Ready-packaged flexible rubber joint

A flexible rubber joint, quick-fit technology, applied in adjustable connection, pipe/pipe joint/pipe fitting, sleeve/socket connection, etc., to achieve easy assembly and installation, compensate thermal expansion and contraction, eliminate vibration and noise the effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

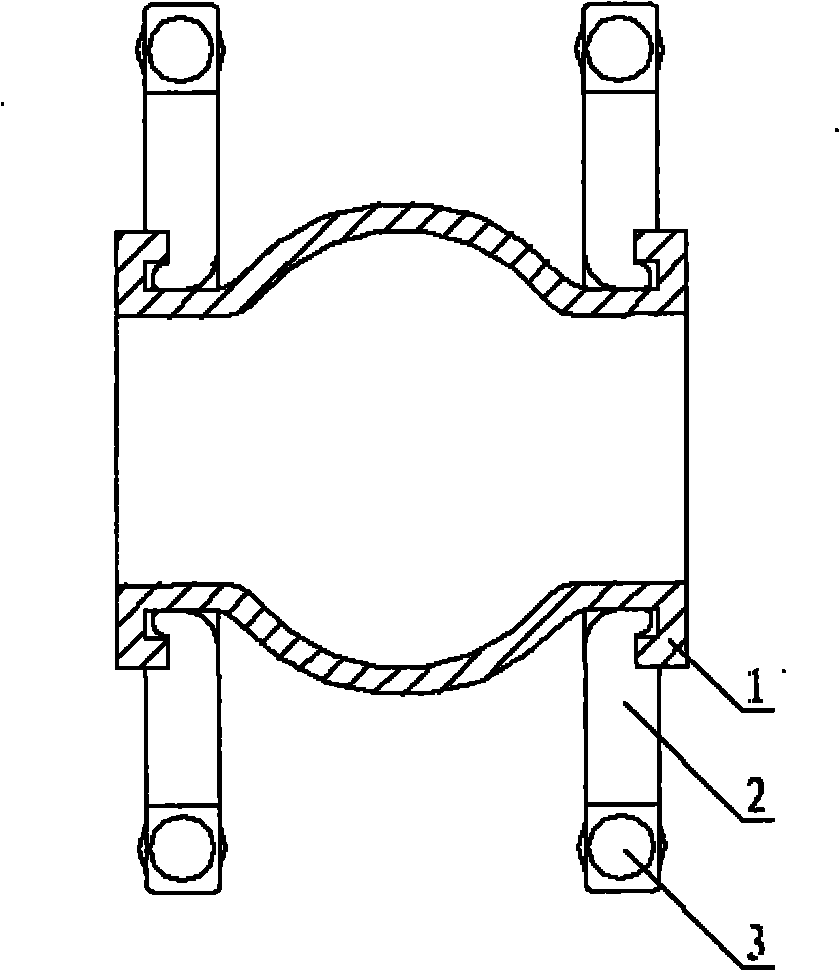

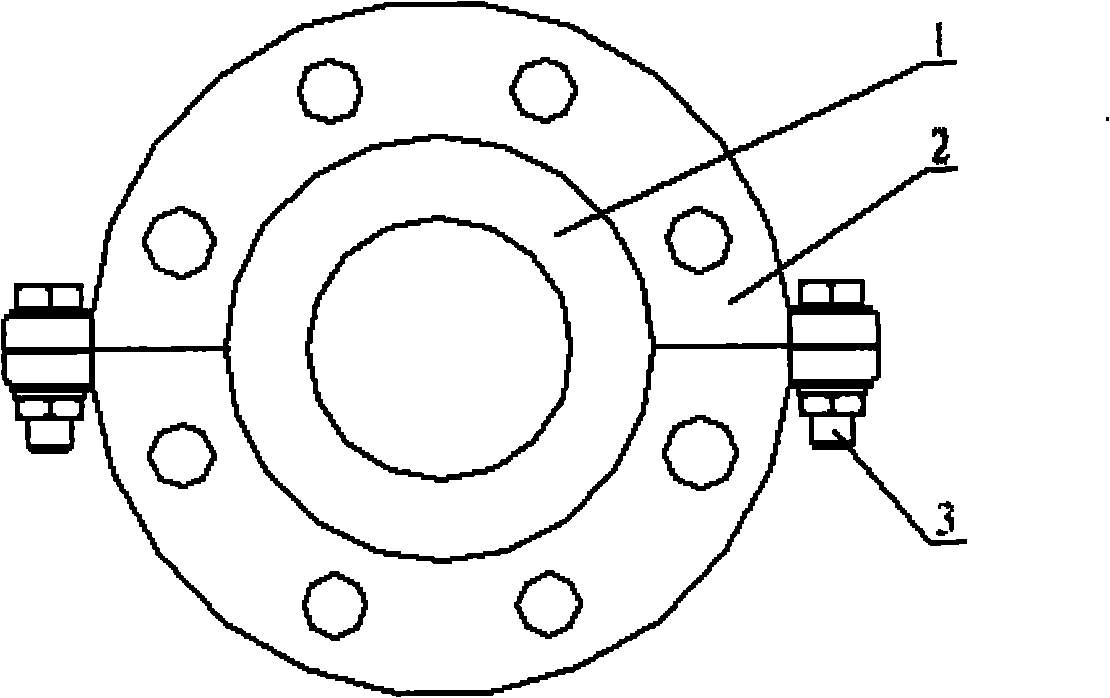

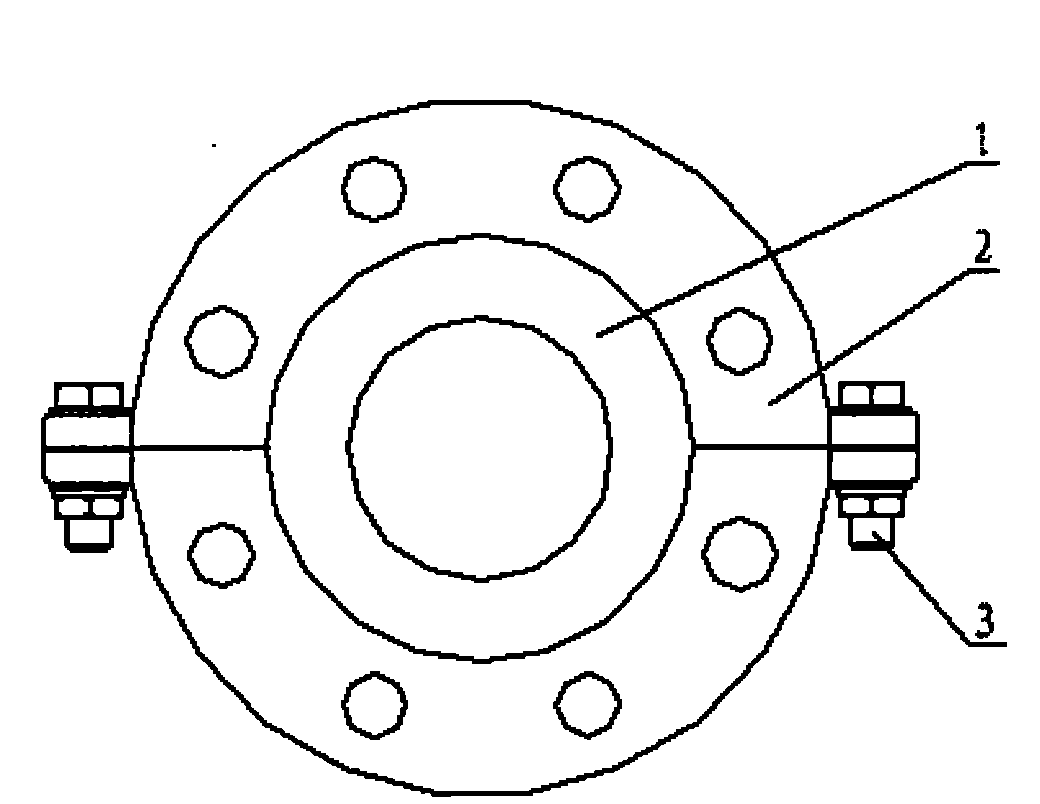

[0010] The specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings:

[0011] The quick-fit flexible rubber joint is composed of a rubber ball (1), a semicircular flange (2), and a fastening bolt (3). The two semicircular flanges (2) pass the fastening bolt (3), A complete flange with a standard connection size is formed, and the flange itself is processed with grooves, and the convex edge of the rubber ball (1) just fits with the flange groove to form a complete flexible rubber joint.

[0012] When assembling the flexible rubber joint, first assemble the semicircular flange (2) with the convex edge of the rubber ball (1), and then fix the two semicircular flanges with the fastening bolts (3) , To form a complete flexible rubber joint. When installing on the pipe network system, you can first place the semicircular flange with the pipe fitting flange with bolts, and then fasten the two semicircular fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com