Integrated hollow cathode

A hollow cathode, one-piece technology, applied in the field of plasma, can solve the problems of low heat preservation efficiency, shorten ignition time, etc., and achieve the effect of improving heat preservation efficiency, prolonging expected service life, and improving heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

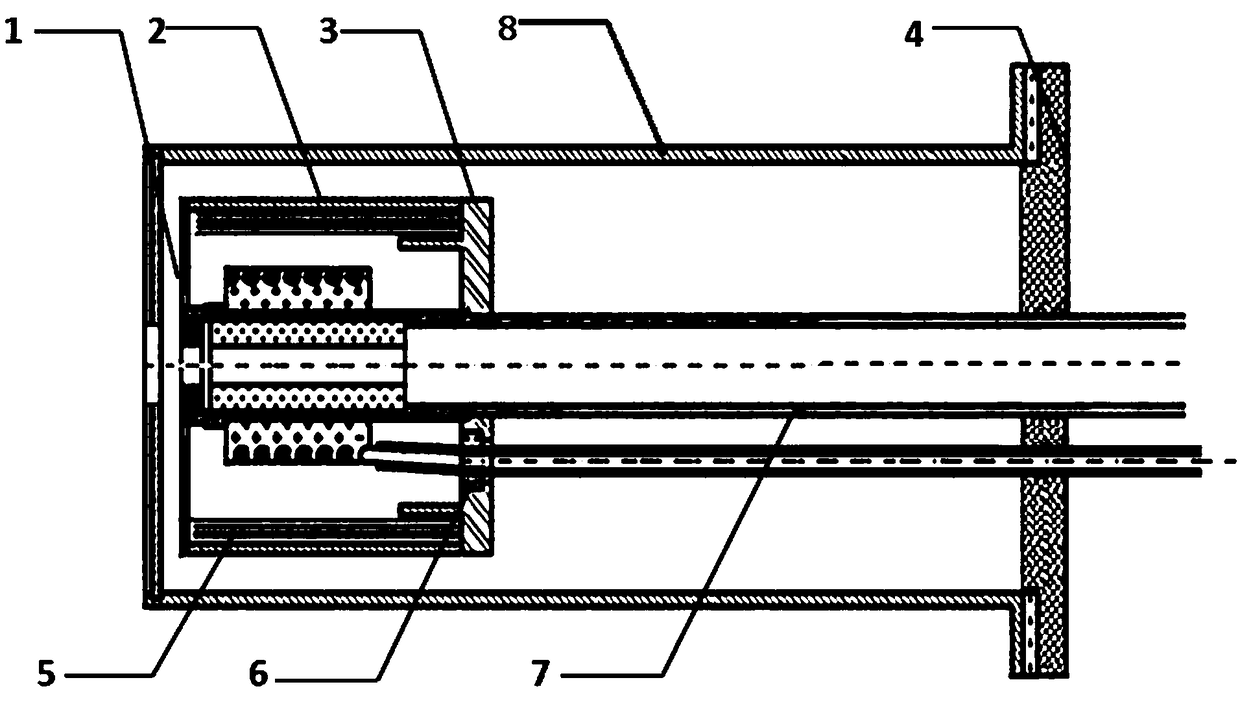

[0020] Such as figure 1 As shown, the integrated hollow cathode of this embodiment includes a heat shield top 1 , a heat shield cylinder 2 , a heat shield support 3 , a support flange 4 , a heat shield insert 5 , a heating wire fixing ceramic 6 , and a heater assembly 7 . The heat shield top 1, the heat shield cylinder 2, the heat shield support 3, the heat shield inlay 5 and the heating wire fixed ceramic 6 jointly form a heat shield assembly.

[0021] Wherein, one end of the heat shielding tube 2 is provided with a heat shield top 1 and the other end is provided with a heat shield support 3 . The top 1 of the heat shield is a tantalum skin with a thickness of 0.4mm, and a hole of 7mm is opened in the center to emit electrons in the emitter. The heat shield support 3 supports the heat shield cylinder 2 and has the same diameter as the heat shield cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com