Lanthanum hexaboride hollow cathode based on welding structure of tungsten-rhenium heating wire and tungsten top

A technology of lanthanum hexaboride and welded structure, which is applied in the field of aerospace electric thruster control, can solve problems such as stable connection, difficulty in cathode top and heater heating wire, etc., to ensure connection strength, strong environmental adaptability, and compensation for thermal expansion The effect of the cold shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

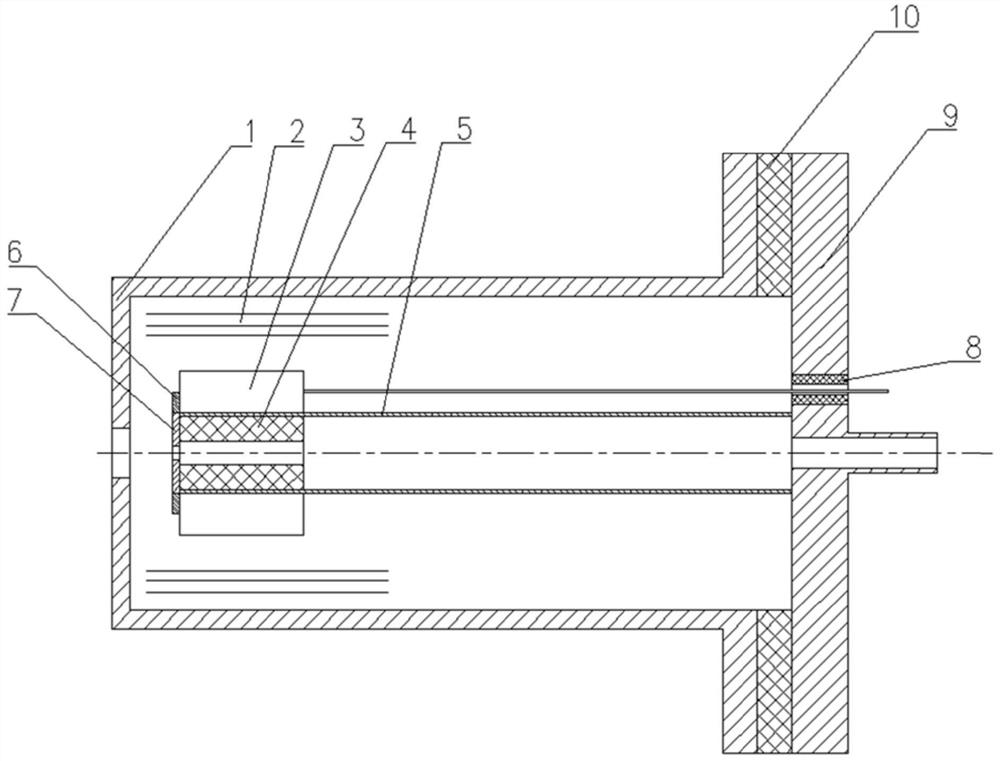

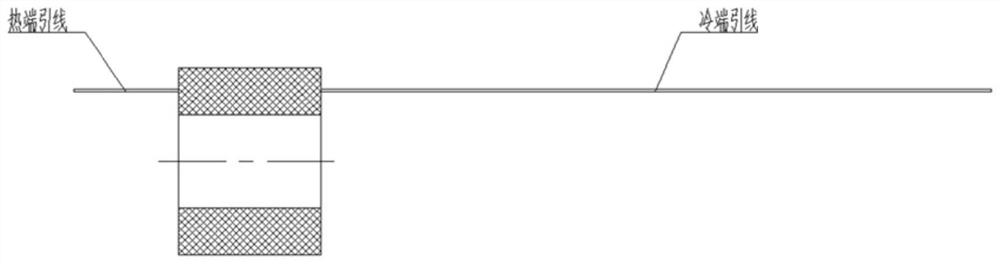

[0032] A lanthanum hexaboride hollow cathode based on the welding structure of a tungsten rhenium heating wire and a tungsten top. The tungsten rhenium heating wire and the tungsten top adopt a tantalum ring transition welding structure. After starting to energize the leads at both ends of the heater, The thermal element continues to heat the lanthanum hexaboride emitter. At this time, the working gas enters the cathode tube at the gas inlet. The lanthanum hexaboride emitter is heated to a specified temperature and emits electrons in the same direction as the xenon gas along the cathode tube. The tantalum ring is melted and wrapped Heat the end face heating wire, the tungsten rhenium heating wire does not melt at this time, the molten tantalum ring wraps the tungsten rhenium heating wire 1 / 2 turn, and the other 1 / 2 turns of the tungsten rhenium heating wire adopts the spiral transition form as a stress relief bend. Wrapped by a molten tantalum ring, it is used to release the wel...

Embodiment 2

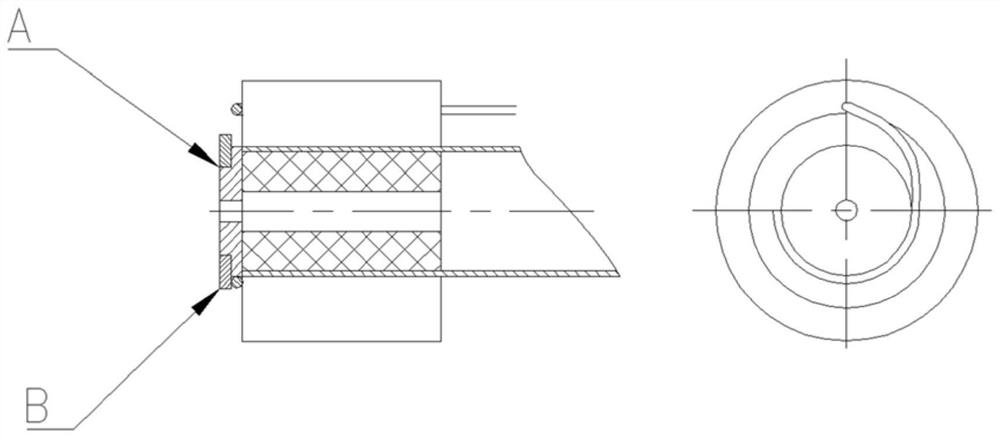

[0037] The tantalum ring is a hollow ring part with an eccentric hole. The material is tantalum metal. The tantalum ring is fitted on the outer cylindrical surface of the tungsten top. There is a clearance fit between the inner hole of the tantalum ring and the outer circle of the tungsten top. Recommended fit The gap is less than 0.05mm, and the tantalum ring and the tungsten top are welded into a whole through the end face welding structure by electron beam welding or laser welding;

[0038] The hot end lead of the thermal element is wound and inserted into the eccentric hole of the tantalum ring in the form of an involute spiral along the rotation direction of the thermal element. The matching gap between the tungsten rhenium heating wire and the eccentric hole of the tantalum ring is less than 0.05 mm. The method of focal electron beam or laser beam welding melts the tantalum around the eccentric hole of the tantalum ring, and the tungsten rhenium heating wire is not melted. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com