Air storage tank for air suspension system and processing equipment thereof

A technology of air suspension and processing equipment, applied in metal processing equipment, suspension, elastic suspension and other directions, can solve the problems of difficult processing and affect the strength of the air storage tank, to ensure light weight, increase welding lightness, The effect of increasing the welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

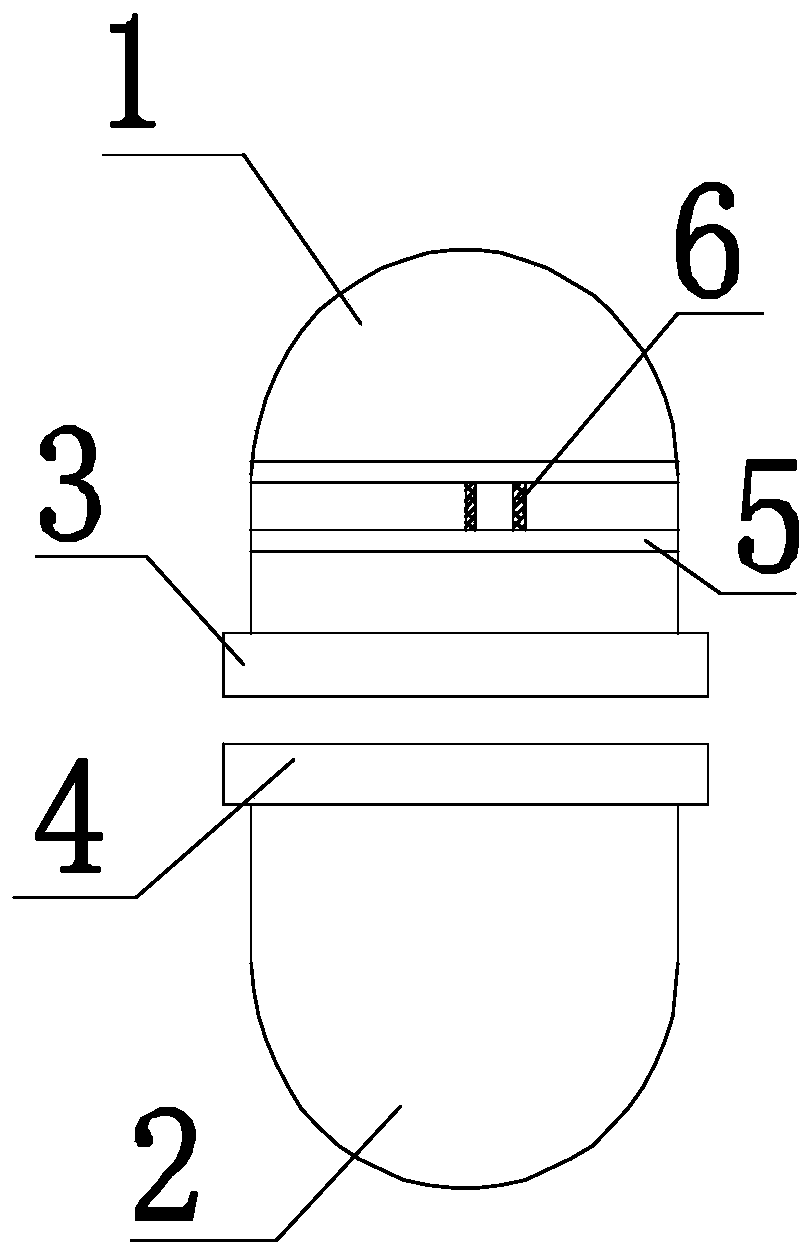

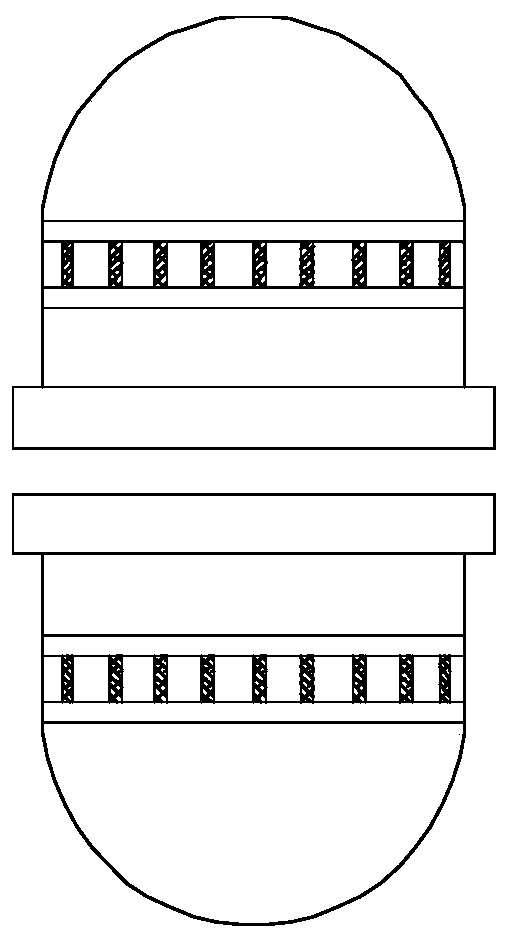

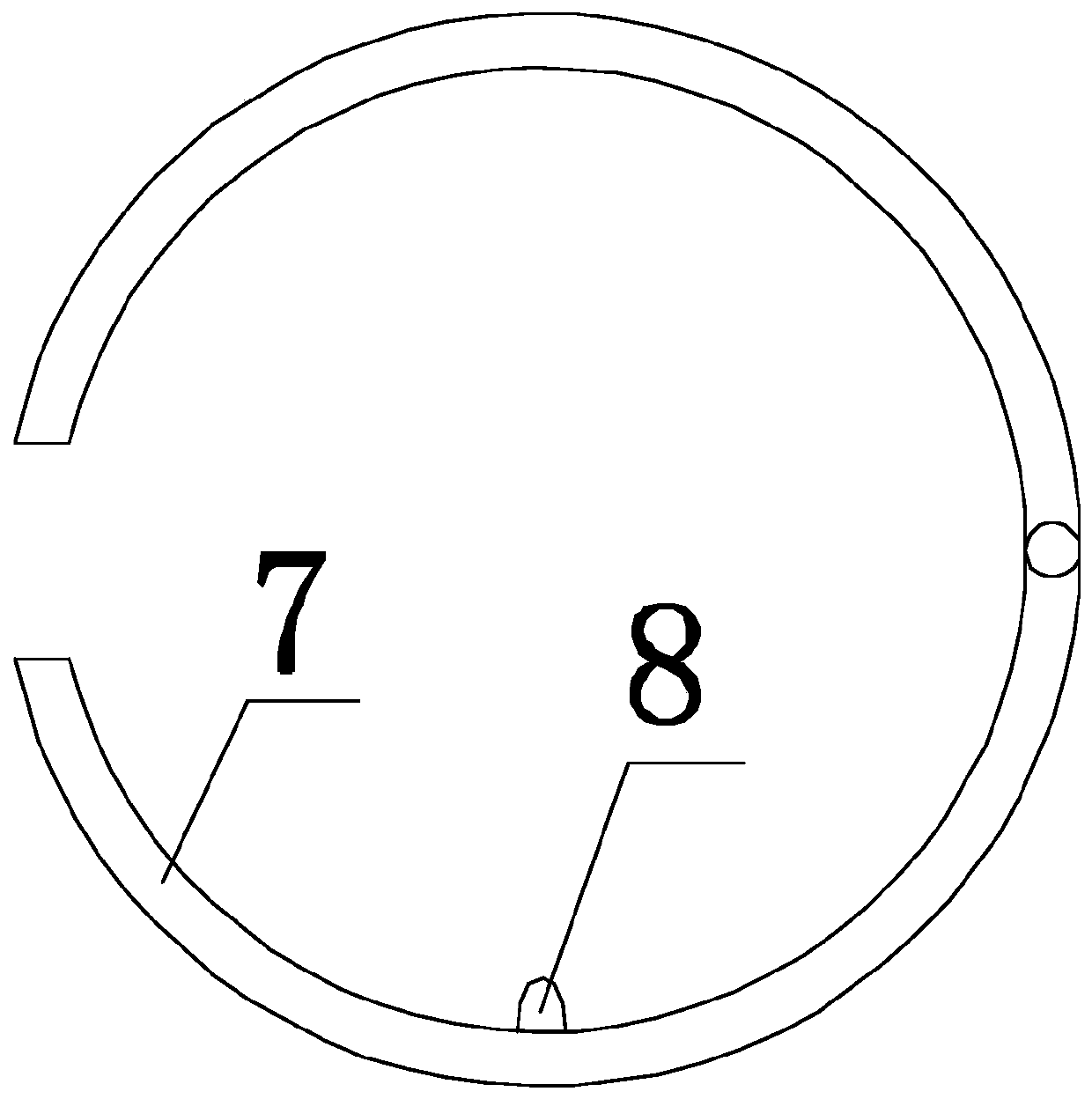

[0022] refer to figure 1 , an air storage tank for an air suspension system proposed by the present invention, the main body of the air storage tank is composed of a symmetrical first half 1 and a second half 2, both of which are Rotationally symmetrical structure. The opening end of the first half 1 is provided with a first stepped flange 3 , and the open end of the second half 2 is provided with a second stepped flange 4 , and the first stepped flange 3 and the second stepped flange 4 are symmetrical. The first stepped flange 3 and the second stepped flange 4 are friction welded.

[0023] The setting of the first step flange 3 and the second step flange 4 increases the welding area of the first half part 1 and the second half part 2, and the first step flange 3 and the second step flange are fixed by rotating friction. 4 Welding increases the lightness of welding and avoids additional welding materials, further ensuring the lightweight of the gas storage tank.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com