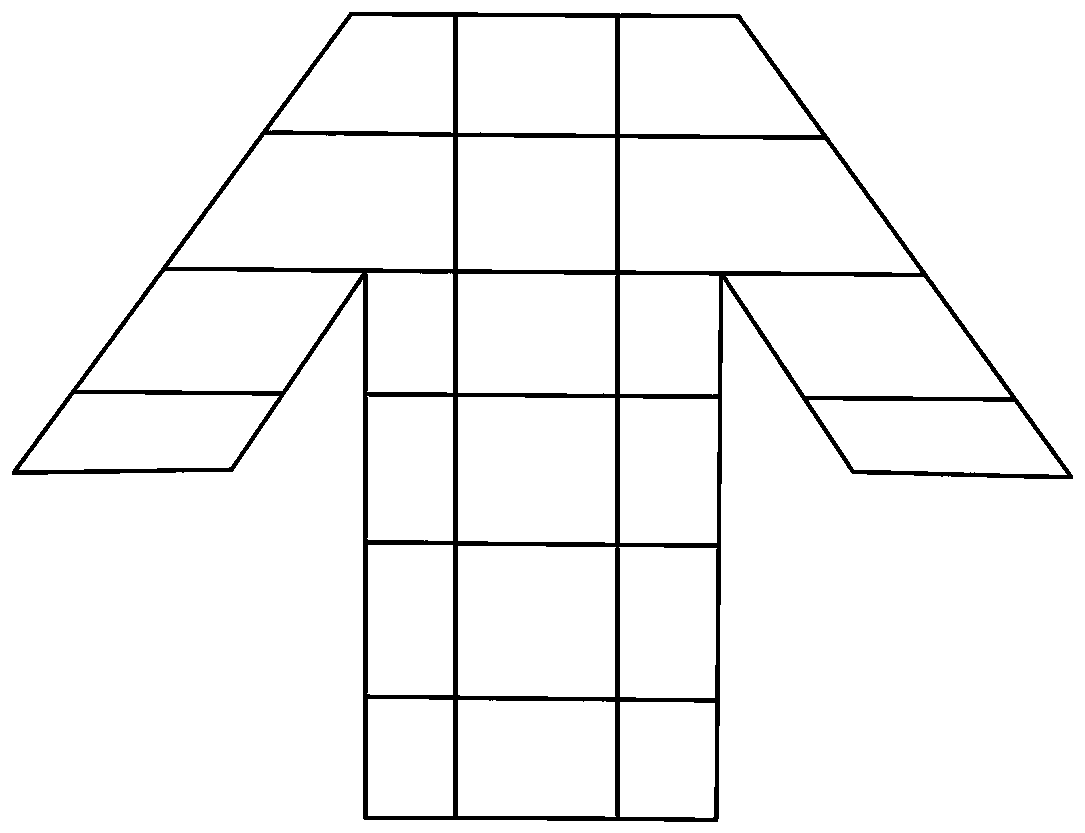

Thermal wear structure

A warm-keeping clothing and warm-keeping technology, which is applied in the field of warm-keeping clothing, can solve problems such as poor heat-retaining ability and inability to fill with heat-retaining materials, and achieve the effect of improving heat-retaining ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

