A double gate air lock wear-resistant valve

An air lock and valve body technology, applied in the field of wear-resistant valves, can solve problems such as the impact of wear-resistant valve sealing performance, and achieve the effect of improving air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is attached Figure 1-4 The application is described in further detail.

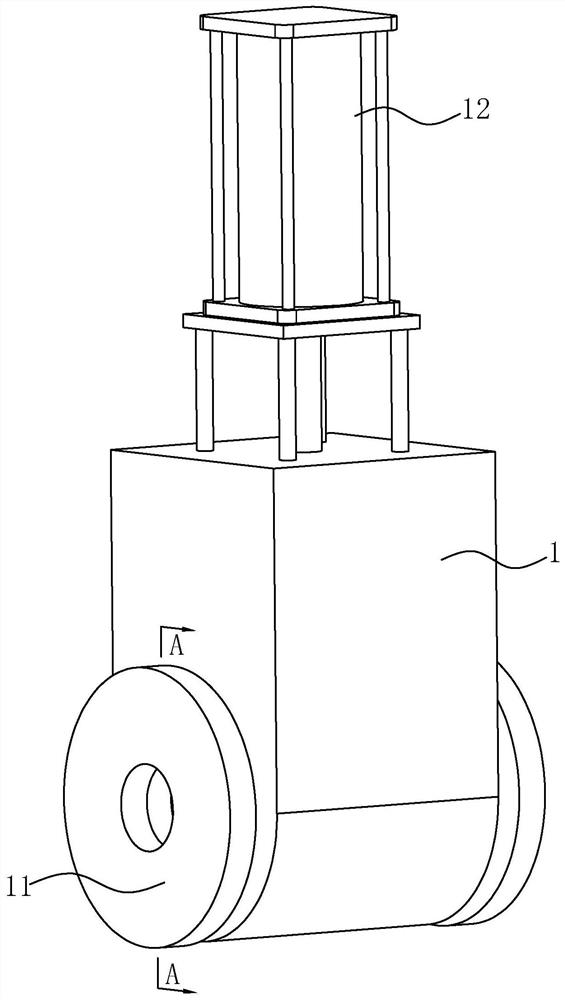

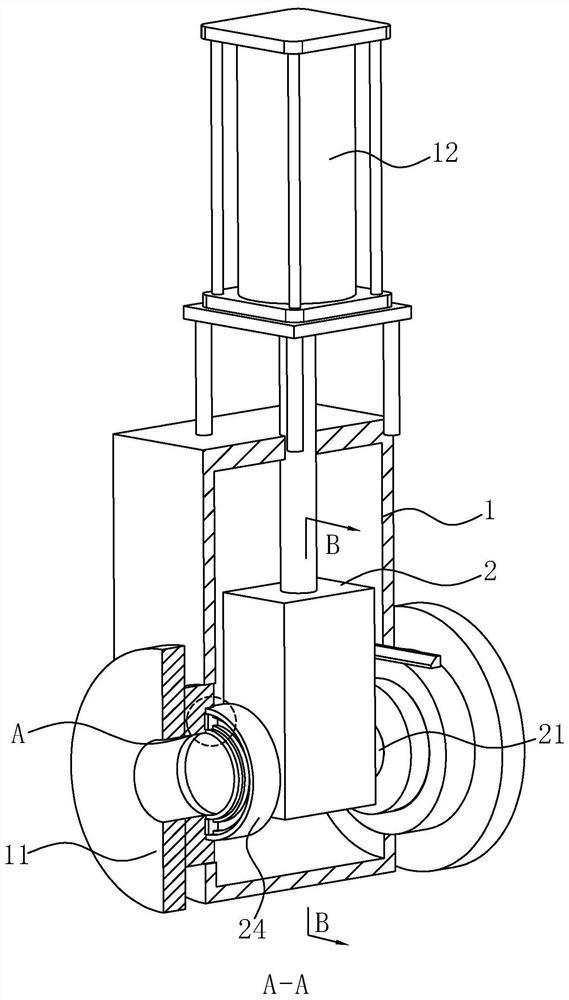

[0033] The embodiment of the application discloses a double-gate airlock wear-resistant valve. refer to figure 1 with figure 2 The wear-resistant valve includes a valve body 1 , water inlet pipes 11 fixed on both sides of the valve body 1 and a cylinder 12 fixed on the top of the valve body 1 . The bottom end of the hydraulic rod of the cylinder 12 is fixed with a control box 2 , and a valve shaft 21 is installed through the control box 2 ; the valve shaft 21 is connected to the control box 2 in rotation.

