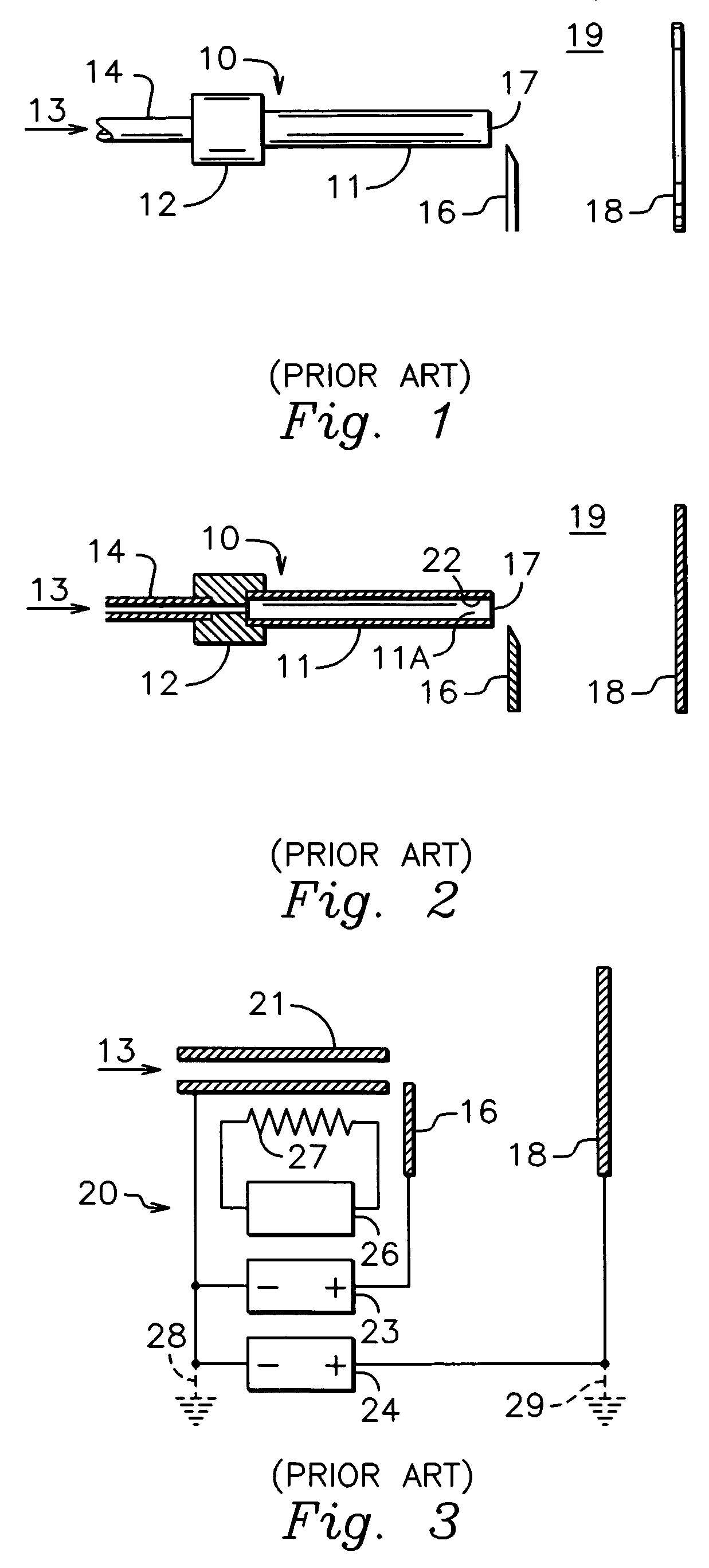

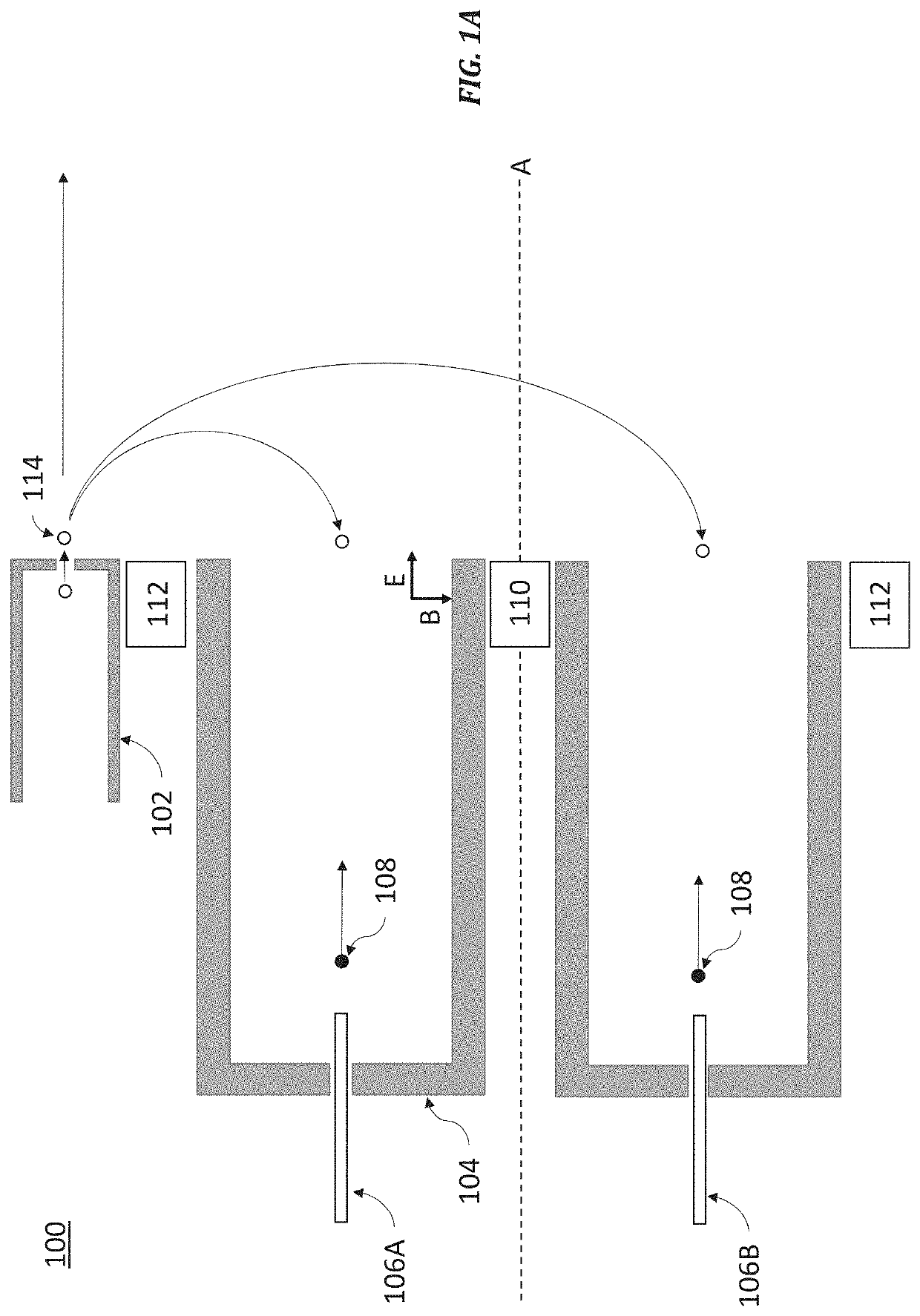

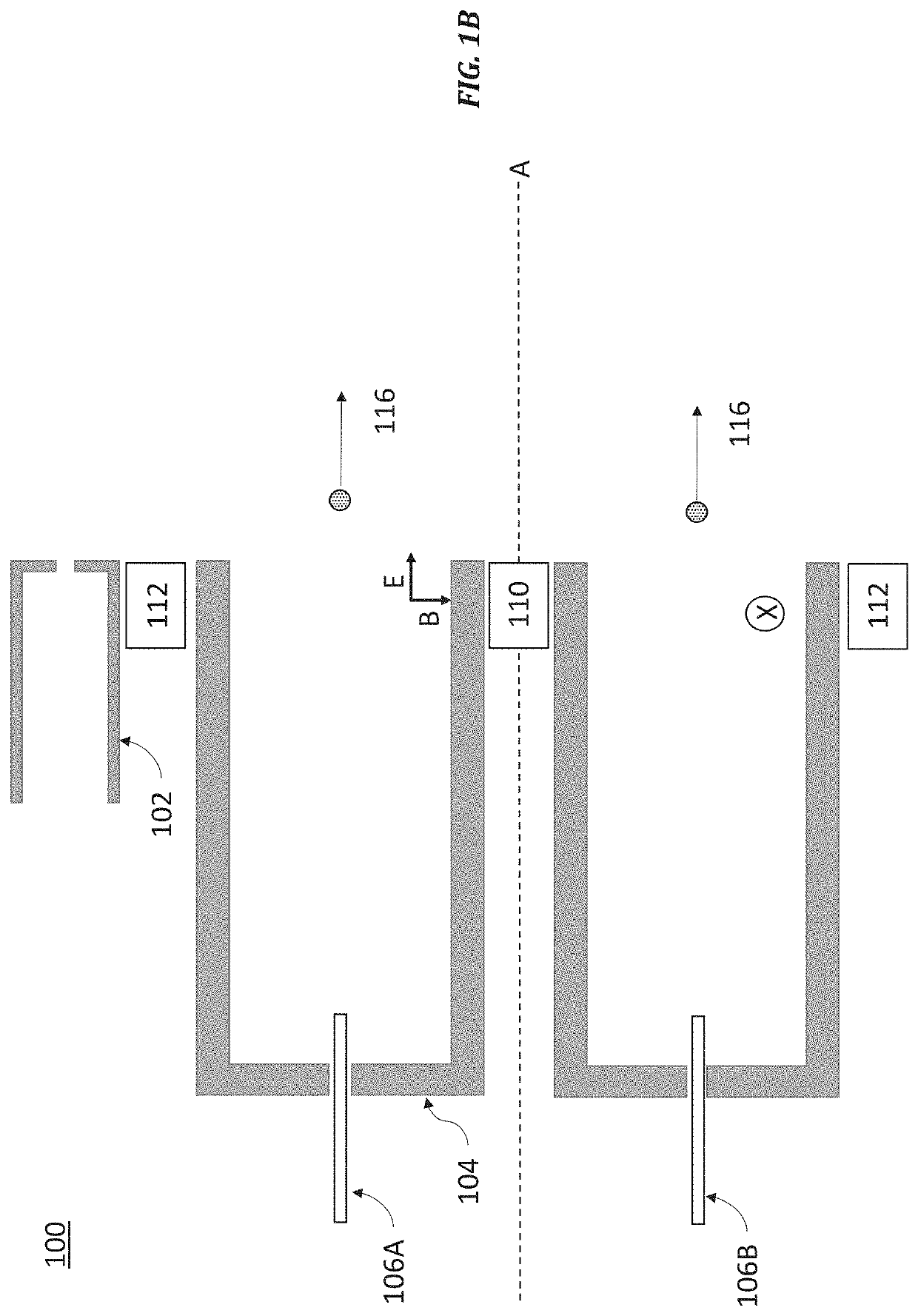

Microdischarge devices and arrays

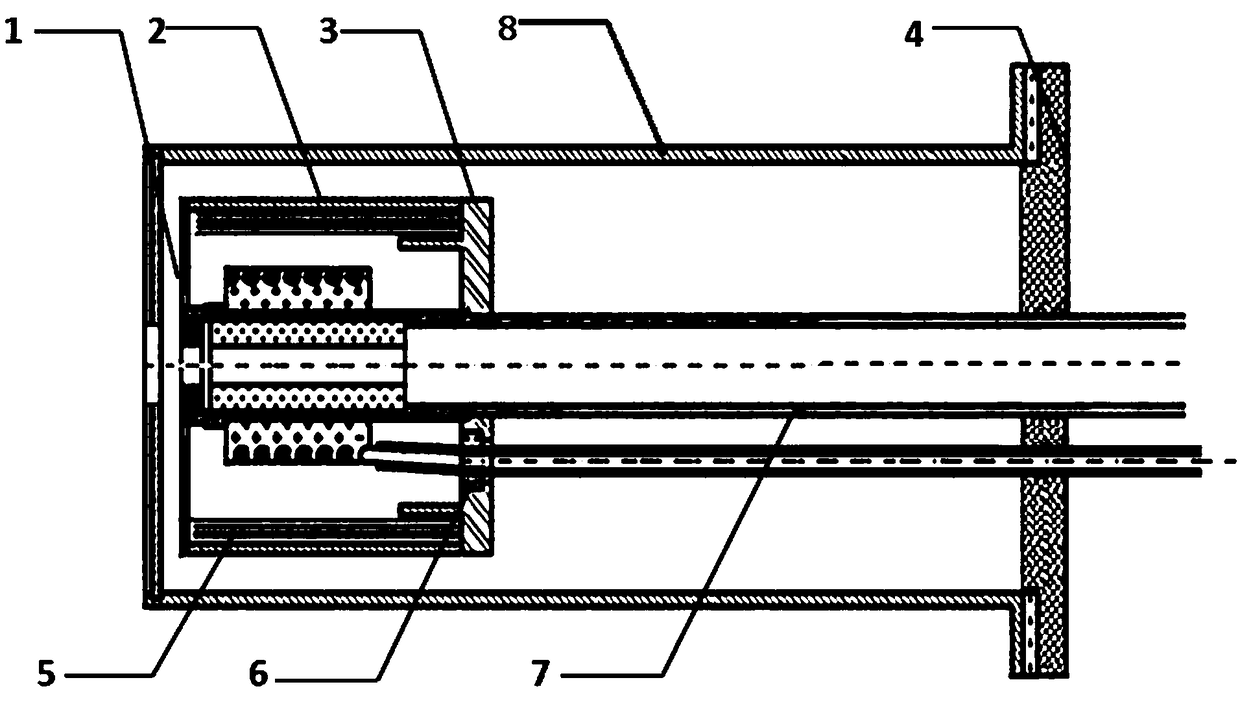

InactiveUS6695664B2Reduce manufacturing costElectrical and optical characteristicMagnetronsDischarge tube luminescnet screensOptoelectronicsDielectric layer

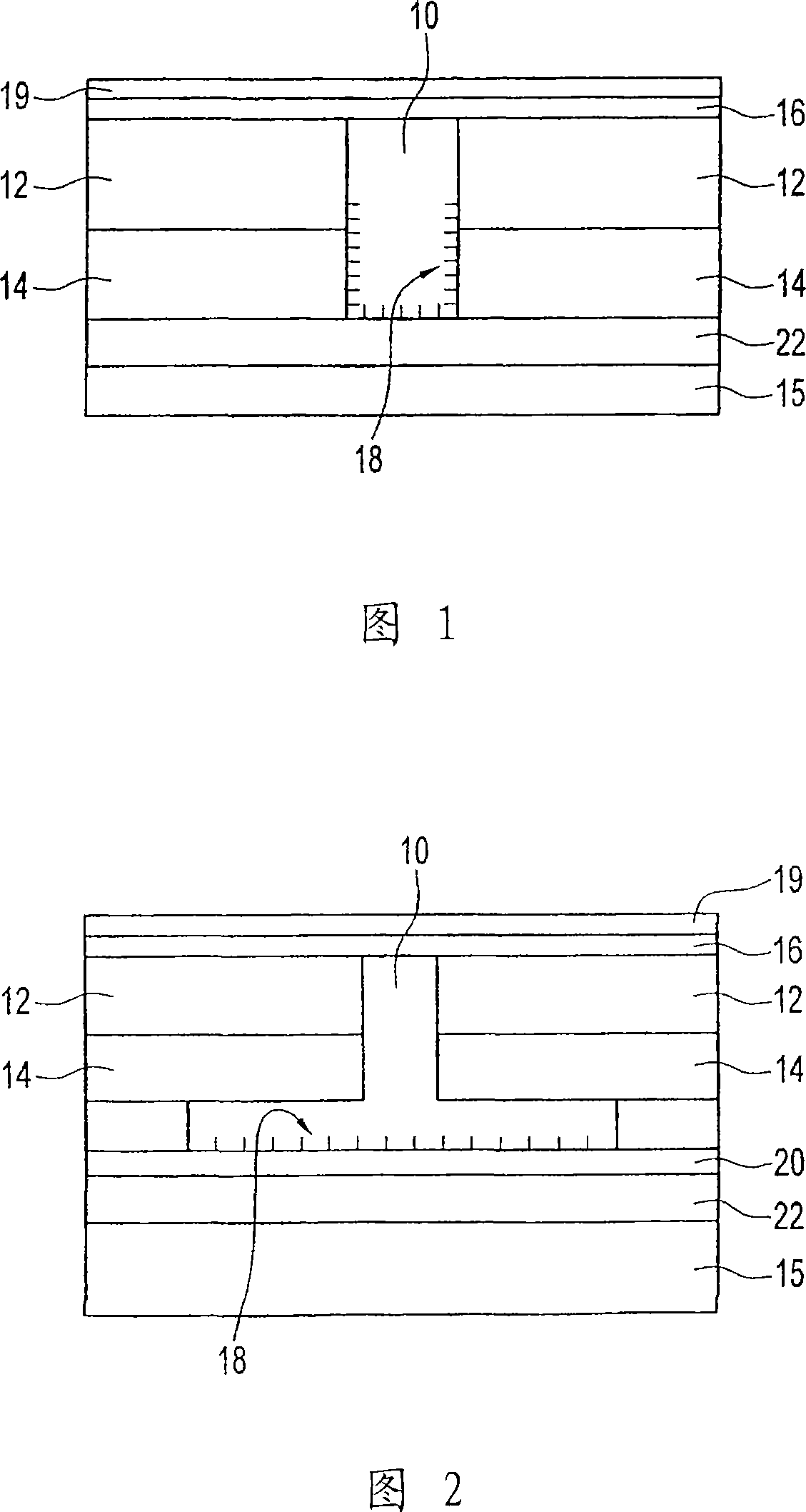

A discharge device is described that contains an anode, a cathode, and an insulating layer disposed between the anode and the cathode. A cavity is extends entirely through at least one of the anode or cathode and penetrates the dielectric layer. At least one of the anode or cathode may include a screen or the dielectric layer may have a plurality of films with at least two different dielectric constants. The voltage differences between the anode and cathode in each of multiple devices electrically connected together may be limited.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Microdischarge devices and arrays

InactiveUS20030080688A1Reduce manufacturing costElectrical and optical characteristicMagnetronsDischarge tube luminescnet screensOptoelectronicsDielectric layer

A discharge device is described that contains an anode, a cathode, and an insulating layer disposed between the anode and the cathode. A cavity is extends entirely through at least one of the anode or cathode and penetrates the dielectric layer. At least one of the anode or cathode may include a screen or the dielectric layer may have a plurality of films with at least two different dielectric constants. The voltage differences between the anode and cathode in each of multiple devices electrically connected together may be limited.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

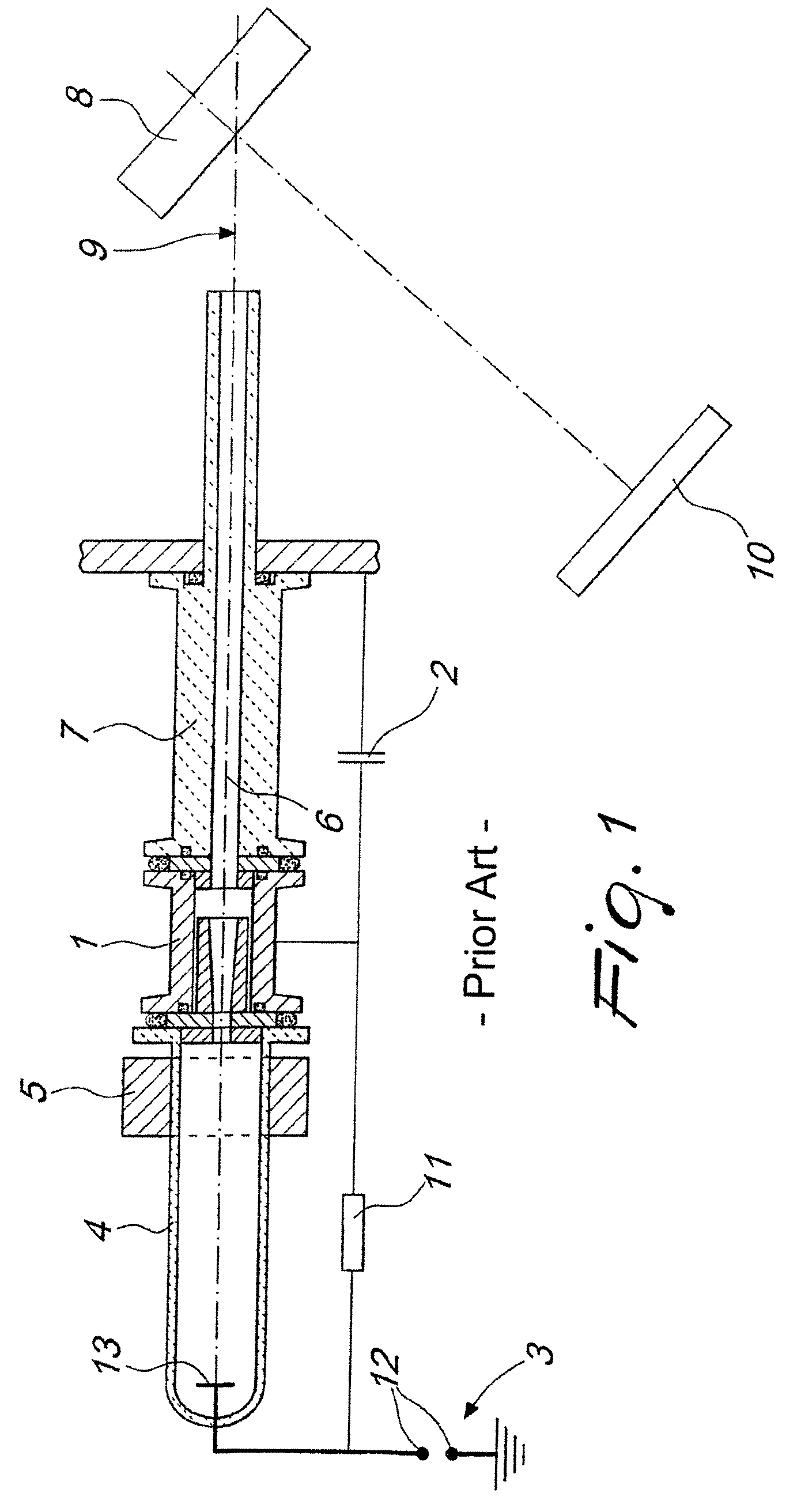

Laser-sustained plasma light source

A laser sustained plasma light source having a cell formed as a continuous tube with a circular cross section, a gas volume contained within the cell, at least one laser directed into the gas volume, for sustaining a plasma within the gas volume, the plasma producing a light, where the gas volume is heated as it leaves the plasma, cools as it circulates around the continuous tube of the cell, and reenters the plasma cooler than when it left the plasma and in a laminar flow, and a reflector for collecting the light and providing the light to a desired location.

