Ordered pore array anode tantalum foil for tantalum capacitors and preparation method thereof

A technology of tantalum capacitors and hole arrays, which is applied in the field of ordered hole array anode tantalum foil and its preparation, can solve the problems of increasing surface area, thin products are easy to break, and difficult to form, so as to increase surface area, save preparation time, and improve effective contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

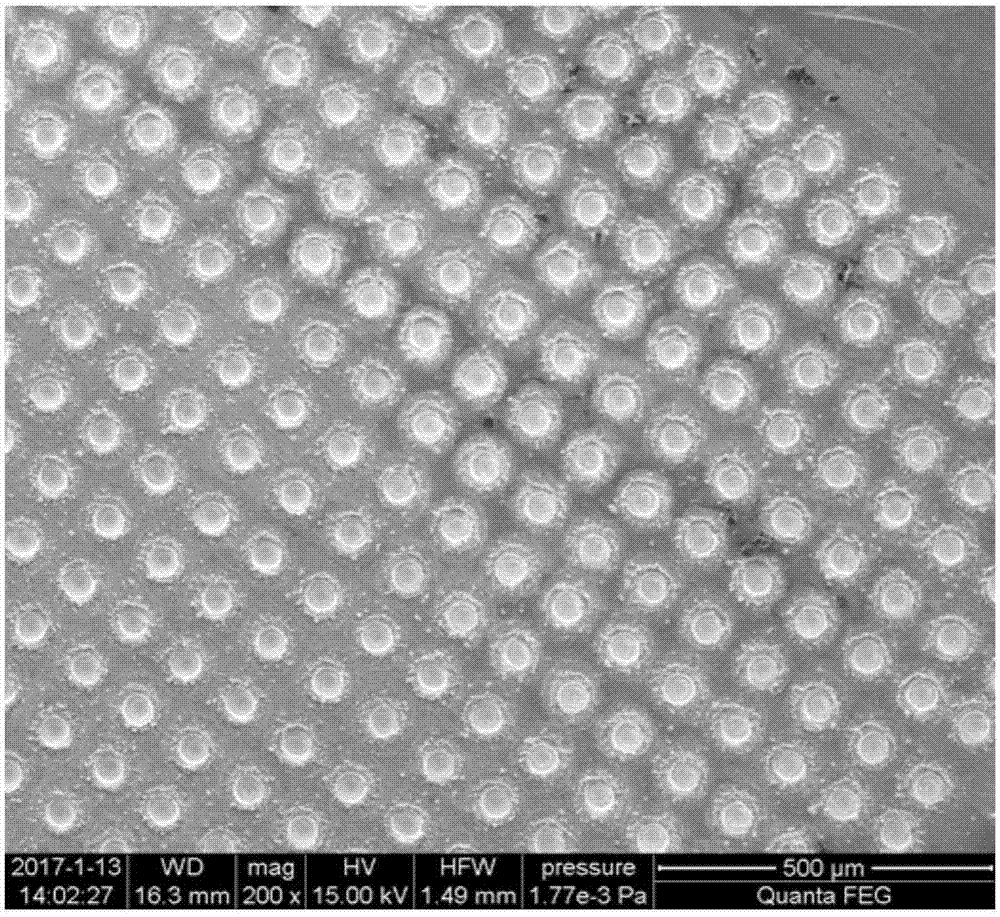

[0021] The ordered hole array anode tantalum foil of this embodiment includes a tantalum sheet with a sheet structure, and an ordered hole array is integrally formed on the upper surface of the tantalum sheet. Its preparation method is as follows:

[0022] Take a tantalum sheet with a thickness of 150 μm, clean it with alcohol to remove oil and dust on the surface of the tantalum sheet; then place the tantalum sheet on the optical table, and use a fixture to position and clamp it; finally adjust the laser parameters and spot diameter to control the laser beam on the tantalum sheet. The point scanning process is performed on the surface of the tantalum sheet, that is, an ordered hole array structure is integrated on the surface of the tantalum sheet. When point scanning the surface of the tantalum sheet, the energy range of the laser is adjusted to 25w, the scanning speed is 800mm / s, the spot diameter is 50μm, and the point spacing is 80μm. The scanning area is smaller than th...