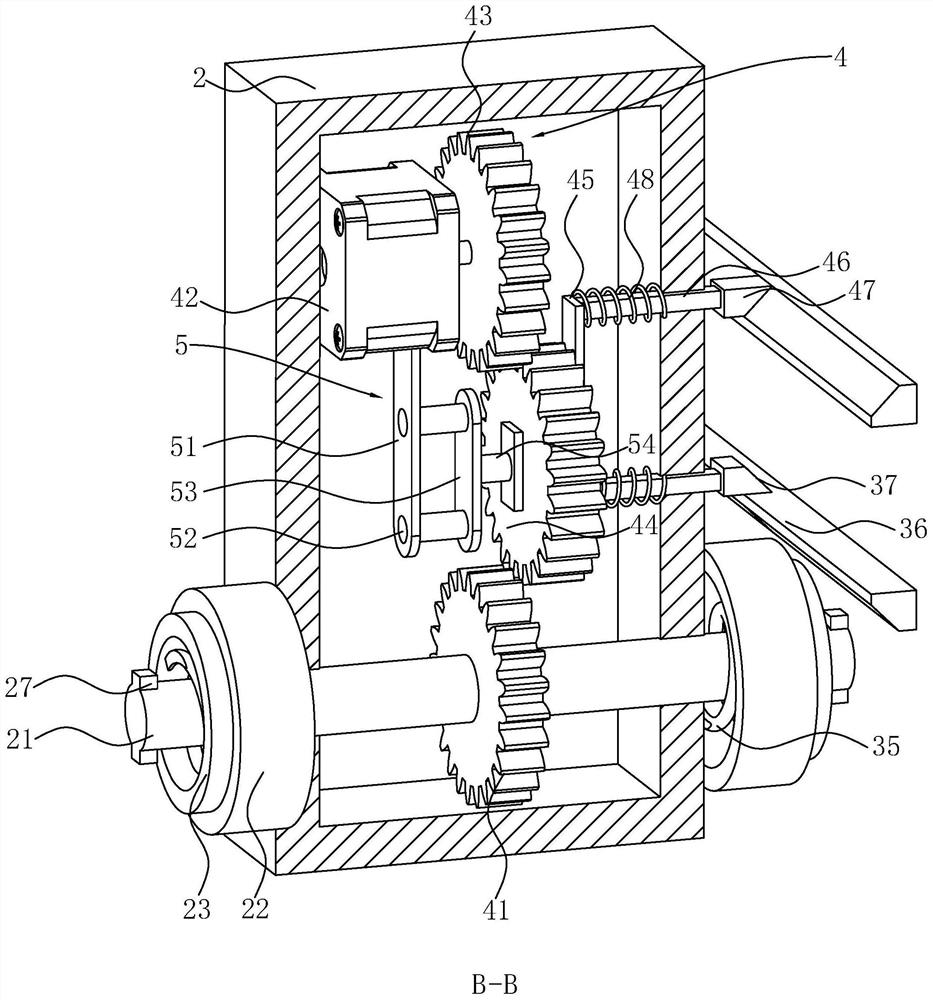

[0034] refer to figure 2 with image 3 , the two sides of the control box 2 are respectively fixed with tail pipes 22, and the two tail pipes 22 are respectively provided with telescopic pipes 23 sliding along the length direction of the control box 2. A valve plate 24 is respectively fixed on the side of each telescopic tube 23 away from the control box 2 . The side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com