Electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus

A liquid metal and testing device technology, applied in the field of liquid metal cyclic heat transfer performance testing devices, can solve problems such as lack of accurate testing devices, and achieve the effect of solving performance testing problems and compensating thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

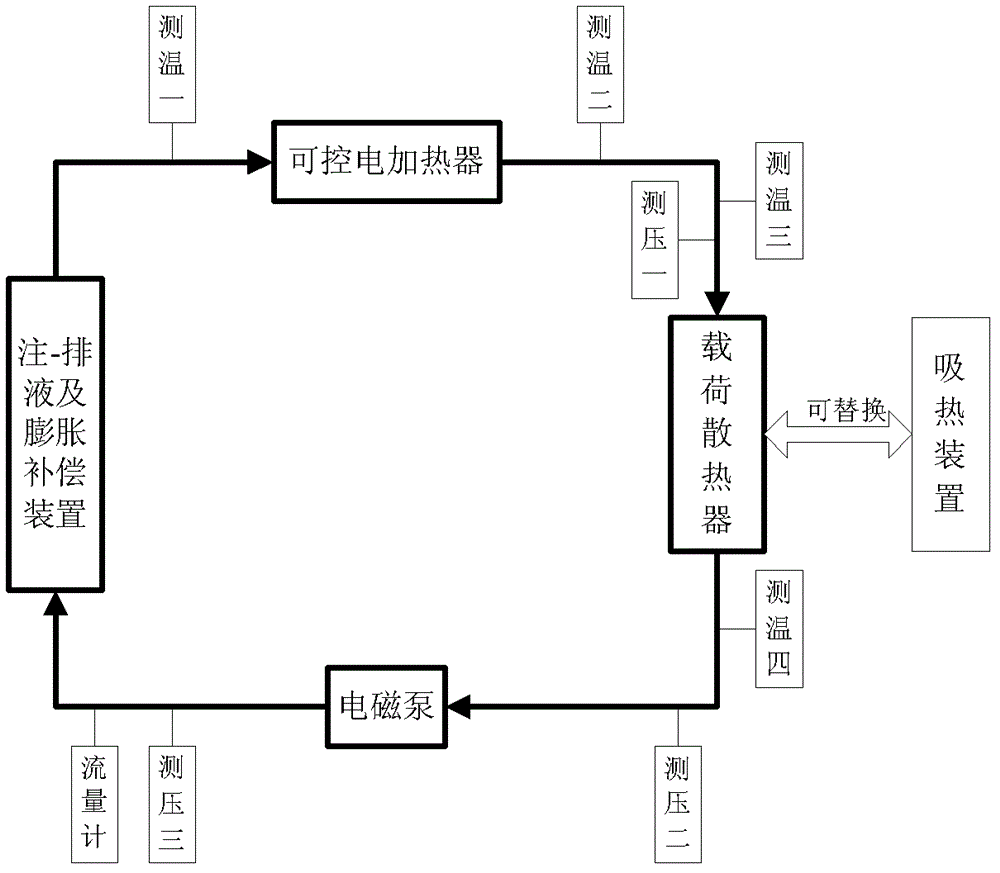

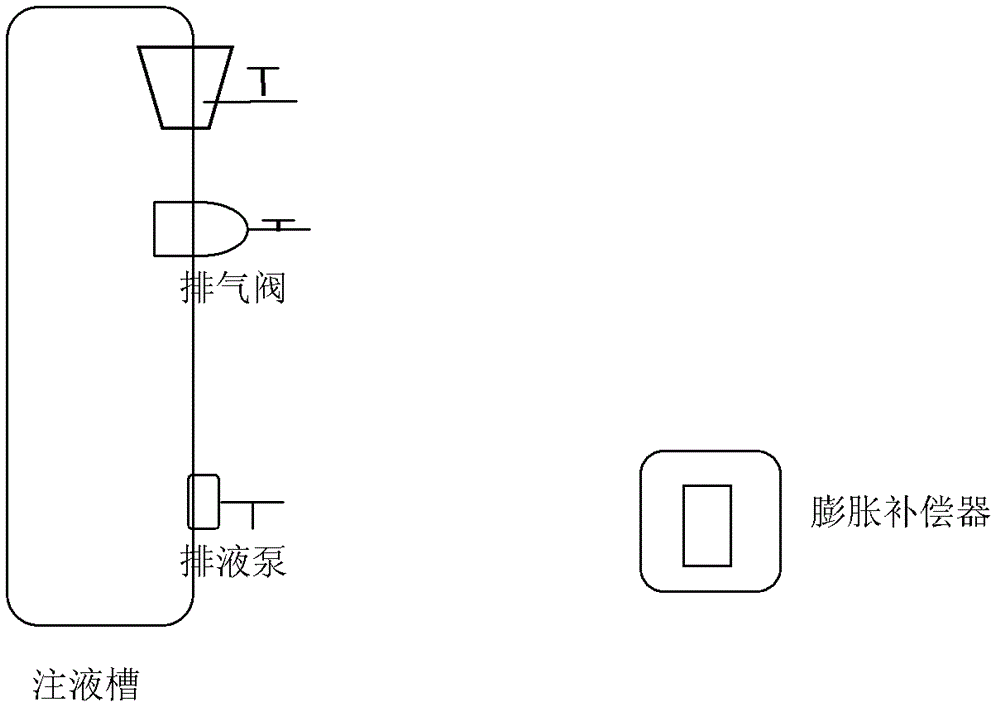

[0020] like figure 1 As shown, an electromagnetic pump drives liquid metal circulation heat transfer performance test device, which mainly includes: electromagnetic pump, controllable electric heater, load radiator, injection-drainage device, expansion compensation device, measurement sensor, pipeline and interface Six parts, each part contains a hollow flow channel to allow liquid metal to circulate, and the overall device adopts industrial general safety protection measures to prevent possible damage to people and equipment caused by high-temperature liquid metal.

[0021] The principle is that:

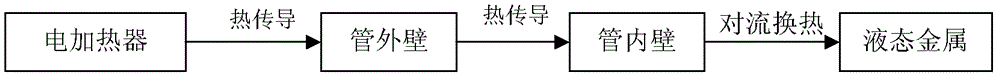

[0022] The electromagnetic pump drives the liquid metal to circulate in various components and pipelines. The liquid metal absorbs heat at the controllable electric heater, and transfers the heat to the load radiator through the flow. The circulation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com