Hollow cathode heater and hollow cathode structure

A hollow cathode and heater technology, applied in the direction of the hollow cathode of the discharge tube, the main electrode of the discharge tube, the machine/engine, etc., can solve the problems such as the thermal shock of the heating wire and the reduction of the thermal efficiency, which can improve the reliability and service life. Reduce thermal shock, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

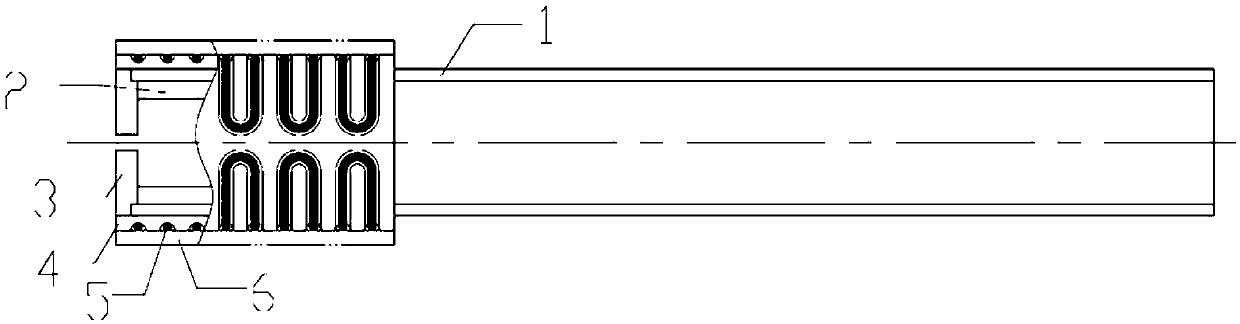

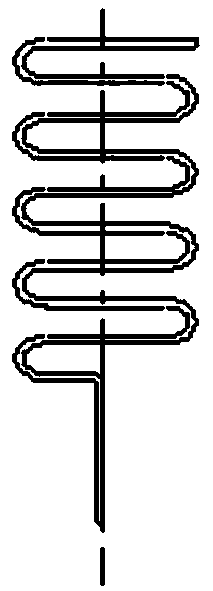

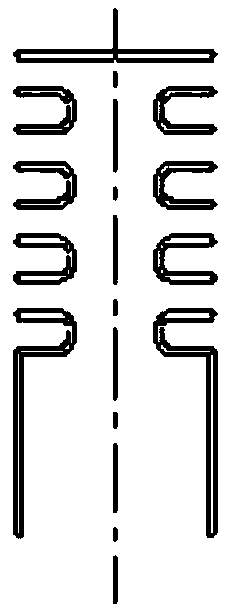

[0051] like Figure 5 and Image 6The two parts a and b of the inner ceramic skeleton 4 are shown respectively, and there are serpentine spiral grooves meandering parallel to the direction of the ceramic axis, and the threads of the part a of the inner ceramic skeleton 4 and the part b of the inner ceramic skeleton 4 are symmetrical to each other . use as figure 2 and image 3 In the first winding method shown, the heating wire 5 is wound along the serpentine spiral grooves on the outer surface of part a and part b of the inner ceramic skeleton 4, and two parts of the heating wire 5 are wound into the inner ceramic skeleton 4 The outer surface position of the heating wire 5 is welded, and the unwelded two ends of the heating wire 5 are respectively connected to the heating positive electrode and the heating negative electrode, and the two parts of the heating wire 5 form a series structure.

[0052] For the serpentine heating wire, the induced magnetic fields at adjacent ...

Embodiment 2

[0054] Embodiment 2 is consistent with Embodiment 1 in that: the inner ceramic skeleton 4 is divided into two parts a and b, and has a serpentine spiral groove parallel to the direction of the ceramic axis. figure 2 and image 3 In the first winding method shown, the heating wire 5 is wound along the serpentine spiral grooves on the outer surface of part a and part b of the inner ceramic skeleton 4; the difference from embodiment 1 is that after the winding is completed, The terminals of the two parts of the heating wire 5 on the top are connected together and then welded on the cathode tube to connect to the negative electrode; the terminals of the two parts of the heating wire 5 at the other end of the inner ceramic skeleton 4 are connected together and connected to the heating positive electrode, and the two heating wires are connected in parallel structure.

[0055] It is also a serpentine heating wire, the current direction of adjacent positions is opposite, and the ind...

Embodiment 3

[0057] like Figure 7 , Figure 8 as well as Figure 9 As shown, the one-piece inner ceramic skeleton 4 distributes protrusions in an array in a direction parallel to the ceramic axis, as shown in Figure 10 As shown, the heating wire 5 is reciprocally wound along the convex part of the inner ceramic skeleton. The two ends of the heating wire 5 are respectively connected to the heating positive electrode and the heating negative electrode without welding. Due to the difficulty of welding and fixing near the top of the cathode tube, and the hollow cathode discharge plasma sputtering is easy to be eroded, and the influence of high temperature on welding reliability, the heater is disconnected due to falling off. This structure saves the welding between the heating wire and the cathode tube, reduces the processing difficulty and improves the reliability.

[0058] At the same time, with the serpentine heating wire, the induced magnetic fields at adjacent positions can cancel e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com