Owner:KLA CORP

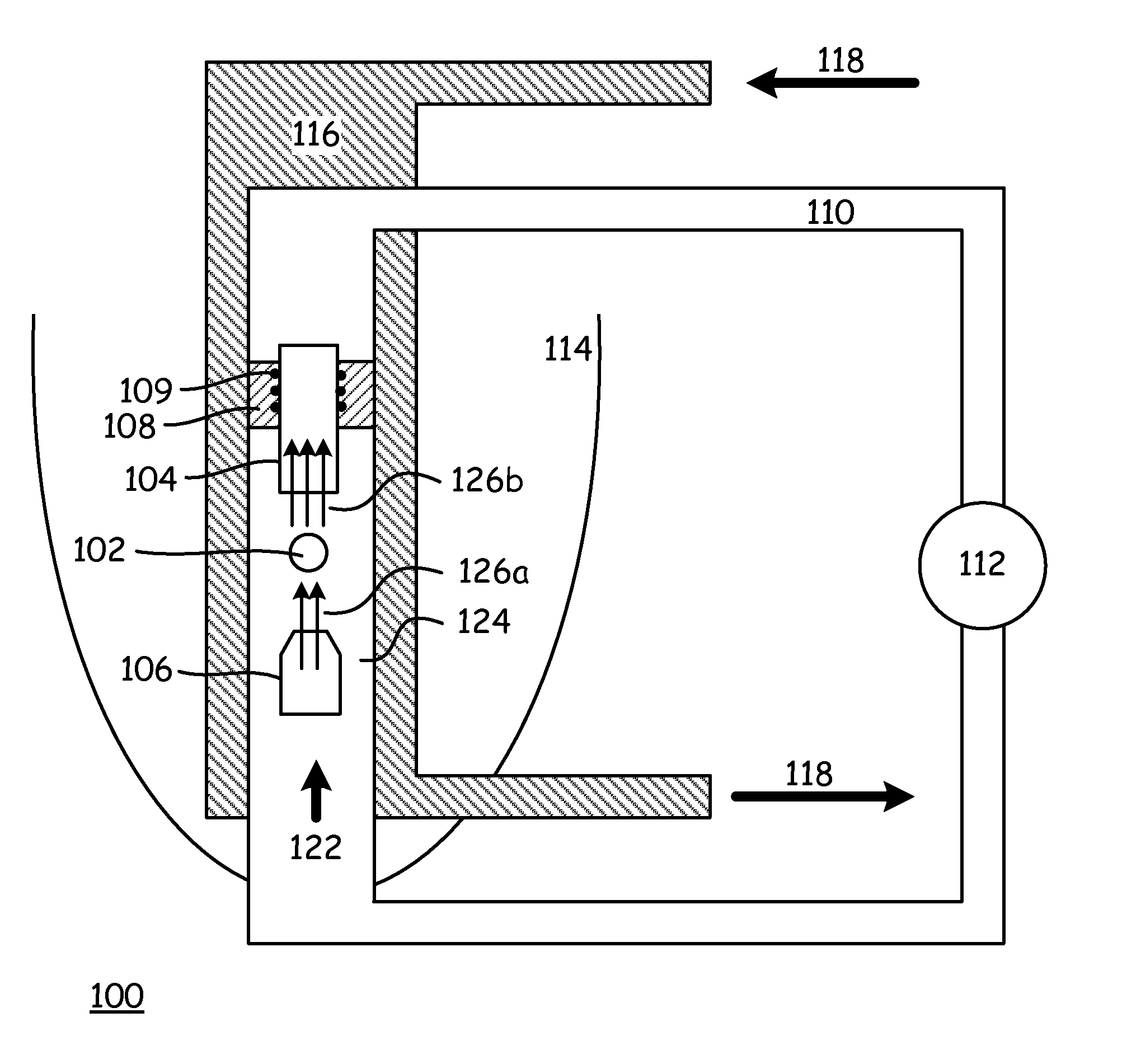

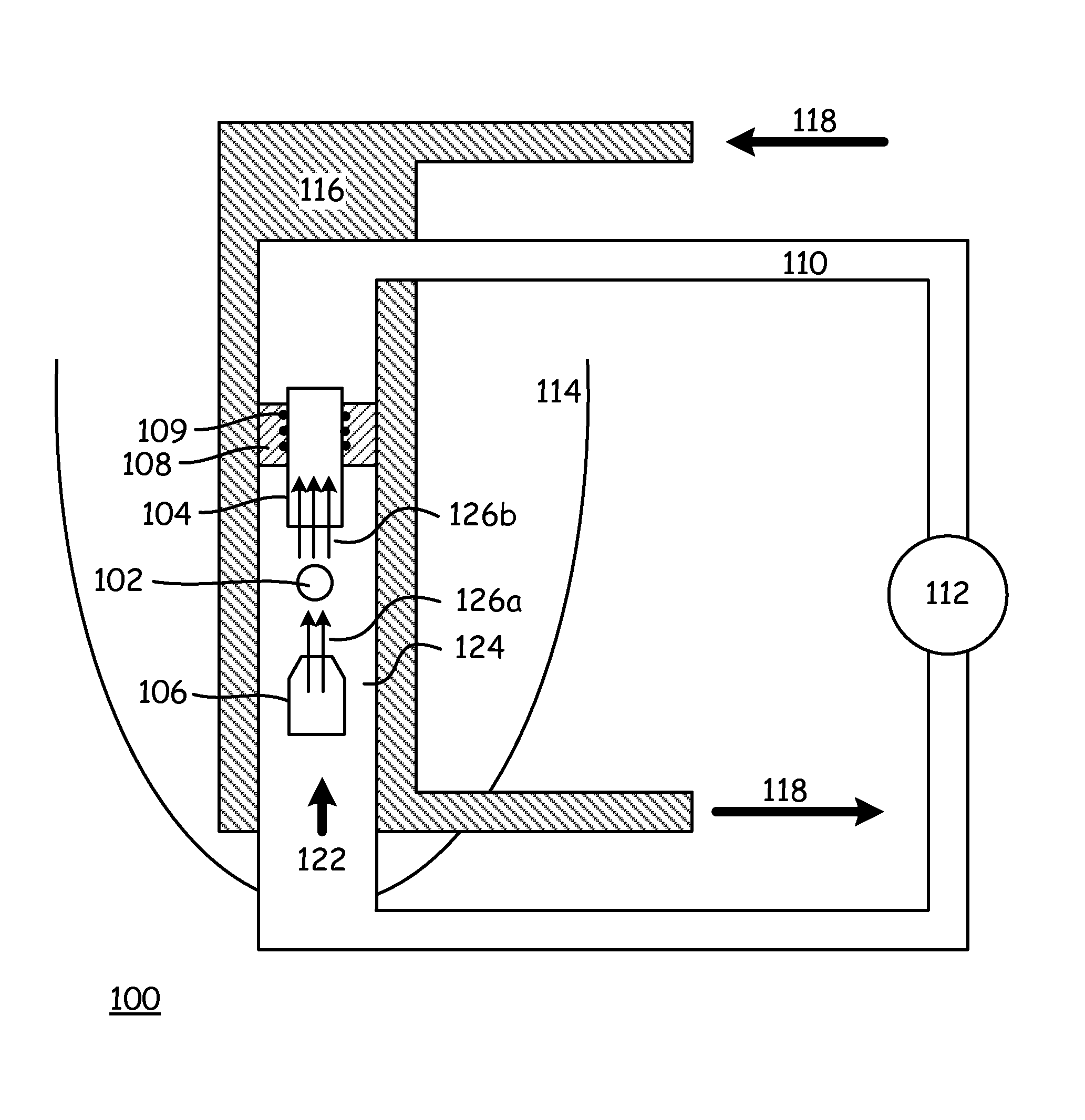

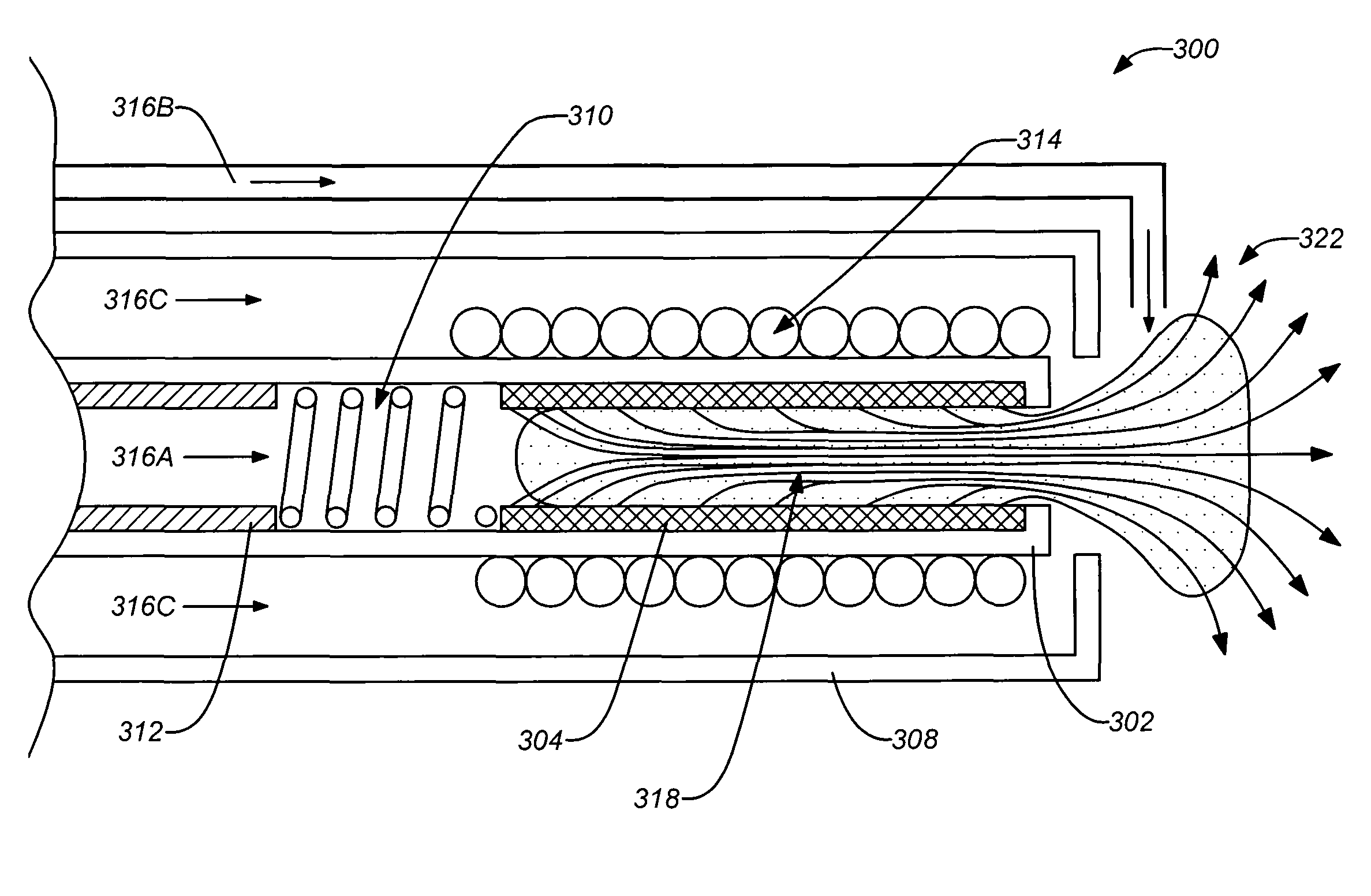

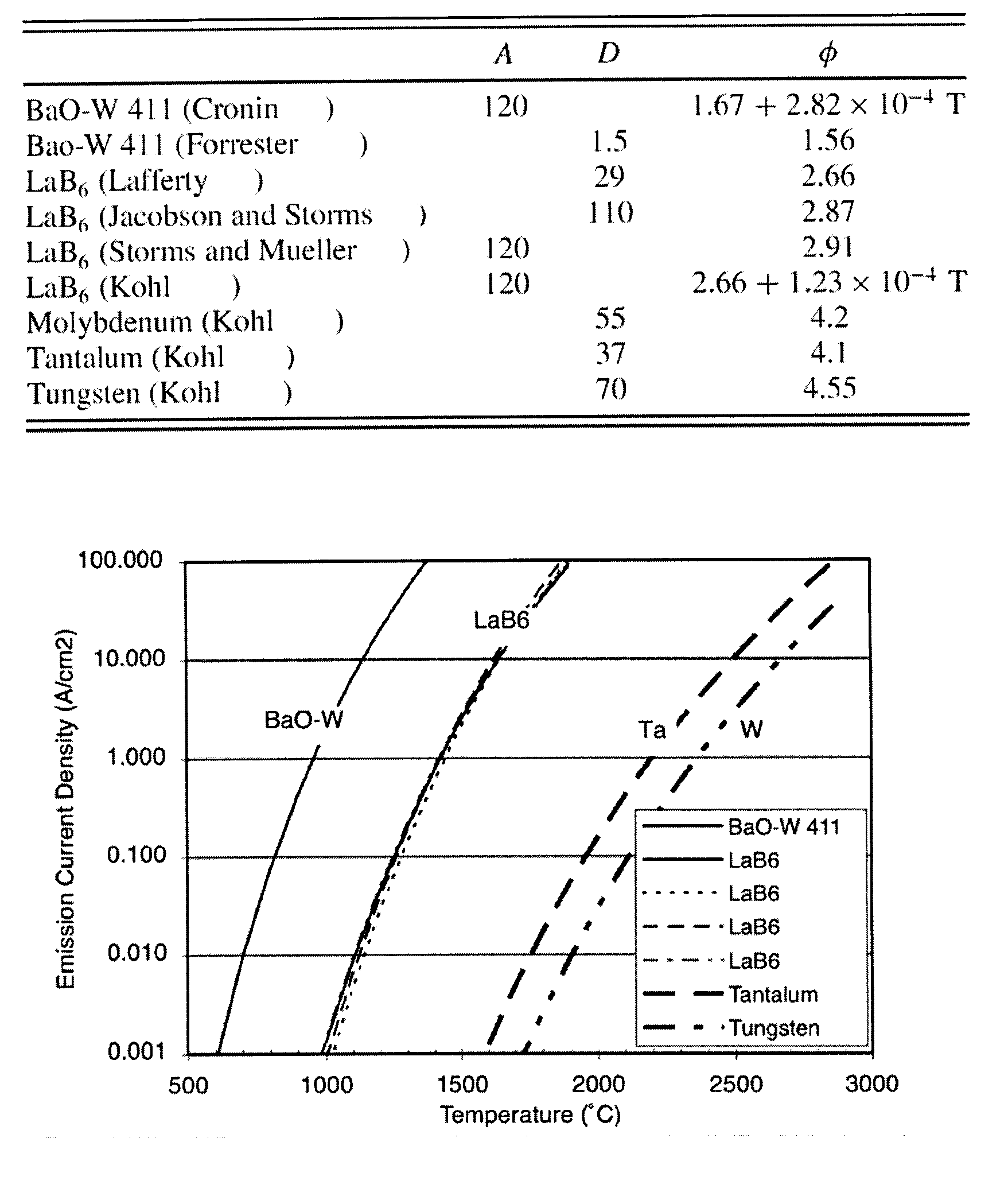

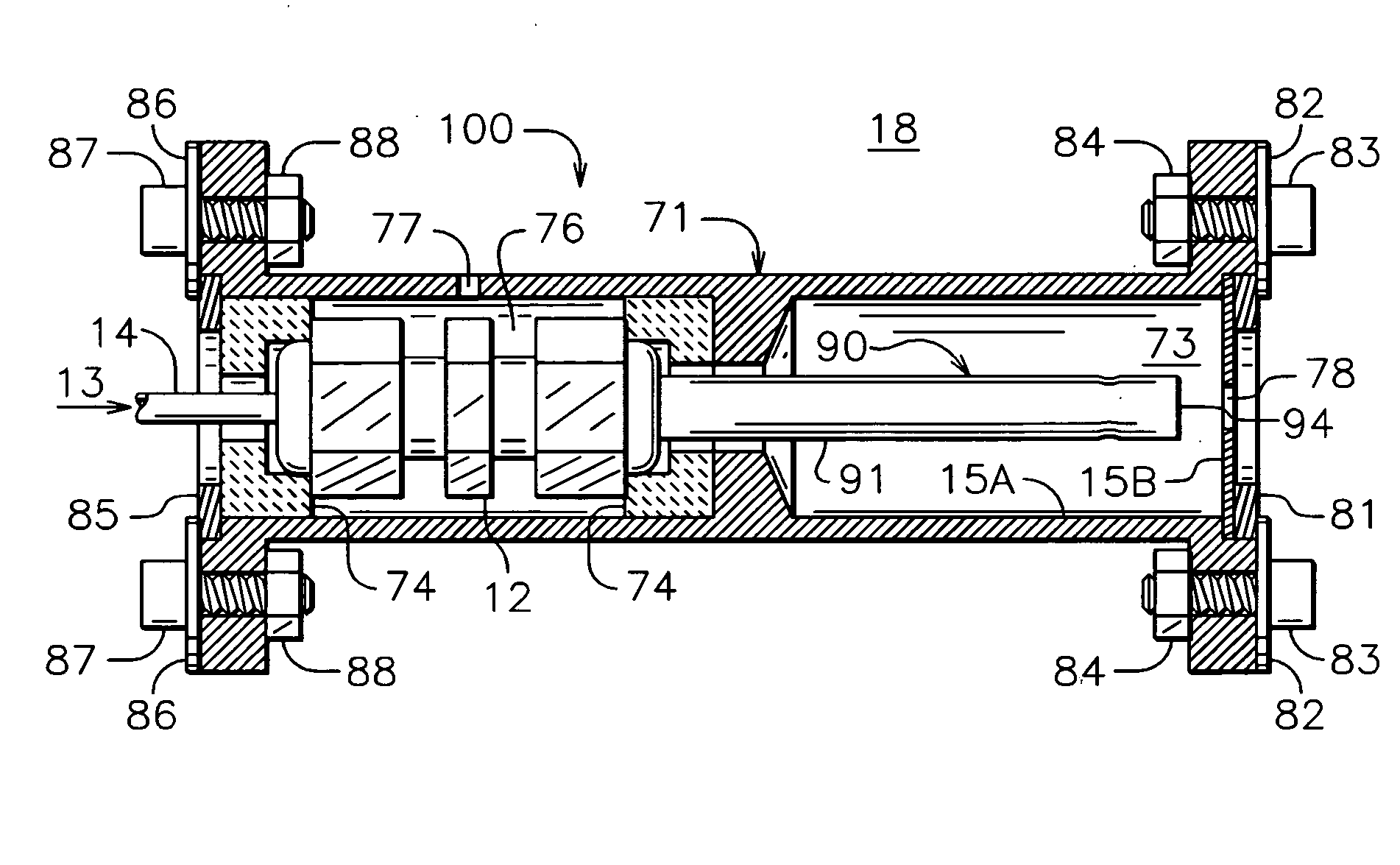

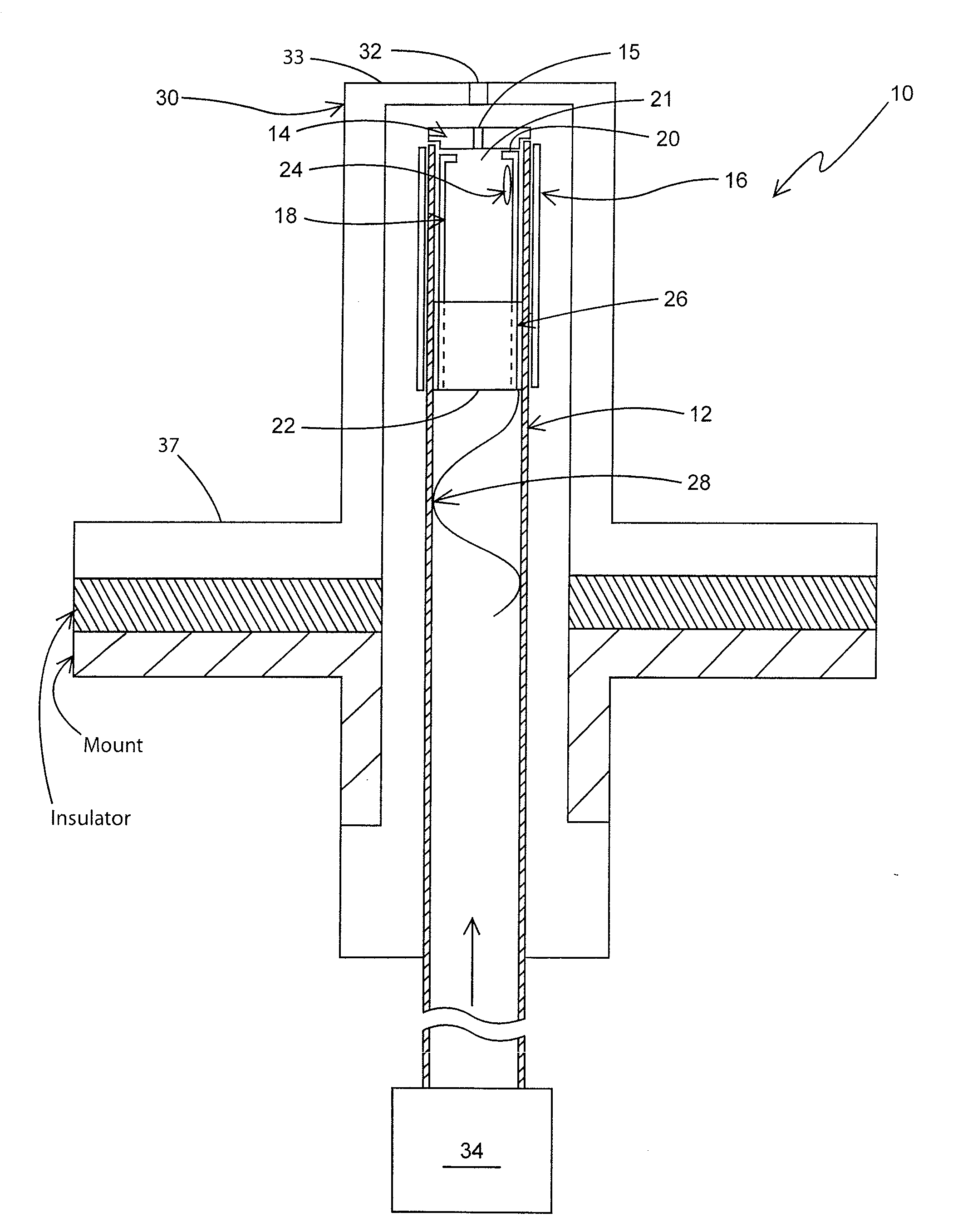

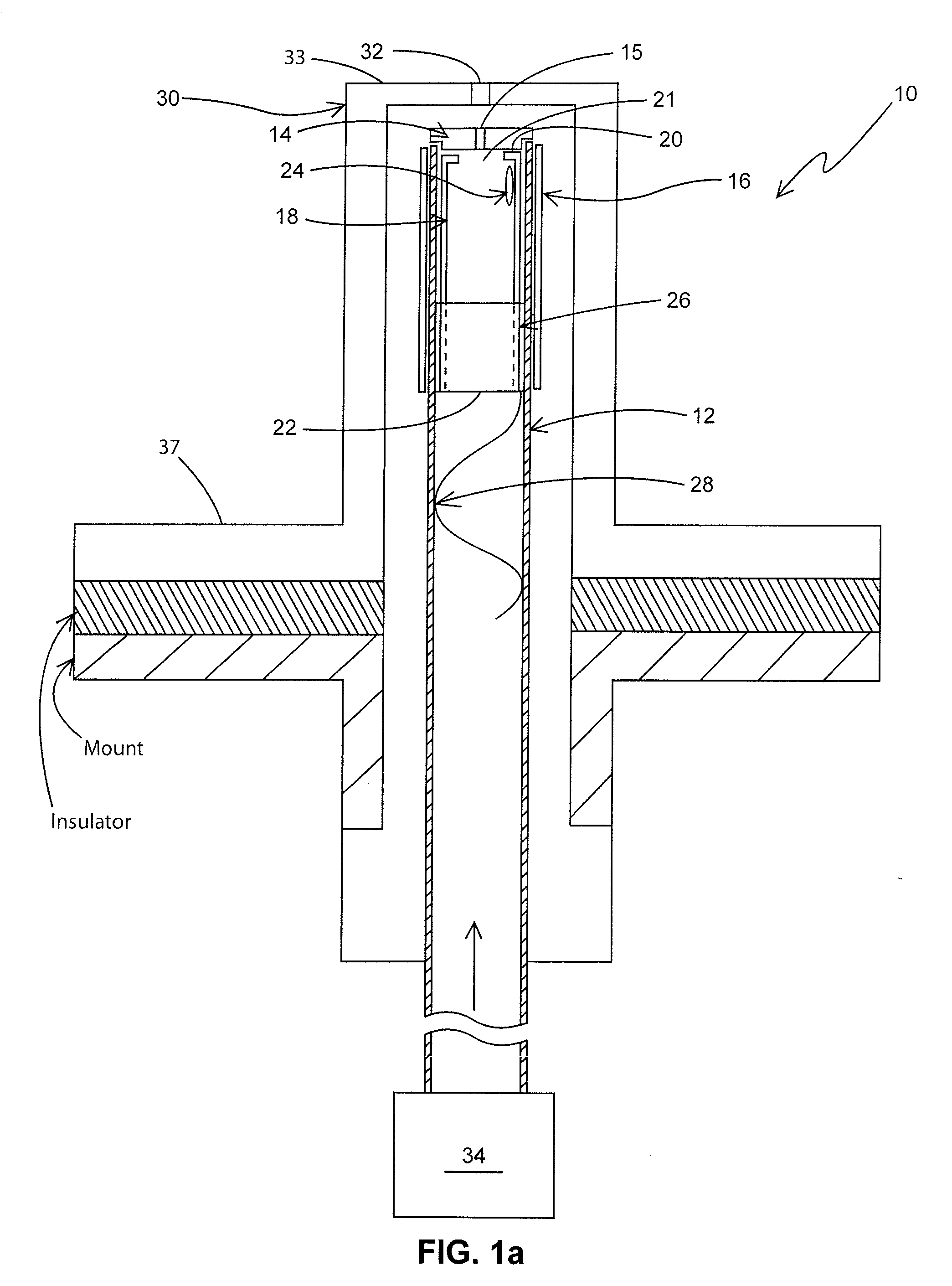

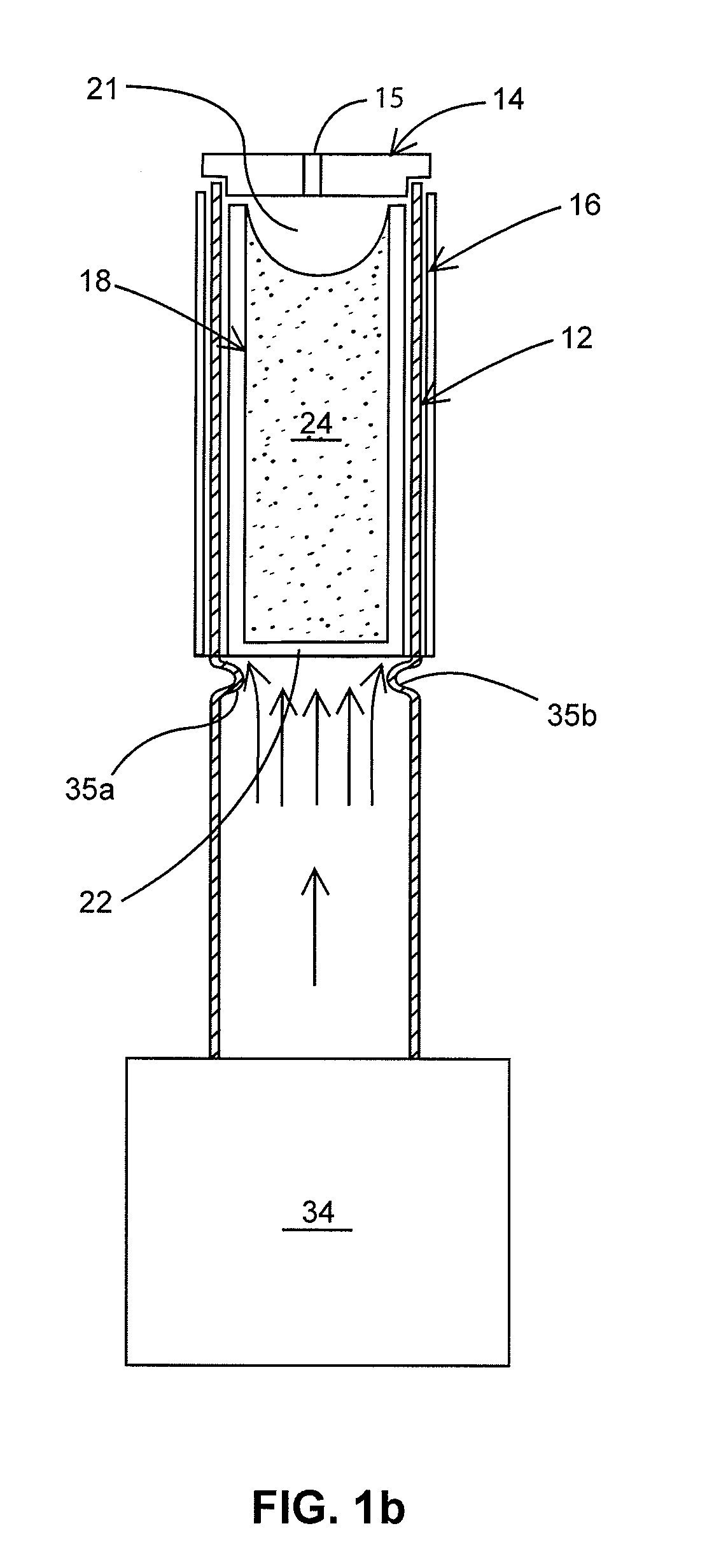

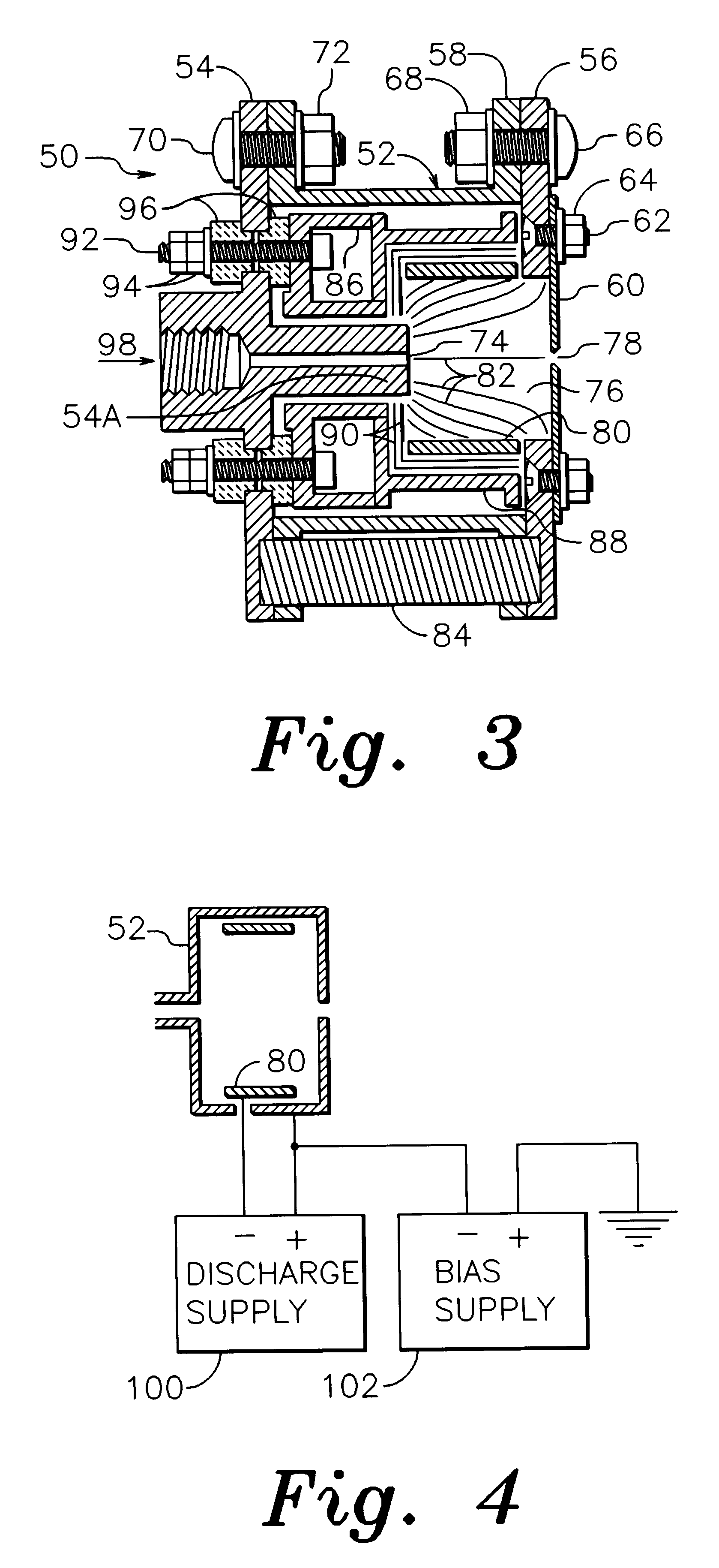

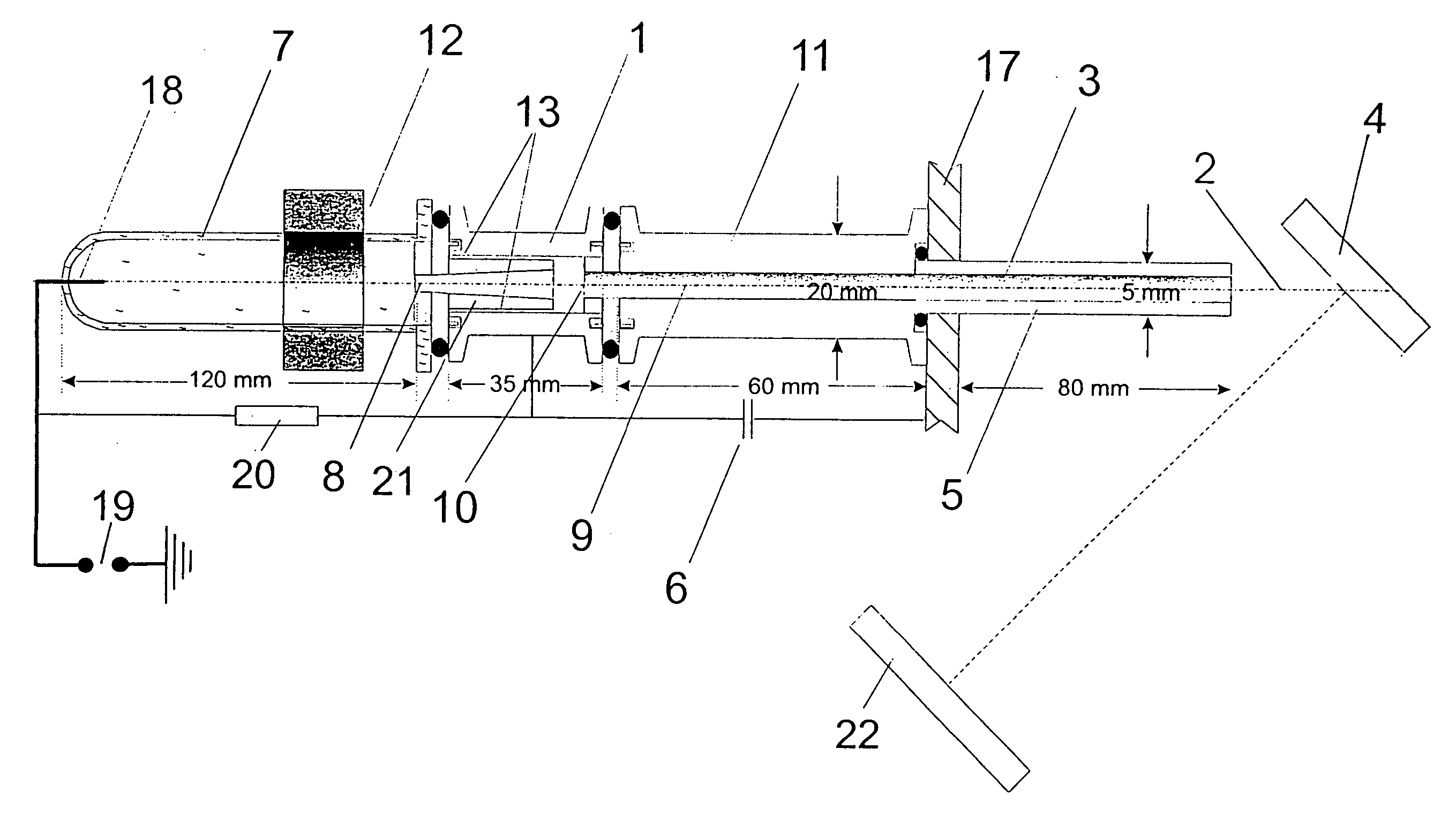

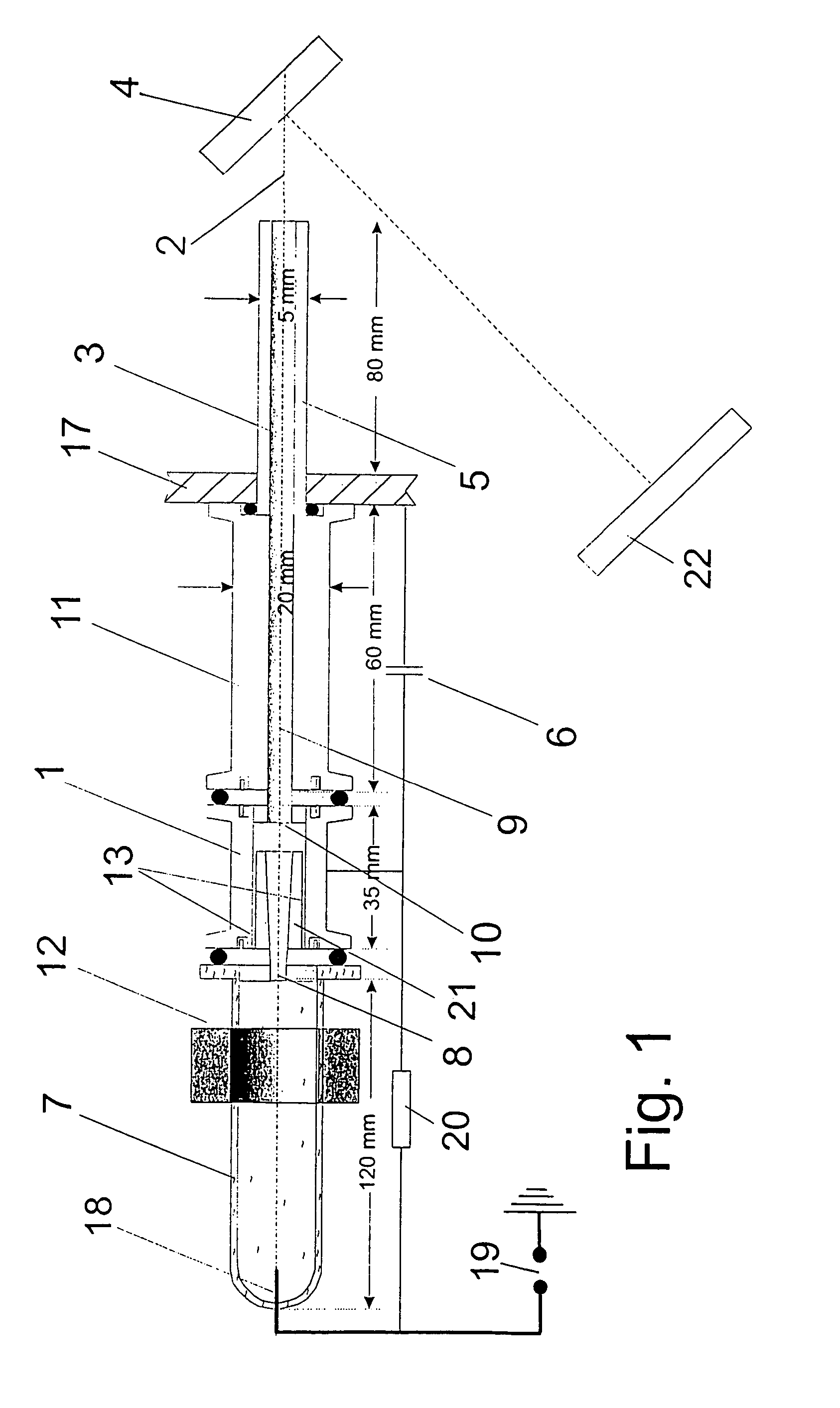

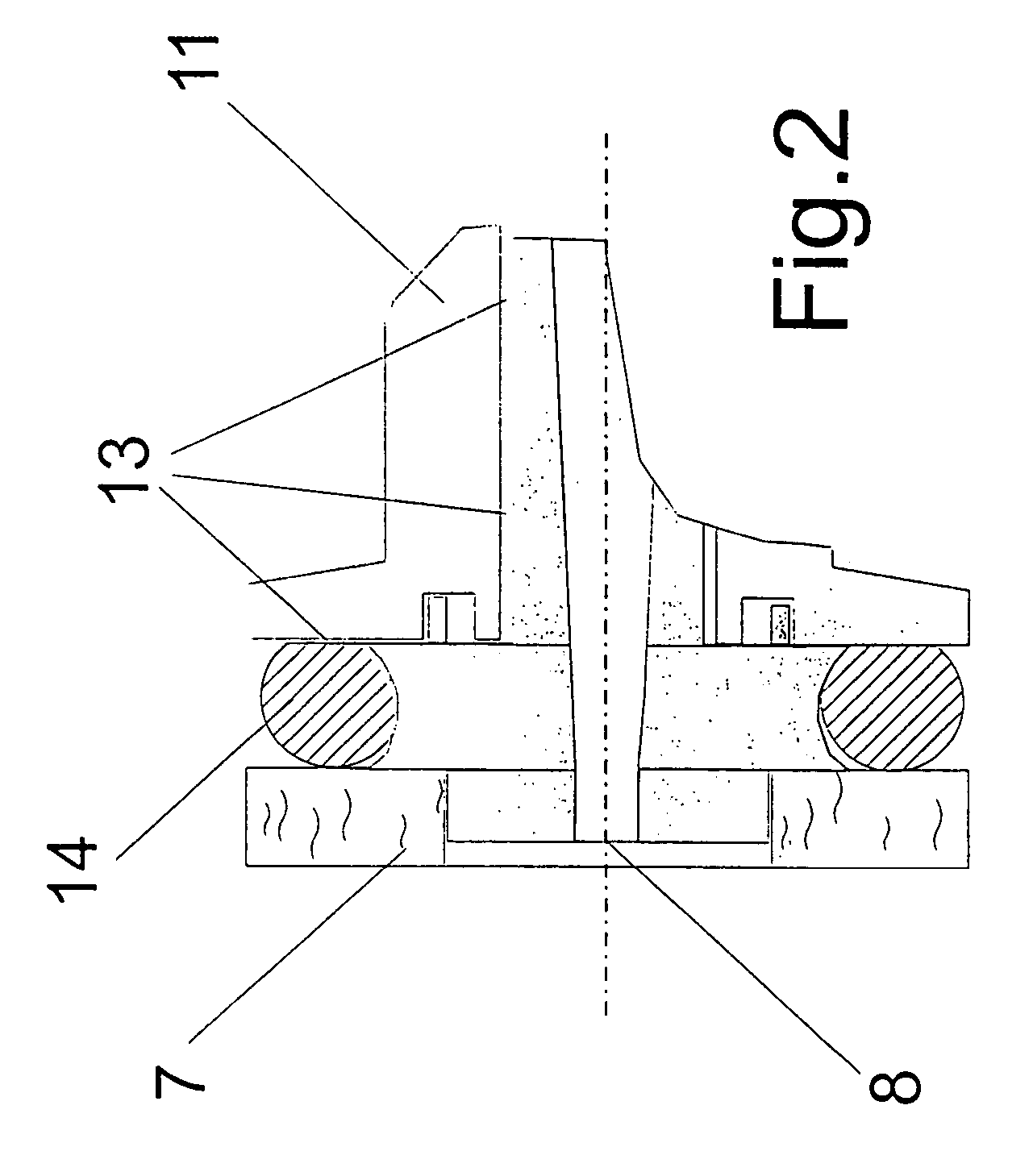

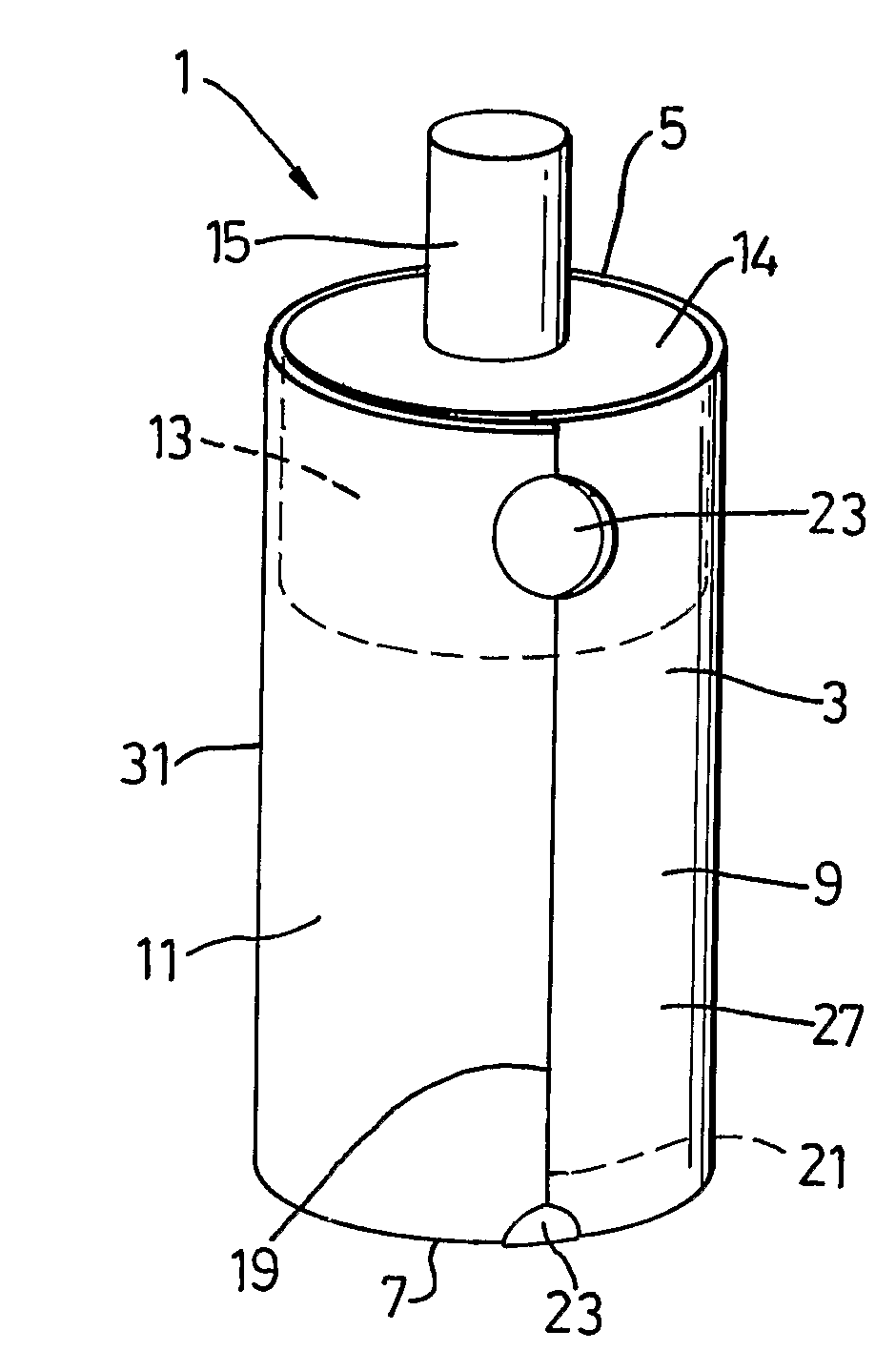

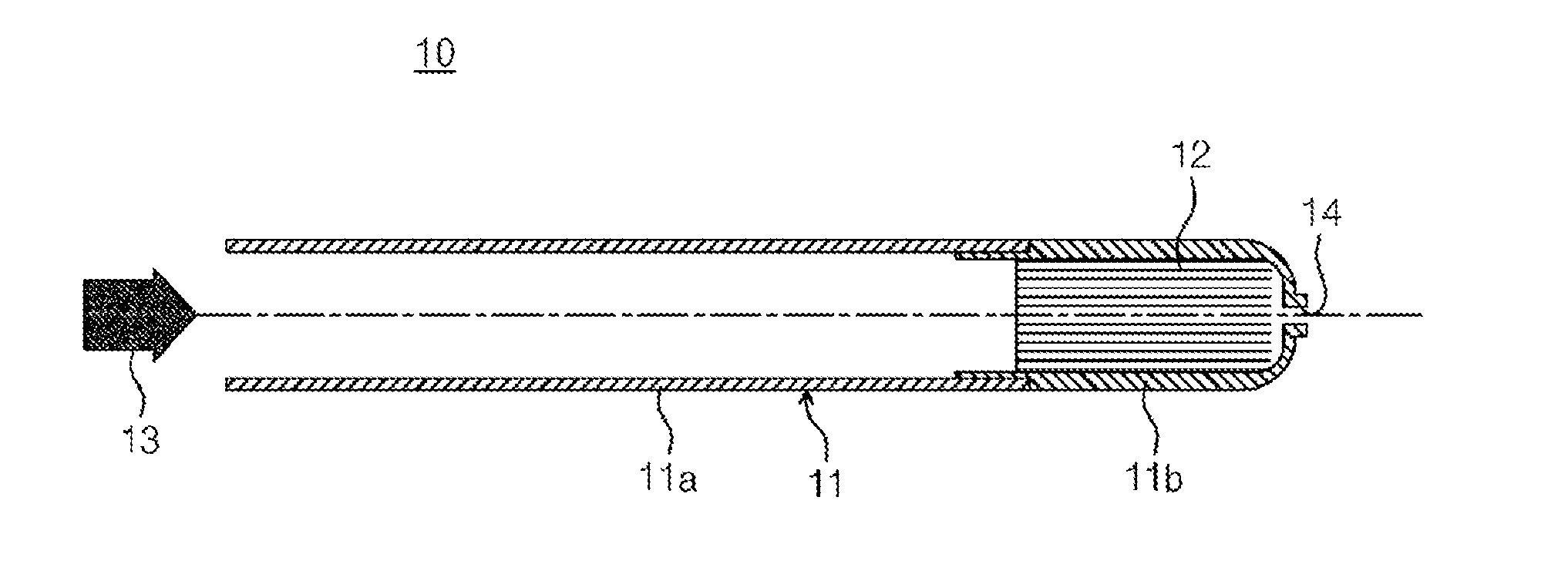

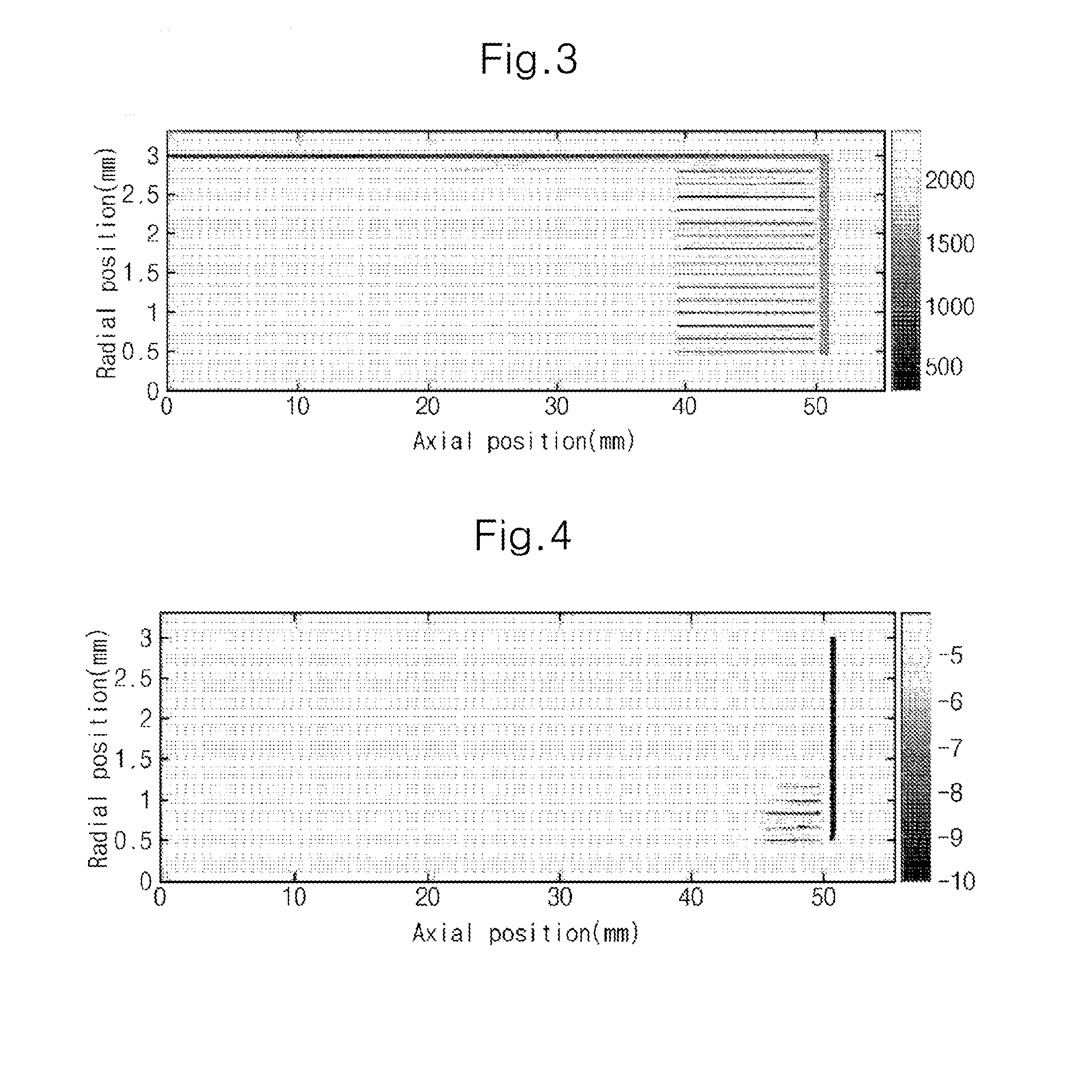

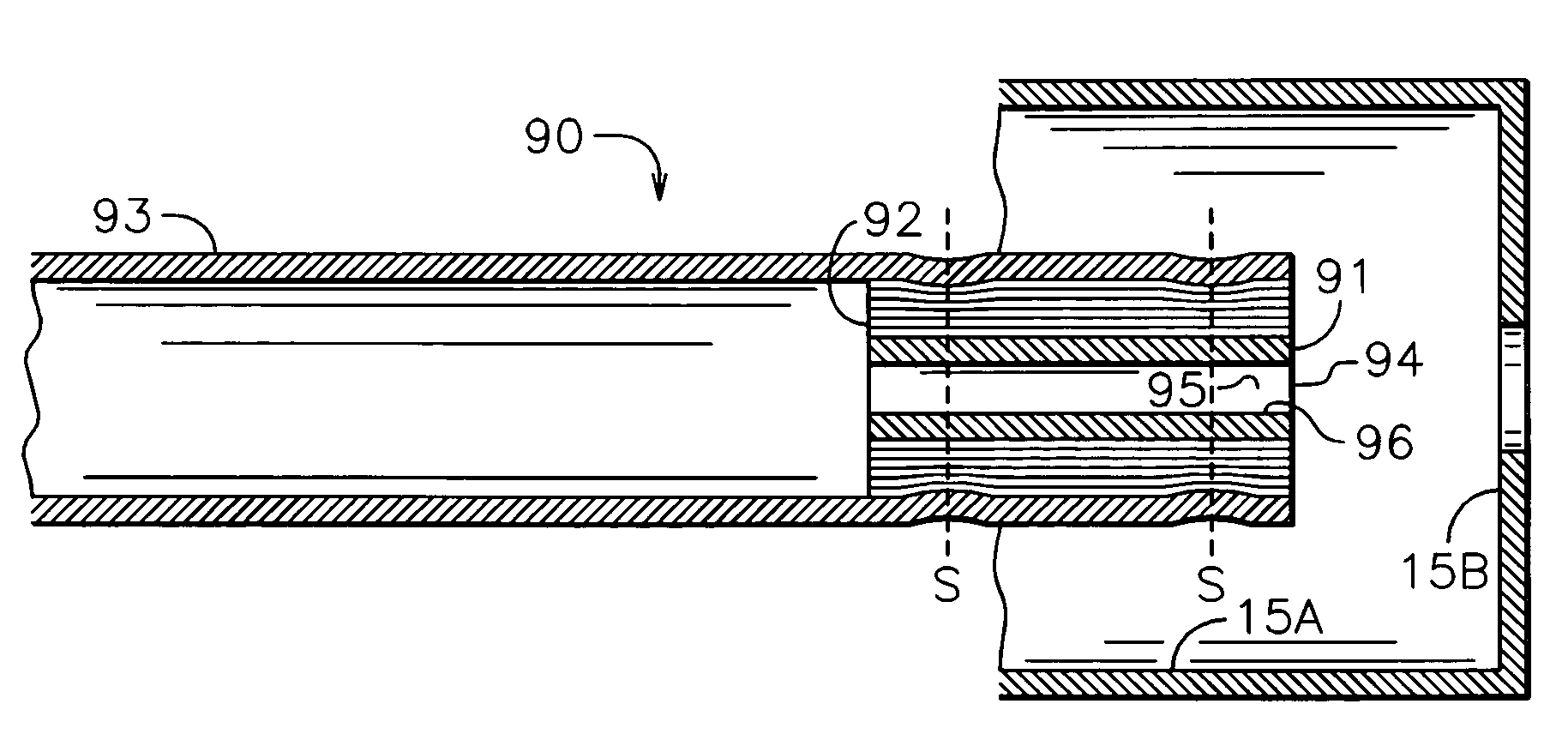

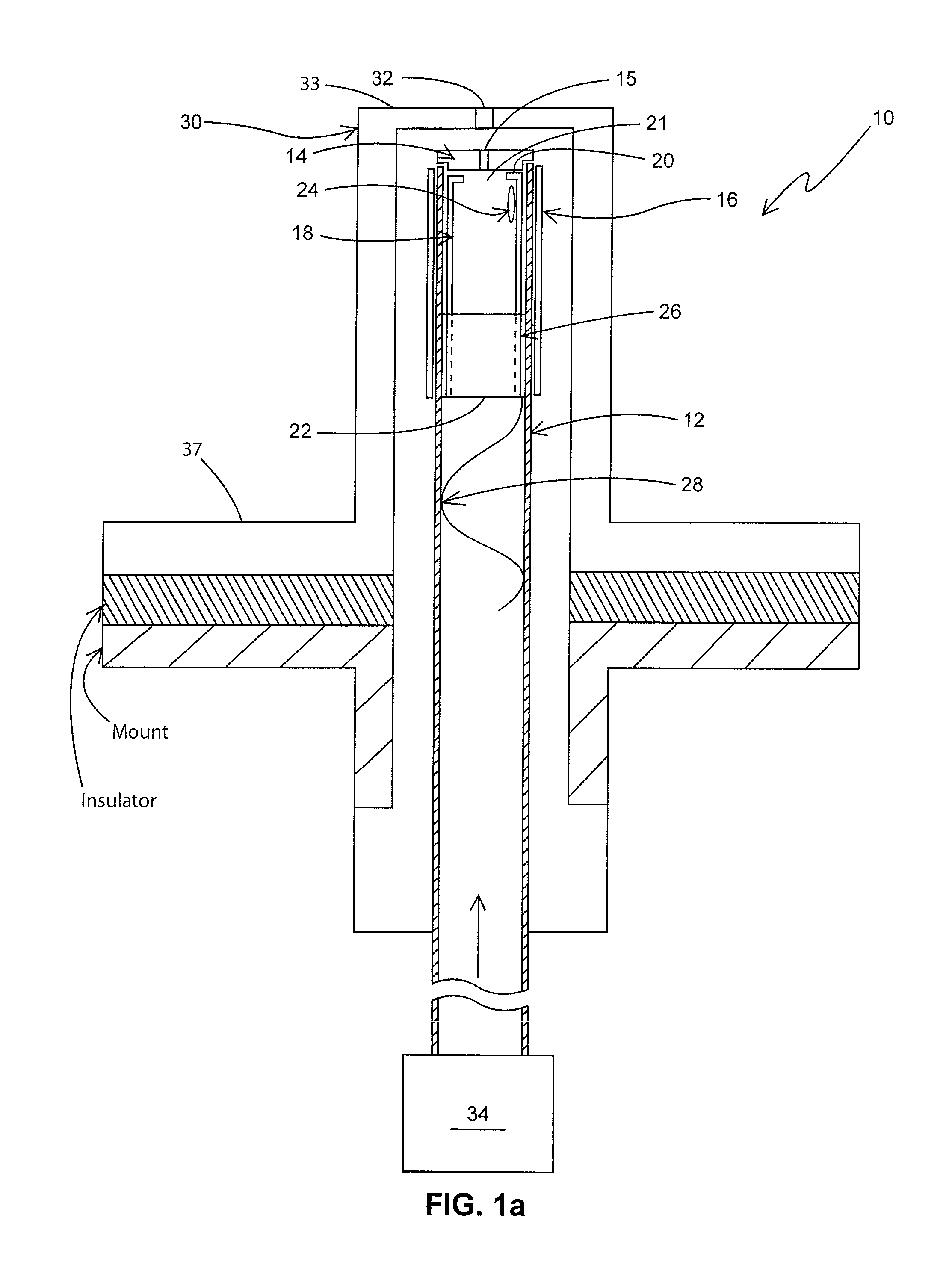

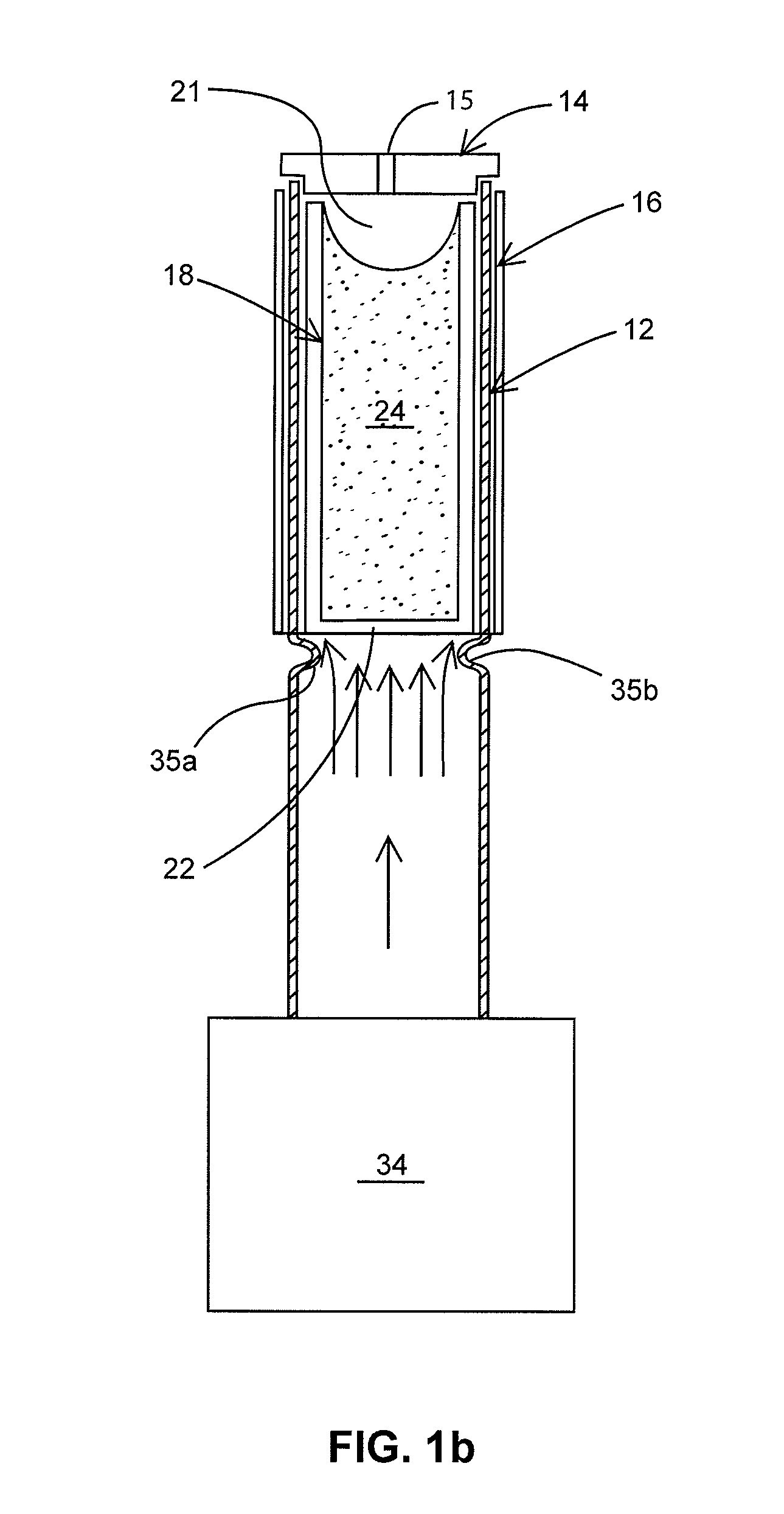

Compact high current rare-earth emitter hollow cathode for hall effect thrusters

ActiveUS8143788B2Improve throughputReduce heat transferCosmonautic vehiclesCosmonautic partsRare-earth elementEngineering

An apparatus and method for achieving an efficient central cathode in a Hall effect thruster is disclosed. A hollow insert disposed inside the end of a hollow conductive cathode comprises a rare-earth element and energized to emit electrons from an inner surface. The cathode employs an end opening having an area at least as large as the internal cross sectional area of the rare earth insert to enhance throughput from the cathode end. In addition, the cathode employs a high aspect ratio geometry based on the cathode length to width which mitigates heat transfer from the end. A gas flow through the cathode and insert may be impinged by the emitted electrons to yield a plasma. One or more optional auxiliary gas feeds may also be employed between the cathode and keeper wall and external to the keeper near the outlet.

Owner:CALIFORNIA INST OF TECH

Compact high current rare-earth emitter hollow cathode for hall effect thrusters

ActiveUS20090058305A1Improve throughputReduce heat transferCosmonautic vehiclesCosmonautic partsRare-earth elementEngineering

An apparatus and method for achieving an efficient central cathode in a Hall effect thruster is disclosed. A hollow insert disposed inside the end of a hollow conductive cathode comprises a rare-earth element and energized to emit electrons from an inner surface. The cathode employs an end opening having an area at least as large as the internal cross sectional area of the rare earth insert to enhance throughput from the cathode end. In addition, the cathode employs a high aspect ratio geometry based on the cathode length to width which mitigates heat transfer from the end. A gas flow through the cathode and insert may be impinged by the emitted electrons to yield a plasma. One or more optional auxiliary gas feeds may also be employed between the cathode and keeper wall and external to the keeper near the outlet.

