Lightweight aggregate prepared from steel mill sludge, and preparation method thereof

A lightweight aggregate and steel mill technology, applied in applications, household utensils, clay products, etc., can solve problems such as non-compliance with requirements, and achieve low water absorption, low density, and good thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

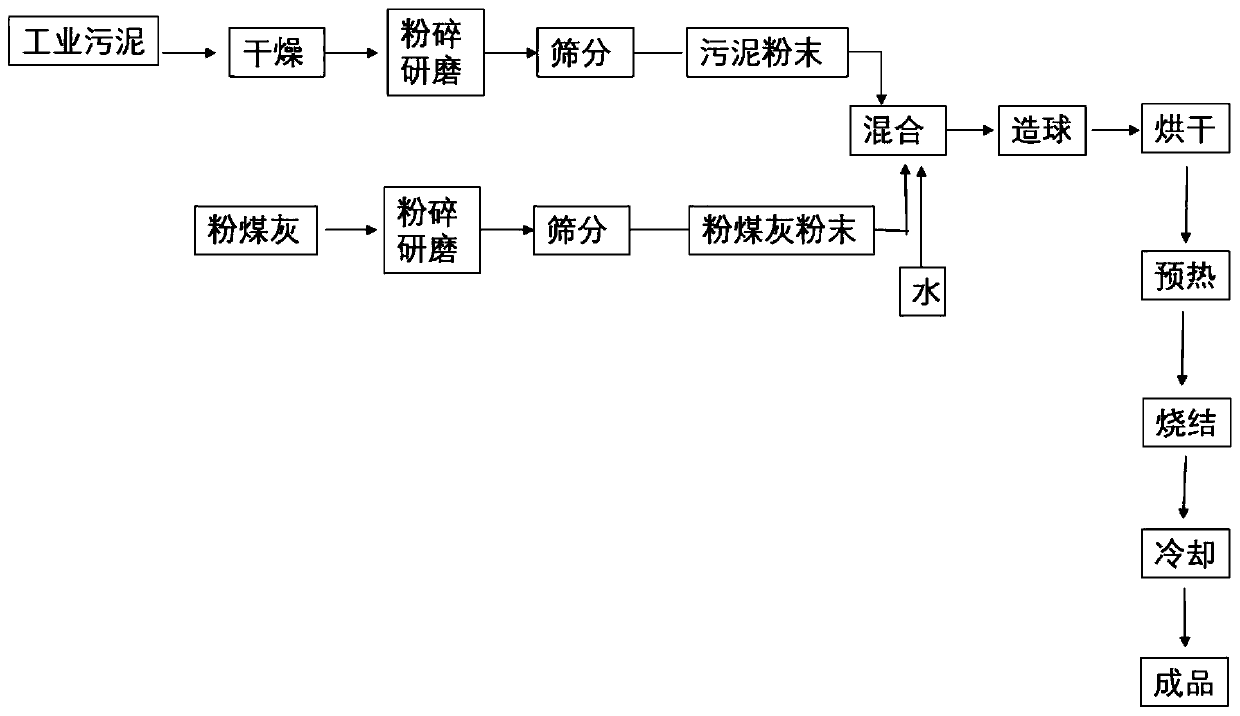

[0037] A method for preparing lightweight aggregate from pure high-calcium sludge, comprising the steps of:

[0038] a. Put the dewatered sludge with a moisture content of 47% into a drying box, dry it at 105°C for 24 hours, then pulverize and grind it into powder, and pass the obtained sludge powder through a 200-mesh sieve;

[0039] b. Take 3kg of sludge powder and pour it into the pelletizing machine, then spray water and feed alternately. After the pelletizing machine rotates 1760 times within 55 minutes, a raw pellet of 10-15mm is obtained, and the finished product volume is 1.1L;

[0040] c. Put the raw meal balls in a drying oven and dry them at 105°C for 1 hour;

[0041] d. Put the dried raw meal balls in a muffle furnace, raise the temperature to 300°C at a heating rate of 10°C / min, keep it at 300°C for 20 minutes, and raise it to 1100°C at a heating rate of 5°C / min, and keep it warm 25min;

[0042] e. The fired aggregate is cooled to room temperature with the furna...

Embodiment 2

[0045] A method for preparing lightweight aggregate by utilizing high-calcium sludge accounting for 80% and fly ash accounting for 20%, comprising the following steps:

[0046] 1. Put the dewatered sludge with a moisture content of 47% into a drying oven, dry it at 105°C for 24 hours, and then pulverize it to make powder, and pass the obtained sludge powder and fly ash through a 200-mesh sieve;

[0047] 2. Mix according to the ratio of sludge weight ratio of 80% and fly ash weight ratio of 20%;

[0048] 3. After mixing evenly, take 3kg of the mixture and pour it into the pelletizing machine, then spray water and feed alternately. The pelletizing machine rotates 2240 times within 70 minutes to get 10-15mm raw material balls, and the finished product volume is 1.8L;

[0049] 4. Put the raw meal balls in a drying oven and dry them at 105°C for 1 hour;

[0050] 5. Put the dried raw meal balls in a muffle furnace, raise the temperature to 300°C at a heating rate of 10°C / min, keep ...

Embodiment 3

[0054] A method for preparing lightweight aggregate by utilizing high-calcium sludge accounting for 60% and fly ash accounting for 40%, comprising the following steps:

[0055] 1. Put the dewatered sludge with a moisture content of 47% into a drying oven, dry it at 105°C for 24 hours, and then pulverize it to make powder, and pass the obtained sludge powder and fly ash through a 200-mesh sieve;

[0056] 2. Mix according to the ratio of sludge weight ratio of 20% and fly ash weight ratio of 80%;

[0057] 3. After mixing evenly, take 3kg of the mixed material and pour it into the pelletizing machine, then spray water and feed alternately. The pelletizing machine rotates 2464 times within 77 minutes to get 10-15mm raw material balls, and the finished product is 2.2L;

[0058] 4. Put the raw meal balls in a drying oven and dry them at 105°C for 1 hour;

[0059] 5. Put the dried raw meal balls in a muffle furnace, raise the temperature to 300°C at a heating rate of 10°C / min, keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com