Novel hollow cathode heater structure

A hollow cathode and heater technology, applied in the aerospace field, can solve the problems of short circuit, open circuit, and easy induction current of the heating wire, so as to avoid falling off, facilitate reliable fixing, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

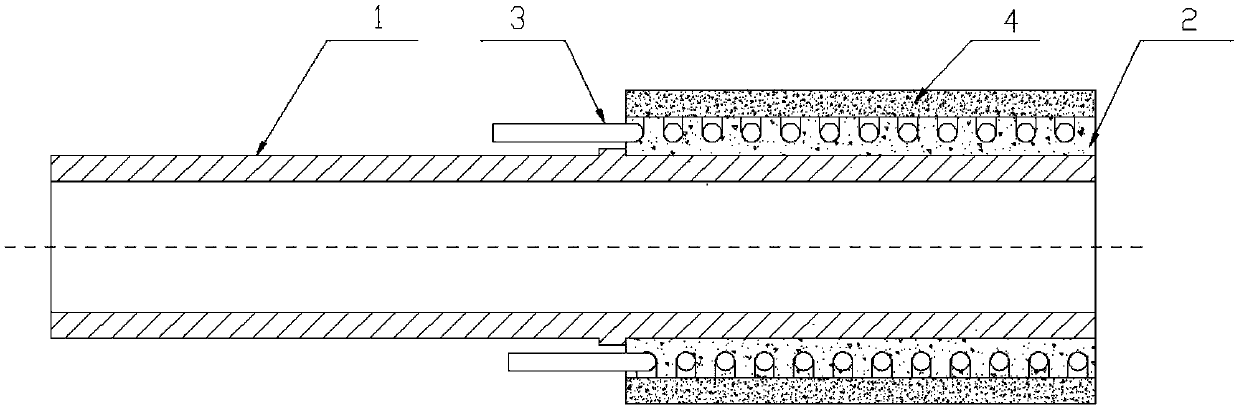

[0018] like figure 1 As shown, a new hollow cathode heater structure is composed of ceramic skeleton, heating wire and outer ceramic. The ceramic frame is nested outside the cathode tube of the hollow cathode, close to the top of the cathode tube. There is a radial spiral groove on the outside of the ceramic frame; the heating wire is spirally inserted into the spiral groove; the outer ceramic is tightly fitted. Outside the ceramic skeleton, the heating wire is effectively confined within the helical groove.

[0019] The groove on the outside of the ceramic skeleton is a double helix groove. The pitch of the double helix is the same. The specific pitch value can be determined according to the actual hollow cathode requirements. The cross-sectional structure of the groove is a semicircle at the bottom and a rectangle at the top. Heating wire.

[0020] The heating wire is inserted into the spiral groove of the ceramic frame in a double helix manner. Both ends of the heating ...

Embodiment 2

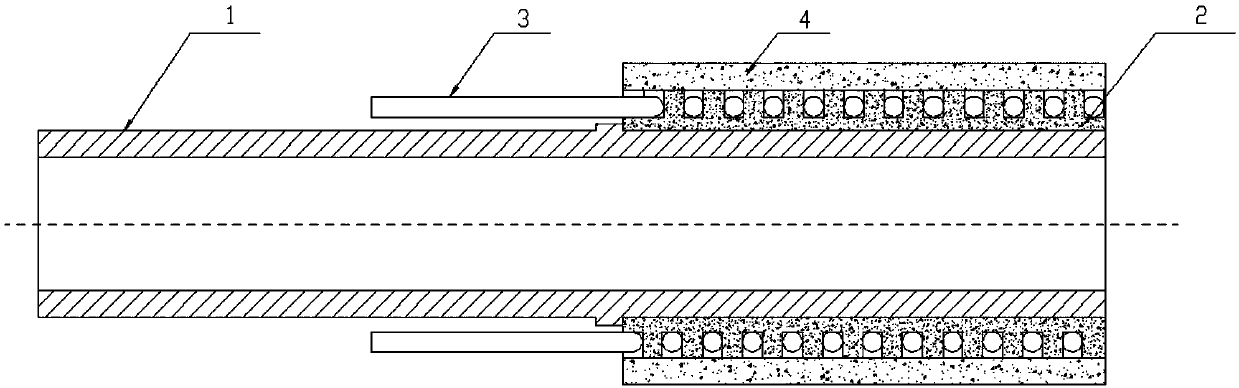

[0022] like figure 2 As shown, a new hollow cathode heater structure is composed of ceramic skeleton, heating wire and outer ceramic. The ceramic frame is nested outside the cathode tube of the hollow cathode, close to the top of the cathode tube. There is a radial spiral groove on the outside of the ceramic frame; the heating wire is spirally inserted into the spiral groove; the outer ceramic is tightly fitted. Outside the ceramic skeleton, the heating wire is effectively confined within the helical groove.

[0023] The groove on the outside of the ceramic skeleton is a double helix groove. The pitch of the double helix is the same. The specific pitch value can be determined according to the actual hollow cathode requirements. The cross-sectional structure of the groove is rectangular, and the groove size must completely accommodate the heating wire.

[0024] The heating wire is inserted into the spiral groove of the ceramic frame in a double helix manner. Both ends of th...

Embodiment 3

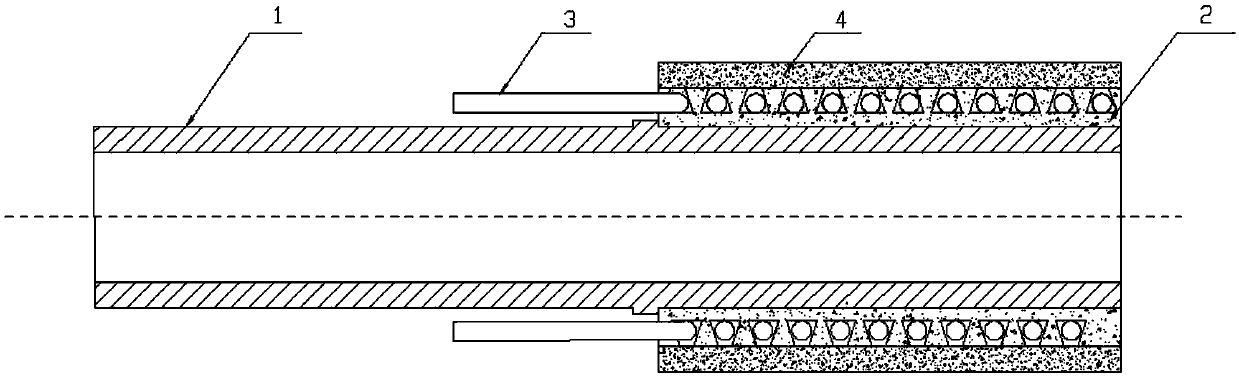

[0026] like image 3 As shown, a new hollow cathode heater structure is composed of ceramic skeleton, heating wire and outer ceramic. The ceramic frame is nested outside the cathode tube of the hollow cathode, close to the top of the cathode tube. There is a radial spiral groove on the outside of the ceramic frame; the heating wire is spirally inserted into the spiral groove; the outer ceramic is tightly fitted. Outside the ceramic skeleton, the heating wire is effectively confined within the helical groove.

[0027] The groove on the outside of the ceramic skeleton is a double helix groove. The pitch of the double helix is the same. The specific pitch value can be determined according to the actual hollow cathode requirements. The cross-sectional structure of the groove is a rectangular dovetail groove structure, and the groove size must completely accommodate the heating wire.

[0028] The heating wire is inserted into the spiral groove of the ceramic frame in a double he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com