Owner:CALIFORNIA INST OF TECH

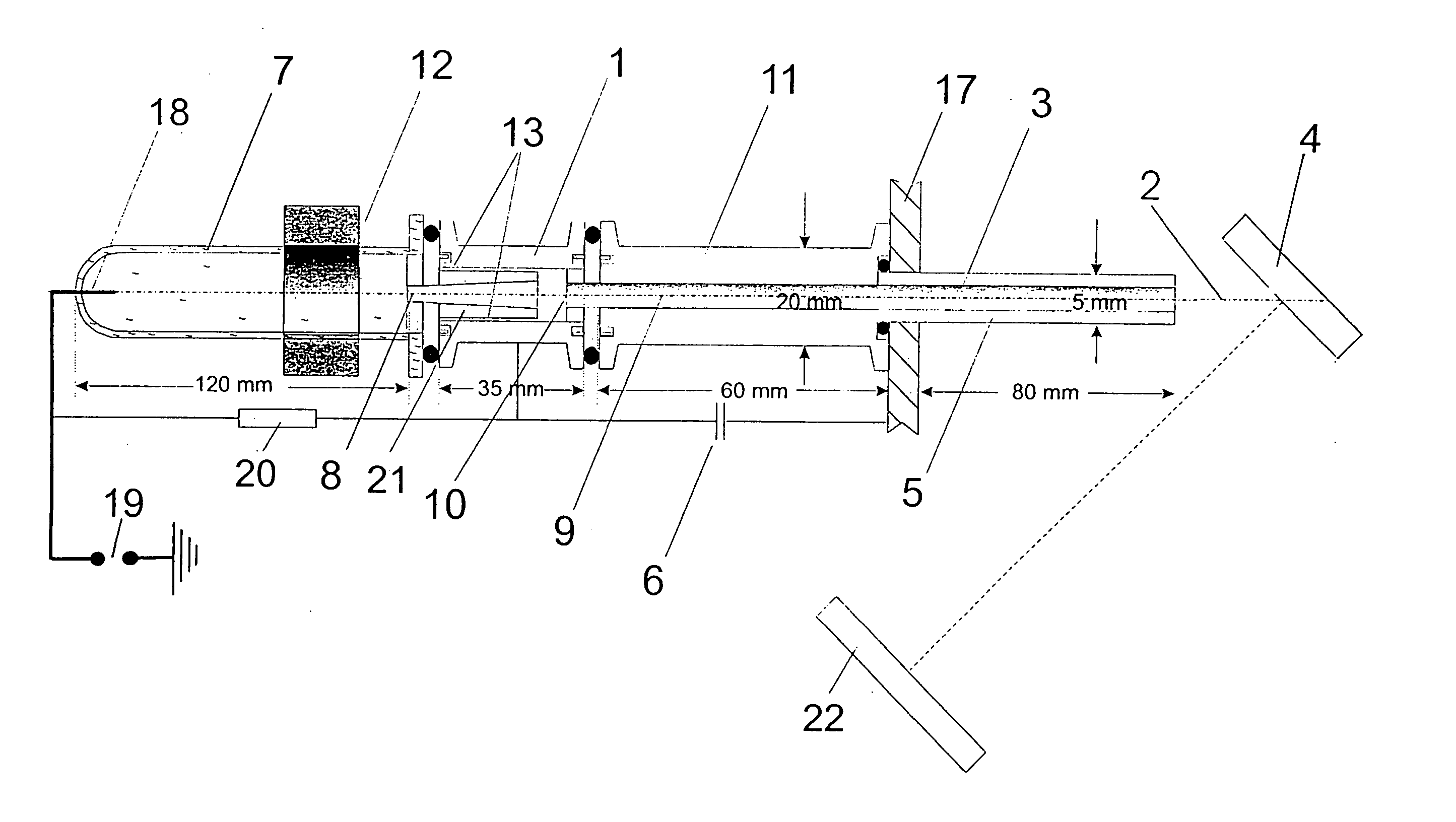

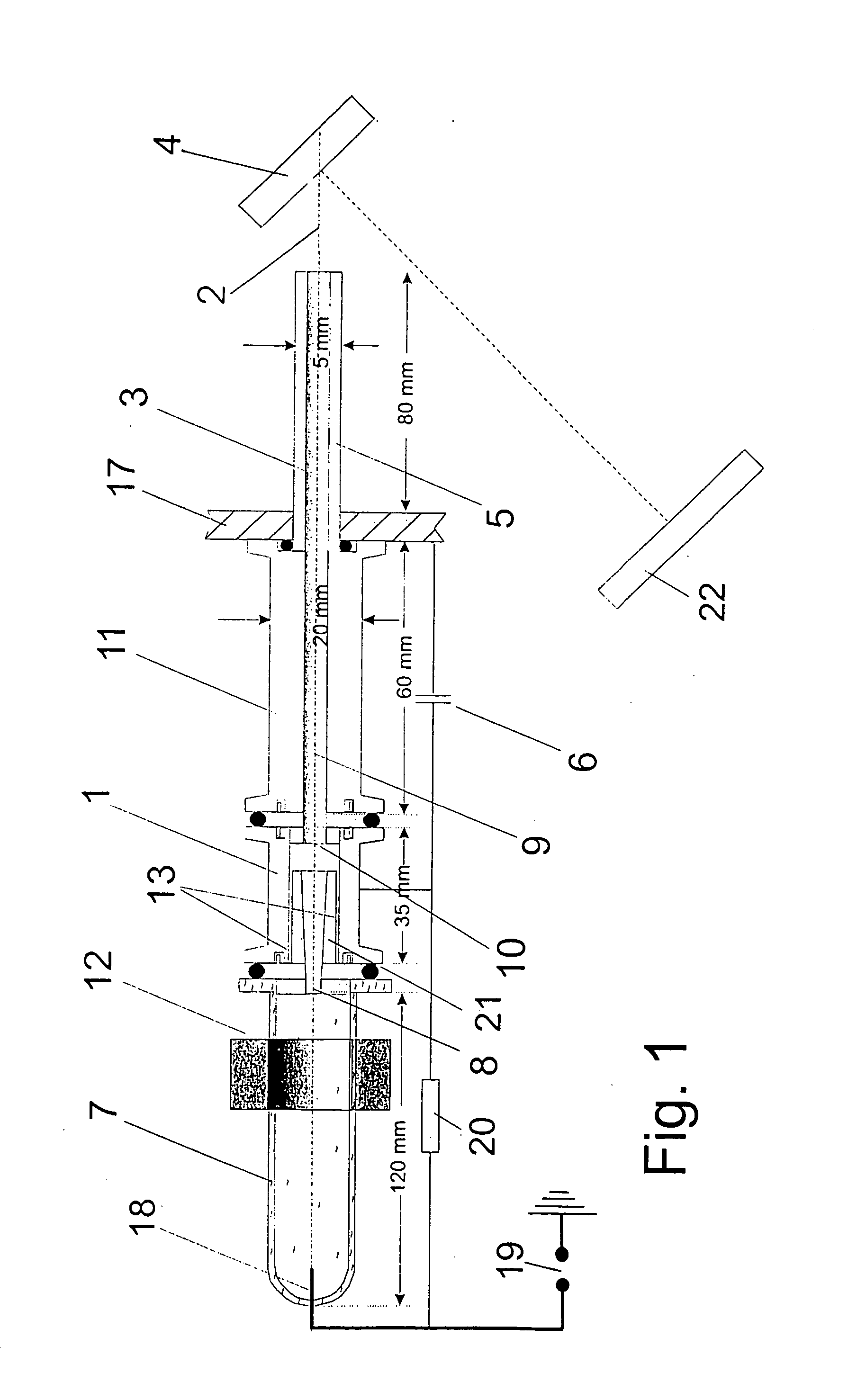

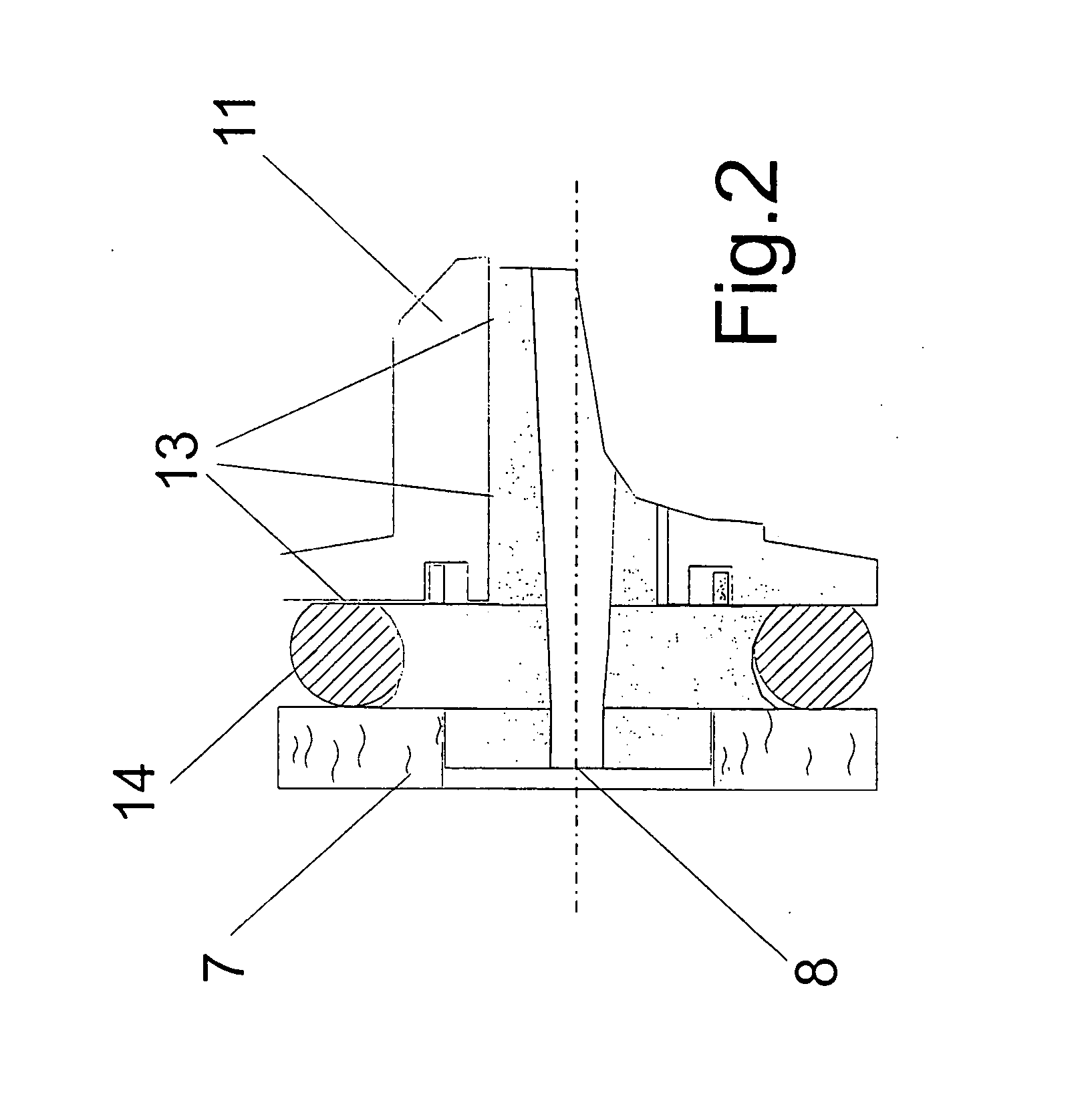

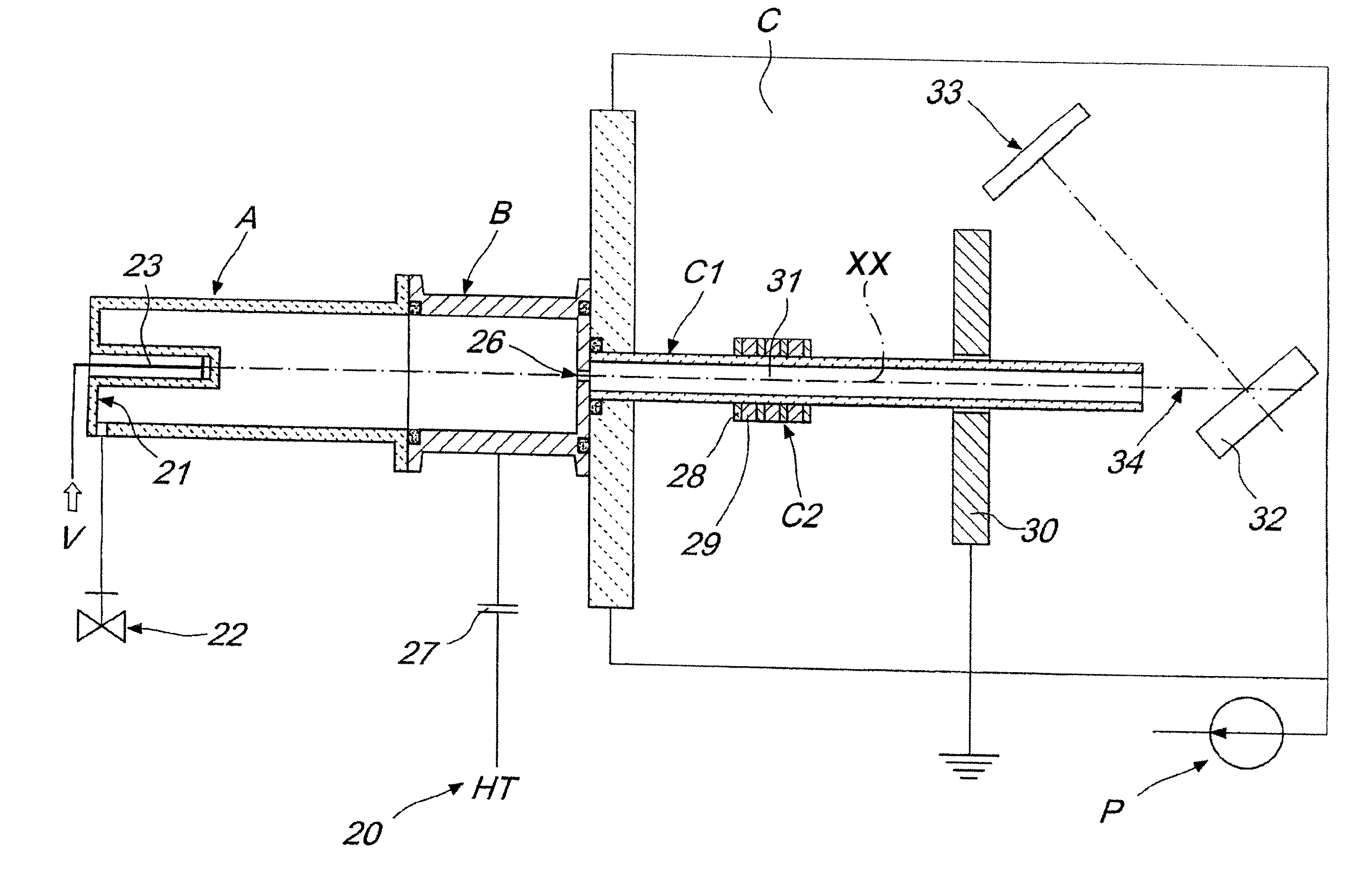

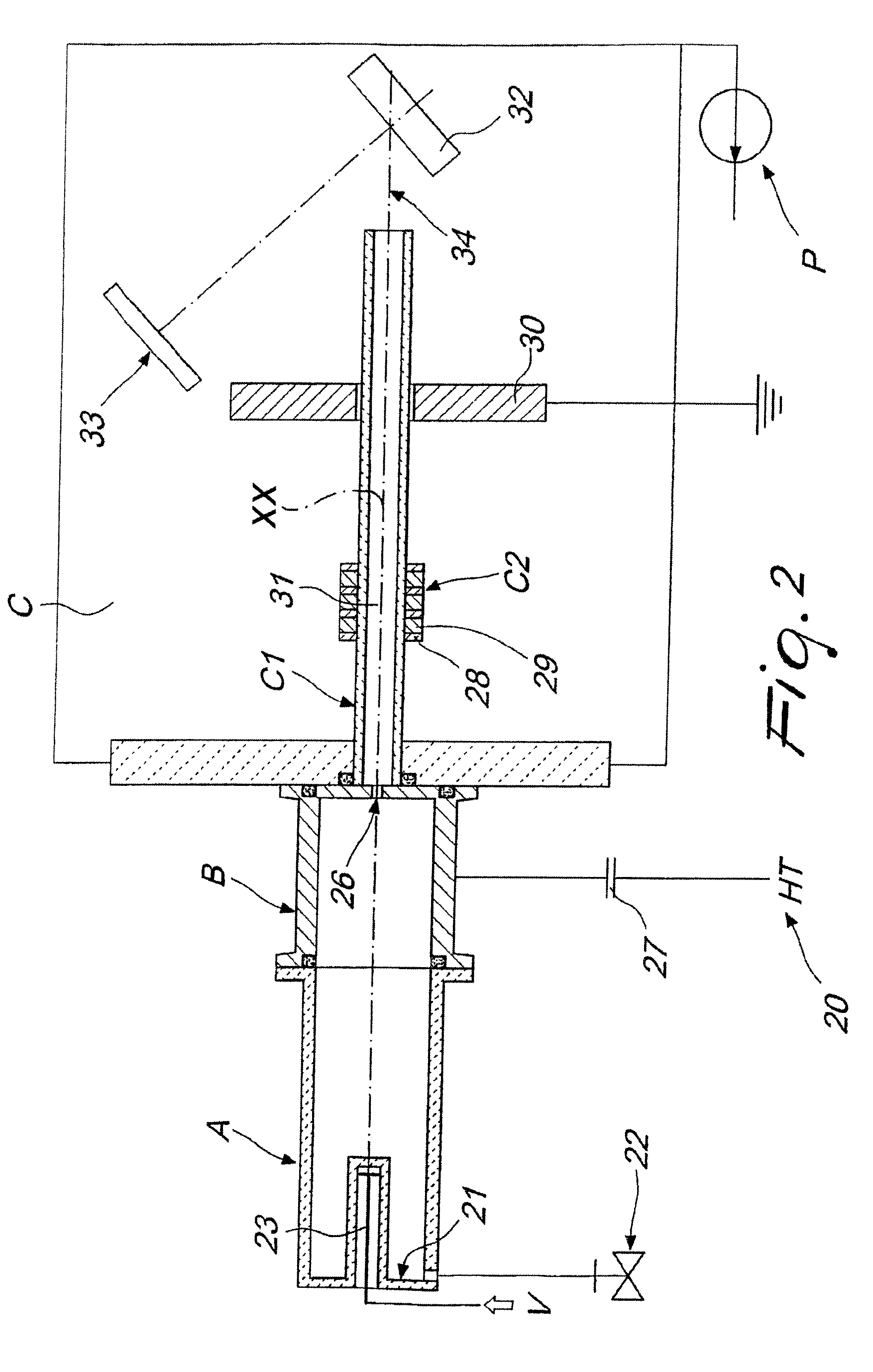

Channel spark source for generating a stable focussed electron beam

ActiveUS20050012441A1Not to damageProlong lifeVacuum evaporation coatingSputtering coatingCharge carrierPressure difference

In a channel spark source triggered by gas discharge for generating a stable focused electron beam, a gas supply for a hollow cathode thereof is provided which generates in the hollow cathode a pressure differential so that the multiplication of charge carriers in a trigger plasma of a trigger plasma source connected to the hollow cathode provides for a reliable gas discharge and the formation of a stable electron beam which exits the arrangement and which does not damage the internal passages of the arrangement.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

