Annealing and strengthening technological method for rolled pure tantalum foil

A tantalum foil and annealing technology, which is applied in the annealing field of rolled tantalum foil, can solve the problems that cannot further meet the performance requirements of tantalum foil, general mechanical properties, etc., and achieve the effect of improving mechanical properties, tensile strength and plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

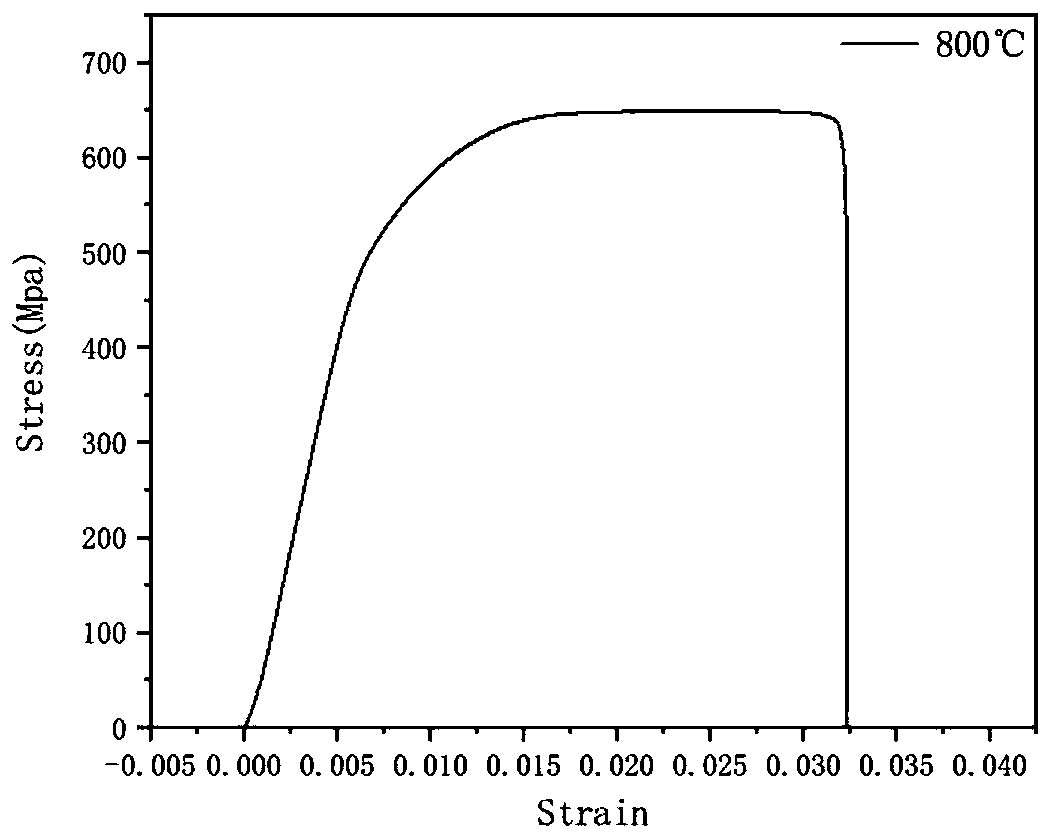

[0036] The tantalum foil with a thickness of 100 μm and a rolling deformation of 50% in this embodiment has the following mechanical properties: the yield strength is 520 MPa, and the elongation after fracture is 1.1%.

[0037] A method for annealing rolled pure tantalum foil provided in this embodiment, the annealing process is as follows:

[0038] Surface treatment: tantalum foil with a rolling deformation of 50% needs to be pickled before annealing. The pickling solution is a mixed solution of 25% to 30% nitric acid, 5% to 10% hydrofluoric acid and water. Pickling time is 30s ~ 60s, then rinse with water first, then with alcohol, and finally dry in an oven to remove impurities and oil on the surface of the foil.

[0039] Vacuum packaging: Since metal tantalum is easily oxidized by reacting with oxygen at high temperature, it is necessary to carry out vacuum packaging treatment on tantalum foil before annealing treatment, and the vacuum used for packaging is 1×10 -3 Pa.

...

Embodiment 2

[0045] In this example, a tantalum foil with a thickness of 100 μm and a rolling deformation of 60% is rolled, and its mechanical properties are: the yield strength is 600 MPa, and the elongation after fracture is 1.0%.

[0046] In this example, the surface treatment and vacuum packaging of the tantalum foil with a cold rolling deformation of 60% are carried out as in Example 1, and then the tantalum foil after surface treatment and vacuum packaging is annealed in a box furnace, and the annealing temperature is 700°C. Heat preservation time 1h, then air-cool to room temperature.

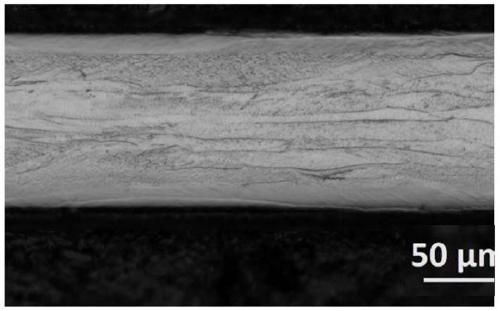

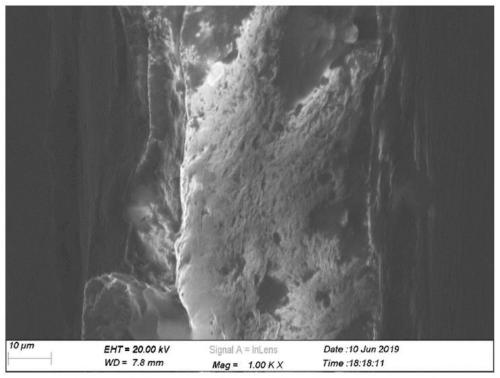

[0047] Such as Figure 4 as shown, Figure 4 It is the metallographic diagram of embodiment two tantalum foil; From Figure 4 It can be seen that the grains of the tantalum foil are still a typical rolling structure, and the grains show no sign of recrystallization, and still maintain the shape elongated along the rolling direction, which shows that the tantalum foil is kept at 700°C for 1h under t...

Embodiment 3

[0051] In this example, a tantalum foil with a thickness of 100 μm and a rolling deformation of 60% is rolled, and its mechanical properties are: the yield strength is 600 MPa, and the elongation after fracture is 1.0%.

[0052] In this example, the surface treatment and vacuum packaging of the tantalum foil with a cold rolling deformation of 60% are carried out as in Example 1, and then the tantalum foil after surface treatment and vacuum packaging is annealed in a box furnace, and the annealing temperature is 750°C. Heat preservation time 1h, then air-cool to room temperature.

[0053] Such as Figure 7 as shown, Figure 7 It is the metallographic diagram of embodiment three tantalum foil; From Figure 7 It can be seen that the grains of tantalum foil are still a typical rolling structure, and the grains do not show signs of recrystallization, and still maintain the shape of elongation along the rolling direction, which shows that the tantalum foil is kept at 750°C for 1h....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com