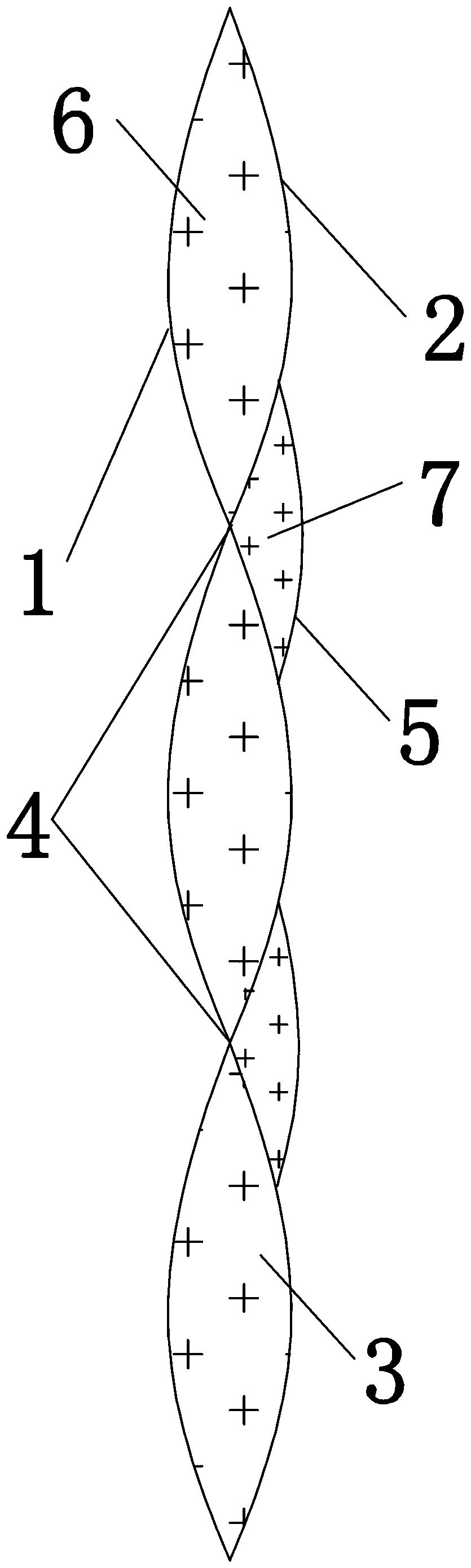

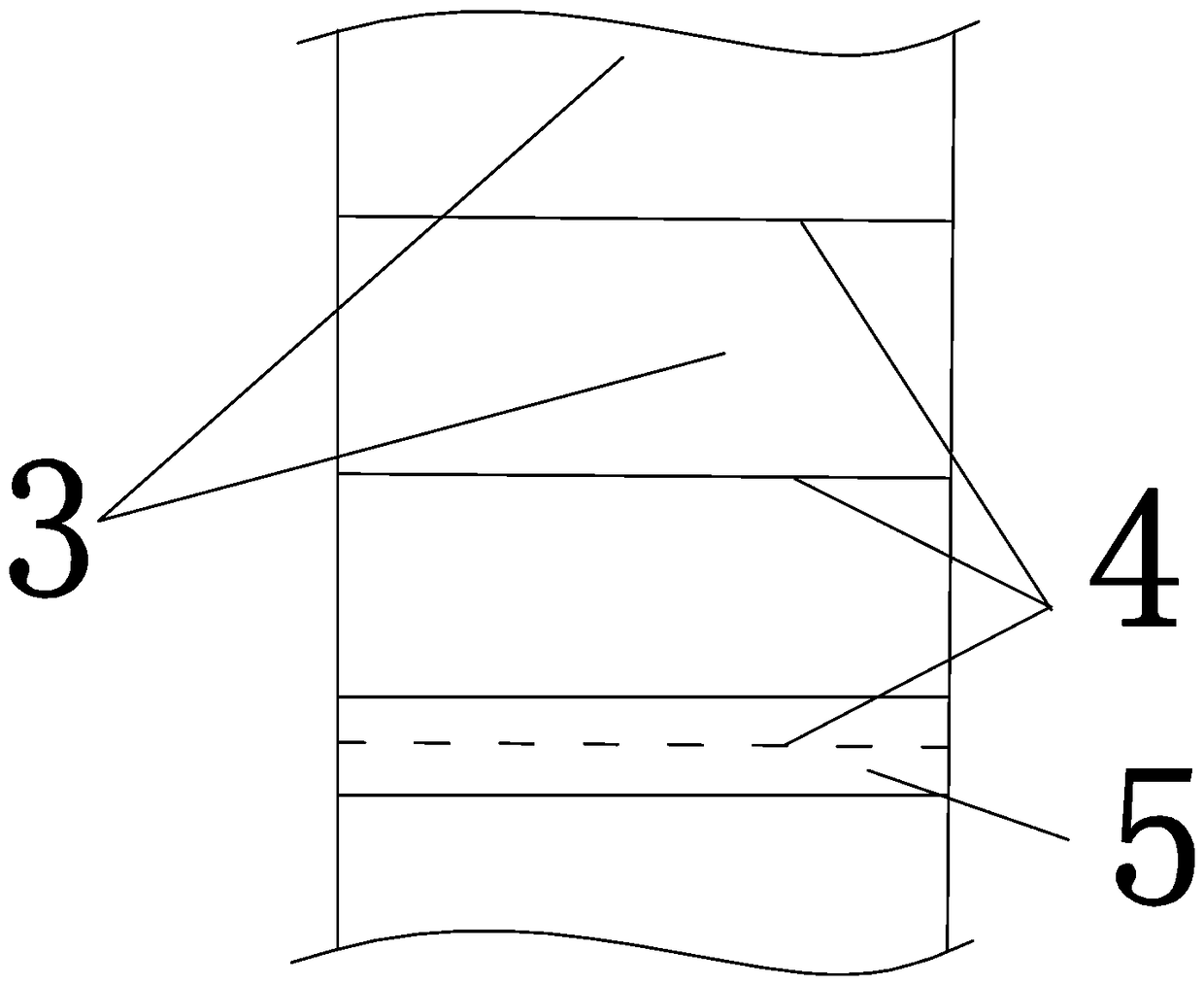

[0019] The thermal clothing structure includes a first cloth layer 1 and a second cloth layer 2 .

[0020] The first cloth layer 1 and the second cloth layer 2 are arranged oppositely, and are sewn together by a plurality of threads to form a plurality of horizontal thermal insulation bags 3 , and lateral gaps 4 are formed at adjacent thermal insulation bags 3 . Thermal insulation material 6 is filled in the thermal insulation bag 3 .

[0021] At each slit 4 places, there are reinforced thermal insulation bags 5 arranged horizontally by seams, and the reinforced thermal insulation bags 5 cover the gap 4, and the reinforced thermal insulation bag thermal insulation material 7 is filled in the reinforced thermal insulation bags 5.

[0022] Reinforcing thermal insulation bag 5 is horizontal bar shape, strengthens thermal insulation bag 5 and can be arranged on the inner side of thermal clothing, and cloth can adopt the conventional cloth of the thermal clothing of making to get f...

Embodiment 2

[0025] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0026] The first cloth layer 1 and the second cloth layer 2 are sewn together by a plurality of threads to form a plurality of longitudinal thermal insulation bags 3 , and the reinforced thermal insulation bags 5 are vertically arranged to cover the gap 4 .

[0027] Thermal insulation material 6 is filled in the thermal insulation bag 3 . Reinforcing thermal insulation bag 5 is filled with reinforced thermal insulation bag thermal material 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com