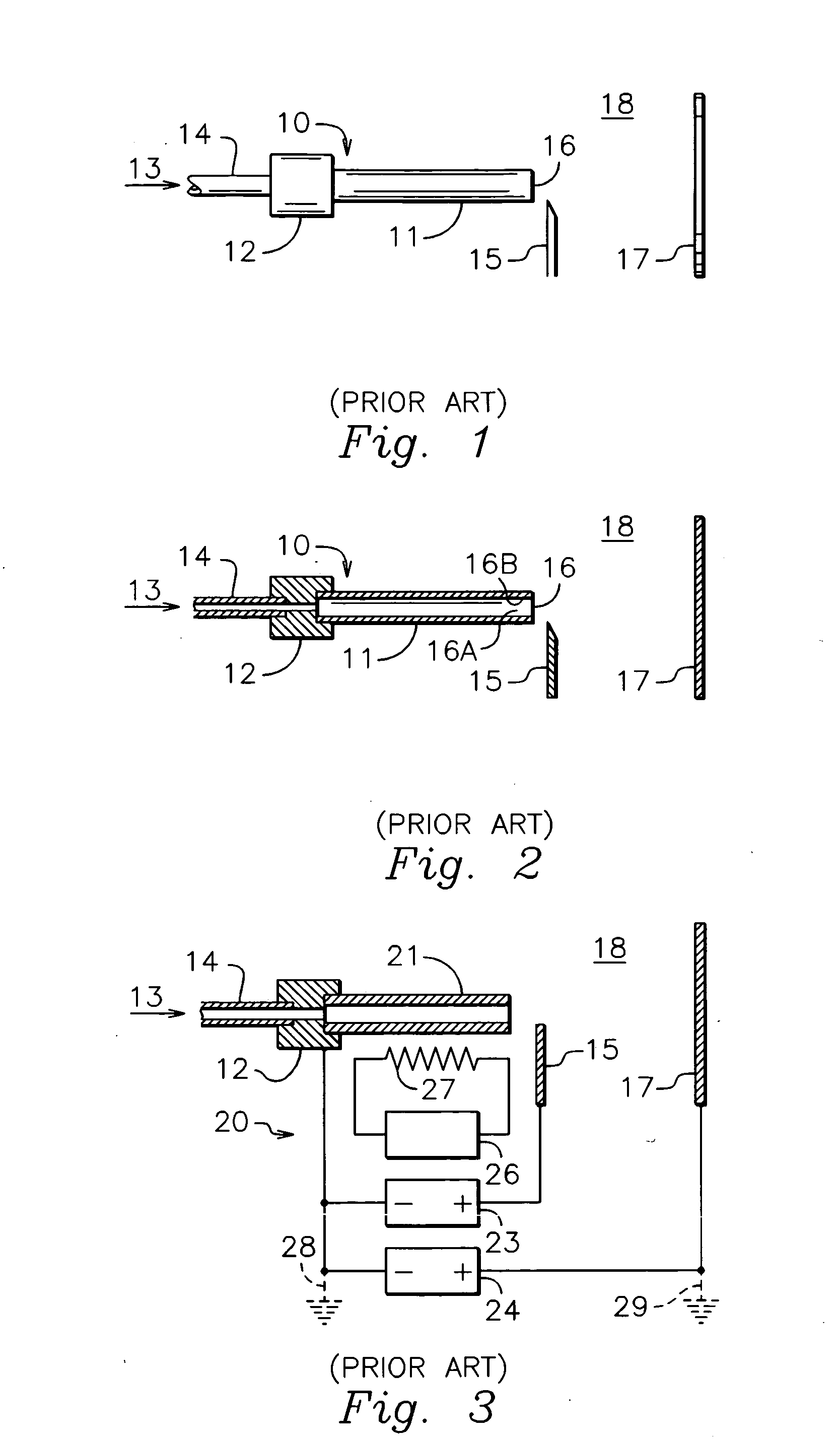

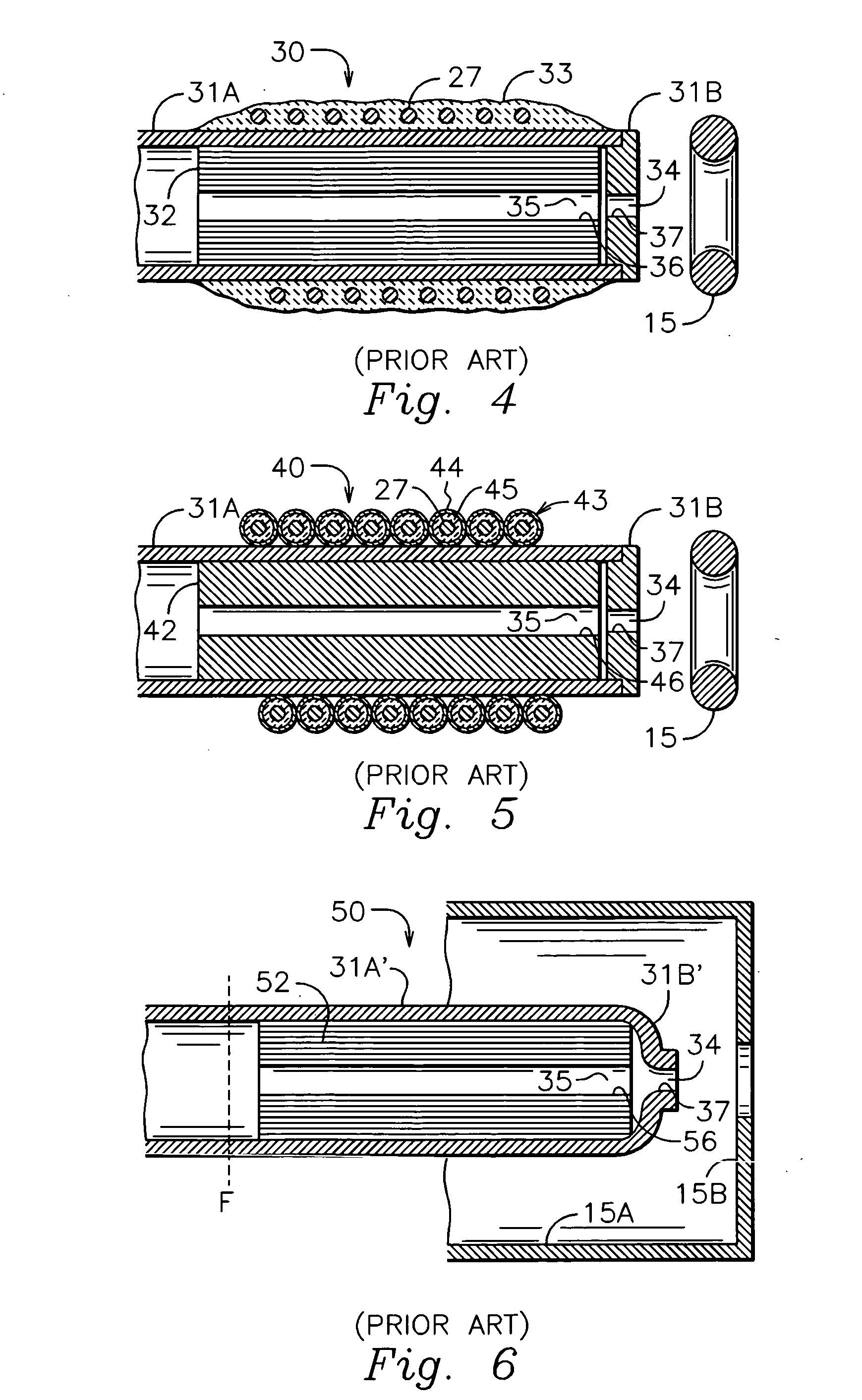

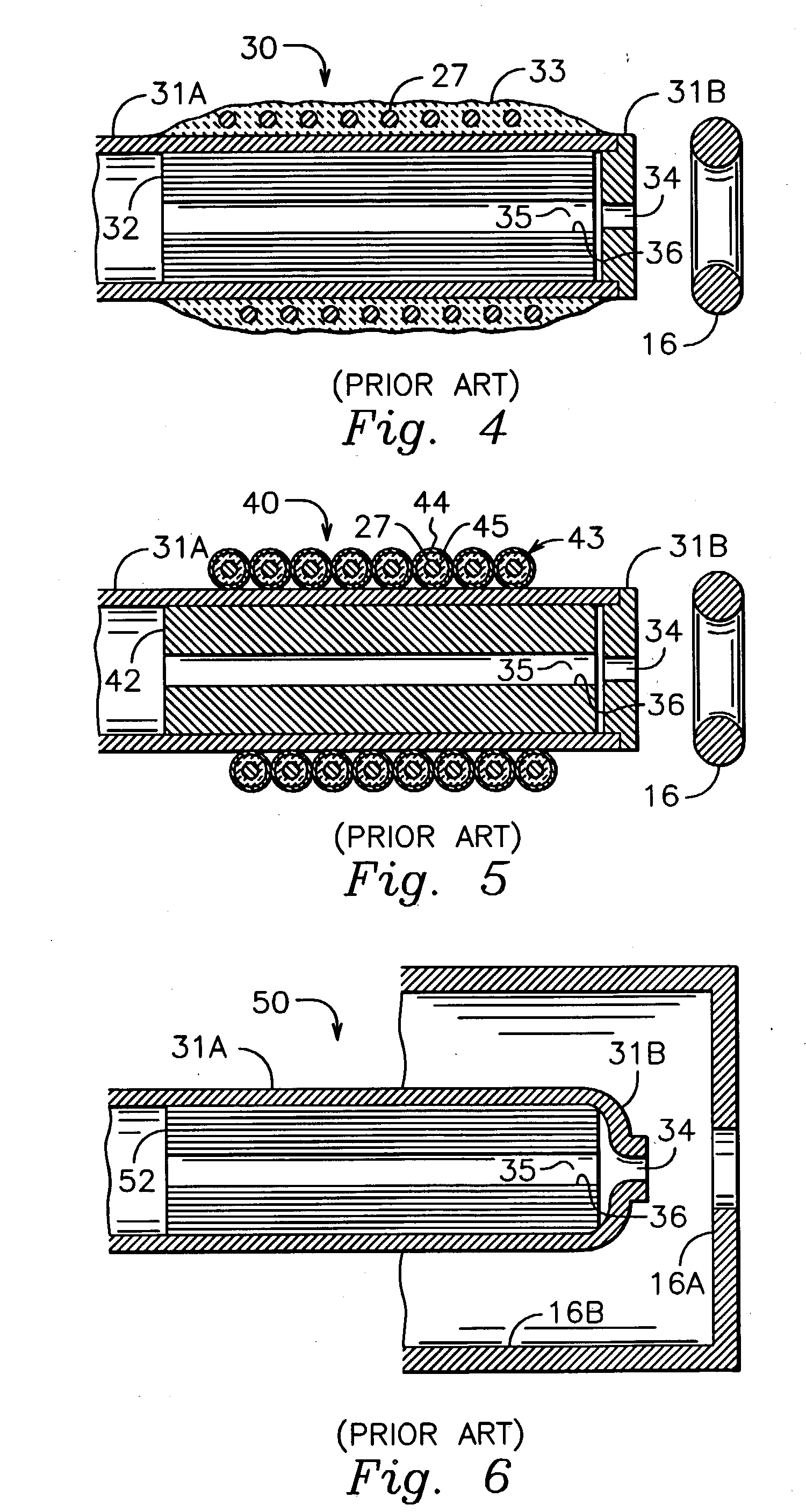

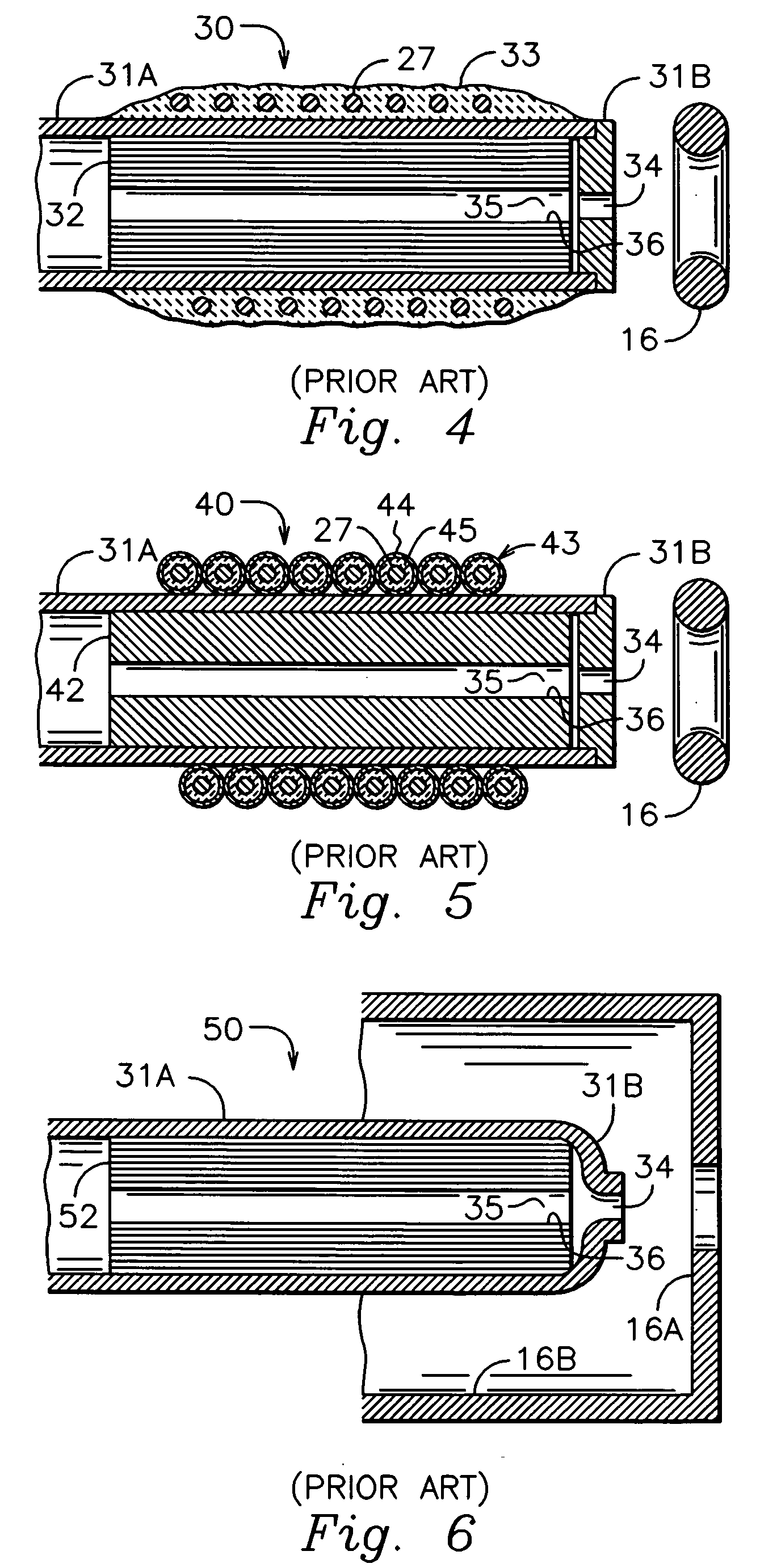

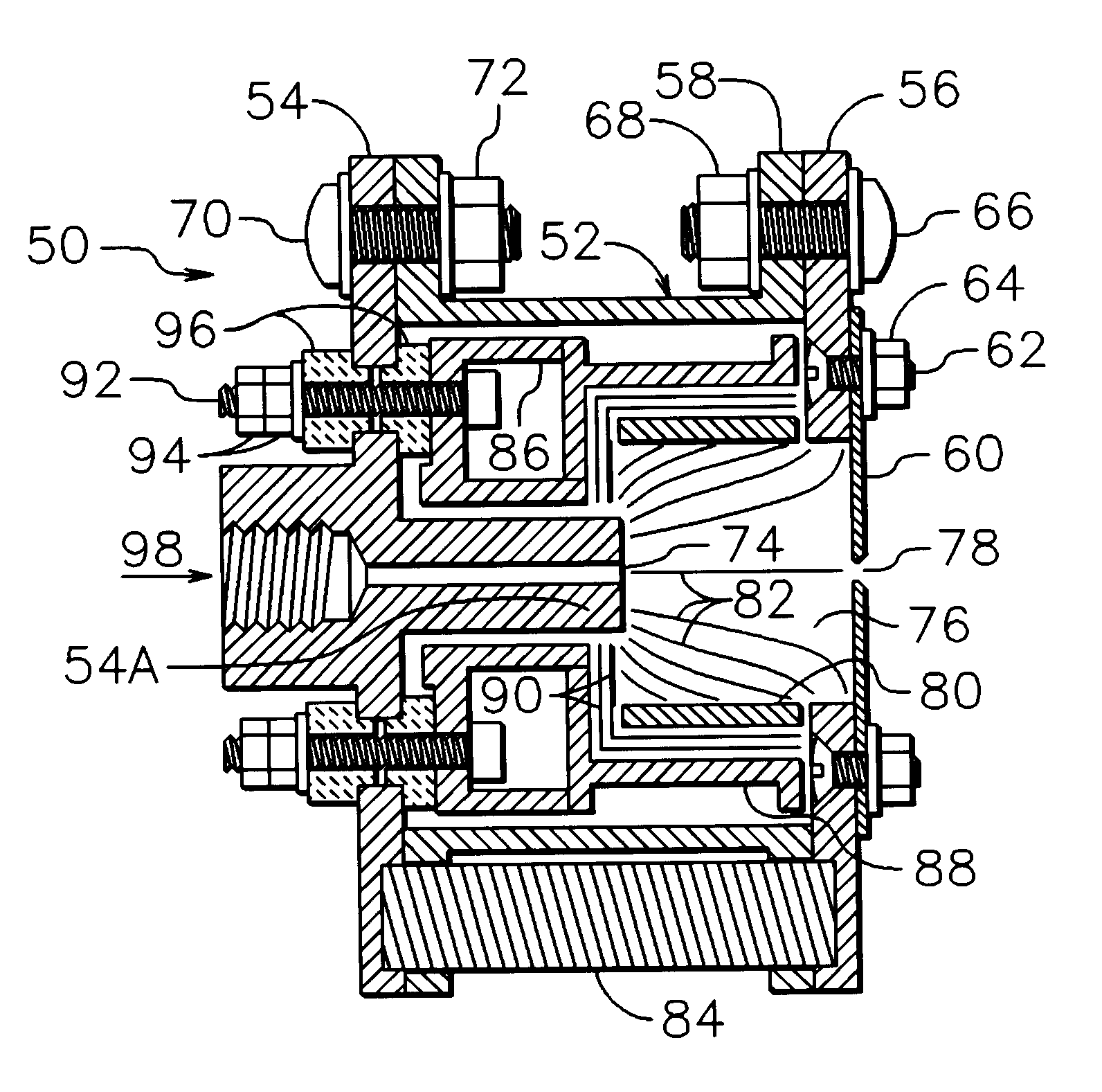

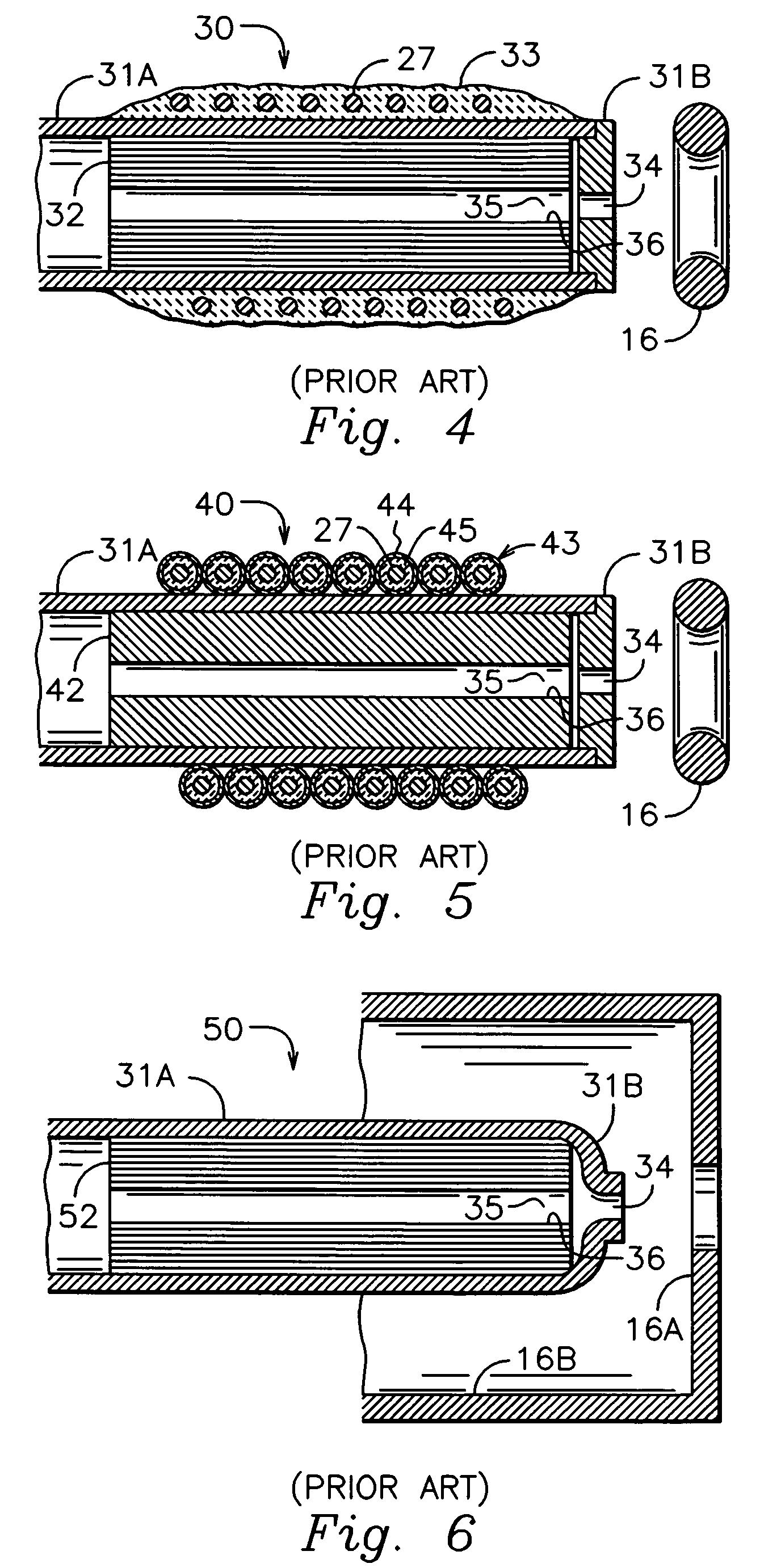

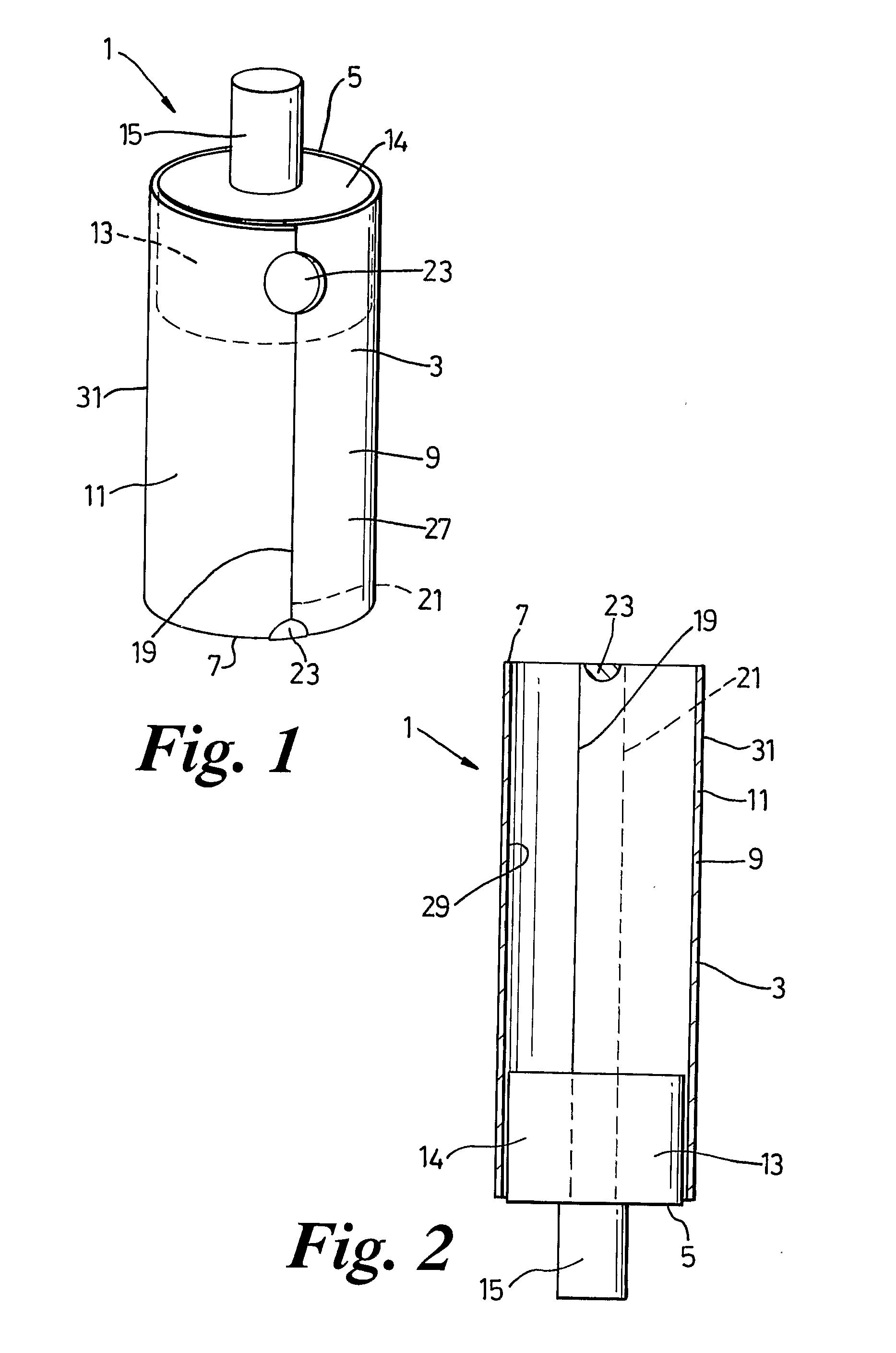

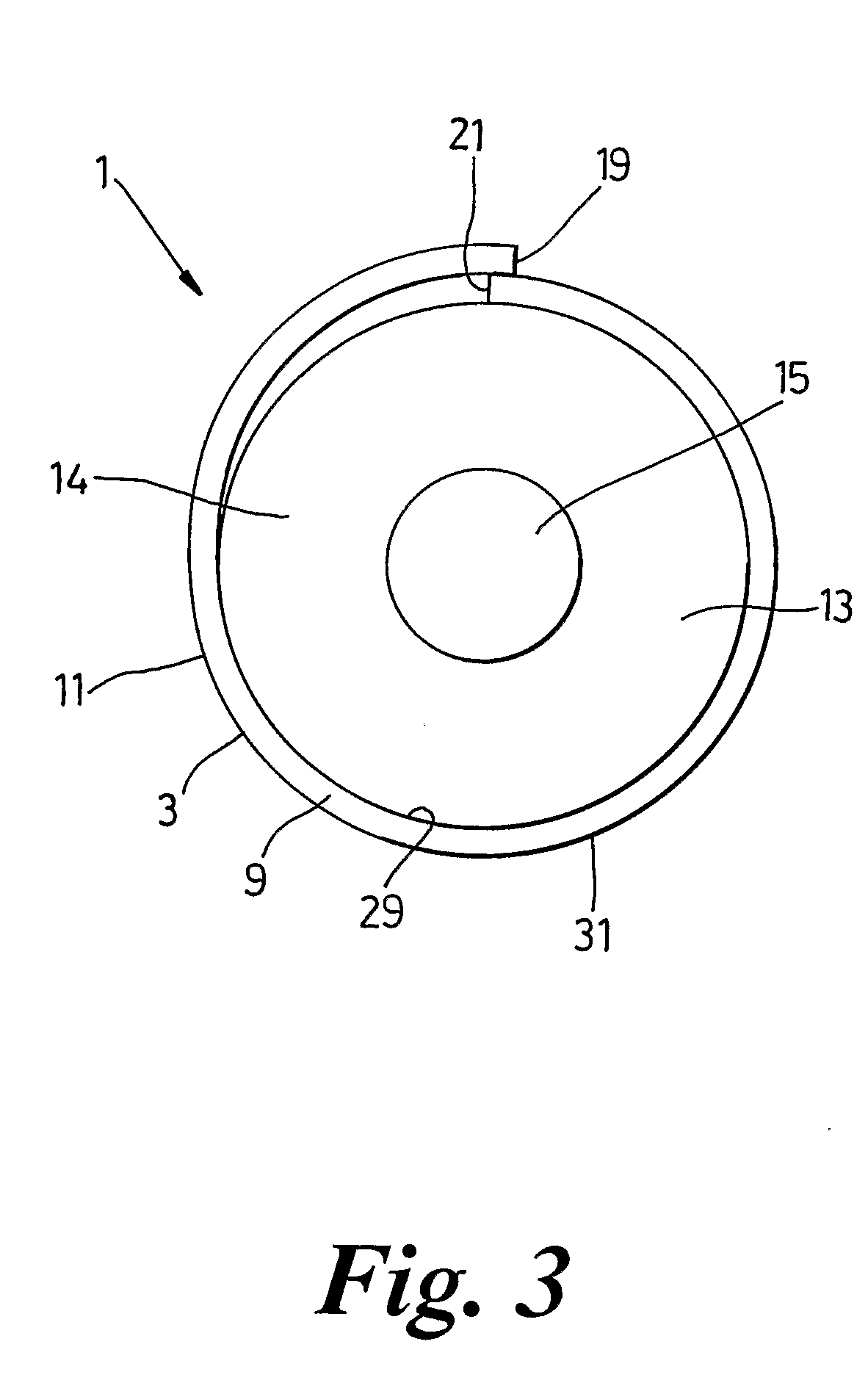

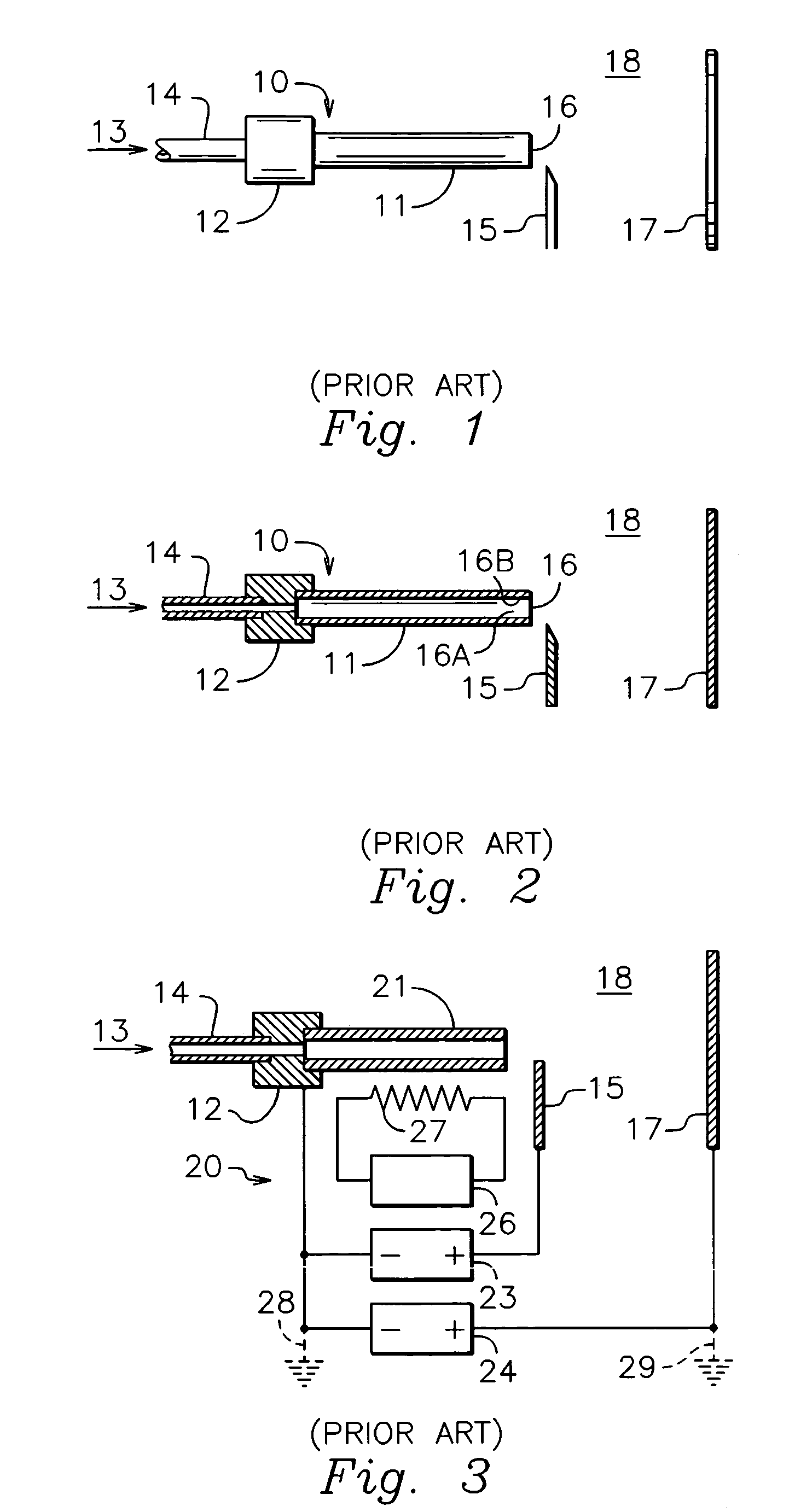

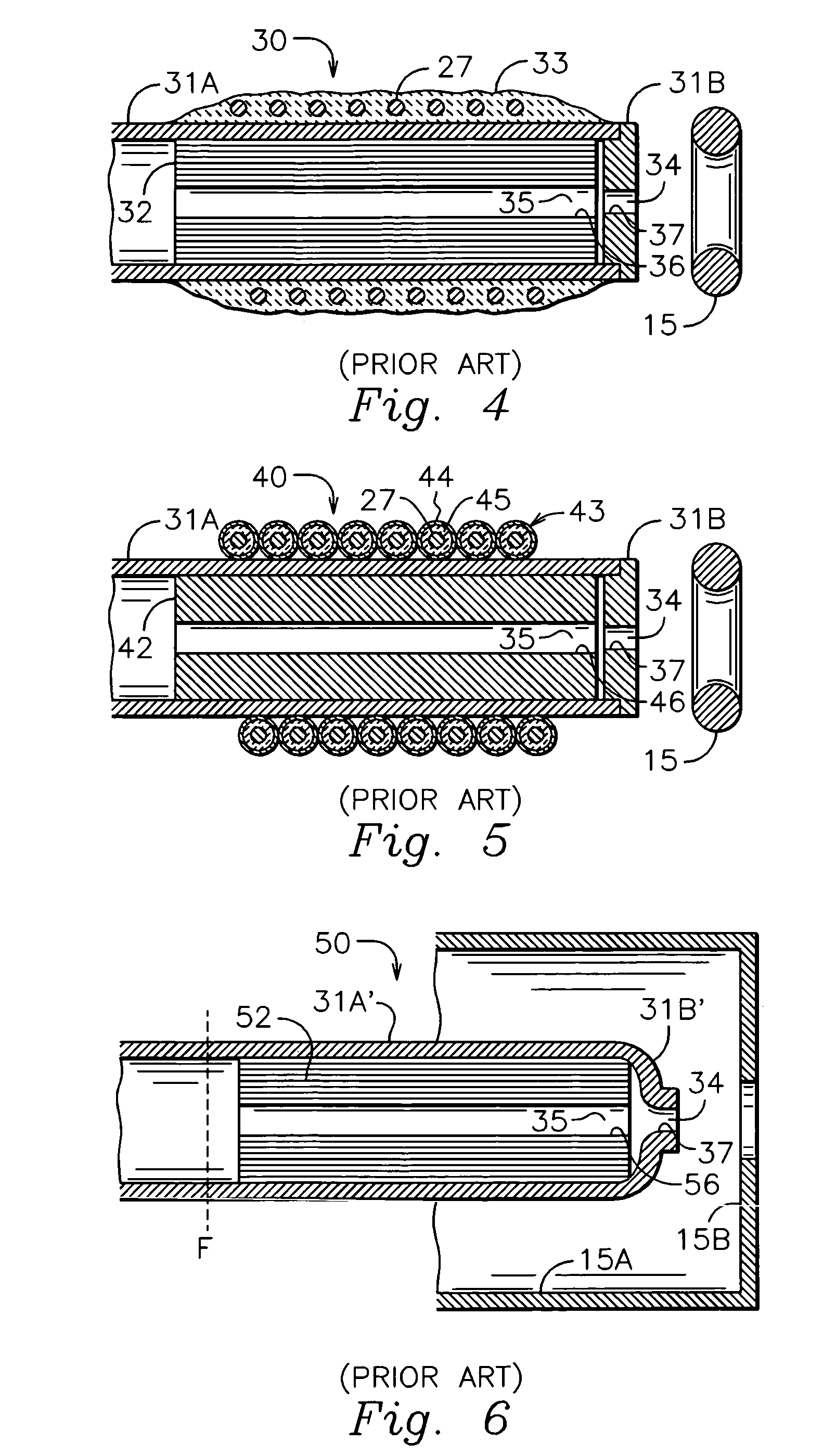

Industrial hollow cathode

ActiveUS20070222358A1Simple to fabricateSimple to useLamp incadescent bodiesThermionic cathodesEngineeringOperating temperature

In accordance with one embodiment, the hollow cathode is comprised of a first tantalum tube, tantalum foil, and a second tantalum tube. The foil is in the form of a spiral winding around the outside of the first tube and is held in place by the second tube, which surrounds the foil. One end of the second tube is approximately flush with one end of the first tube. The other end of the second tube extends to a cathode support through which the working gas flows. To start the cathode, a flow of ionizable inert gas, usually argon, is initiated through the hollow cathode and out the open end of the first tube. An electrical discharge is then started between an external electrode and the first tube. When the first tube is heated to operating temperature, electrons are emitted from the open end of the first tube.

Owner:KAUFMAN & ROBINSTON

Industrial hollow cathode

InactiveUS20040000853A1Simple to fabricateSimple to useThermionic cathodesDischarge tube solid thermionic cathodesEngineeringRadiation shield

In accordance with one embodiment of the present invention, the hollow-cathode apparatus comprises a small-diameter tantalum tube with a plurality of tantalum-foil radiation shields, wherein the plurality of shields in turn comprise one or more spiral windings external to that tube and approximately flush with the open end from which electron emission takes place. The axial length of at least one of the inner windings (closer to the tantalum tube) is equal to or less than approximately half the length of the tantalum tube. An enclosed keeper surrounds the cathode. To start the cathode, a flow of ionizable inert gas, usually argon, is initiated through the cathode and out the open end. An electrical discharge is then started between the keeper and the hollow cathode. When heated to operating temperature, electrons exit from the open end of the hollow cathode.

Owner:KAUFMAN & ROBINSON

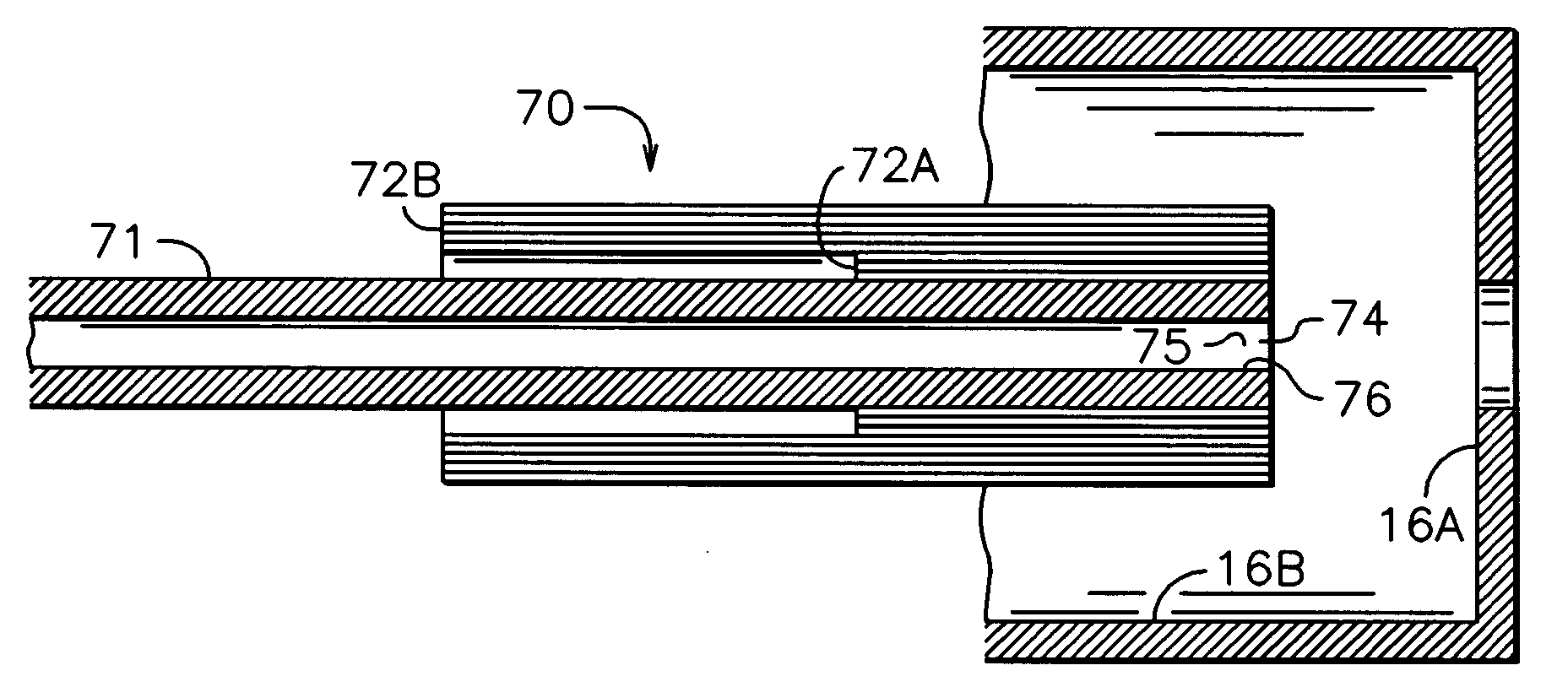

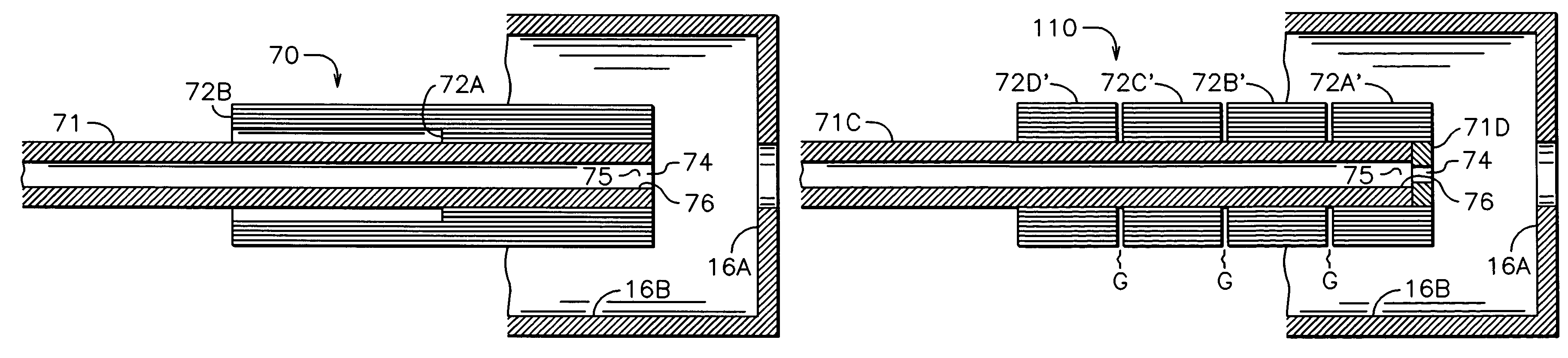

Industrial hollow cathode with radiation shield structure

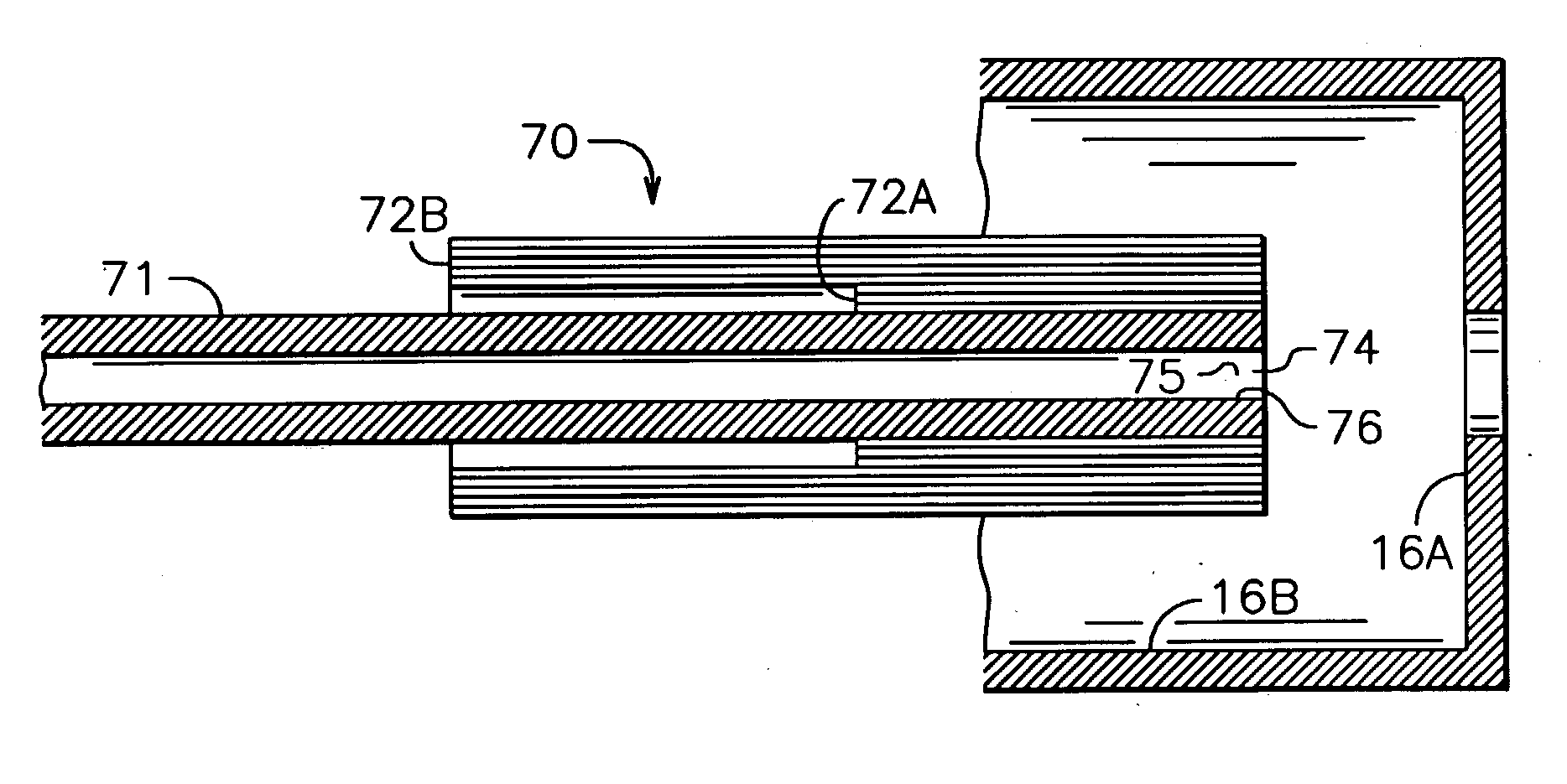

ActiveUS20060132017A1Simple to fabricateSimple to useThermionic cathodesMachines/enginesConductor CoilOperating temperature

In accordance with one embodiment of the present invention, the hollow-cathode apparatus comprises a small-diameter tantalum tube with a plurality of tantalum-foil radiation shields, wherein the plurality of shields in turn comprise one or more spiral windings external to that tube and approximately flush with the open end from which electron emission takes place. The axial length of at least one of the inner windings (closer to the tantalum tube) is equal to or less than approximately half the length of the tantalum tube. An enclosed keeper surrounds the cathode. To start the cathode, a flow of ionizable inert gas, usually argon, is initiated through the cathode and out the open end. An electrical discharge is then started between the keeper and the hollow cathode. When heated to operating temperature, electrons exit from the open end of the hollow cathode.

Owner:KAUFMAN & ROBINSON

Apparatus and process for generating, accelerating and propagating beams of electrons and plasma

InactiveUS7872406B2Increase energy densitySparking plugsMaterial nanotechnologyElectricityHigh density

An apparatus and a process for generating, accelerating and propagating beams of electrons and plasma at high density, the apparatus comprising: a first dielectric tube, which contains gas; a hollow cathode, which is connected to said first dielectric tube; a second dielectric tube, which is connected to said hollow cathode and protrudes inside, and is connected to, a deposition chamber; an anode, which is arranged around said second dielectric tube, in an intermediate position; means for applying voltage to said cathode and said anode; means for evacuating the gas from the chamber; and means for spontaneous conversion of gas in the first dielectric tube into plasma.

Owner:MATACOTTA FRANCESCO CINO +1

12CaO-7Al2O3 ELECTRIDE HOLLOW CATHODE

ActiveUS20140354138A1Lower work functionBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangements12CaO.7Al2O3Engineering

The use of the electride form of 12CaO-7Al2O3, or C12A7, as a low work function electron emitter in a hollow cathode discharge apparatus is described. No heater is required to initiate operation of the present cathode, as is necessary for traditional hollow cathode devices. Because C12A7 has a fully oxidized lattice structure, exposure to oxygen does not degrade the electride. The electride was surrounded by a graphite liner since it was found that the C12A7 electride converts to it's eutectic (CA+C3A) form when heated (through natural hollow cathode operation) in a metal tube.

