Field emission assisted microdischarge devices

A field emission and electrical device technology, applied in the direction of discharge tube/lamp parts, discharge tube, electrical components, etc., can solve the problems of limiting the length and diameter of carbon nanotubes, the surface number density of carbon nanotubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

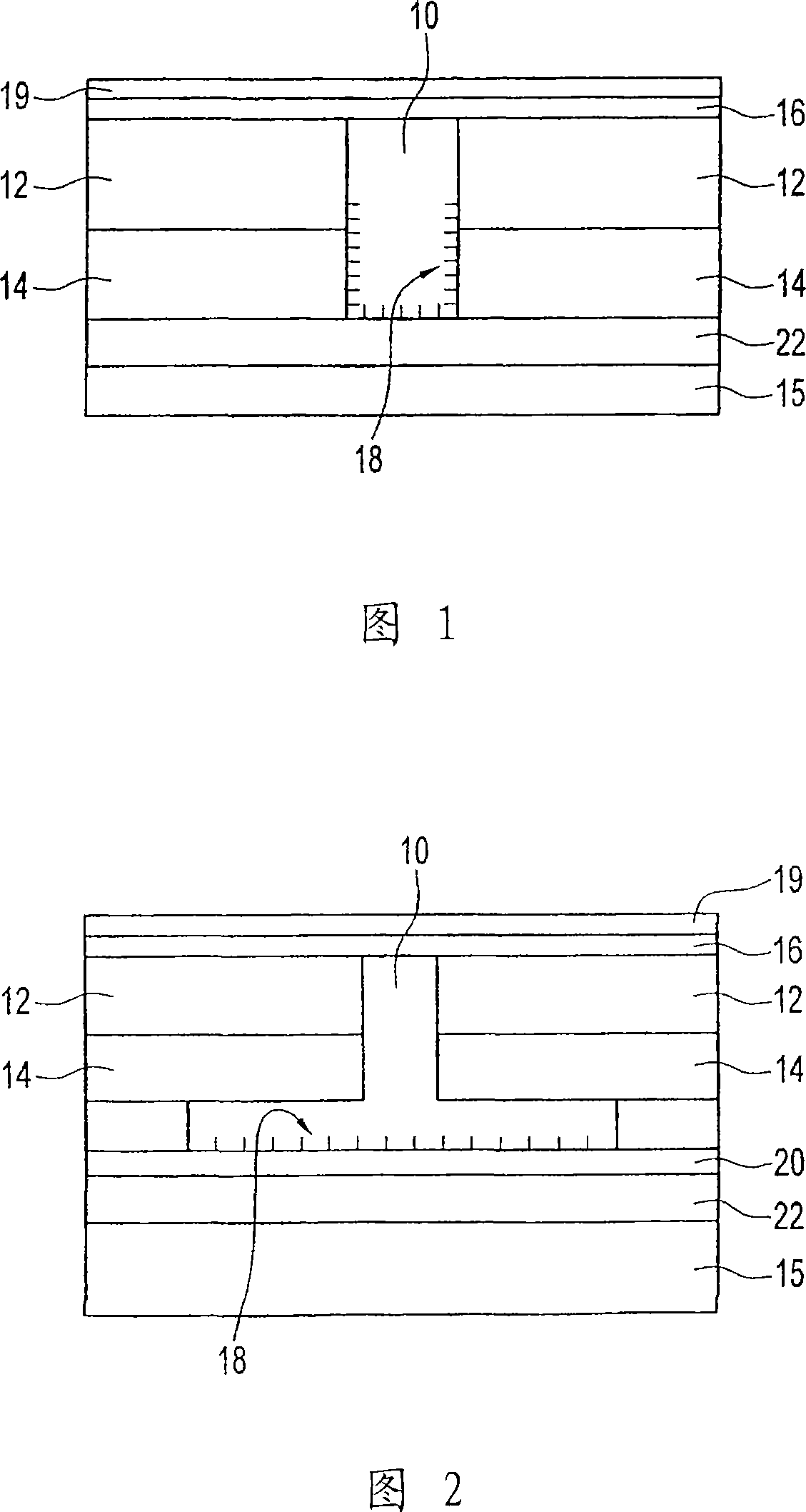

[0018] The present invention relates to a micro-discharge device with field emission nanostructure assisting work. Example embodiments of the present invention include microdischarge devices having field emission nanostructures integrated into the device and microdischarge devices having field emission nanostructures disposed near the cathode of the device. Exemplary methods of the present invention include the use of field emission nanostructures to assist in the operation of microdischarge devices. An exemplary array of the present invention includes a plurality of microdischarge devices, where each device (pixel) has a field emission nanostructure to assist in its operation.

[0019] The present invention is applicable to many different microdischarge devices, including those described in the US patents and US / PCT patent applications listed in the Background section. The invention will now be illustrated by a discussion of the preferred embodiment device. The skilled pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com