Embodiment 2

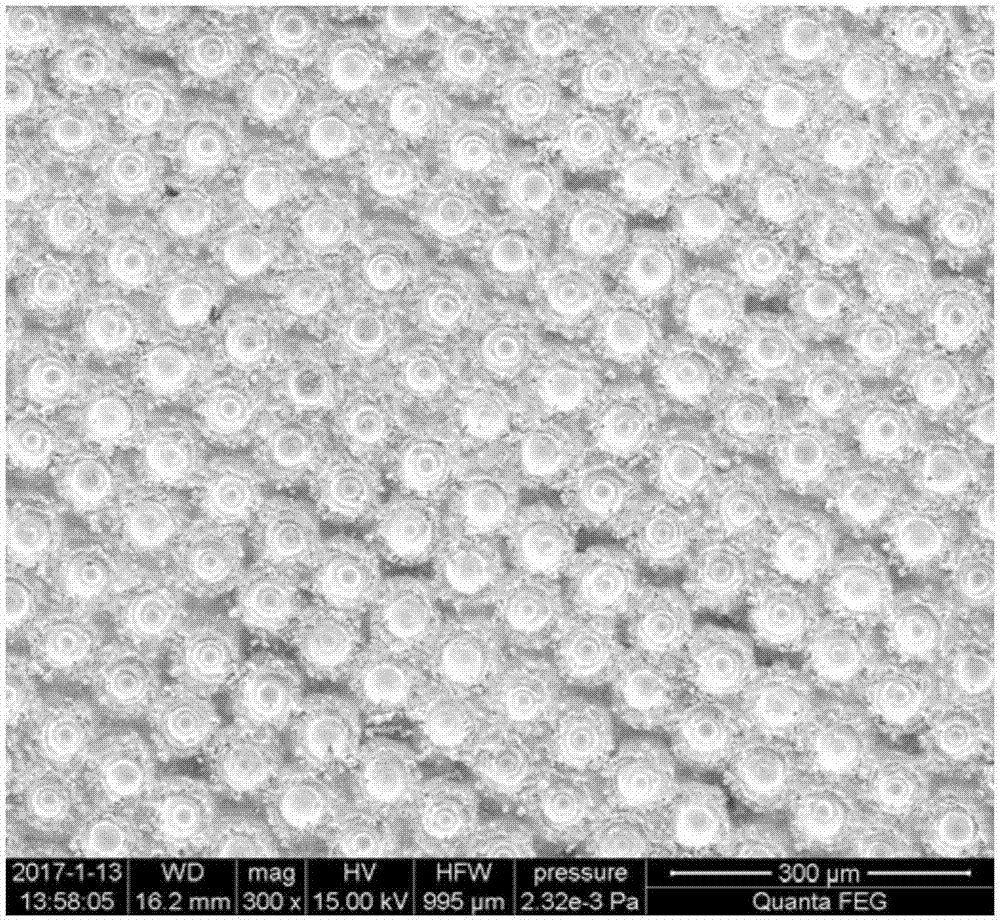

[0025] The ordered pore array anode tantalum foil of this embodiment and its preparation method are the same as those in Example 1, except that the area of the ordered pore array is equal to the area of the upper surface of the tantalum sheet.

Embodiment 3

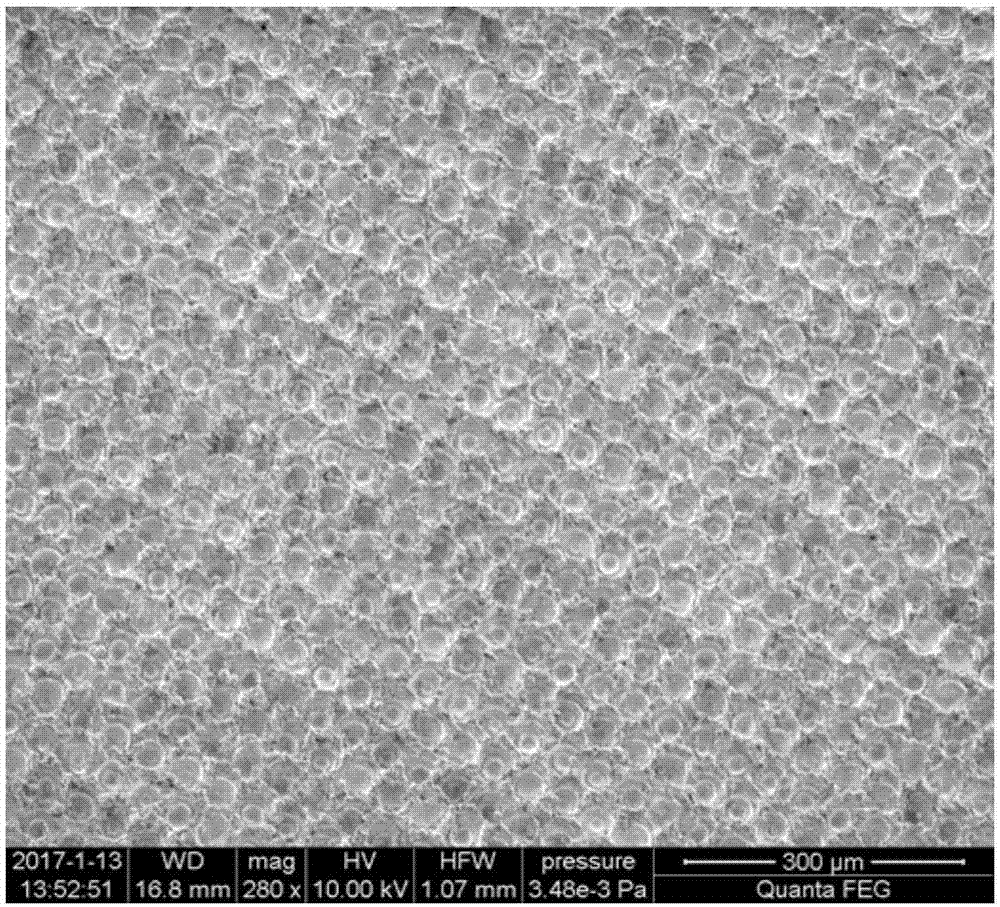

[0027] The ordered pore array anode tantalum foil and its preparation method in this embodiment are the same as those in Example 1, except that the ordered pore array structure is formed on both the upper and lower surfaces of the tantalum sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com