Owner:COLORADO STATE UNIVERSITY

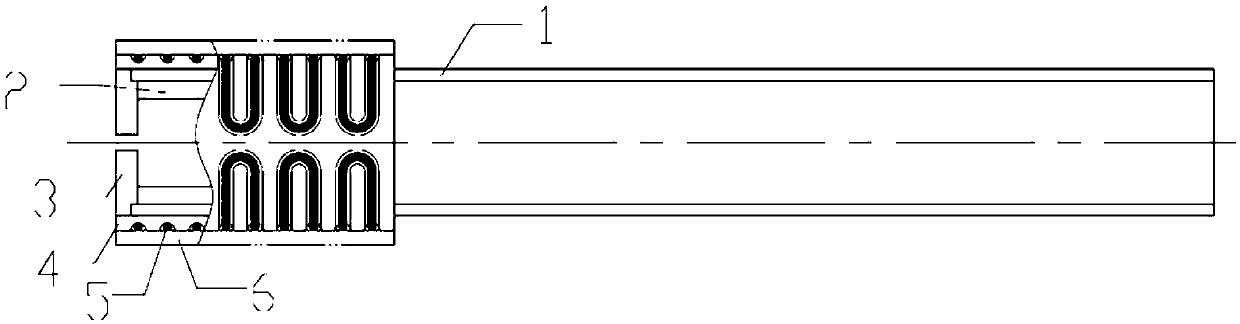

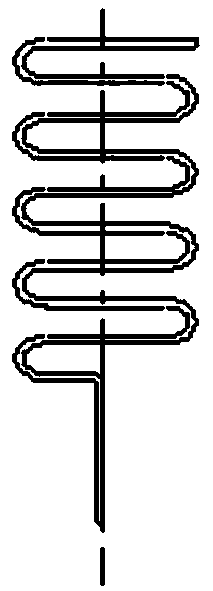

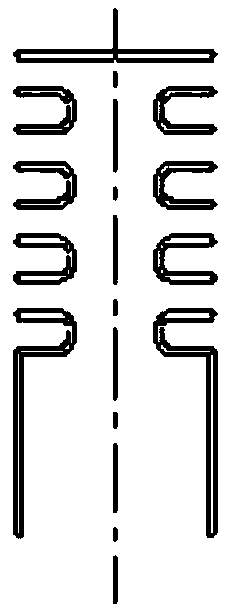

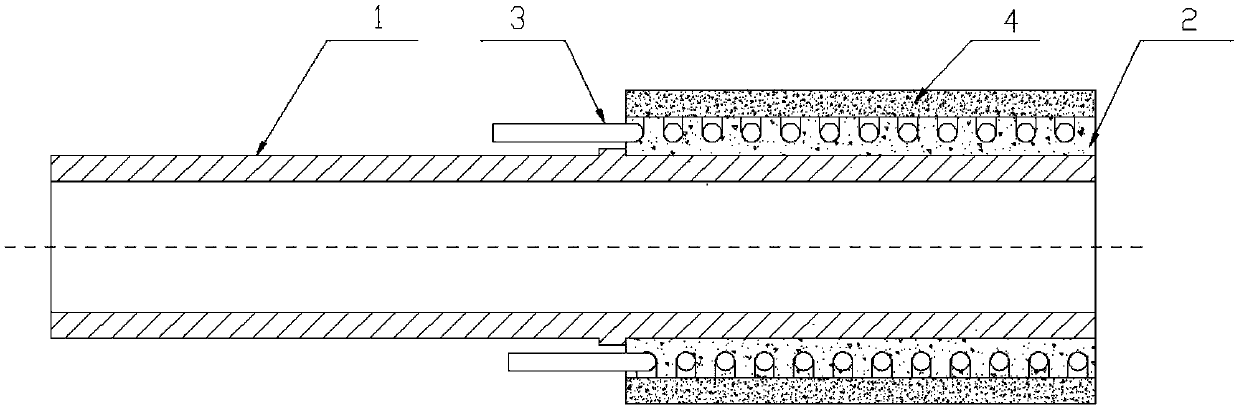

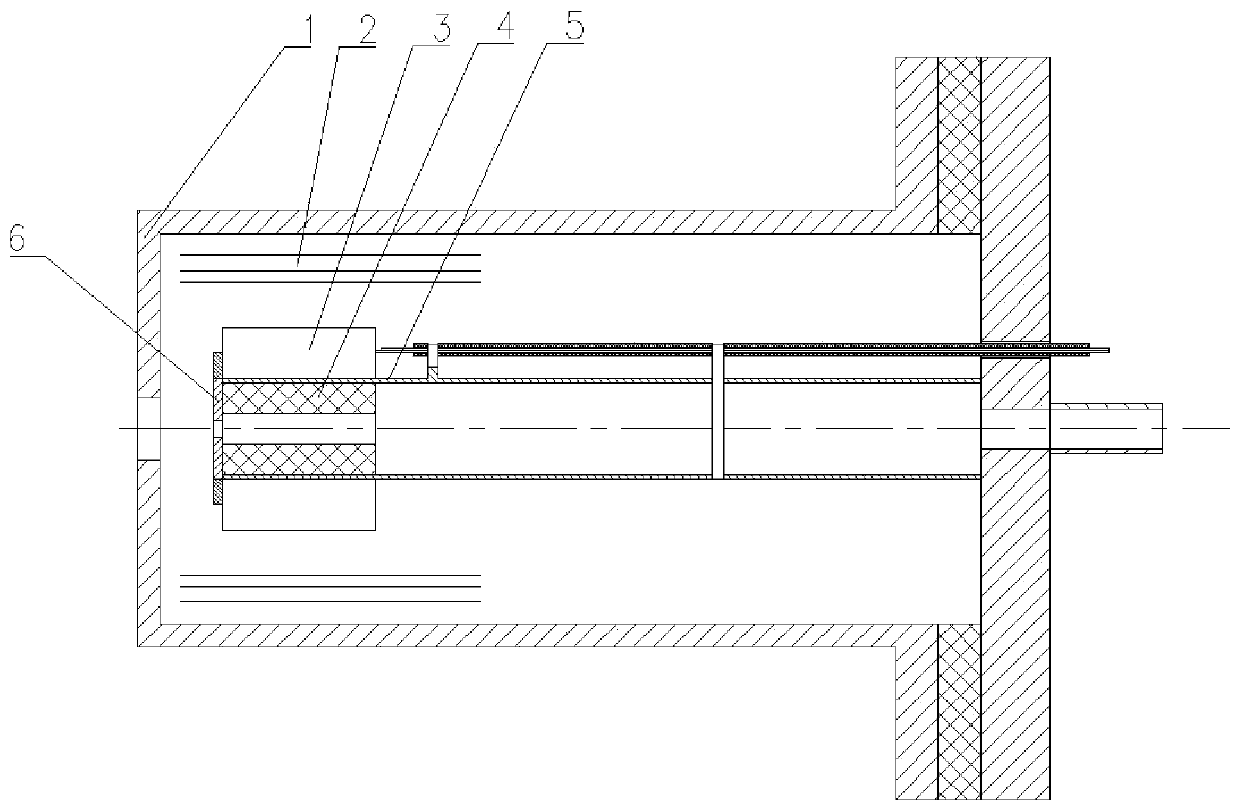

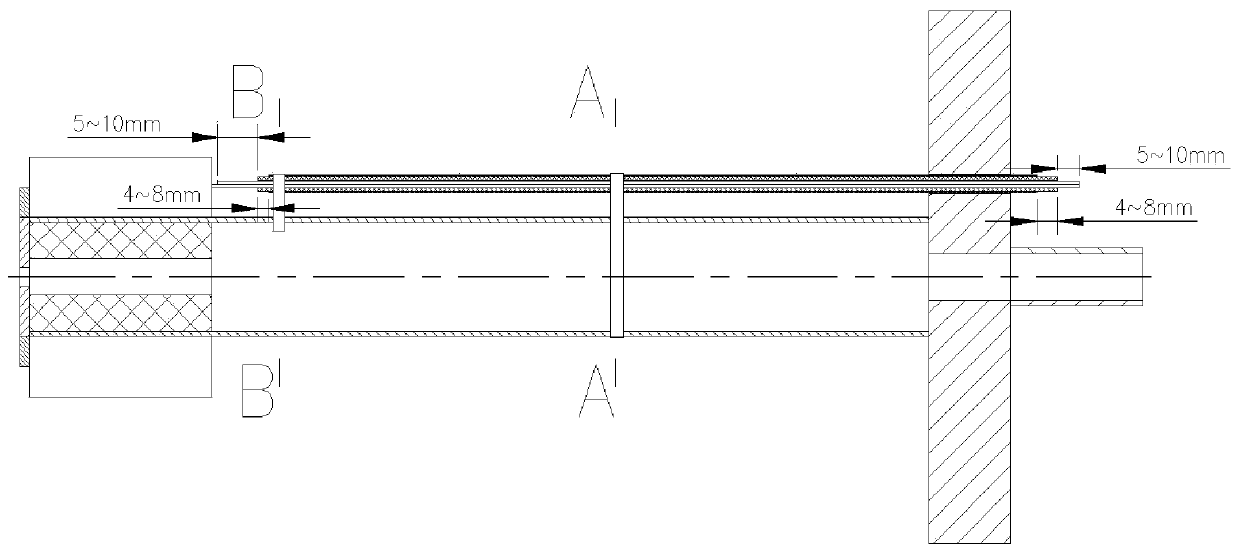

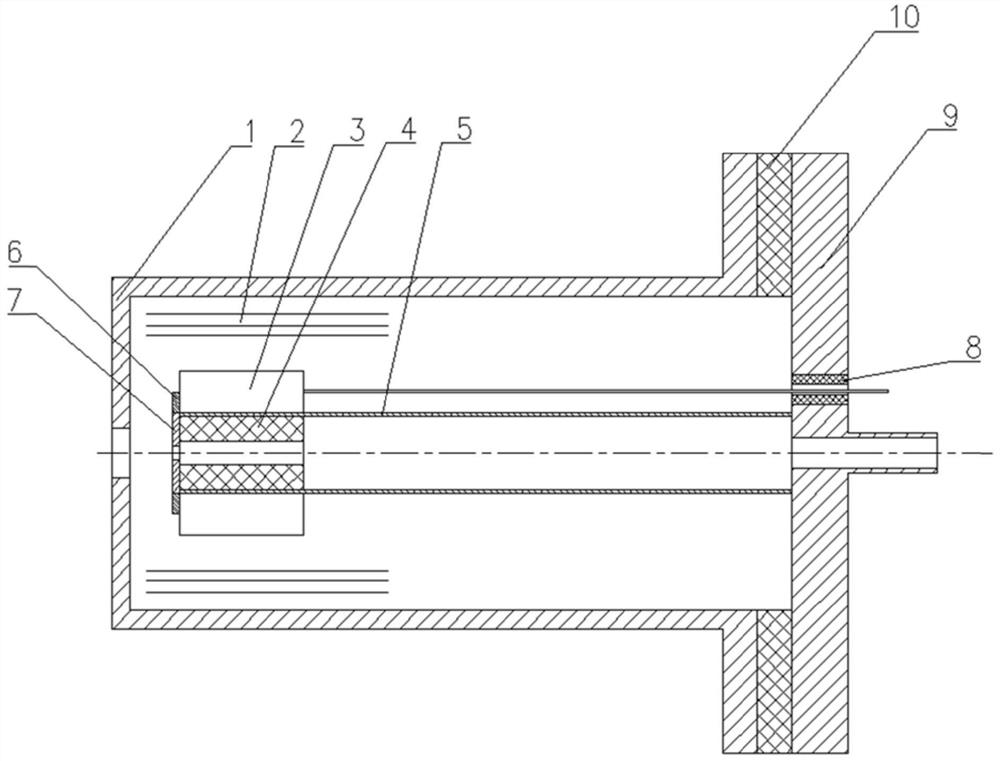

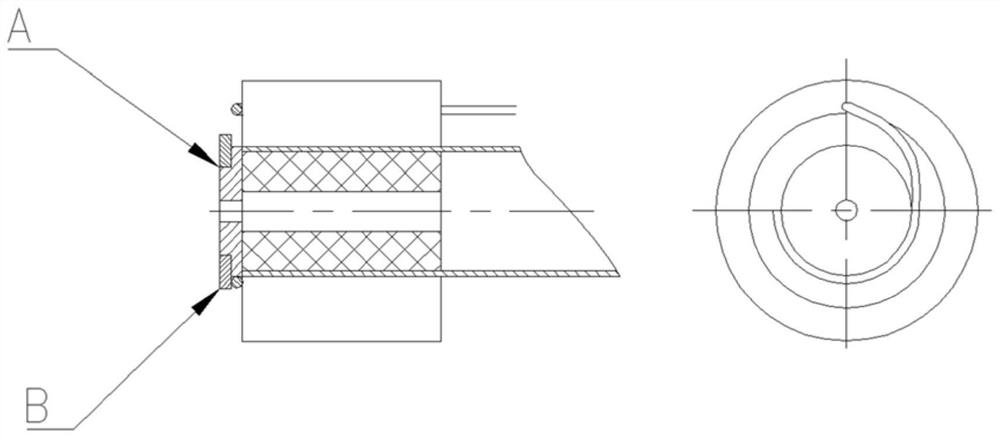

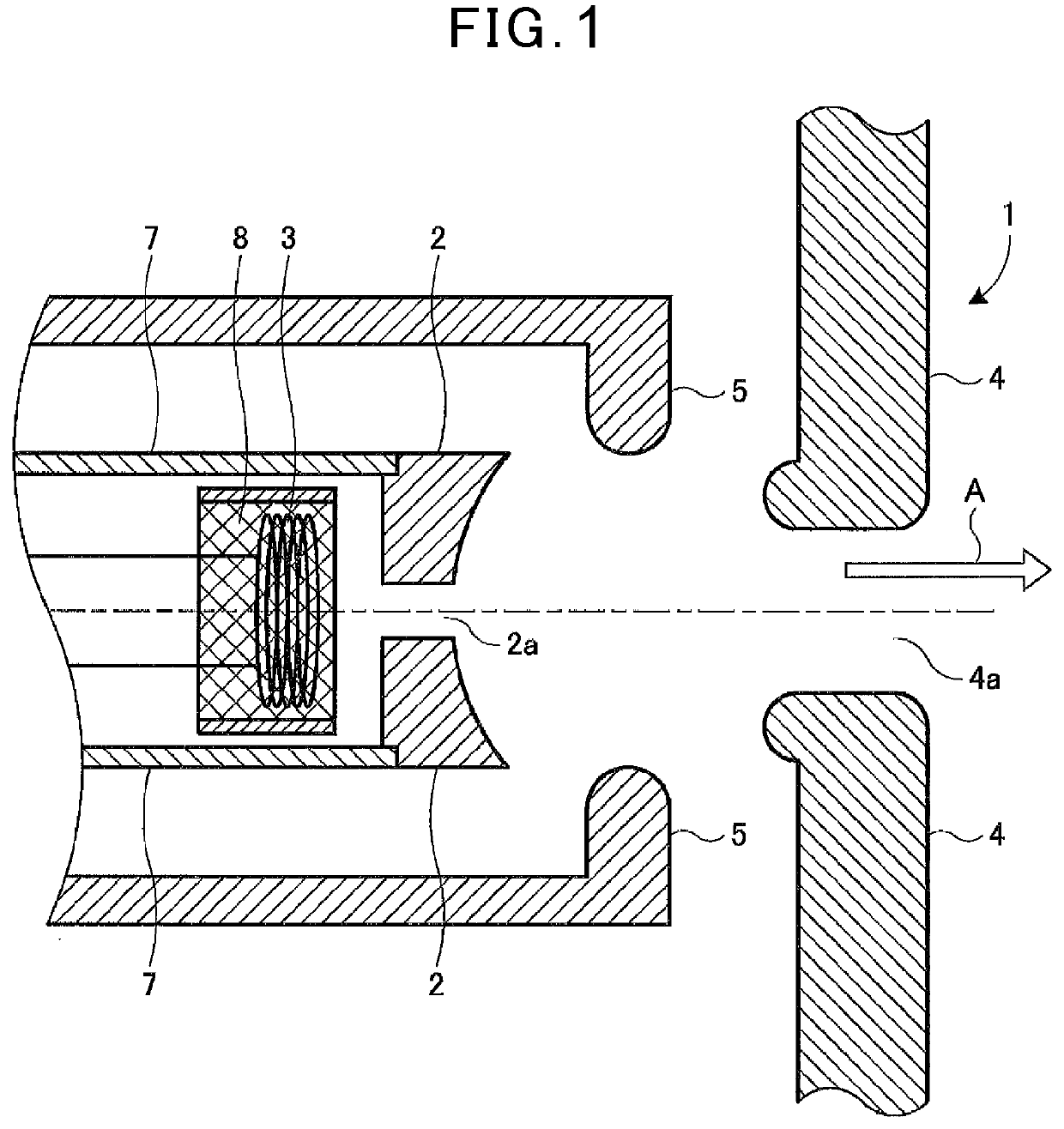

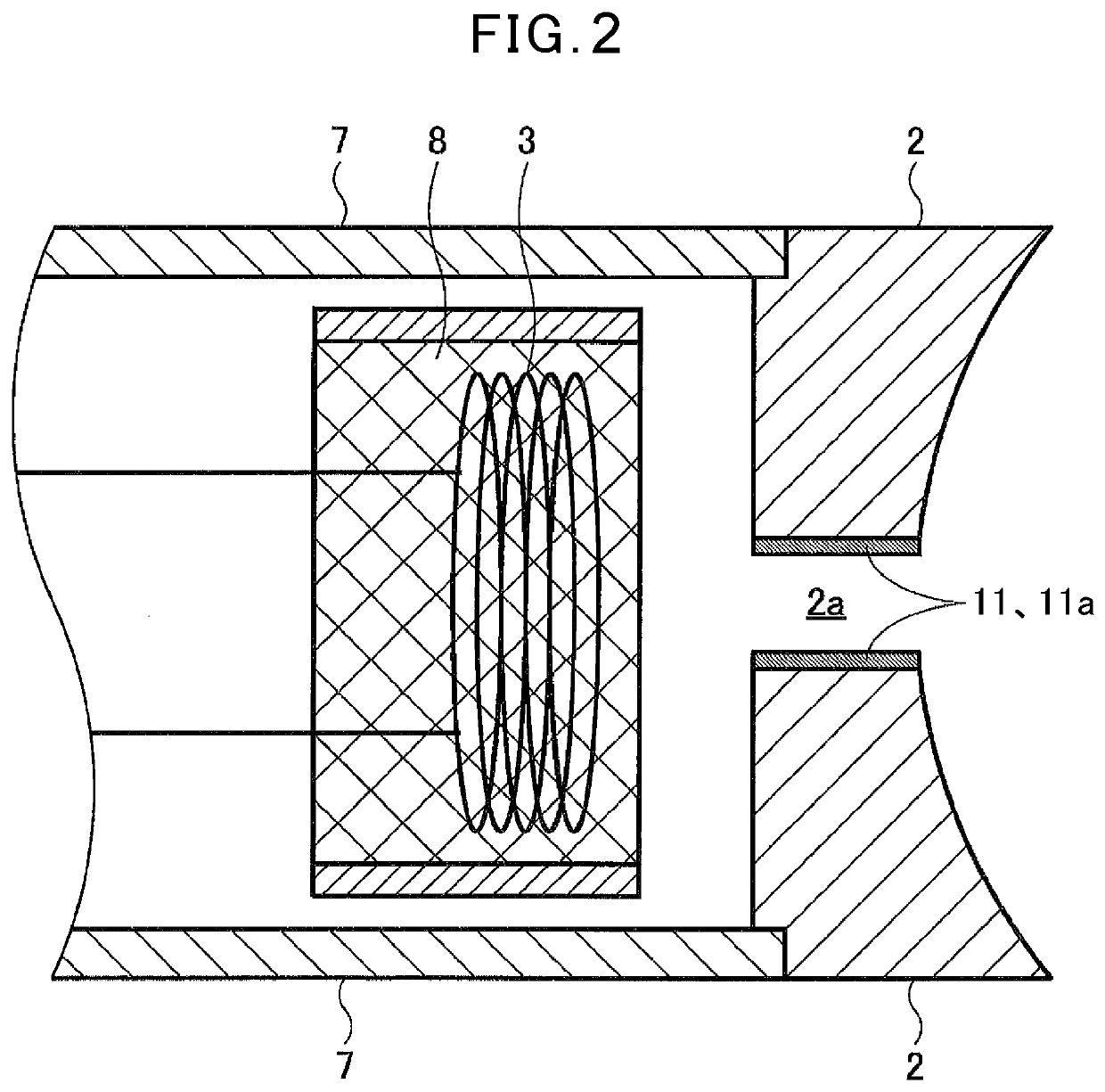

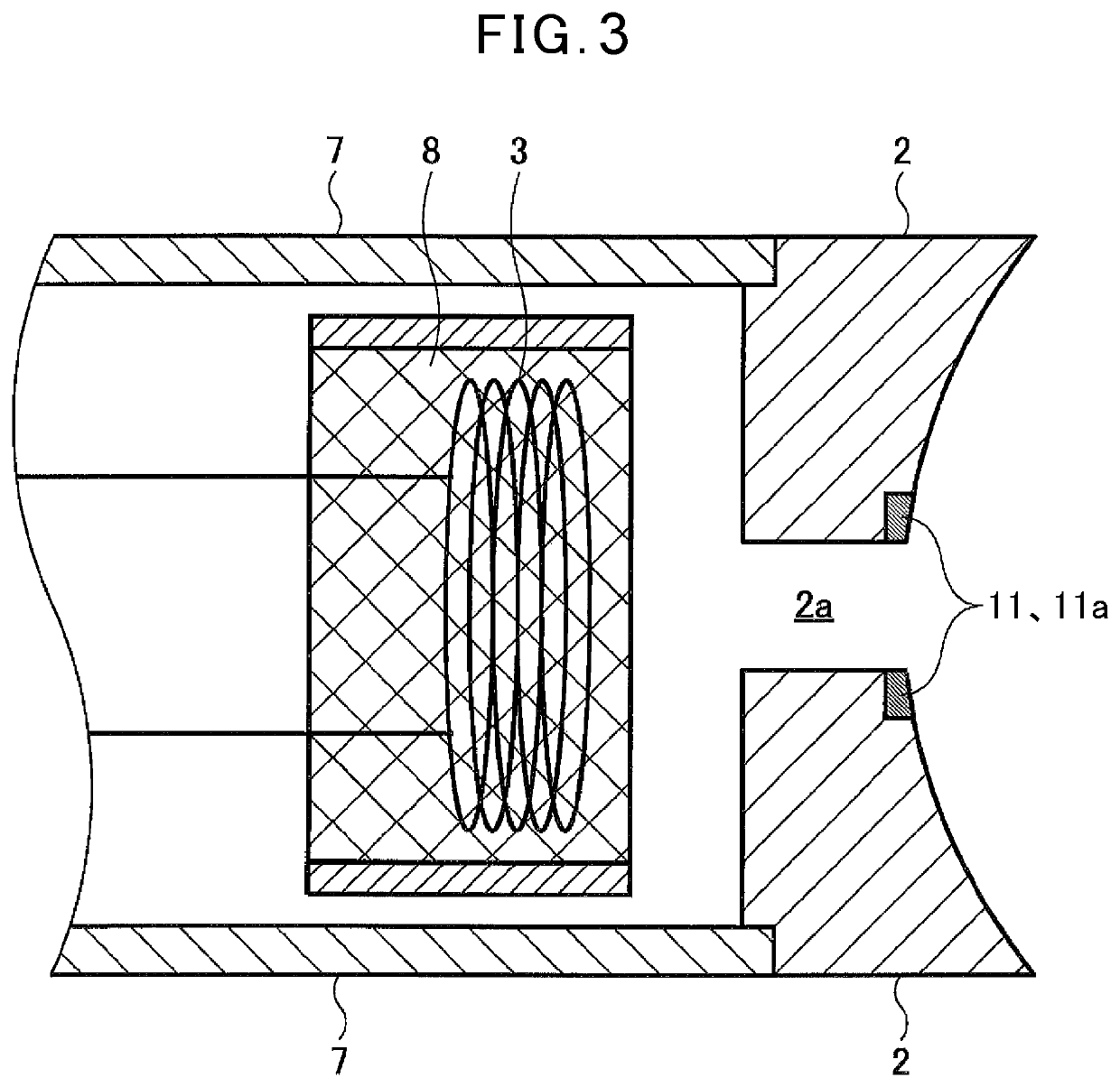

Hollow cathode heater and hollow cathode structure

ActiveCN109599309AEasy processing and assemblyHigh mechanical strengthMachines/enginesDischarge tube hollow cathodesThermal shockLife span

The present invention discloses a hollow cathode heater and a hollow cathode structure, the heater comprises an inner ceramic skeleton (4), a heating wire (5) and an outer ceramic sleeve (6); outer side of the inner ceramic skeleton (4) and / or inner side of the outer ceramic sleeve (6) has a first a structure; the first structure is any one or any combination of a protrusion, a groove or a smoothsurface; the outer ceramic sleeve (6) is nested outside the inner ceramic skeleton (4), a first space is surrounded and formed between the outer side of the inner ceramic skeleton (4) and the inner side of the outer ceramic sleeve (6) through the first structure. The hollow cathode heater is easy to process and assemble, has high mechanical strength and high reliability, and has a serpentine heating wire, with induced magnetic fields at adjacent positions cancelling each other, can effectively reduce an induced voltage and an induced current generated by the induced magnetic fields at the ignition moment, reduce thermal shock of the heating wire and improve reliability and life span of a space electric propulsion system.

Owner:SHANGHAI INST OF SPACE PROPULSION

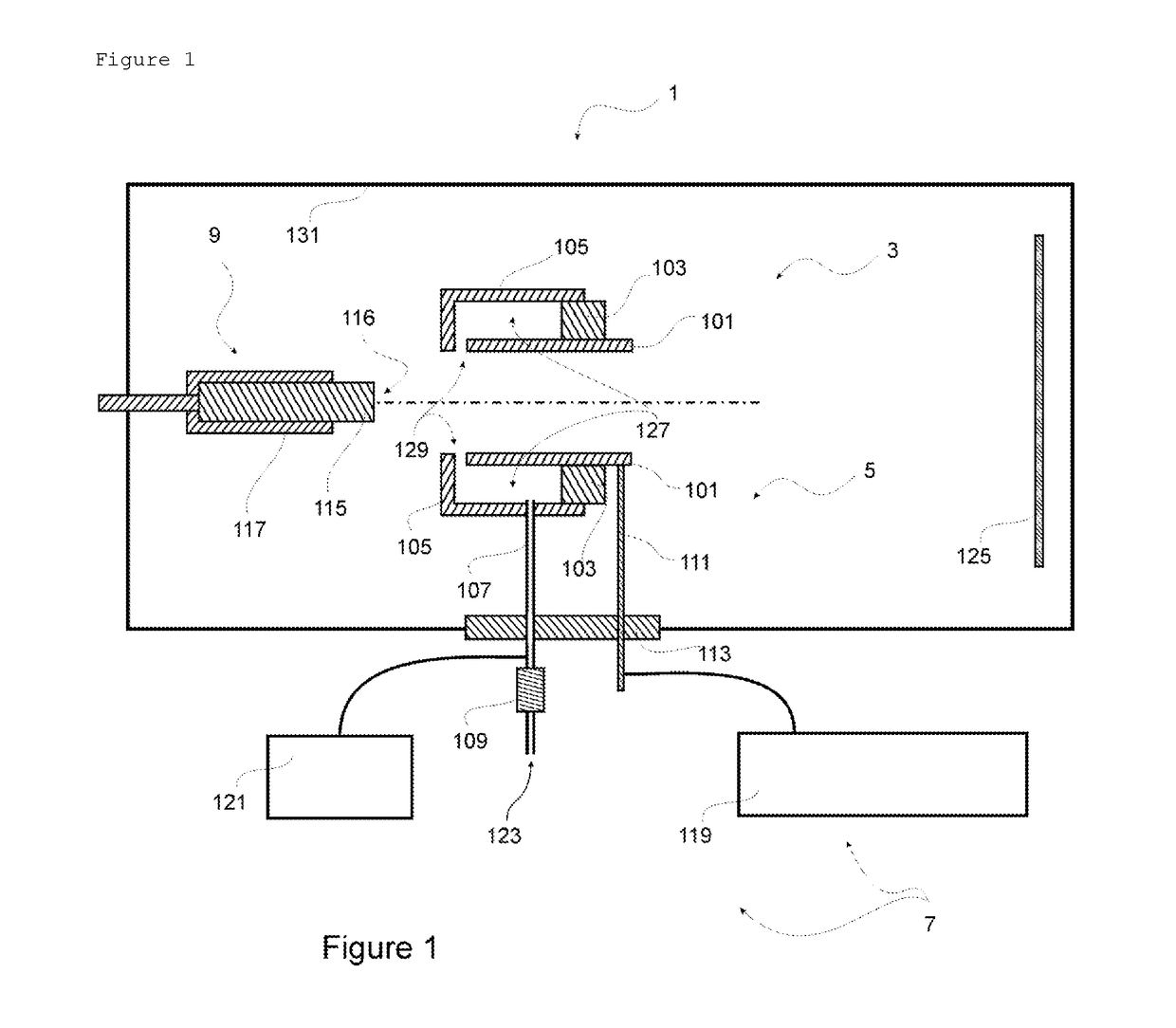

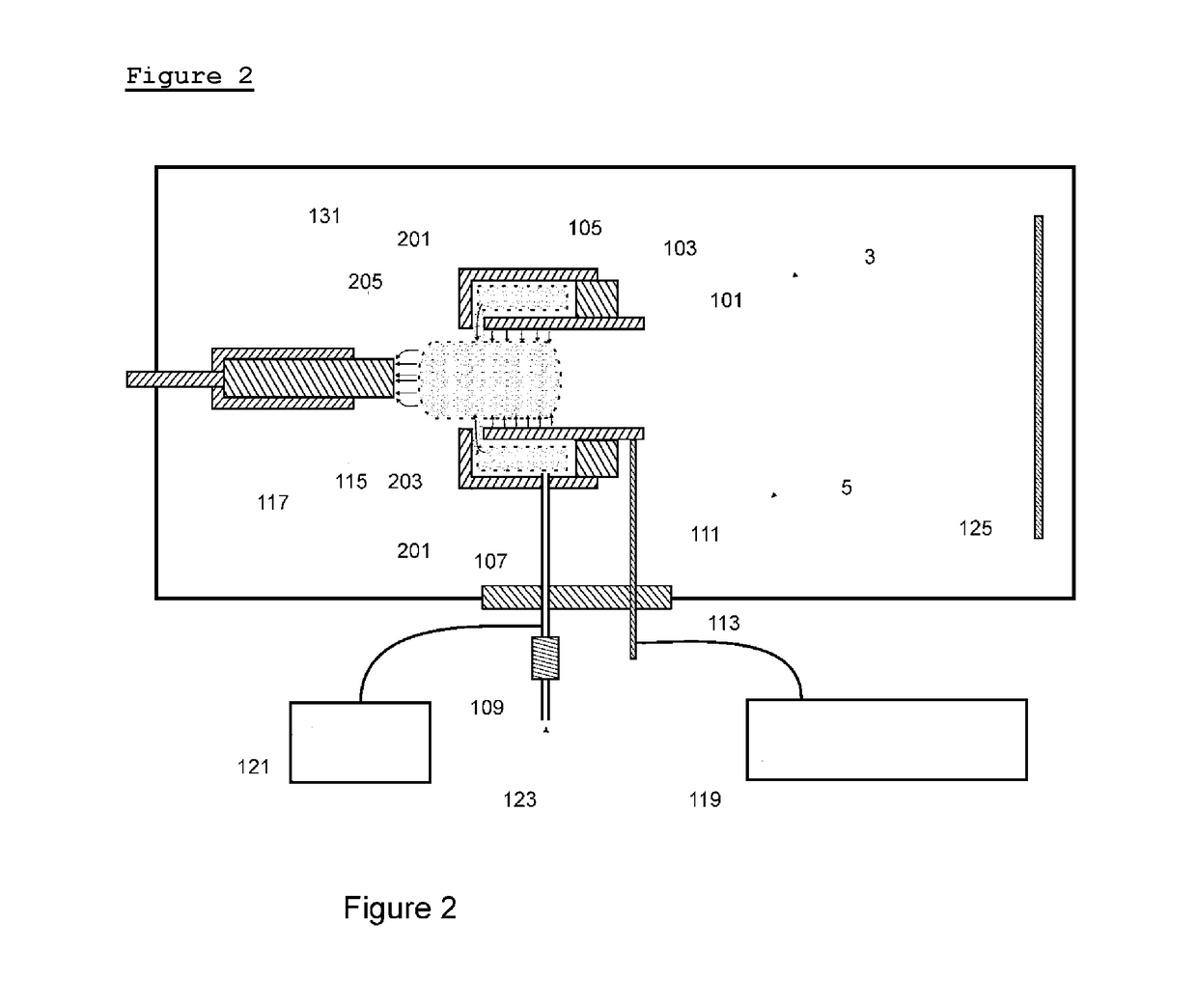

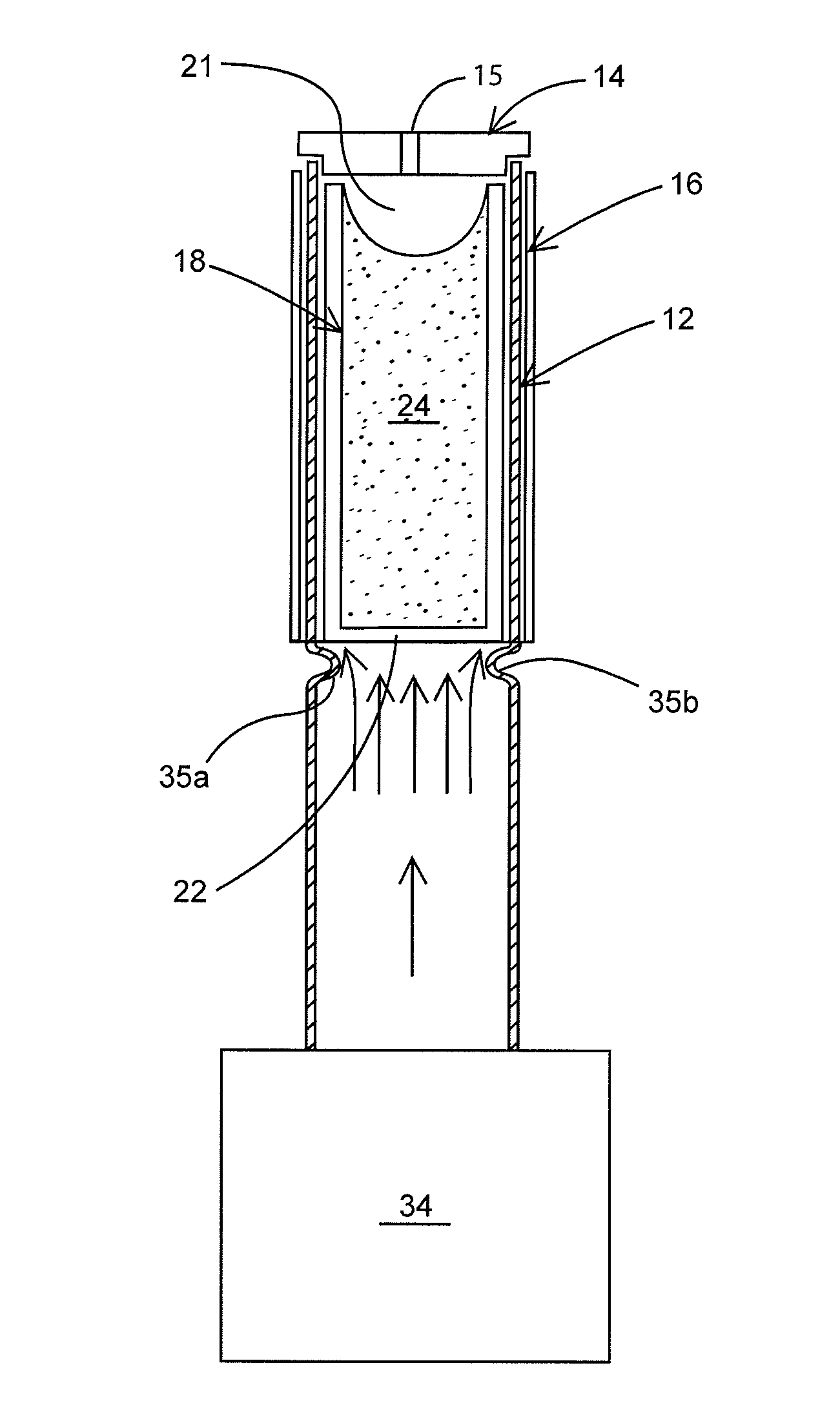

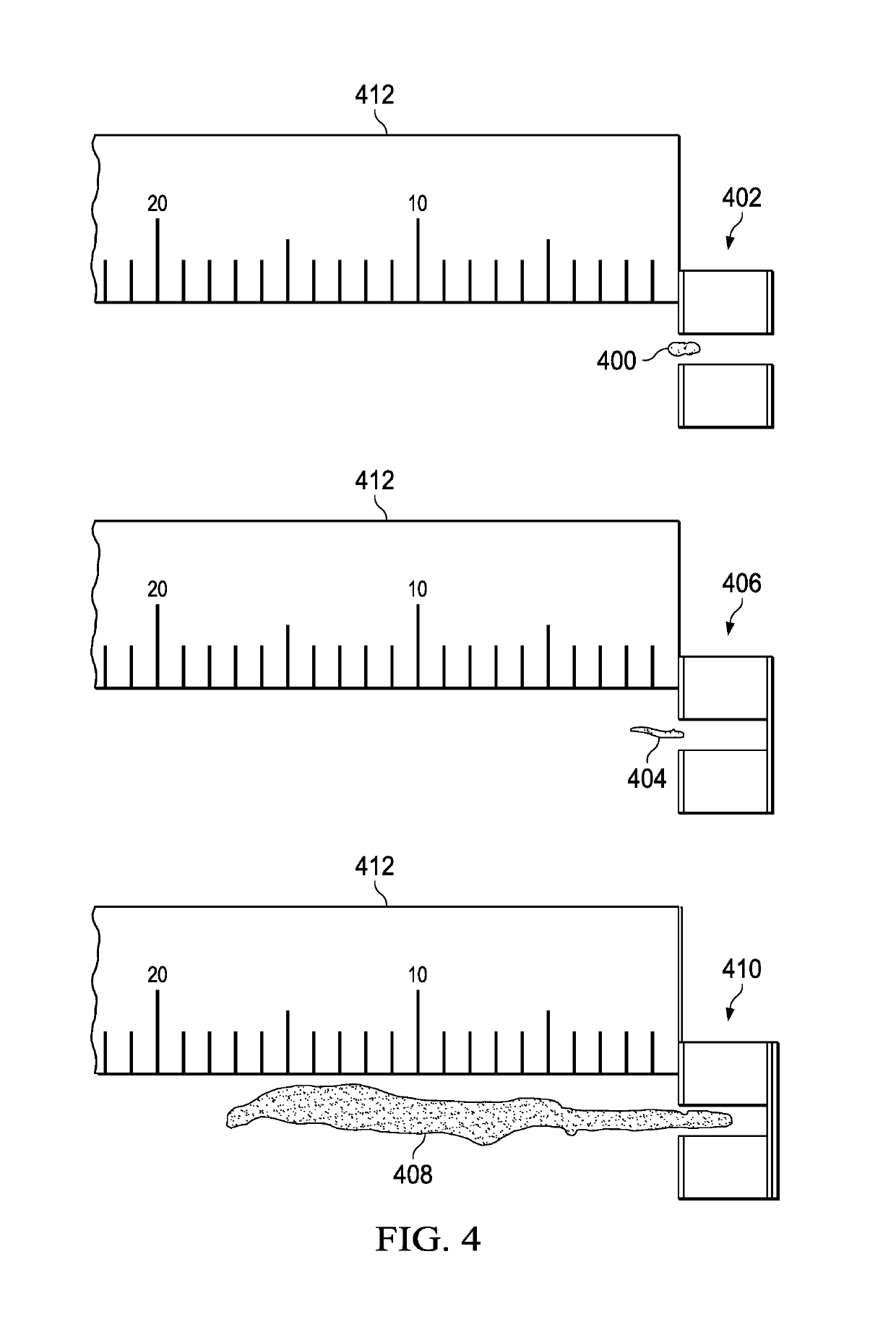

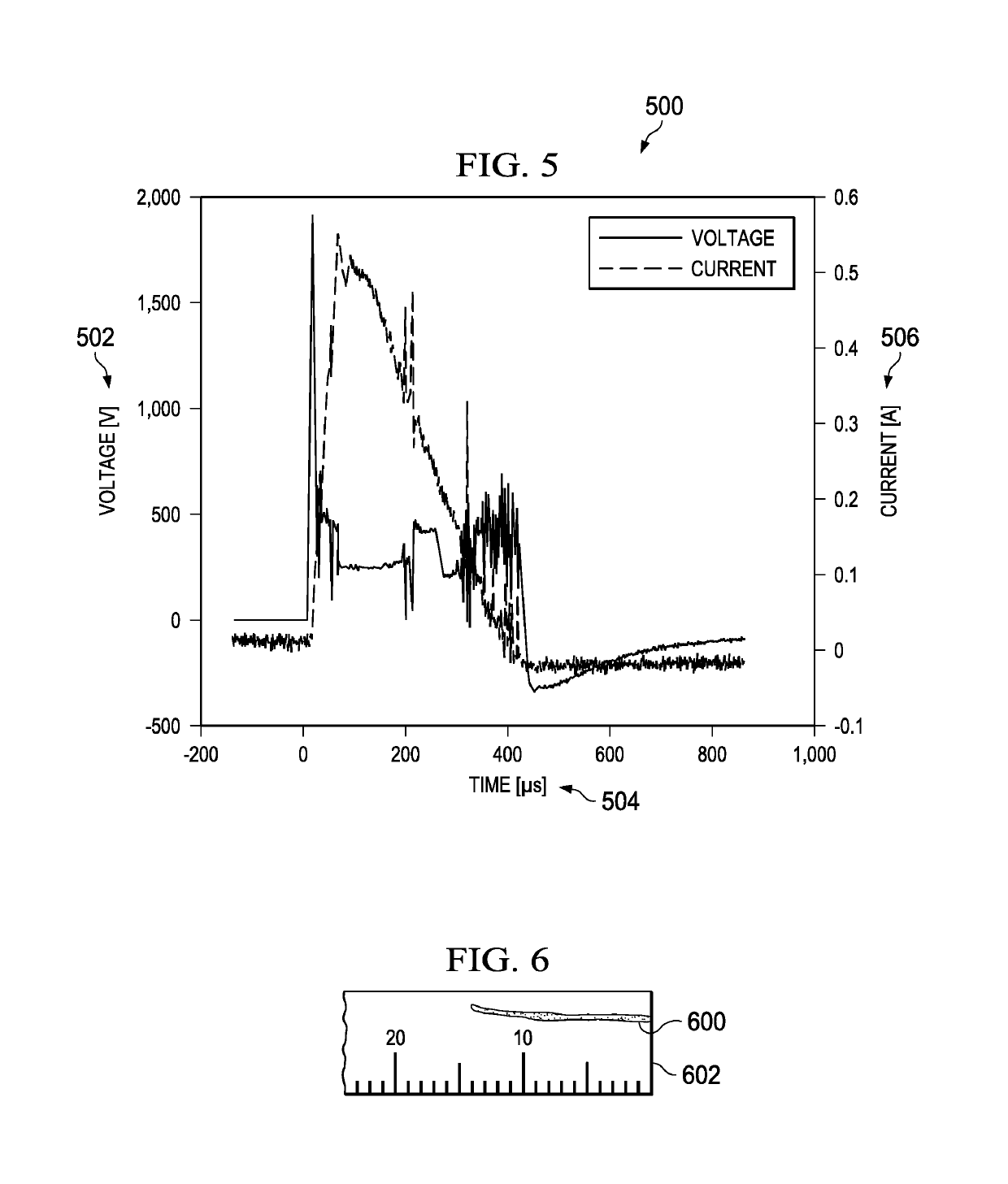

Virtual cathode deposition (VCD) for thin film manufacturing

ActiveUS20170247789A1Sufficient ablationElectric discharge tubesVacuum evaporation coatingHigh densityElectrical impulse

A virtual cathode deposition apparatus utilises virtual plasma cathode for generation of high density electron beam to ablate a solid target. A high voltage electrical pulse ionizes gas to produce a plasma which temporarily appears in front of the target and serves as the virtual plasma cathode at the vicinity of target. This plasma then disappears allowing the ablated target material in a form of a plasma plume to propagate toward the substrate. Several virtual cathodes operating in parallel provide plumes that merge into a uniform plasma which when condensing on a nearby substrate leads to wide area deposition of a uniform thickness thin film.

Owner:META MATERIALS INC

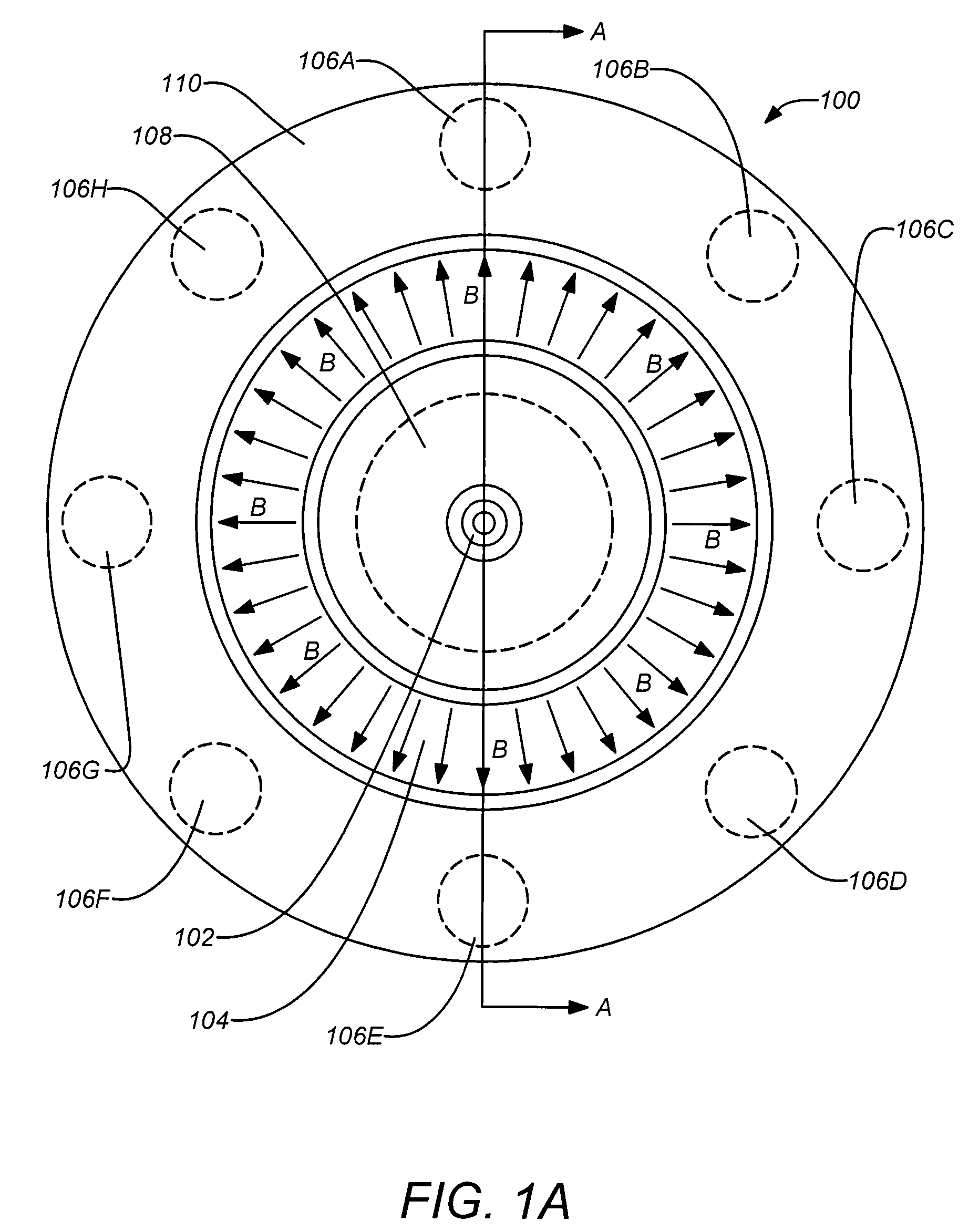

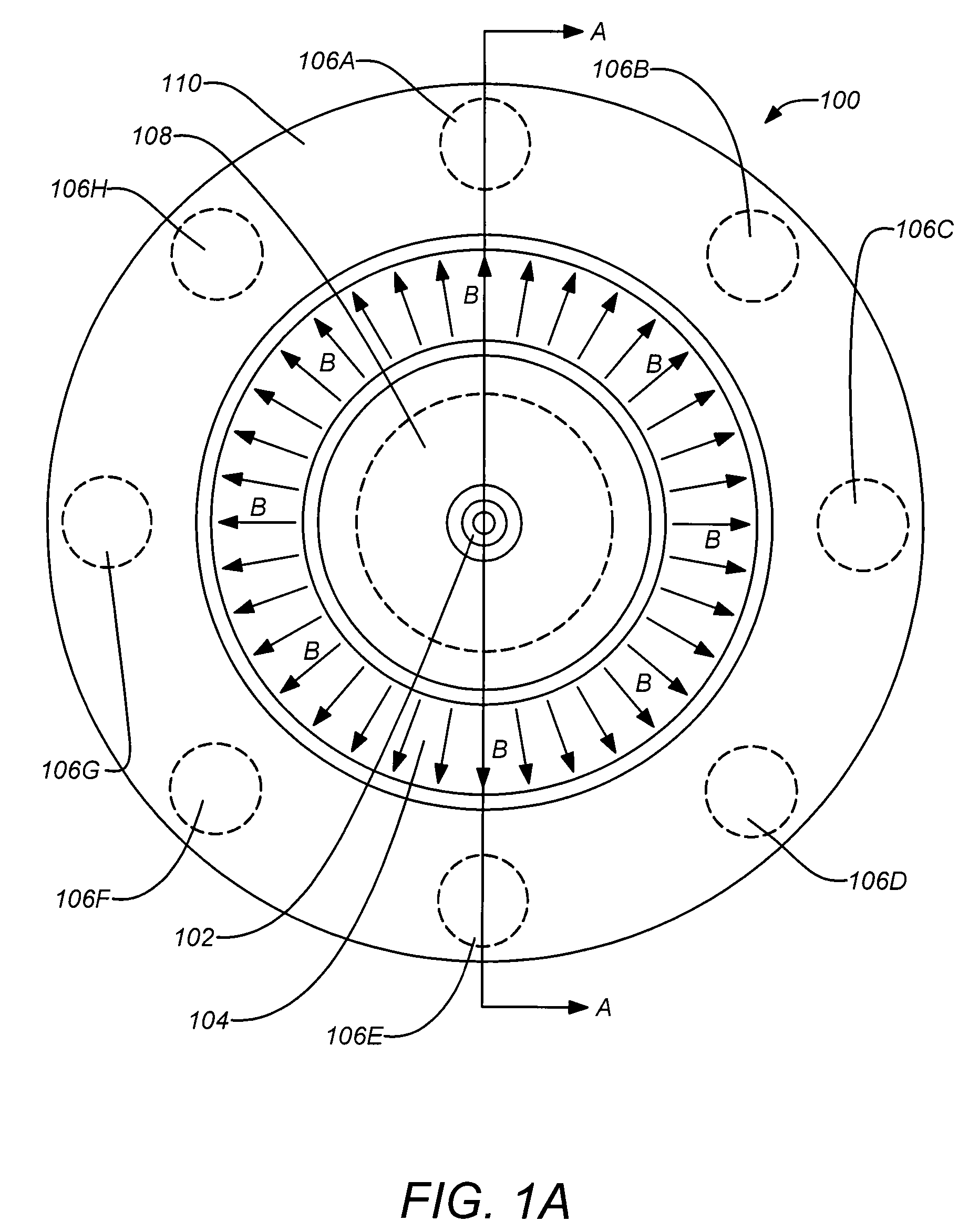

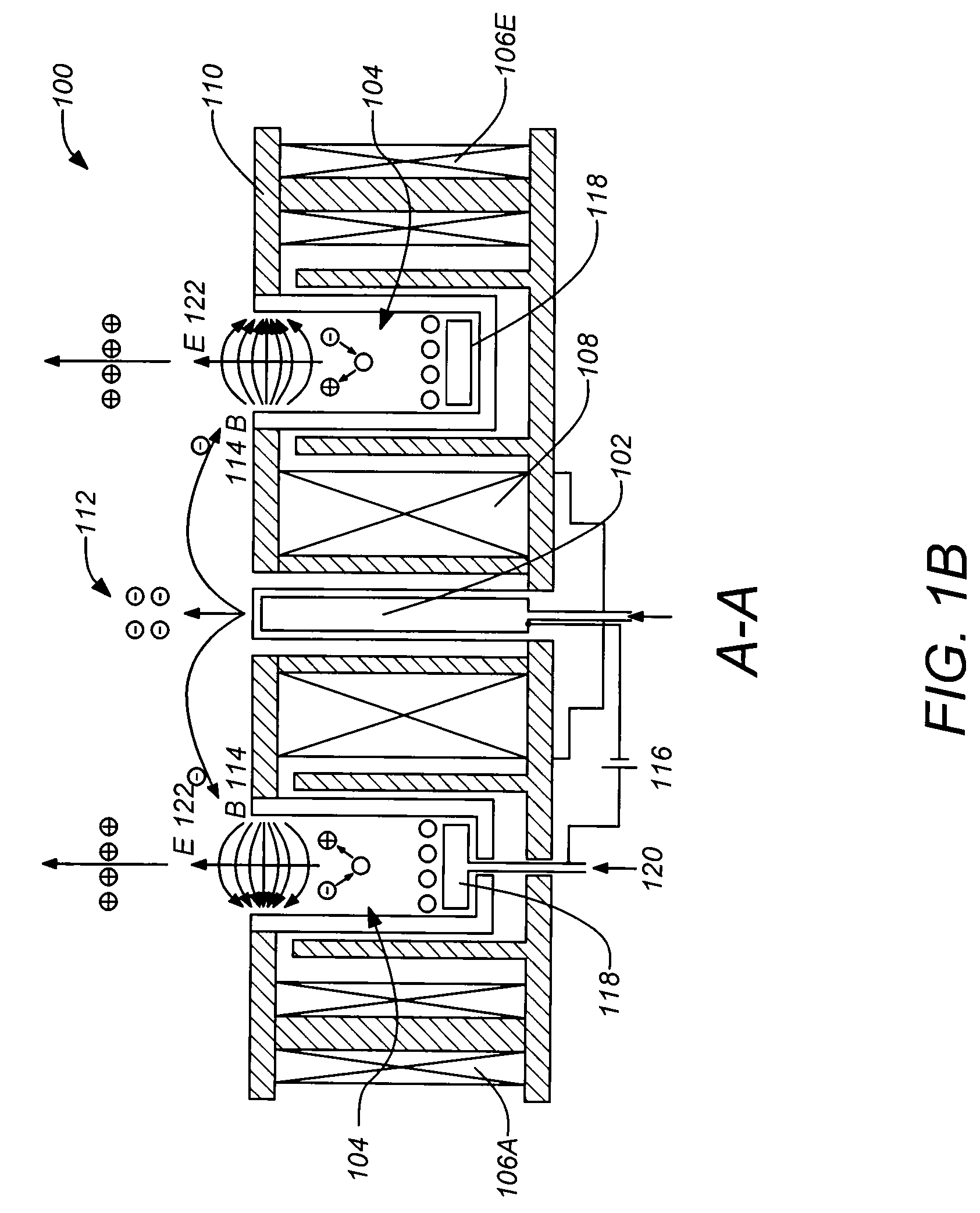

Closed drift hollow cathode

InactiveUS6323586B1Increase blockingMaintain temperatureBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsAxis of symmetryField electron emission

In accordance with one specific embodiment of the present invention, the closed drift hollow cathode comprises an axisymmetric discharge region into which an ionizable gas is introduced, an annular electron emitting cathode insert disposed laterally about that discharge region, a surrounding enclosure, an aperture in that enclosure disposed near the axis of symmetry and at one end of that region, and a magnetic field within that region which is both axisymmetric and generally disposed transverse to a path from the cathode insert to the aperture. An electrical discharge is established between the cathode insert and the enclosure. The electrons emitted from the cathode insert drift in closed paths around the axis, collide with molecules of ionizable gas, and sustain the discharge plasma by generating additional electron-ion pairs. Ions from the plasma bombard the cathode insert, thereby maintaining an emissive temperature. Electrons from the plasma diffuse to and escape through the aperture to provide the electron emission. The closed drift nature of the discharge circumferentially distributes the heating of the cathode insert and the utilization of the electron emitting capabilities thereof. The discharge current controls the maximum value of the electron emission.

Owner:KAUFMAN & ROBINSON

Industrial hollow cathode with radiation shield structure

In accordance with one embodiment of the present invention, the hollow-cathode apparatus comprises a small-diameter tantalum tube with a plurality of tantalum-foil radiation shields, wherein the plurality of shields in turn comprise one or more spiral windings external to that tube and approximately flush with the open end from which electron emission takes place. The axial length of at least one of the inner windings (closer to the tantalum tube) is equal to or less than approximately half the length of the tantalum tube. An enclosed keeper surrounds the cathode. To start the cathode, a flow of ionizable inert gas, usually argon, is initiated through the cathode and out the open end. An electrical discharge is then started between the keeper and the hollow cathode. When heated to operating temperature, electrons exit from the open end of the hollow cathode.

Owner:KAUFMAN & ROBINSON

Integrated hollow cathode

InactiveCN108461366AImprove heat retentionImproved resistance to ion bombardmentDischarge tube hollow cathodesRetention efficiencyIon bombardment

The invention provides an integrated hollow cathode so that a defect of low heat retention efficiency of the separate heat shield assembly can be overcome and thus the high-efficiency heat retention can be realized, the ignition time can be shortened, and the service life can be prolonged. According to the invention, a heat shield assembly previously separated from a heater assembly is connected with the heater assembly together; a heating filament mounting hole is formed in a heat shield support; a heating filament is fixed with the heater assembly through the heating filament mounting hole;the space between the heating filament and the heating filament mounting hole is filled with a heating filament fixation ceramic; and the heating filament is insulated from the heat shield support bythe heating filament fixation ceramic to obtain an integrated heat shield assembly. With the integrated heat shield assembly, heat losses caused by the hollow cathode along the axial direction are reduced and the heat retention efficiency of the heater assembly is improved, so that the heat retention, ion bombardment resistance, service life, and insulating properties of the hollow cathode are improved effectively, the working efficiency of the hollow cathode is improved; and the expected service life of the hollow cathode product is prolonged.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Channel spark source for generating a stable focused electron beam

ActiveUS7183564B2Not to damageProlong lifeVacuum evaporation coatingSputtering coatingCharge carrierPressure difference

In a channel spark source triggered by gas discharge for generating a stable focused electron beam, a gas supply for a hollow cathode thereof is provided which generates in the hollow cathode a pressure differential so that the multiplication of charge carriers in a trigger plasma of a trigger plasma source connected to the hollow cathode provides for a reliable gas discharge and the formation of a stable electron beam which exits the arrangement and which does not damage the internal passages of the arrangement.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

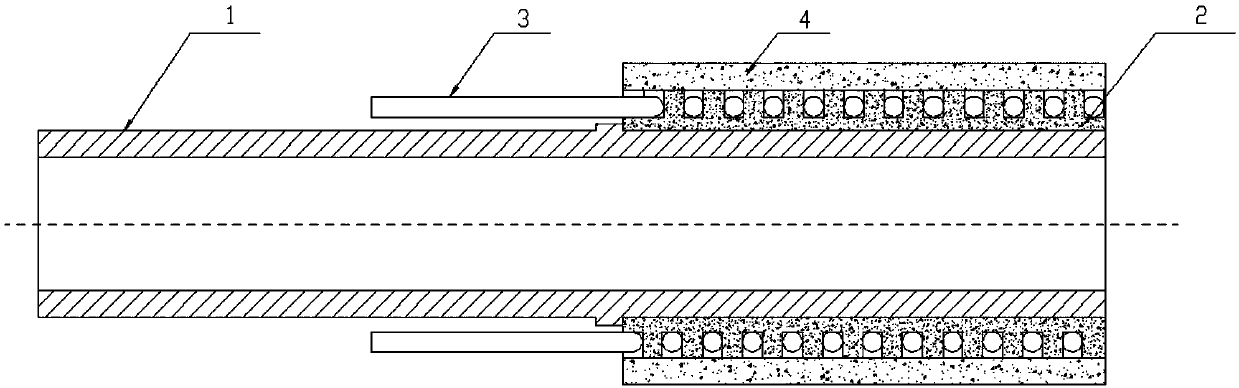

Novel hollow cathode heater structure

ActiveCN109585237AInhibit sheddingImprove reliabilityMachines/enginesDischarge tube hollow cathodesPower flowMetallurgy

The invention discloses a novel hollow cathode heater structure. The novel hollow cathode heater structure is composed of a ceramic framework, a heating wire and an outer ceramic sleeve, and the ceramic framework is embedded outside a cathode tube of a hollow cathode and is close to the top end of the cathode tube. A radial spiral groove is formed in the outer side of the ceramic framework. The heating wire is spirally sleeved in the spiral groove and arranged between the outer ceramic sleeve and the ceramic framework, and the two ends of the heating wire are led out from the inner side end ofthe ceramic framework; And the ceramic framework is sleeved with the outer sleeve ceramic in a tight fit mode, and the heating wire is effectively limited in the spiral groove. The hollow cathode heater is simple in structure, high in reliability and capable of effectively restraining induced current interference and reducing electromagnetic oscillation and can be used for heating and ignition starting of the hollow cathode for space electric propulsion.

Owner:SHANGHAI INST OF SPACE PROPULSION

Electrodes

InactiveUS20090226752A1Long lastingIncrease brightnessContact member manufacturingVehicle componentsElectrical devicesBiomedical engineering

Owner:BLACKBURN MICROTECH SOLUTIONS

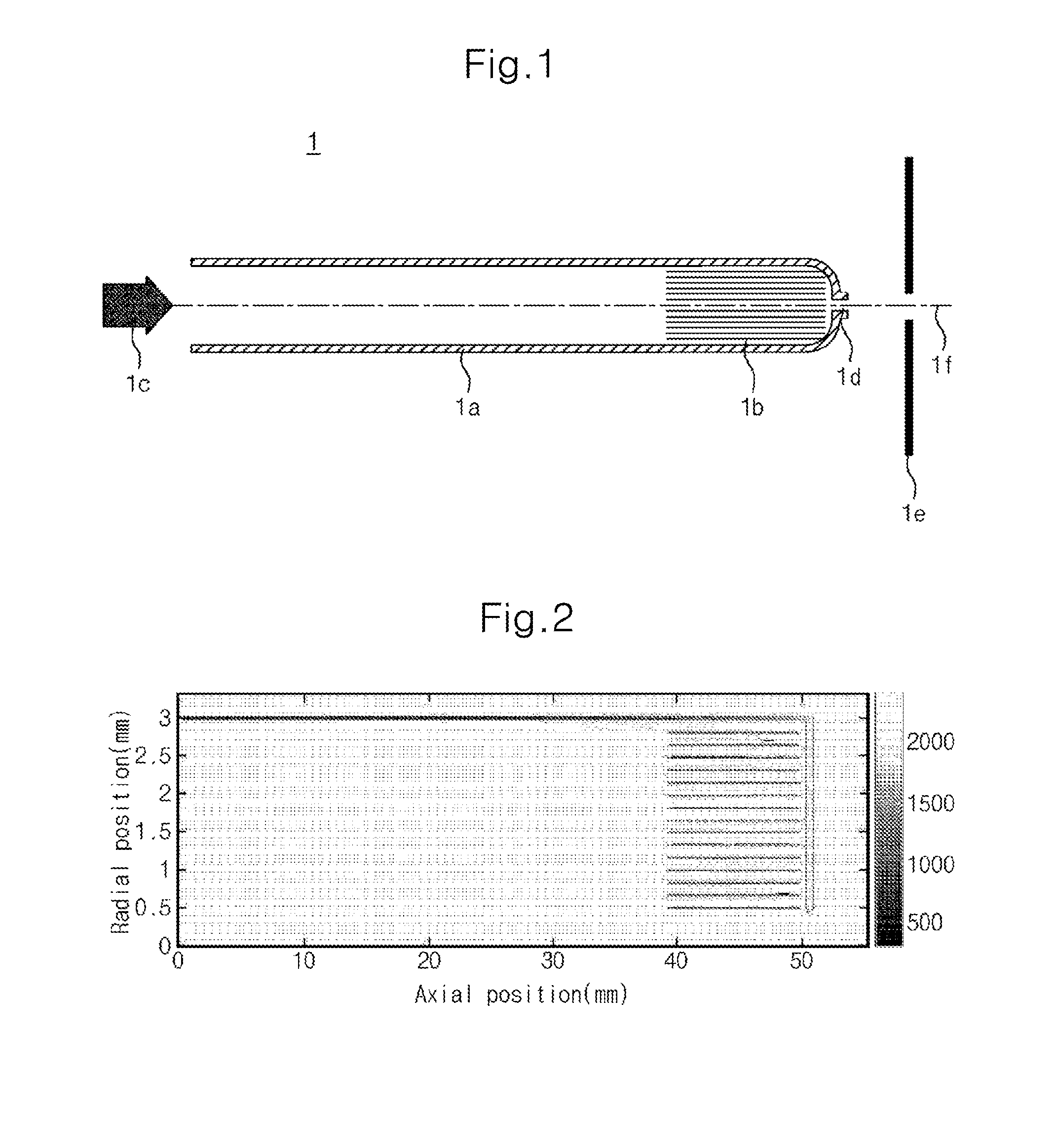

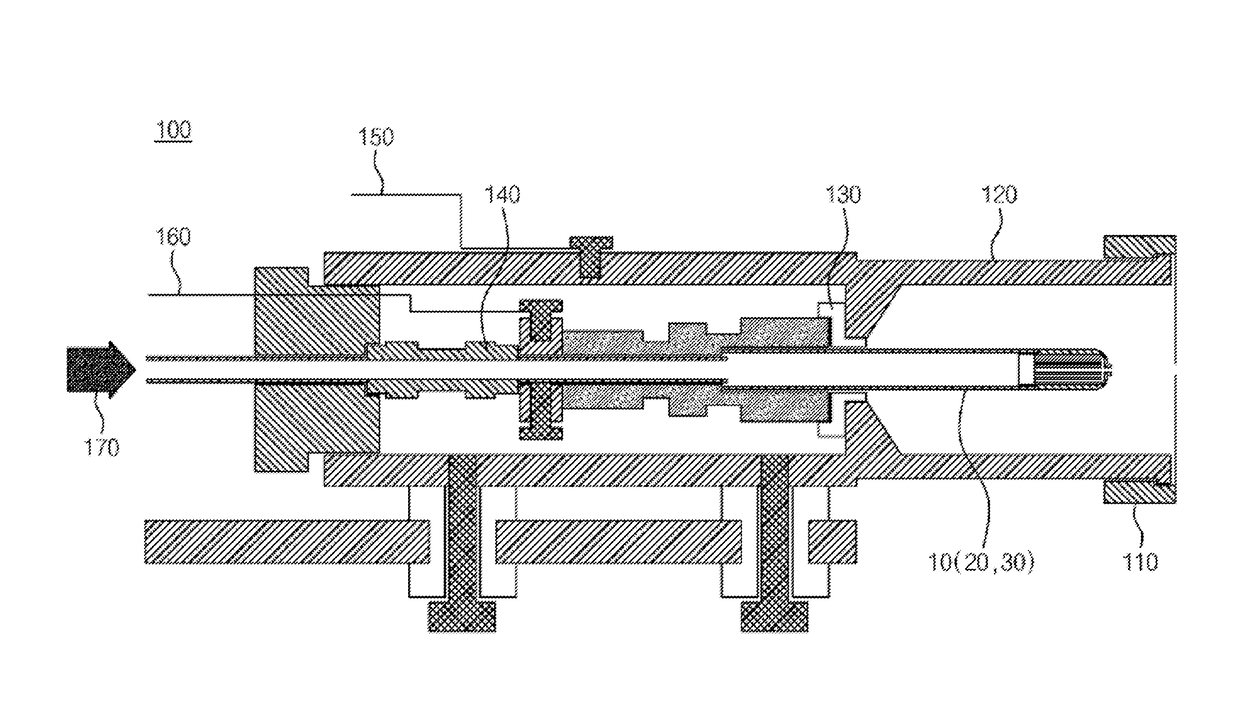

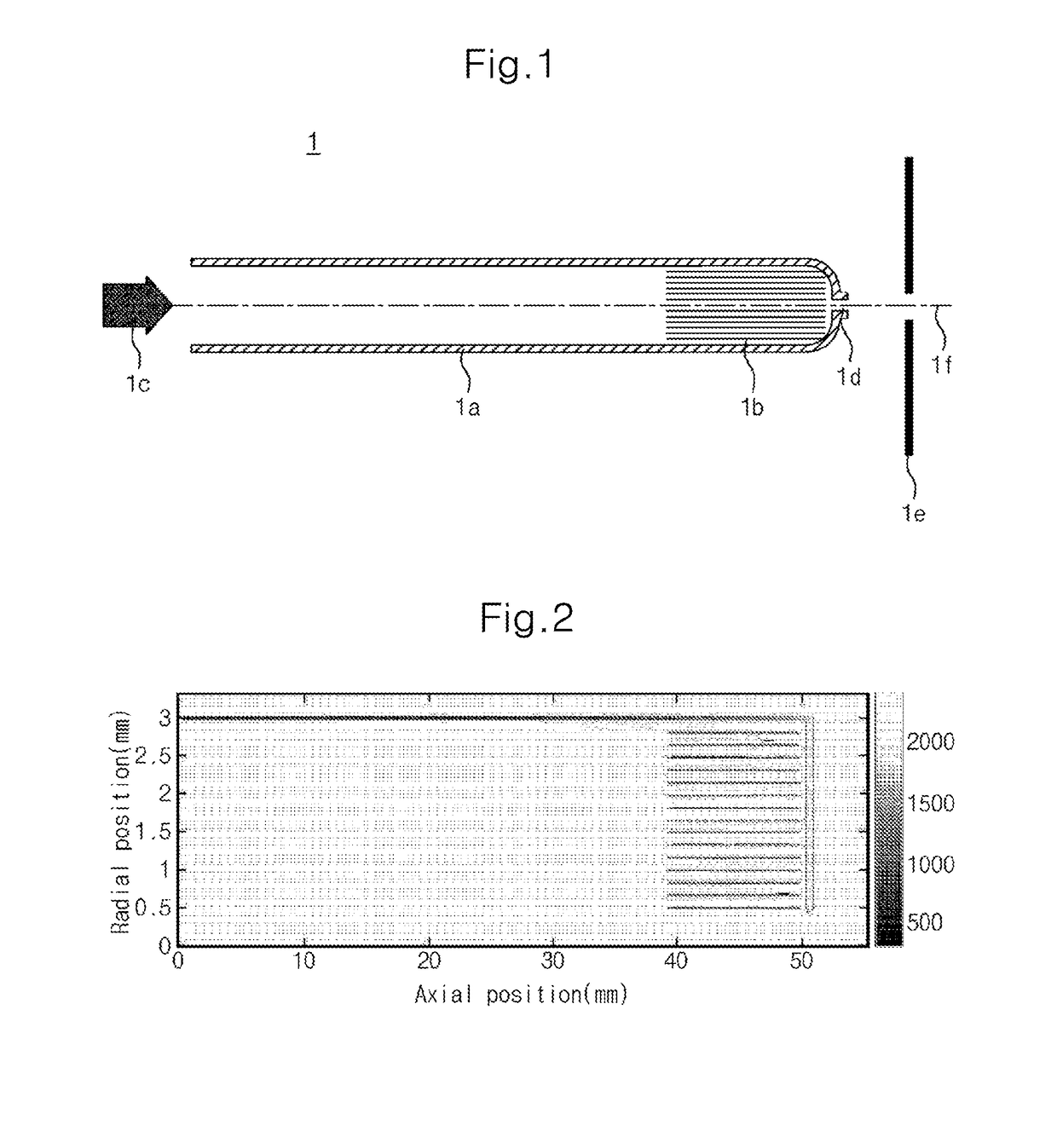

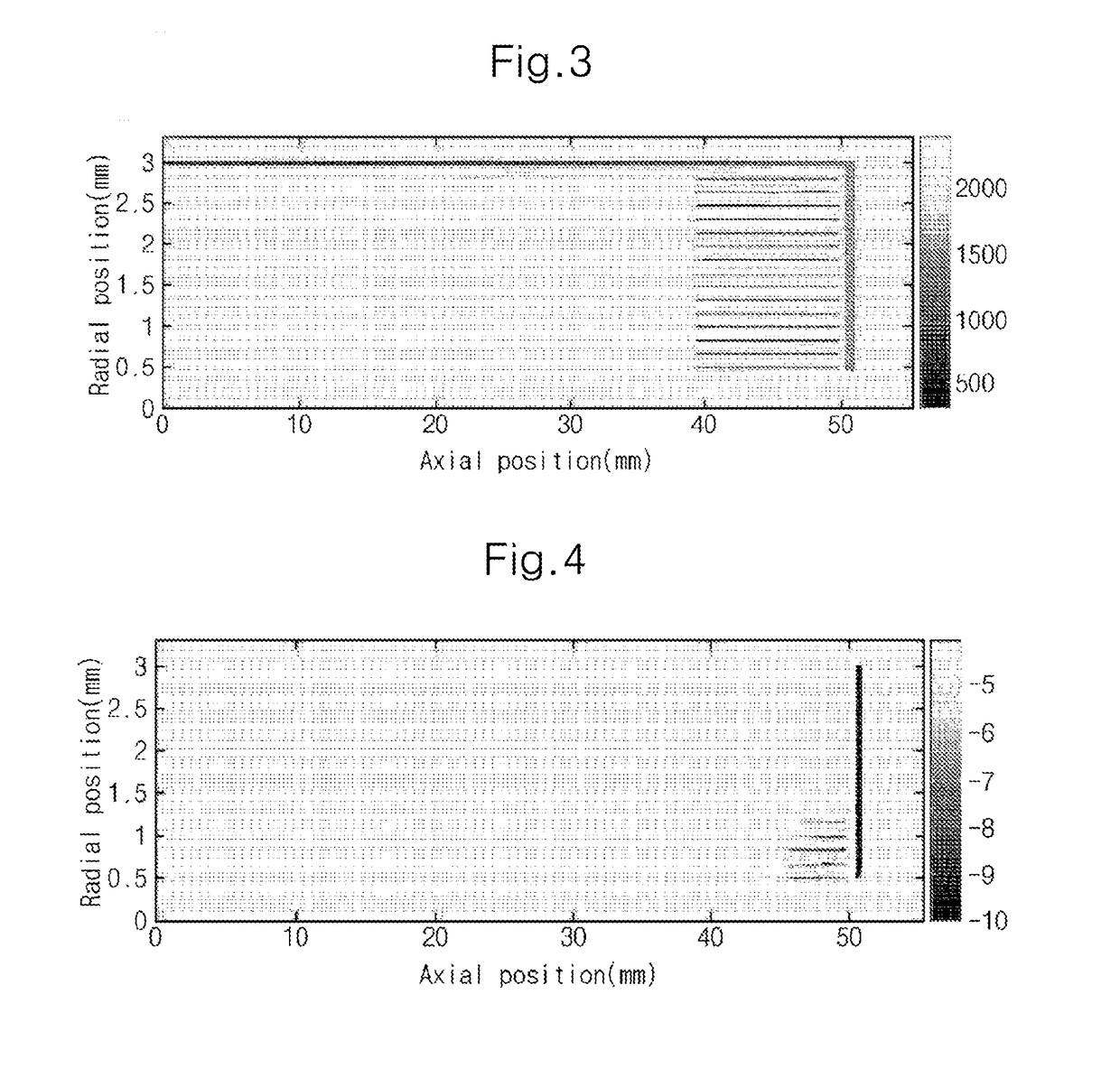

High Efficiency Hollow Cathode and Cathode System Applying Same

The present invention relates to a high efficiency hollow cathode and a cathode system applying the same, and comprises: a tube comprising at least two refractory metal parts; a gas providing unit and a gas outlet which are respectively formed at the distal ends of the tube; and an insert mounted inside the tube. According to the present invention, since the present invention constitutes a hollow cathode using more than two substances, the present invention can not only enhance thermal stability, lifespan and efficiency, but also can reduce costs accordingly.

Owner:KOREA ADVANCED INST OF SCI & TECH

Industrial hollow cathode

ActiveUS7728498B2Simple to fabricateSimple to useLamp incadescent bodiesThermionic cathodesOperating temperatureTantalum foil

Owner:KAUFMAN & ROBINSTON

Virtual cathode deposition (VCD) for thin film manufacturing

A virtual cathode deposition apparatus utilises virtual plasma cathode for generation of high density electron beam to ablate a solid target. A high voltage electrical pulse ionizes gas to produce a plasma which temporarily appears in front of the target and serves as the virtual plasma cathode at the vicinity of target. This plasma then disappears allowing the ablated target material in a form of a plasma plume to propagate toward the substrate. Several virtual cathodes operating in parallel provide plumes that merge into a uniform plasma which when condensing on a nearby substrate leads to wide area deposition of a uniform thickness thin film.

Owner:META MATERIALS INC

12CaO-7Al2O3 electride hollow cathode

Owner:COLORADO STATE UNIVERSITY

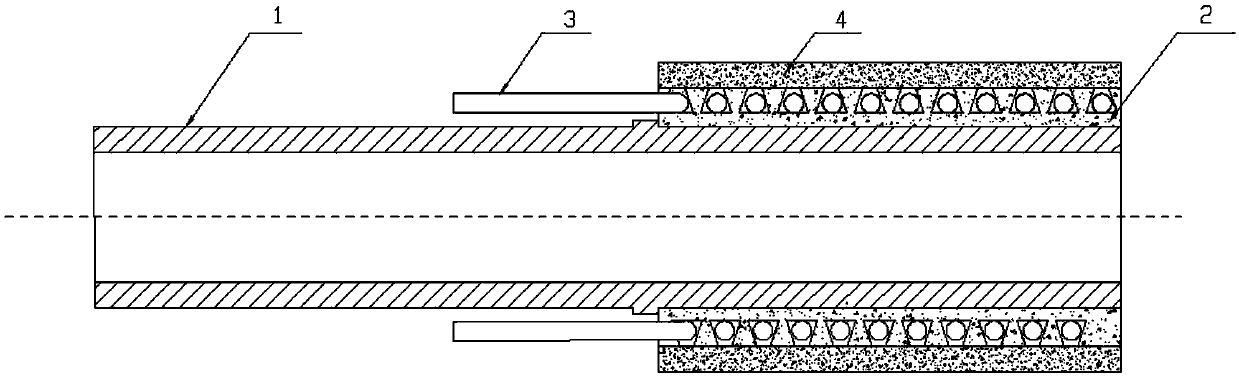

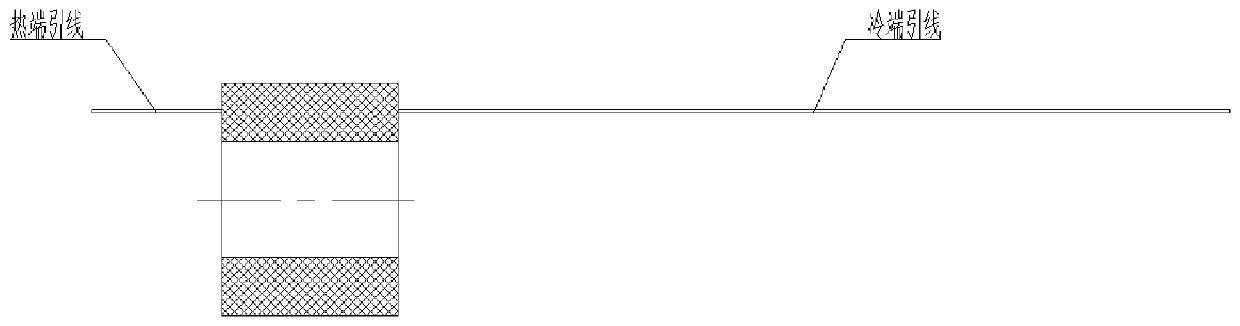

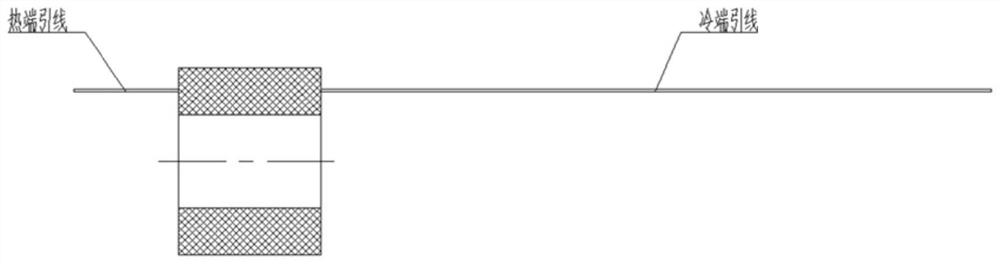

Lanthanum hexaboride hollow cathode heater heating wire cold end leading-out method

ActiveCN110335794AIncrease the equivalent conductive cross sectionLower resistanceMounting/support/spacing/insulation of electrode assembliesDischarge tube hollow cathodesSpot weldingLanthanum hexaboride

The invention provides a lanthanum hexaboride hollow cathode heater heating wire cold end leading-out method, which comprises the following steps: 1) at the heater heating wire cold end leading-out section, a plurality of metal wires and a heater heating wire are closely arranged side by side; 2) the metal wires arranged in parallel serve as a whole, and the outer surface of the metal wires is closely wrapped with multiple layers of tantalum foil, wherein the diameter obtained after wrapping of the tantalum foil is uniform, and the multiple layers of tantalum foil are fixed through spot welding; 3) the tantalum foil is coated with a single single-hole ceramic tube, wherein the ceramic tube cannot slide out freely; 4) the ceramic tube is externally sleeved by multiple layers of tantalum foil, wherein one part at each of the two ends of the ceramic tube is not wrapped with the tantalum foil, and the two layers of tantalum foil are fixed through spot welding; and 5) the cold end leading-out section is tightened and fixed to a cathode tube by utilizing a long-strip tantalum foil. The method can effectively reduce the power of the cold end leading-out section and reduce the temperatureof the cold end leading-out section, thereby preventing the heat from returning to the cold end, ensuring anti-mechanical properties of the cold end and preventing cold end leading-out wires from being broken in the satellite emission process.

Owner:BEIJING INST OF CONTROL ENG

Lanthanum hexaboride hollow cathode based on welding structure of tungsten-rhenium heating wire and tungsten top

ActiveCN111779646ACompensation for thermal expansion and contractionEffective fusionNuclear energy generationMachines/enginesThermal breakThermal insulation

The invention provides a lanthanum hexaboride hollow cathode based on a welding structure of a tungsten-rhenium heating wire and a tungsten top. The lanthanum hexaboride hollow cathode comprises an ignition electrode, a thermal insulation layer, a thermal element, a lanthanum hexaboride emitter, a cathode tube, a tantalum ring and a cathode top, wherein a molten soldering structure with tantalum ring transition is adopted between the tungsten-rhenium heating wire and the cathode top, the tungsten-rhenium heating wire is covered by the molten tantalum ring, the molten tantalum ring wraps the tungsten-rhenium heating wire, the tungsten-rhenium heating wire can maintain the original plasticity of the tungsten-rhenium heating wire material without melting, effectively compensate the thermal expansion and contraction effect of the tungsten-rhenium heating wire, eliminate thermal stress, and has a strong environmental adaptability.

Owner:BEIJING INST OF CONTROL ENG

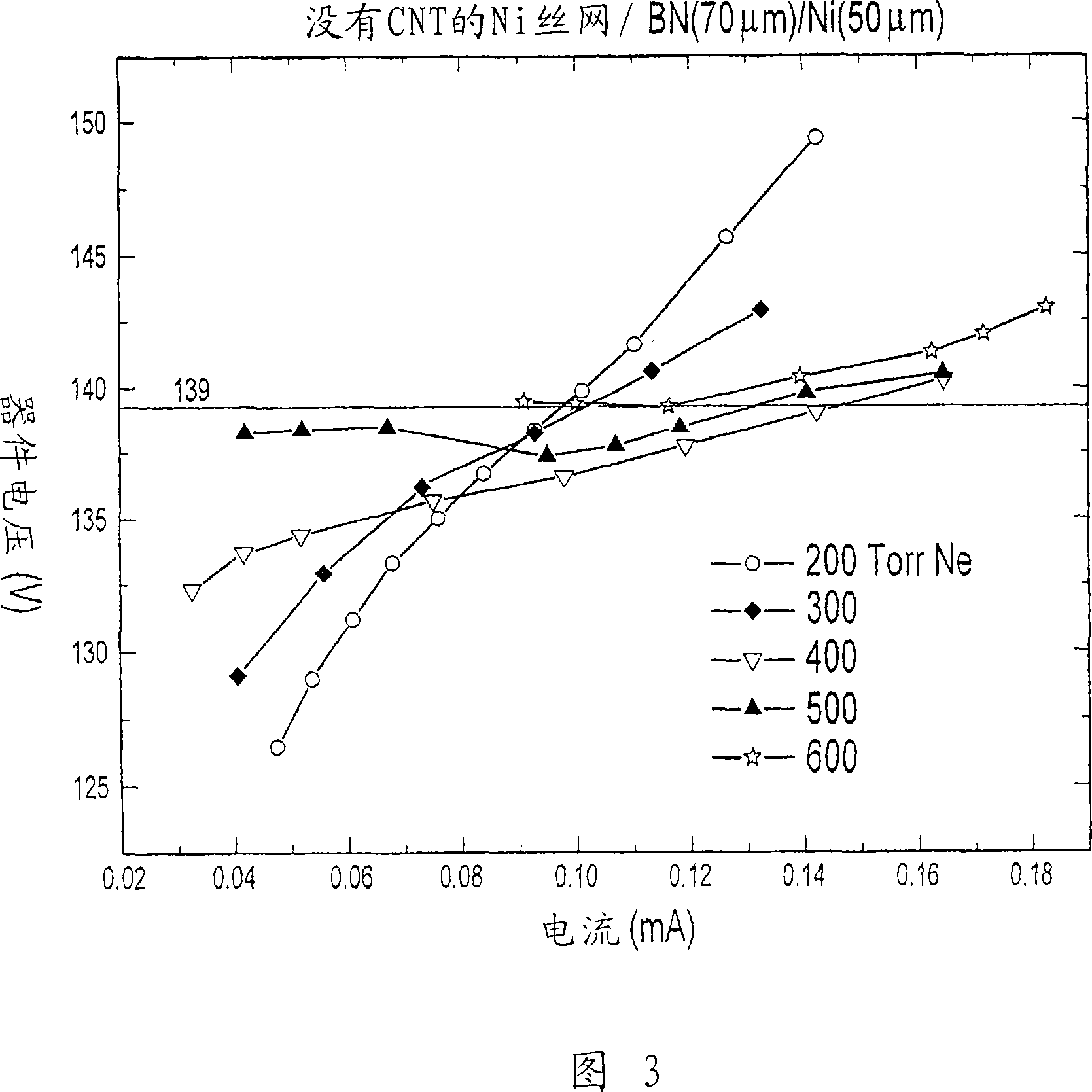

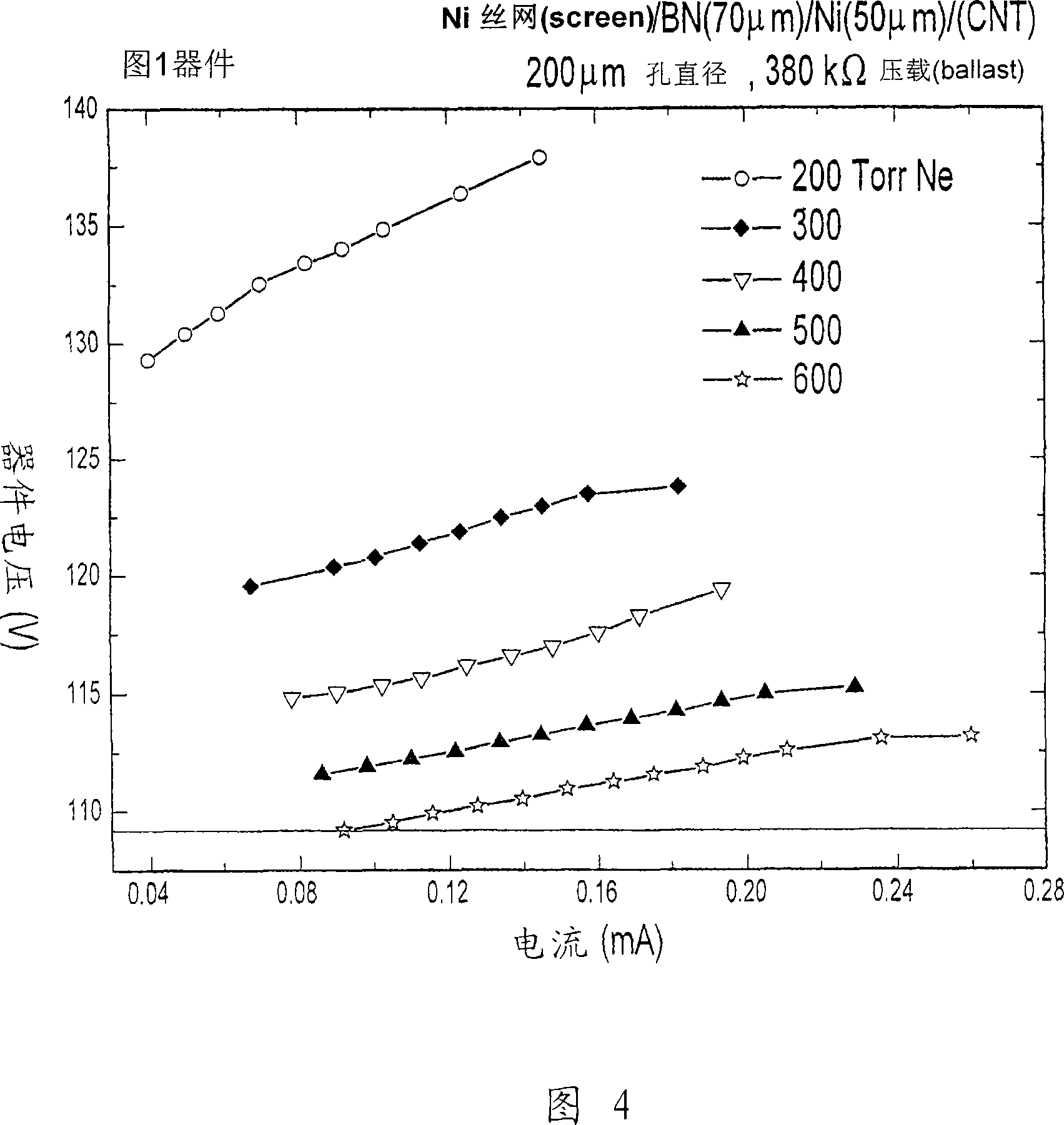

Field emission assisted microdischarge devices

InactiveCN101019200AIncreased Radiation OutputWork lessDischarge tube luminescnet screensSolid cathodesNanostructureIgnition voltage

Field emission nanostructures (18) assist operation of a microdischarge device. The field emission nanostructures are integrated into the microdischarge device(s) or are situated near an electrode (14, 16, 36, 38) of the microdischarge device(s). The field emission nanostructures reduce operating and ignition voltages compared to otherwise identical device lacking the field emission nanostructures, while also increasing the radiative output of the microdischarge device(s).

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

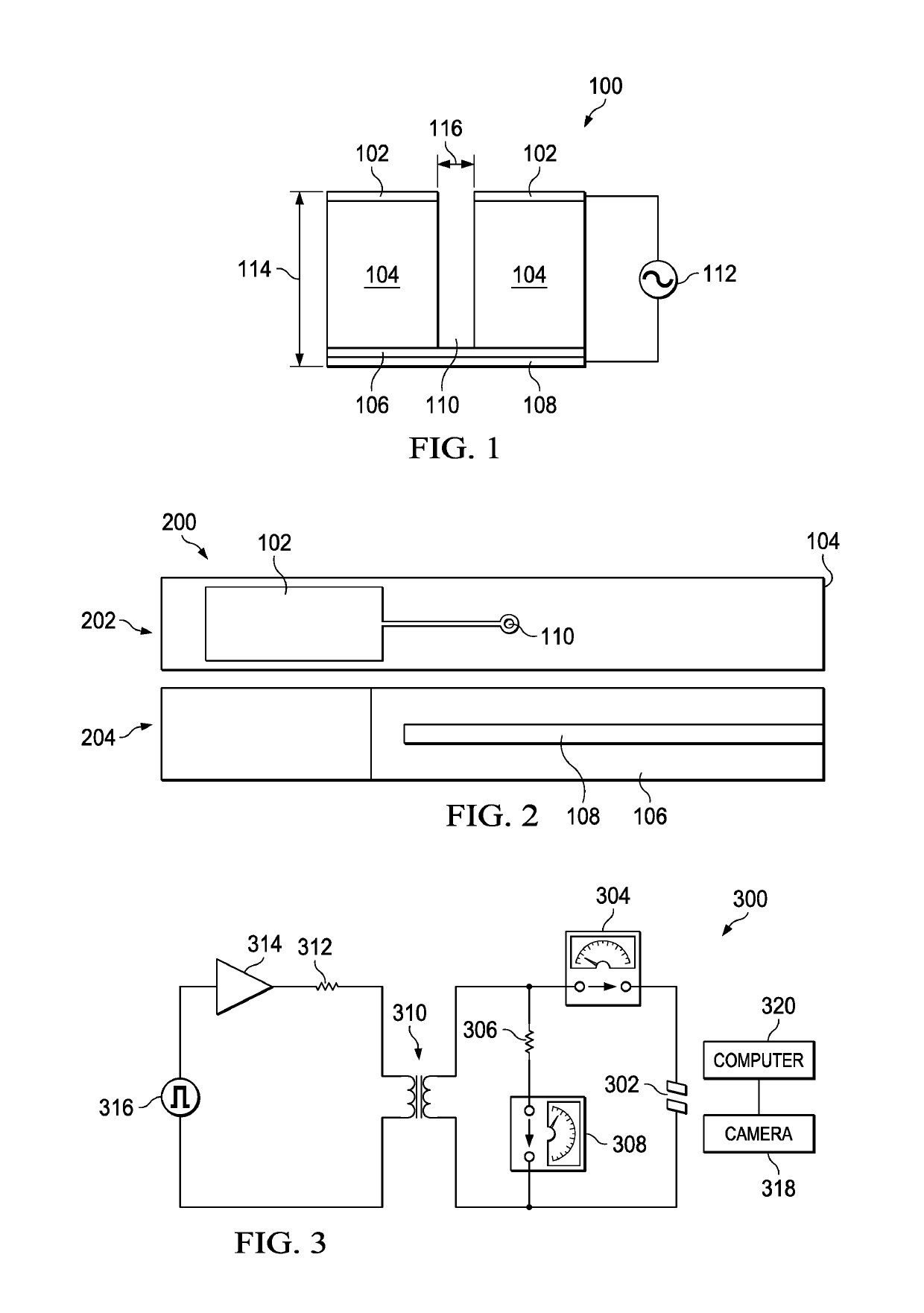

Semiconductor micro-hollow cathode discharge device for plasma jet generation

ActiveUS10271415B2Low-pressure discharge lampsDischarge tube ion gunsPlasma jetSemiconductor materials

A micro-hollow cathode discharge device. The device includes a first electrode layer comprising a first electrode. A hole is disposed in the first electrode layer. The device also includes a dielectric layer having a first surface that is disposed on the first electrode layer. The hole continues from the first electrode layer through the dielectric layer. The device also includes a semi-conducting layer disposed on a second surface of the dielectric layer opposite the first surface. The semi-conducting layer is a semiconductor material that spans across the hole such that the hole terminates at the semi-conducting layer. The device also includes a second electrode layer disposed on the semi-conducting layer opposite the dielectric layer.

Owner:THE BOEING CO

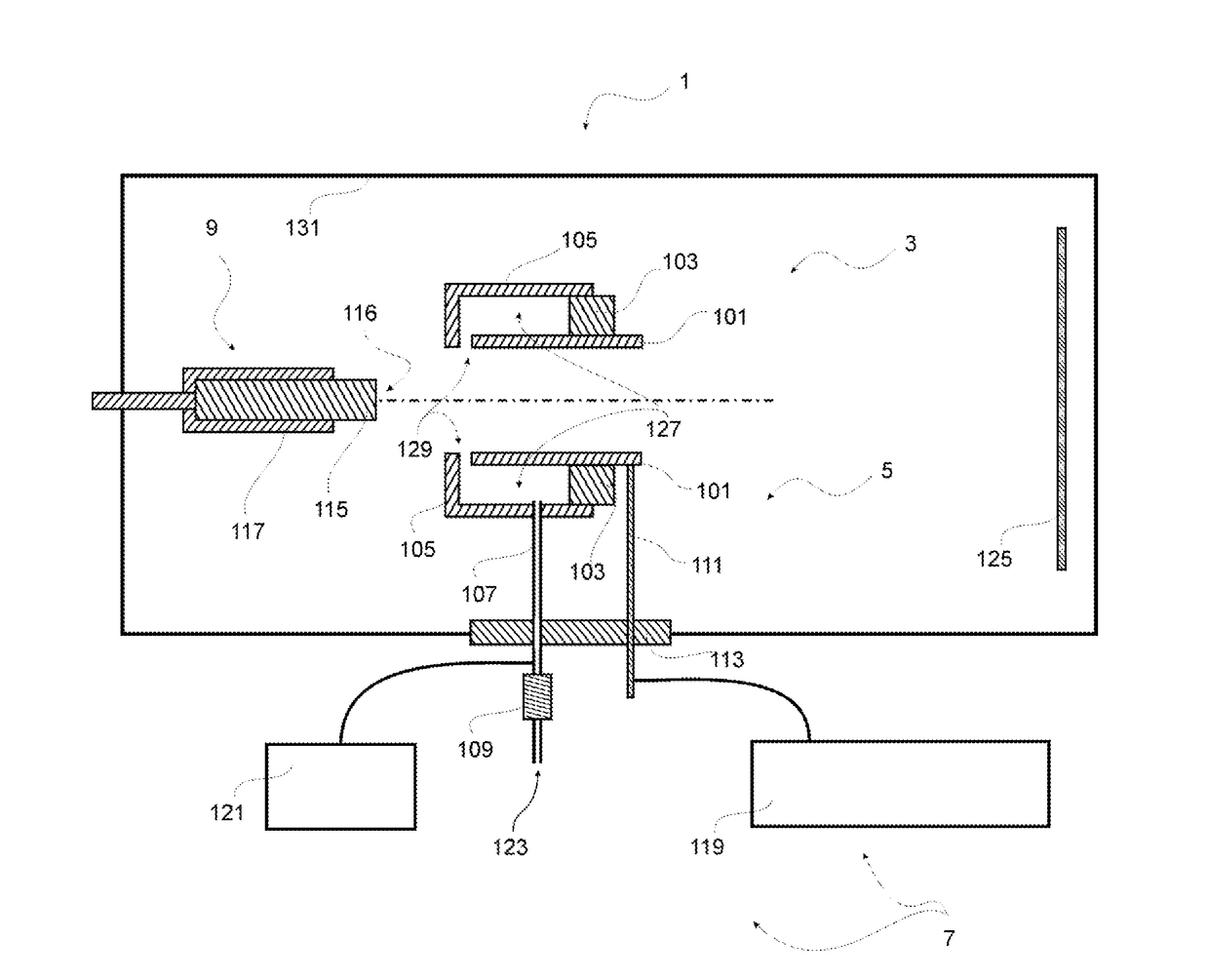

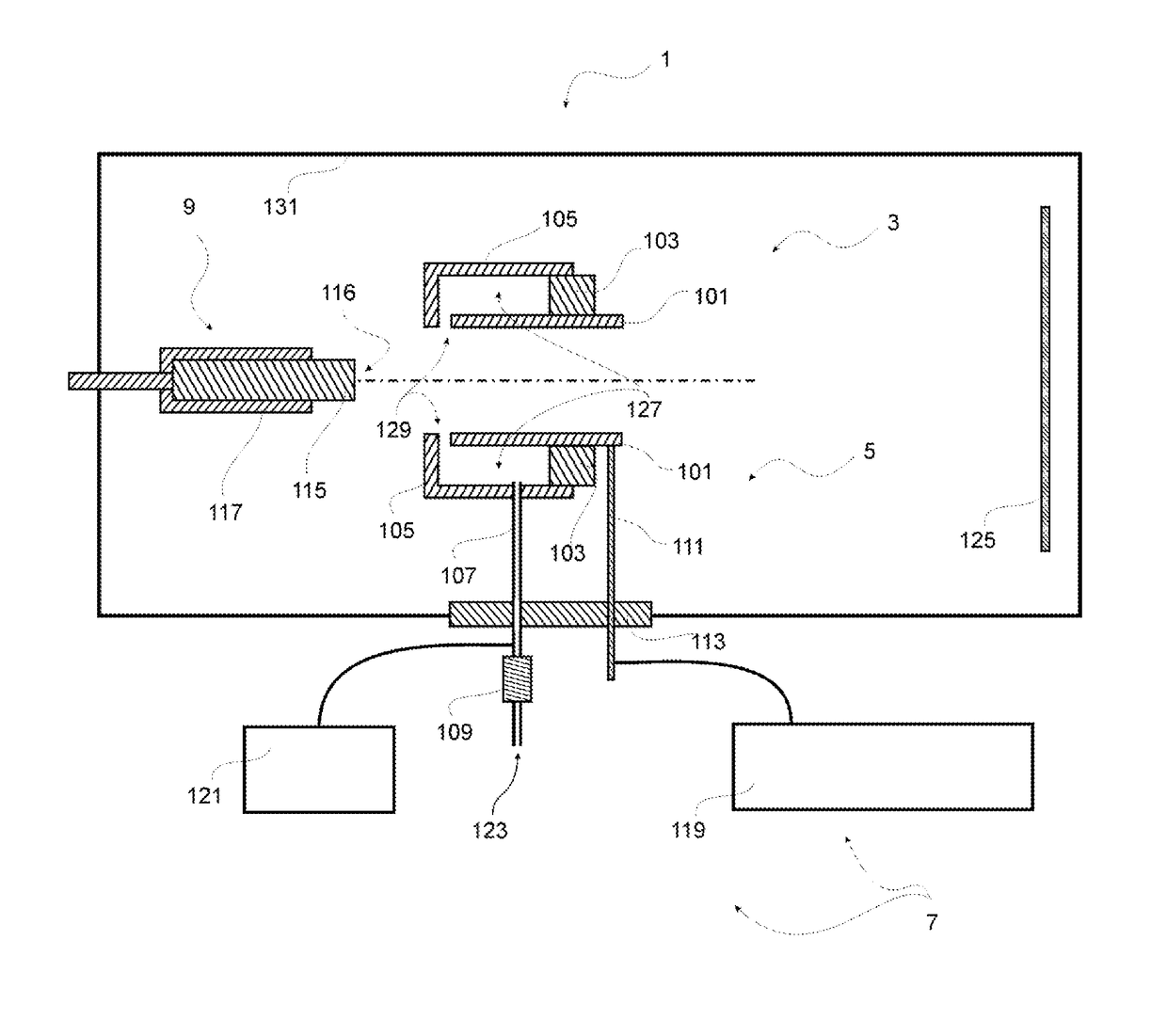

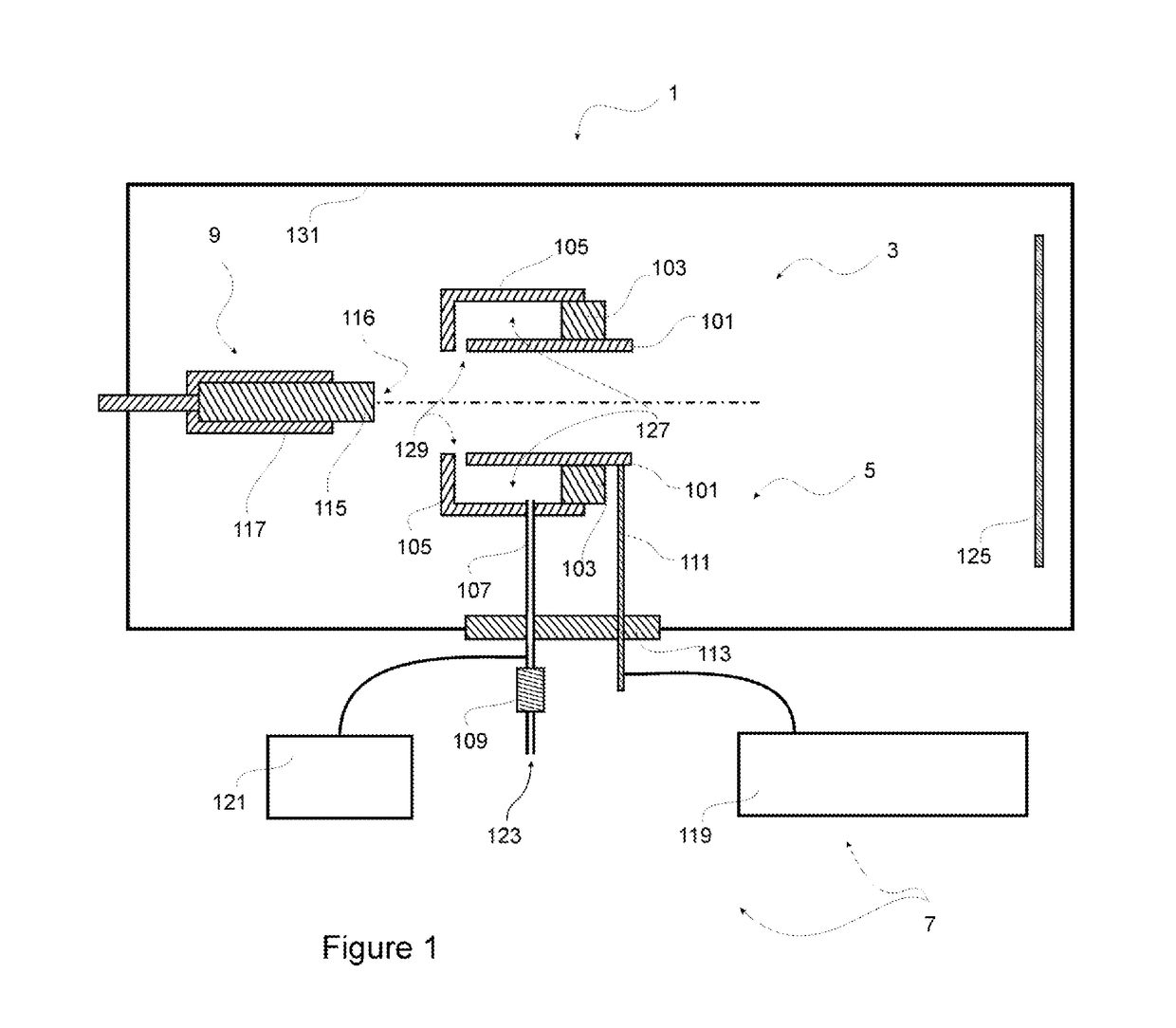

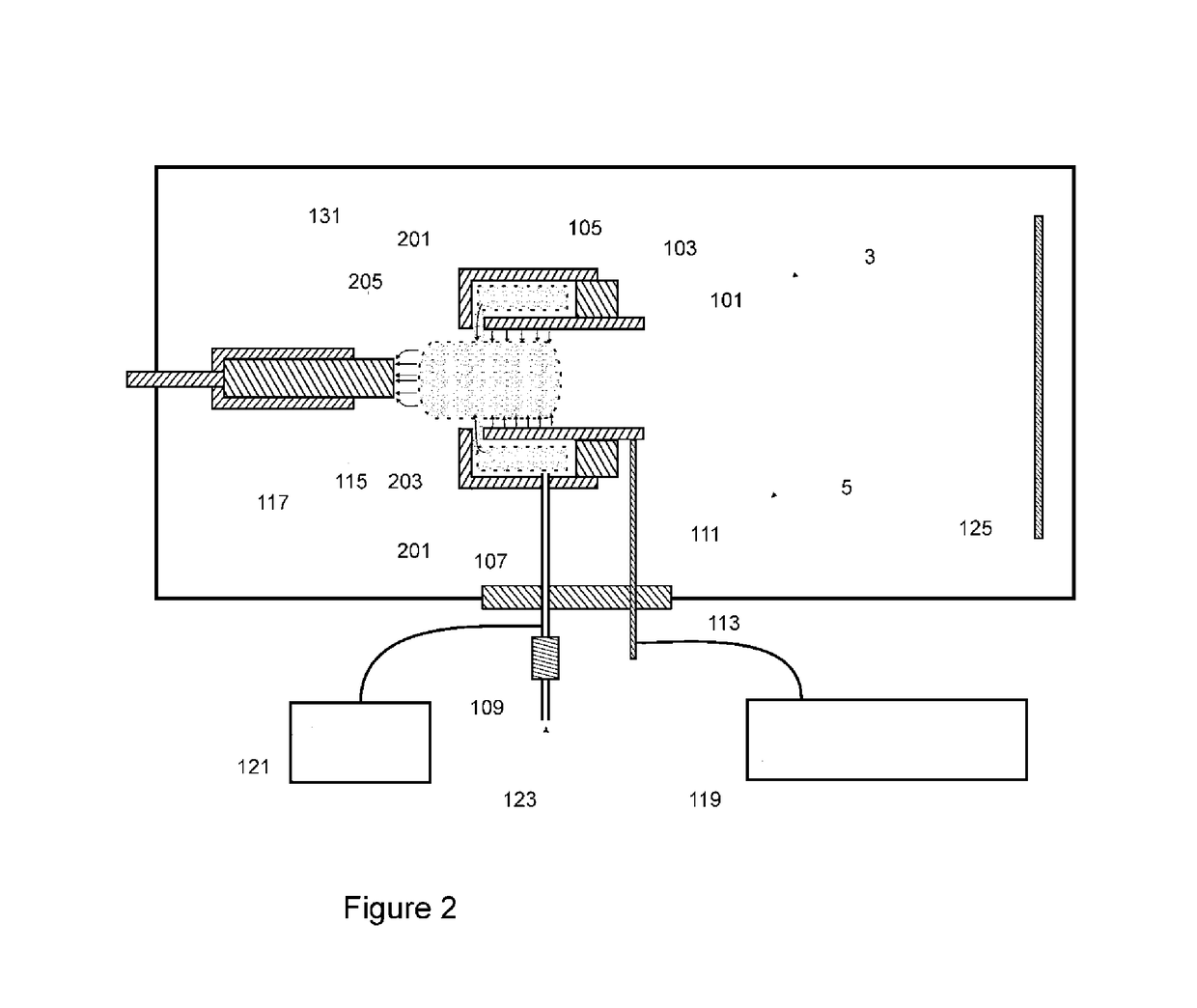

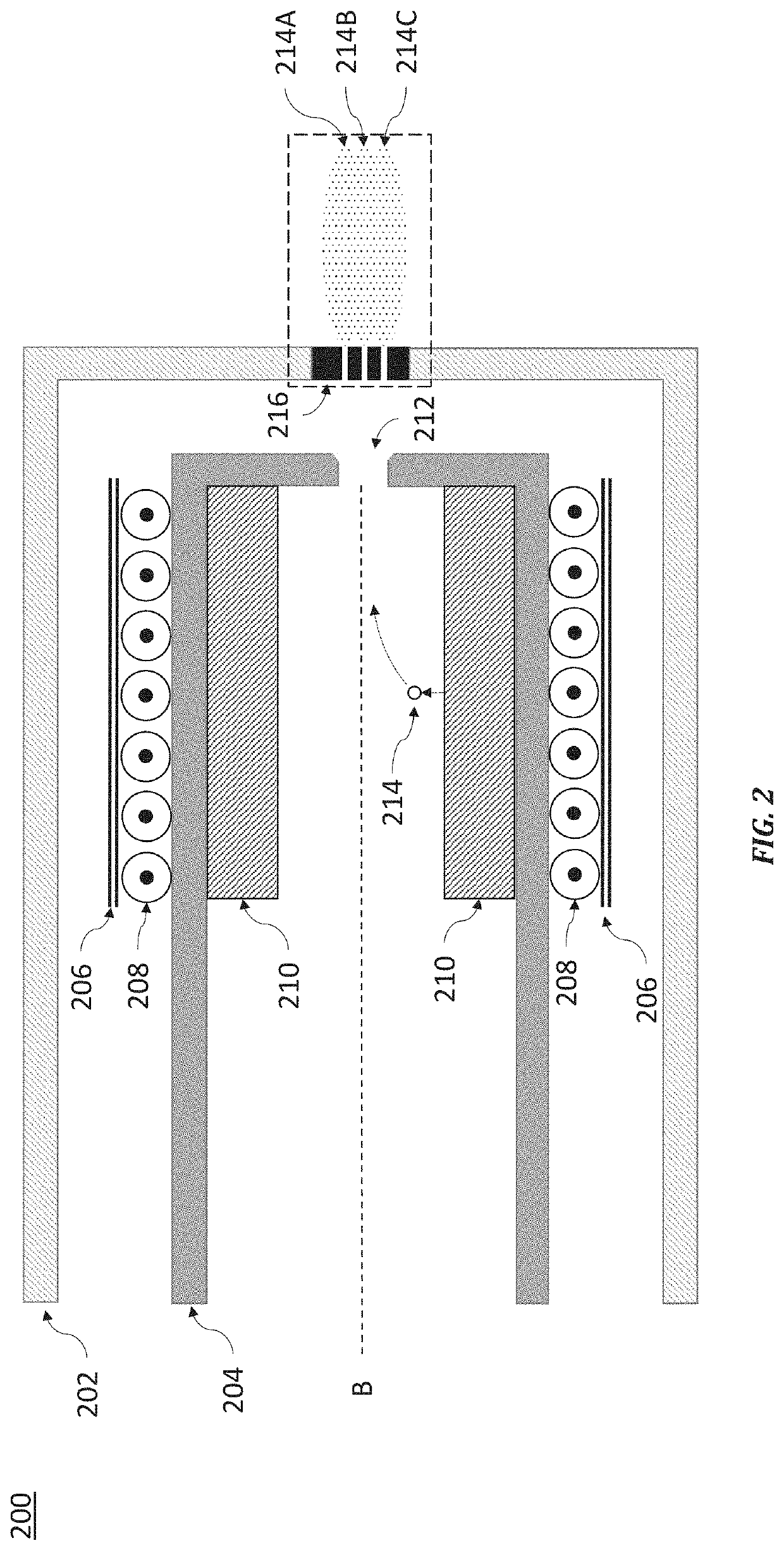

Methods and apparatuses for emitting electrons from a hollow cathode

ActiveUS20210204388A1Reduce limitationsElectric discharge tubesMachines/enginesParticle physicsPlasma

Methods and apparatuses for emitting electrons from a hollow cathode are provided. The cathode includes a plasma holding region configured to hold a plasma, a gas supply source configured to supply gas to the plasma holding region, and an orifice plate disposed on a periphery of the plasma holding region. The orifice plate comprises a plurality of openings constructed to receive electrons from the plasma. The plurality of openings decouple gas conductance and electrical conductance across the orifice plate. The diameters of the plurality of openings are within a range of 20%-60%, inclusive, of a diameter of a circular opening with an area equal to a sum of the areas of the plurality of openings.

Owner:UNITED STATES OF AMERICA

Electron gun and manufacturing method therefor

ActiveUS20210125805A1Inhibit productionEliminate emissionsTravelling-wave tubesElectrode and associated part arrangementsParticle physicsMaterials science

An electron gun comprising a cathode having an electron emitting surface and whose planar shape is circular, a heater to increase the temperature of the cathode, and an anode to apply a positive electric potential relative to the cathode to extract electrons in a predetermined direction is provided. The cathode comprises a through hole at a central portion thereof along a central axis of the cathode, and either the cathode comprises a no-emitting layer at at least one of an opening edge on the electron emitting surface side of the through hole and an inner surface of the through hole, or the opening edge on the electron emitting surface side of the through hole is a chamfered C surface or a chamfered R surface.

Owner:NEW JAPAN RADIO CORP

High efficiency hollow cathode and cathode system applying same

ActiveUS10032594B2Cosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringThermal stability

The present invention relates to a high efficiency hollow cathode and a cathode system applying the same, and comprises: a tube comprising at least two refractory metal parts; a gas providing unit and a gas outlet which are respectively formed at the distal ends of the tube; and an insert mounted inside the tube. According to the present invention, since the present invention constitutes a hollow cathode using more than two substances, the present invention can not only enhance thermal stability, lifespan and efficiency, but also can reduce costs accordingly.

Owner:KOREA ADVANCED INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com